Construction method applying lifting clamp hook

A lifting clamp hook and masonry technology, which is applied in the field of granite sliding beam masonry in acid-resistant brick lining, can solve the problems of easy-to-squeeze sliding beams, rubber layers squeezed together, pollution, etc., and achieve good masonry quality Guarantee, fast masonry speed, simple production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with the embodiments and the accompanying drawings.

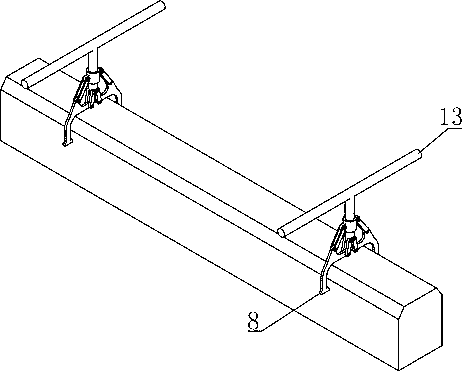

[0024] The masonry method of the granite sliding beam in the pickling tank provided by the invention is to drill two pairs of small holes on the side of the granite sliding beam before masonry, then hook the small holes with a lifting clamp hook, and then lift the granite sliding beam smoothly by construction workers Masonry is carried out, and at the same time, the installation holes on the side of the granite provide convenience for replacing the sliding beam after production. see Figure 1 to Figure 7 , the steps of the method include:

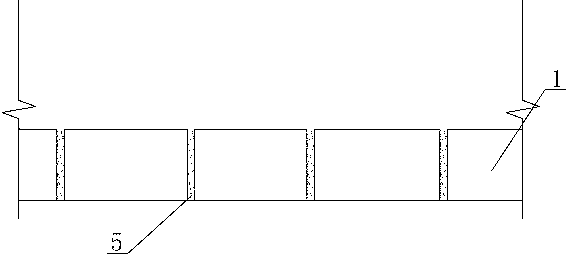

[0025] first step, such as figure 1 , first complete the masonry of the first layer of masonry 1 according to the design requirements.

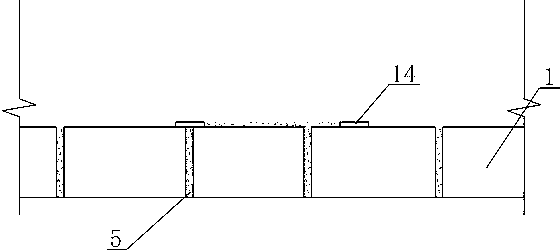

[0026] The second step, such as figure 2 , Lay the mortar plaster template 14 on the first l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com