Construction method of torpedo hot metal mixer car fireproof bricks

A technology for refractory bricks and mixed-iron trucks is applied in the directions of casting molten material containers, metal processing equipment, casting equipment, etc., and can solve the problems of high labor intensity, low masonry efficiency of refractory bricks for iron-concrete trucks, and poor masonry quality, etc. Achieve the effect of reducing labor intensity, ensuring masonry quality and saving refractory materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

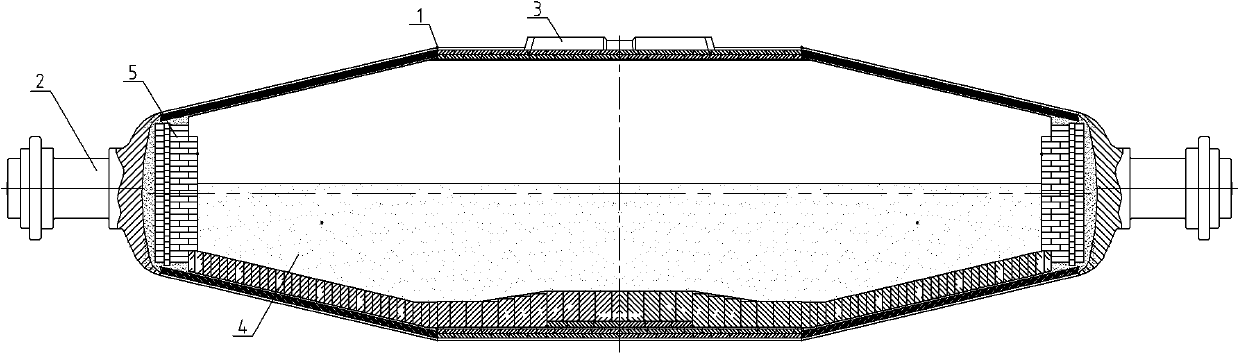

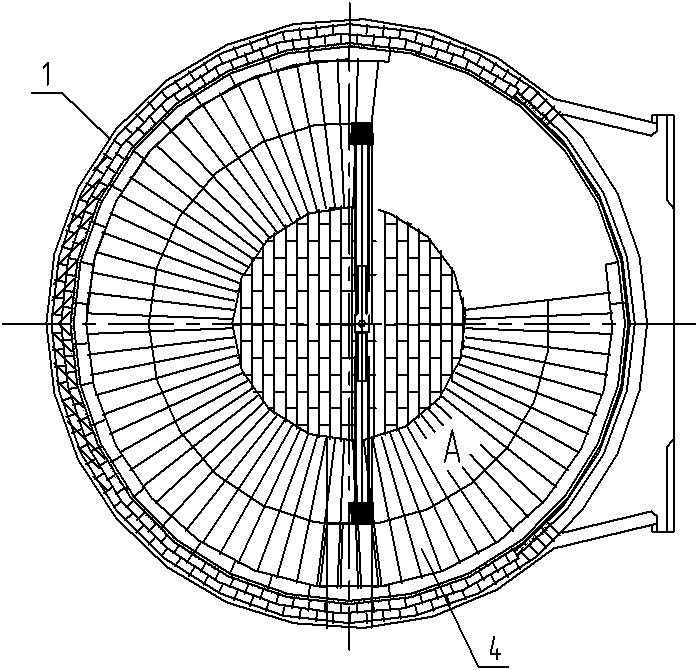

[0021] A method for building refractory bricks for a mixed-iron car according to the invention utilizes the characteristic that the drum-shaped tank body 1 of a mixed-iron car can rotate around the trunnion 2, and builds refractory bricks 4 in sections along the radial direction of the tank body, so that the ground work is always maintained , the order of construction is as follows:

[0022] 1) see figure 1 Place the tank mouth 3 of the mixed iron truck upwards, build refractory bricks 4 along the inner wall of the tank body 1 to a position 200-300 mm above the center line of the tank body, and complete the refractory bricks on the end walls 5 on both sides ;

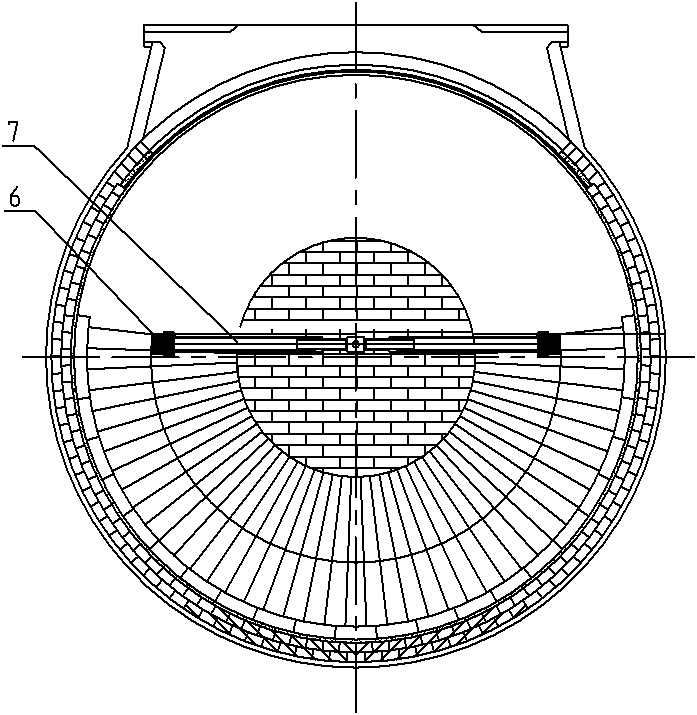

[0023] 2) see figure 2 , set the hard miscellaneous wood 6 along the stop end of the refractory brick that has been built, use the push rod 7 to withstand the hard miscellaneous wood 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com