Novel method for building slope air course of coke dry quenching furnace

A new method, technology of CDQ, applied in coke oven, coke cooling, petroleum industry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

[0016] The present invention will be described in detail below with reference to the accompanying drawings.

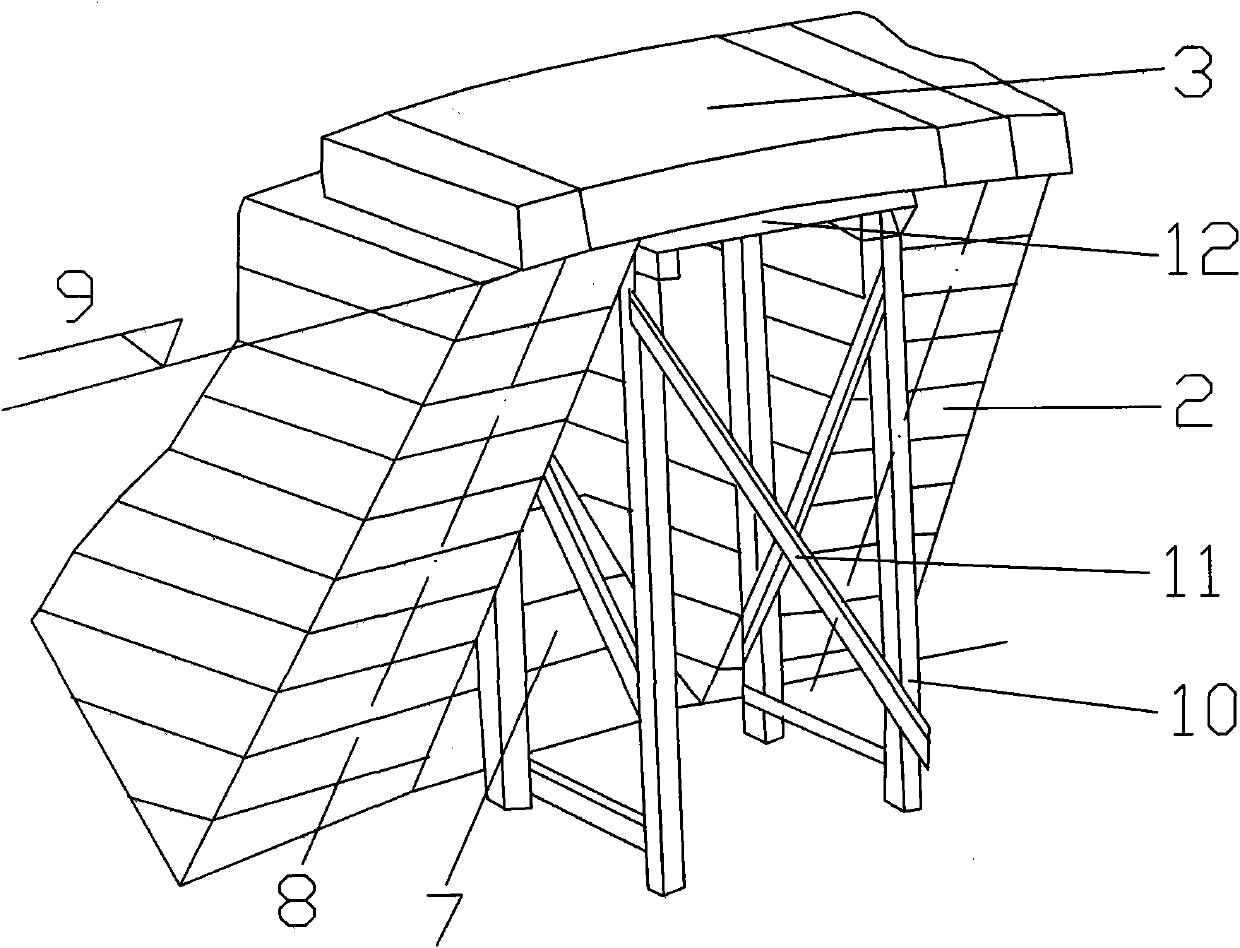

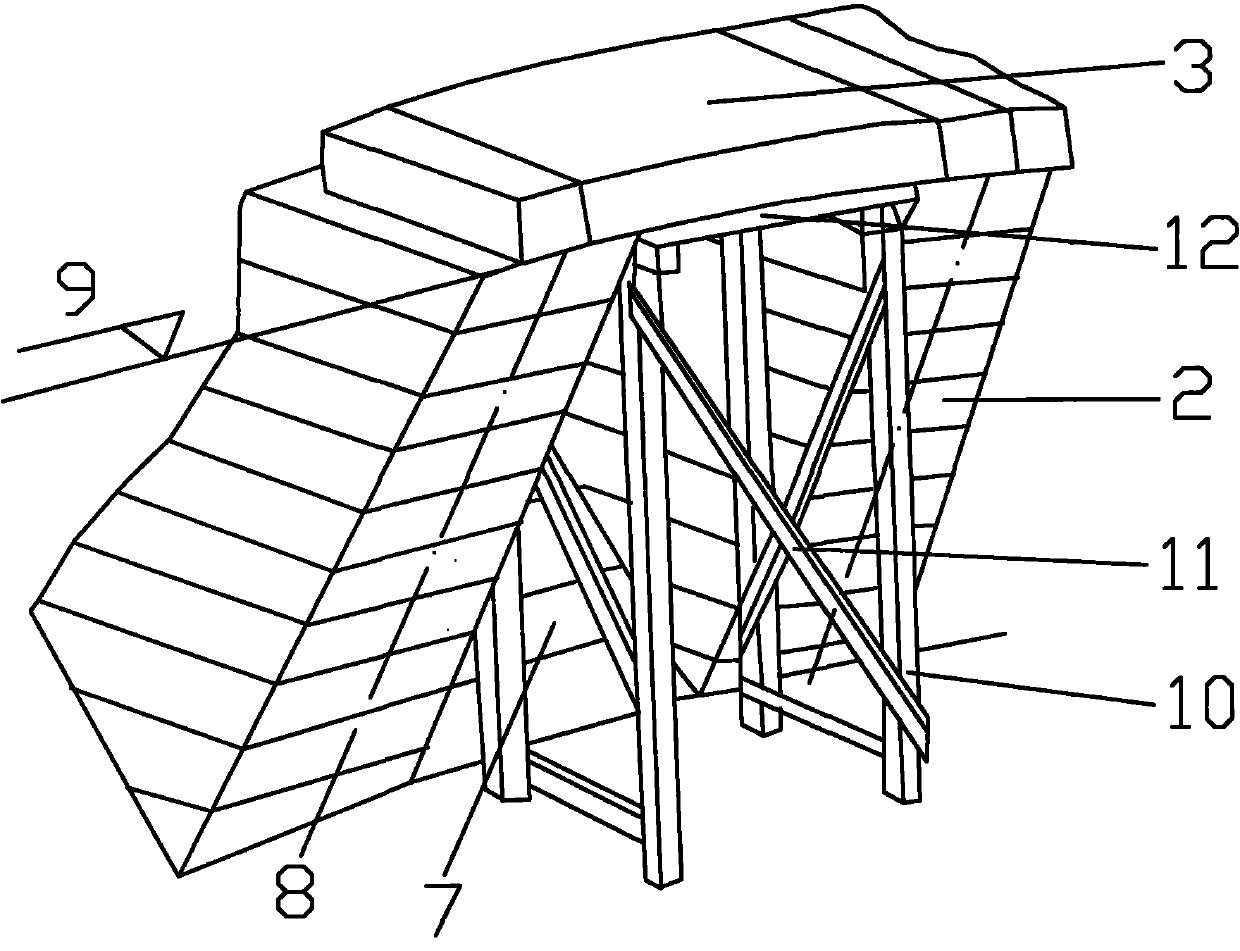

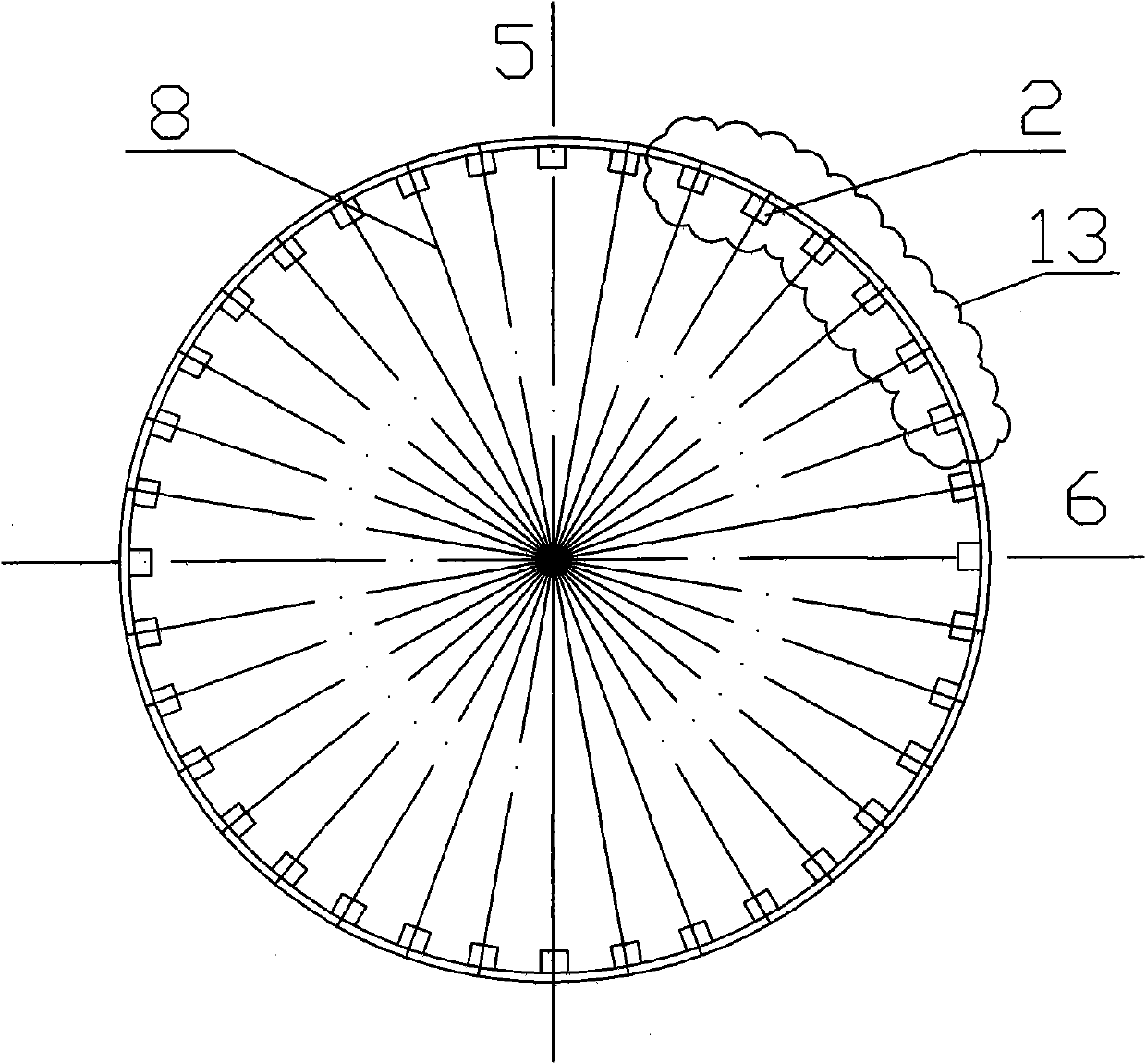

[0017] refer to figure 1 , figure 2 , image 3 , the masonry position of the present invention is at figure 1 In the circle, it can be seen that this part is a key part; firstly, the initial elevation line and each corbel axis 8 are released at the bottom of the ramp corbel 2, and then the ramp inner wall 7 and the corbel brick 2 are built, and the ramp corbel Each layer of bricks in the leg masonry must use a special control panel with an elevation scale to control the elevation, and the mortar joints must be kept full. Each person in the ramp area will build 6 corbel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com