Modular mounting device and method for riser lining of coke oven

A technology for installing devices and pipe linings, which is applied to coke ovens, coke oven parts, coke oven heating, etc., which can solve problems such as gas leakage, brick falling off, and riser pipe body burn-through, and reduce labor costs. Strength, ensuring masonry quality, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

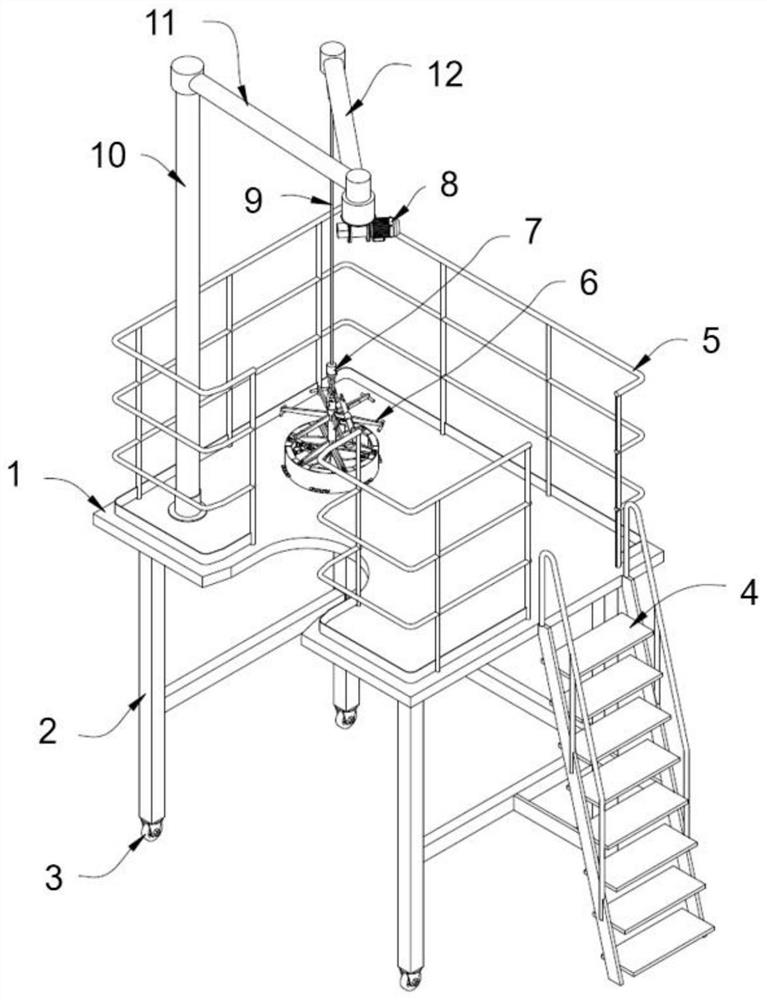

[0049] The coke oven riser lining modular installation device includes a ring-shaped masonry installation vehicle. The ring-shaped masonry installation vehicle mainly includes a construction vehicle, a jib crane and a ring masonry spreader. The jib crane is connected to the construction vehicle. The masonry spreader is connected to the jib crane, the ring masonry spreader is used to clamp a ring of pipe bricks built by masonry, the jib crane is used to lift the ring masonry spreader and connect the ring masonry spreader and pipe bricks Hoisted together to a suitable position, the construction vehicle includes a vehicle frame 2 and a platform 1, the platform 1 is horizontally installed on the vehicle frame 2, and one side of the platform 1 is provided with an opening matching the pipe arc of the riser pipe 43.

[0050] Preferably, the above-mentioned coke oven riser lining modular installation device, the construction vehicle also includes a roller 3, a ladder 4 and a railing 5,...

Embodiment 2

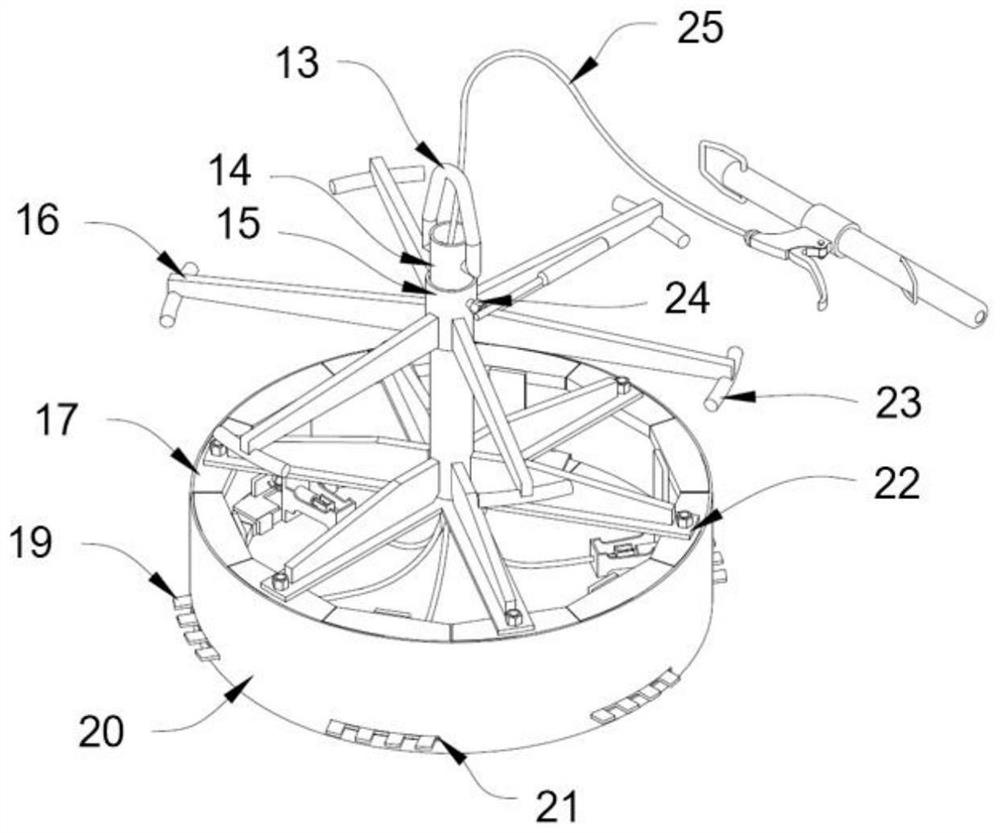

[0052] Based on Embodiment 1, Embodiment 2 further defines the ring-shaped masonry spreader.

[0053] For the coke oven riser lining modular installation device described above, the annular masonry spreader includes, from bottom to top, a hanging form, a hanger 22, a positioning bracket 16, a telescopic hook 19 and a traction mechanism 25, wherein the hanging The mold is a cylindrical structure, and its outer diameter matches the inner diameter of the riser lining; the hanger 22 is a bracket of a radial structure, and the center is connected with a suspender 14, and the upper part of the hanger is connected to the bracket of the radial structure of the hanger in the circumferential direction. There are a plurality of telescopic hooks 19, which are evenly distributed around the center of the hanging mold, and the telescopic hooks 19 are driven by the traction mechanism 25 to stretch out the hanging mold or shrink in the hanging mold; the positioning bracket 16 is a support of a ...

Embodiment 3

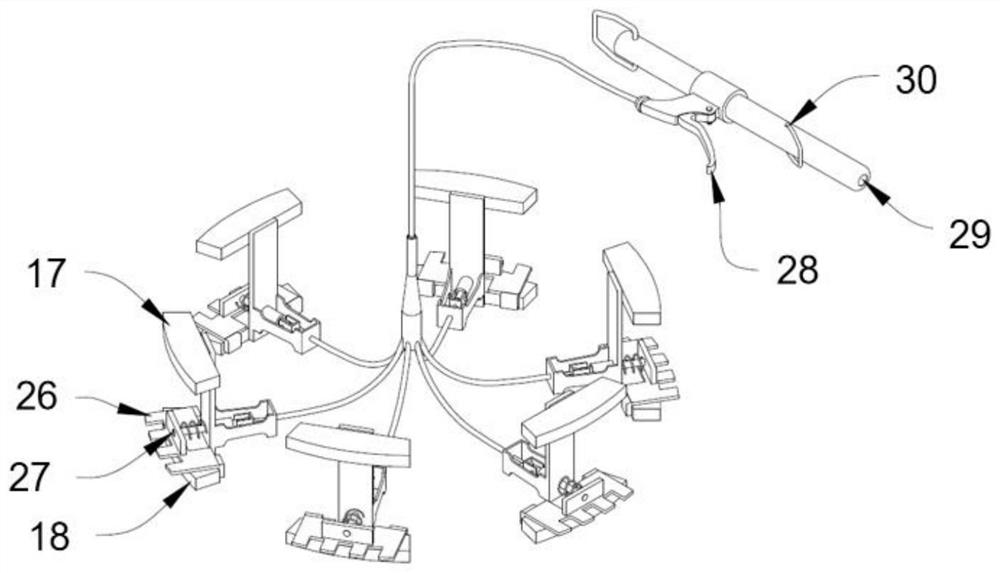

[0057] Based on Embodiment 2, Embodiment 3 further defines the telescopic hook.

[0058] In the coke oven riser lining modular installation device described above, the telescopic hook 19 includes a hook head 26, a baffle plate 34, a limit plate 32, a telescopic rod 27, a vertical plate 31, a spring 33, a sleeve 35, and a casing limit plate. The bit frame 38, the traction head 37, the pin shaft 36, the hook head 26 is a supporting plate for carrying pipe bricks, the front end of the hook head 26 is tooth-shaped, so that after being pulled out from the brick joint, the mortar will automatically collapse, and the tail end of the hook head 26 is connected Limit plate 32, precise control of hook head 26 extension length, hook head 26 upper surface is vertically connected with baffle plate 34, the inner side of baffle plate 34 is fixedly connected with telescopic rod 27, the top and bottom end of vertical plate 31 are respectively connected with upper rib The plate 17 is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com