Novel slope-forming brick for wall of ladle and slope forming process

A technology for sloping bricks and molten steel tanks, which is used in manufacturing tools, metal processing equipment, casting molten material containers, etc. to achieve the effect of extending service life, ensuring masonry quality, and eliminating steel penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

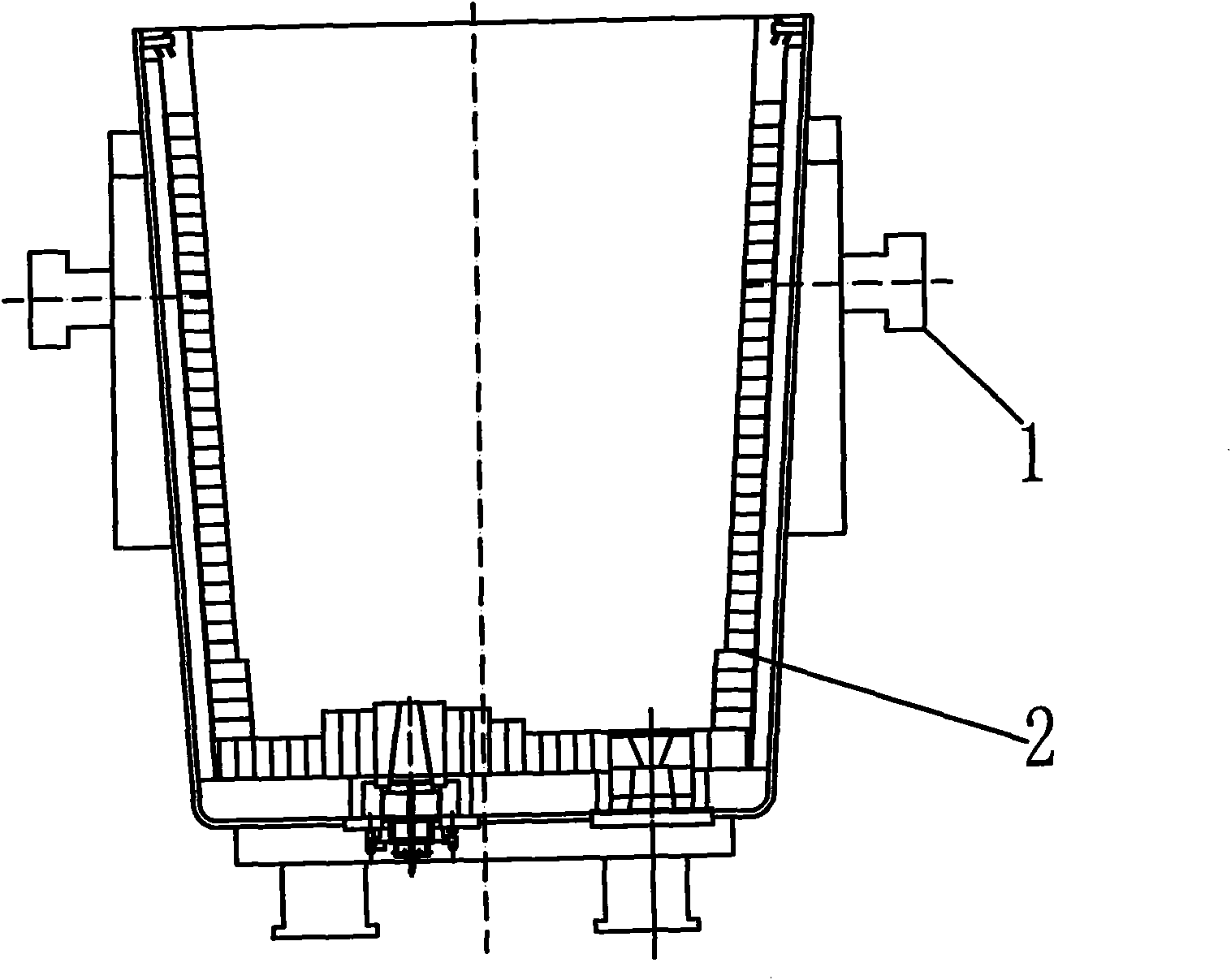

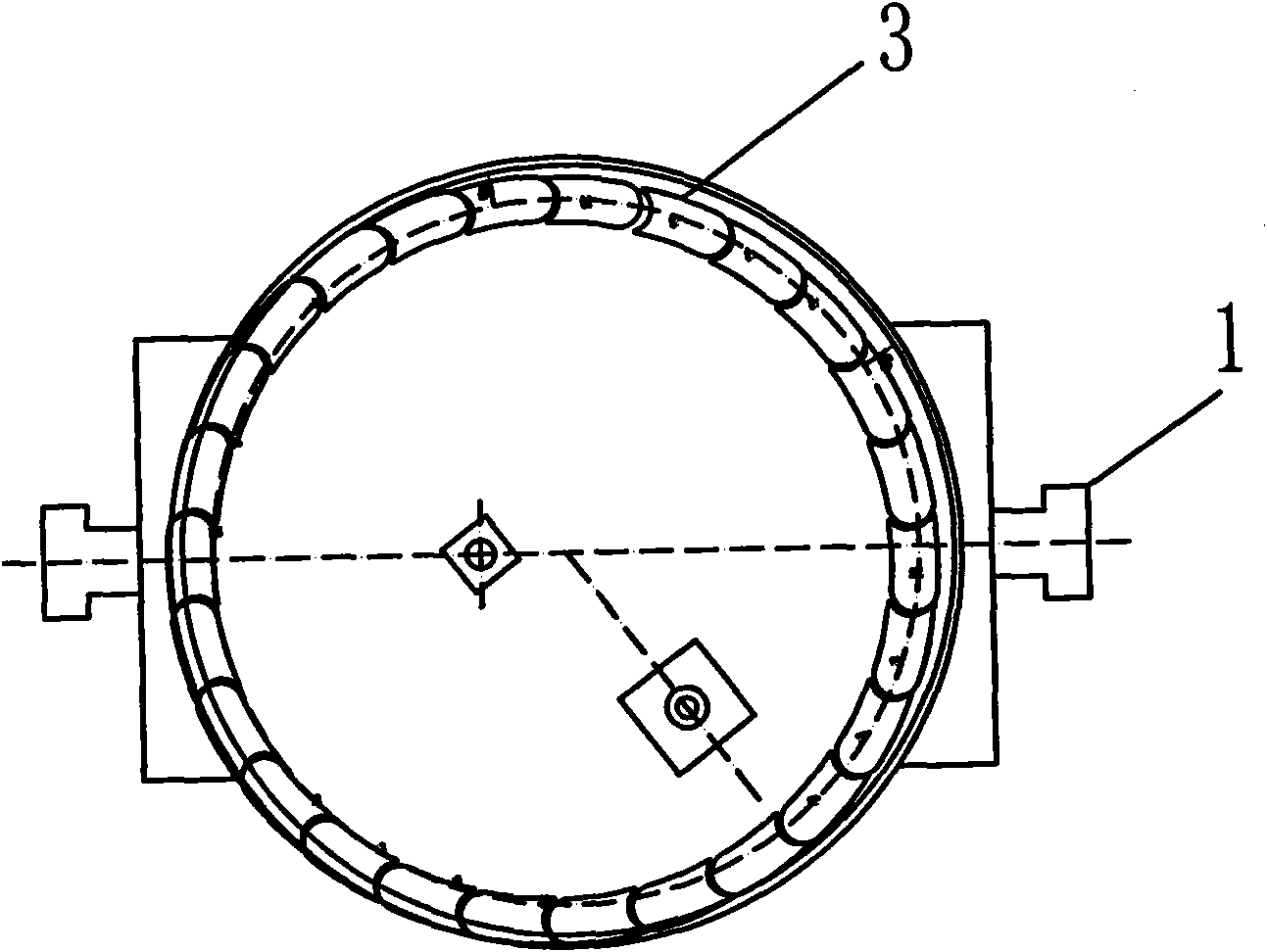

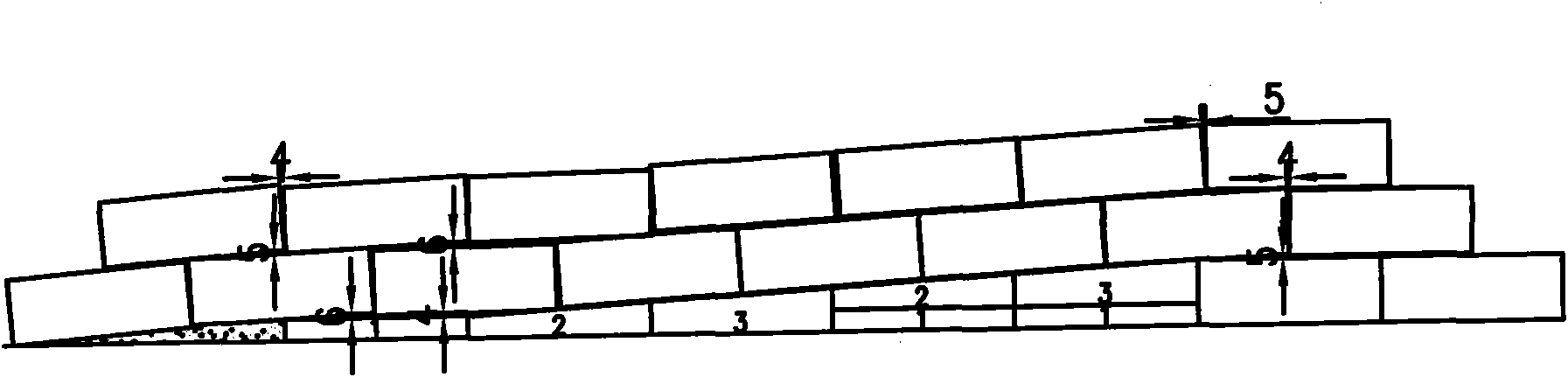

[0027] Below in conjunction with accompanying drawing, the present invention is further described: as Pic 4-1 , 4-2 The new type of slope brick for molten steel tank shown in , is an arc-shaped thin sheet with a flat top and bottom, and is wedge-shaped with one end thick and the other end thin. The angle between the side surface and the top surface is > 90 degrees, especially: the angle between the thick end side and the bottom surface of the slope brick is 90 degrees.

[0028] As a special case, the side profiles of the rising bricks are symmetrical about the central axis.

[0029] Compared with the slope bricks of the prior art, the shape has been changed. The slope bricks used at present are that the bottom surface is perpendicular to the side surface, and the top is a slope to form a single-sided wedge shape. When the right-angled basic bricks are combined, since the basic bricks are on the slope and the slope bricks are on the plane, the splicing surface must form a g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com