Mortar spreading device

A technology for laying mortar and mortar, applied in the field of mortar laying devices, can solve the problems of high labor intensity, difficult operation, high labor intensity of construction personnel, etc., and achieve the effects of reducing labor intensity, ensuring masonry quality, and improving masonry efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiments of the present invention will be described in more detail below with reference to the schematic diagrams. The advantages and features of the present invention will become more apparent from the following description. It should be noted that the accompanying drawings are all in a very simplified form and in an inaccurate scale, and are only used to facilitate and clearly assist the purpose of explaining the embodiments of the present invention.

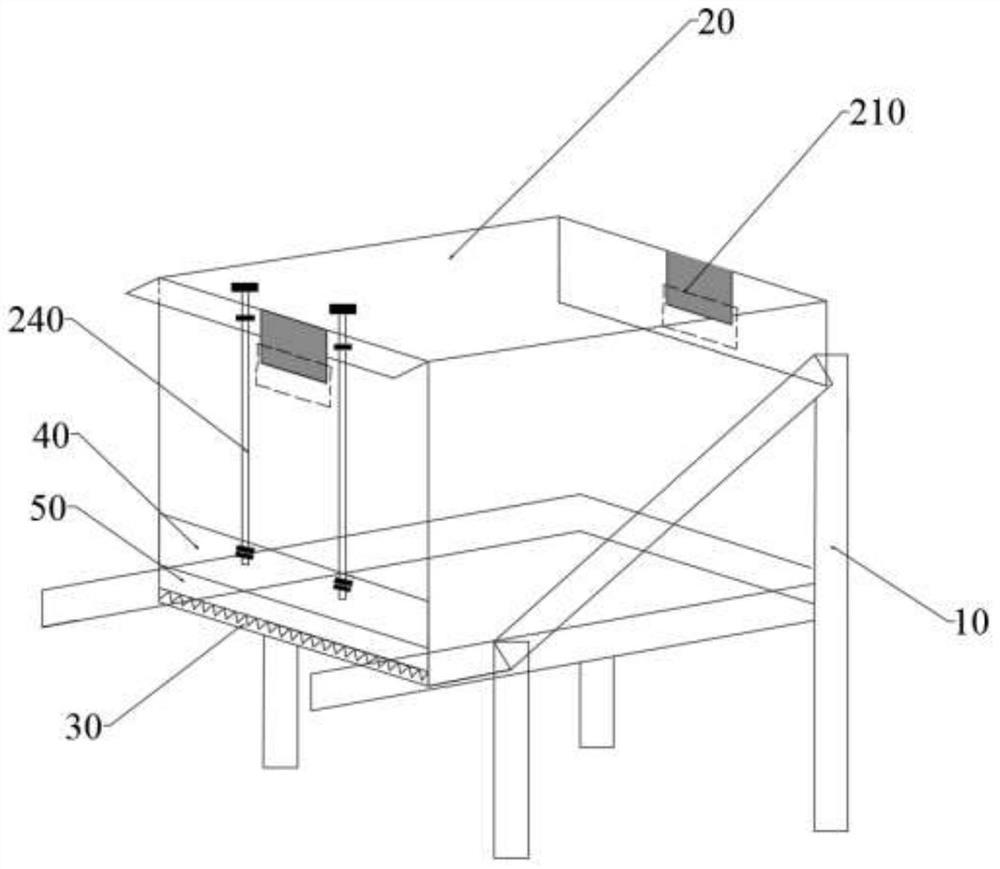

[0035] like figure 1 As shown, the present embodiment provides a slurry laying device, including:

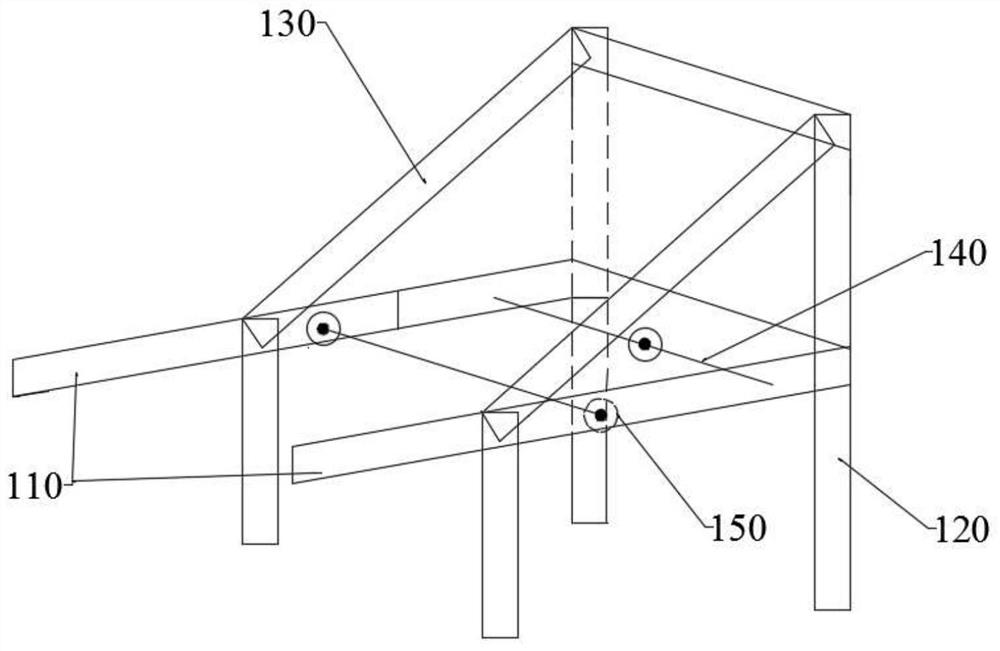

[0036] The fixing bracket 10 is arranged on a brick wall;

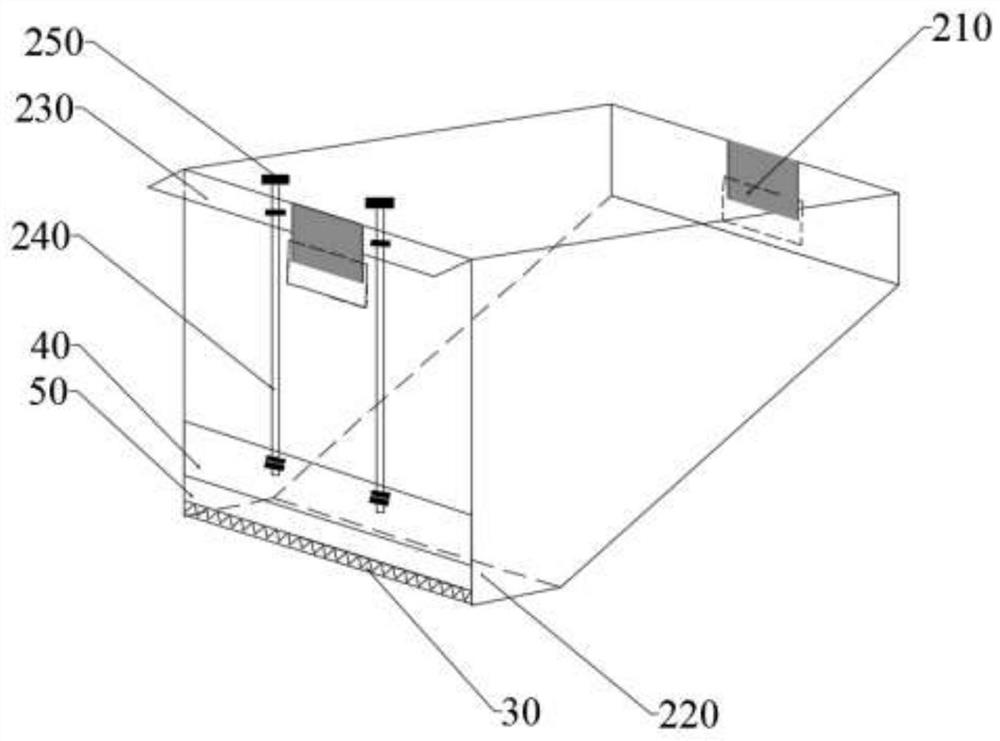

[0037] The slurry storage bucket 20 is arranged on the fixing bracket 10 and stores mortar inside. The slurry storage bucket 20 can move along the length direction of the brick wall and drive the fixing bracket 10 to move on the brick wall, A discharge port 30 is provided on the side wall of the slurry storage bucket 20, and the mortar is relea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com