Method for building upper semi-circular arch roof lining of industrial furnace pipeline

A technology for lining and industrial furnace, applied in furnace, lining repair, furnace components, etc., can solve problems such as the decline in the quality of the insulation layer masonry, the decline in the plumpness of the block mortar, and the opening of the mortar joints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

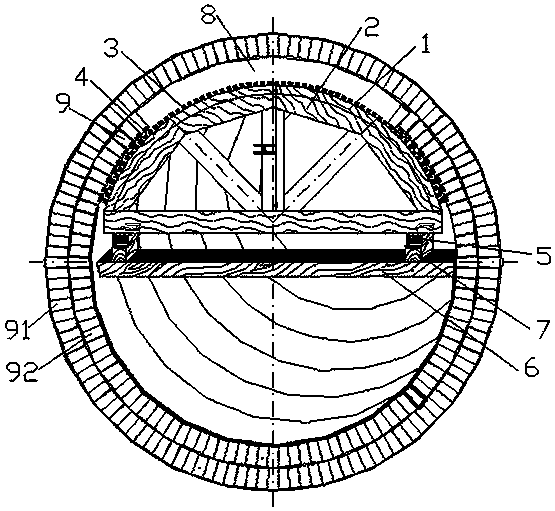

[0017] Example figure 1 As shown, the method for building the semi-circular arch lining on the industrial furnace pipeline of the present invention comprises the following steps:

[0018] Step 1. Manufacturing last tires and accessories. The last tires include the first tire last piece 1, the second tire last piece 2 and the tire last strip 3. The accessories include small wooden wedges 4, large wooden wedges 5, cross-arm wood 6, and raised sleepers 7 ;According to the diameter D of the masonry layer 砌 Subtract the thickness δ of the last tire 3 to calculate the diameter D of the first last tire 1, D=D 砌 -δ, the calculation formula for the diameter d of the second last tire 2 is d=(D- 10~20mm), the arch height H of the first last tire 1 and the second last tire 2 =D 砌 / 2-100~300mm; the length of last tire strip 3 is the brick length plus 20~30mm;

[0019] Step 2: Assembling nails and supporting the tire last, the cross-arm 6 is horizontally arranged under the masonry layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com