An automatic stacking machine and a wall-building control method

An automatic, wall-based technology, applied in the direction of program-controlled manipulators, manipulators, manufacturing tools, etc., can solve the problems of difficult to guarantee the accuracy of wall building, complex equipment structure, and difficult to popularize and apply, so as to automatically adapt to length changes, expand the scope of application, Simple structure and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

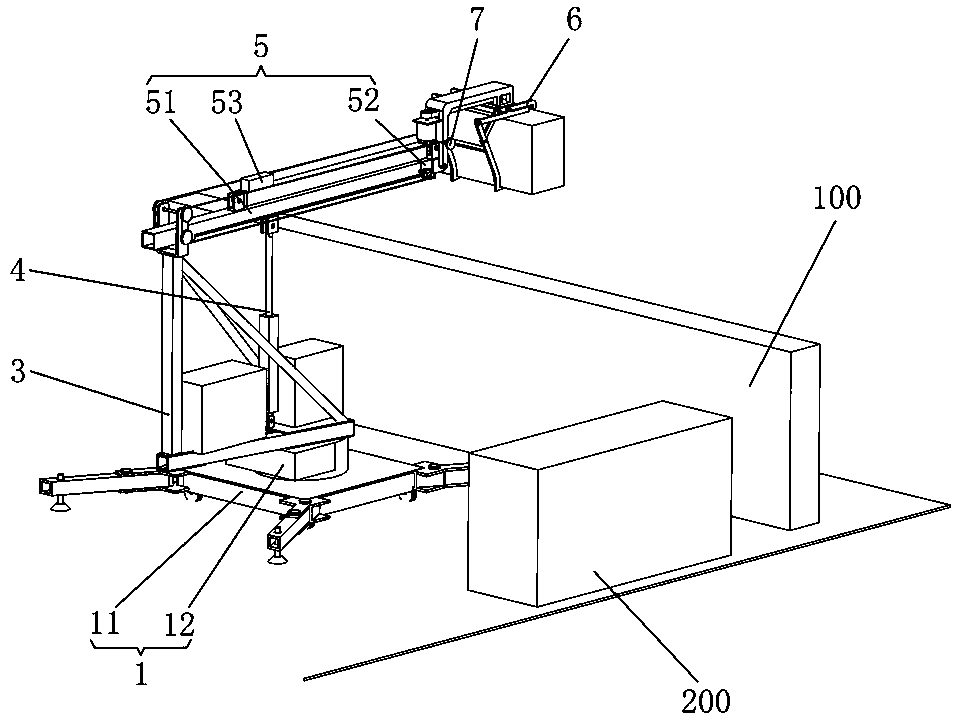

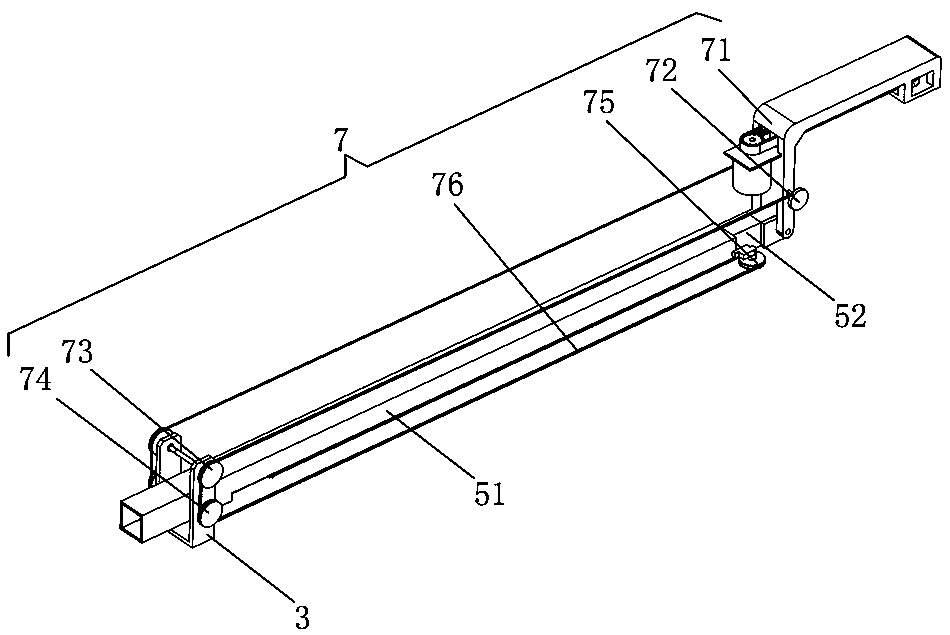

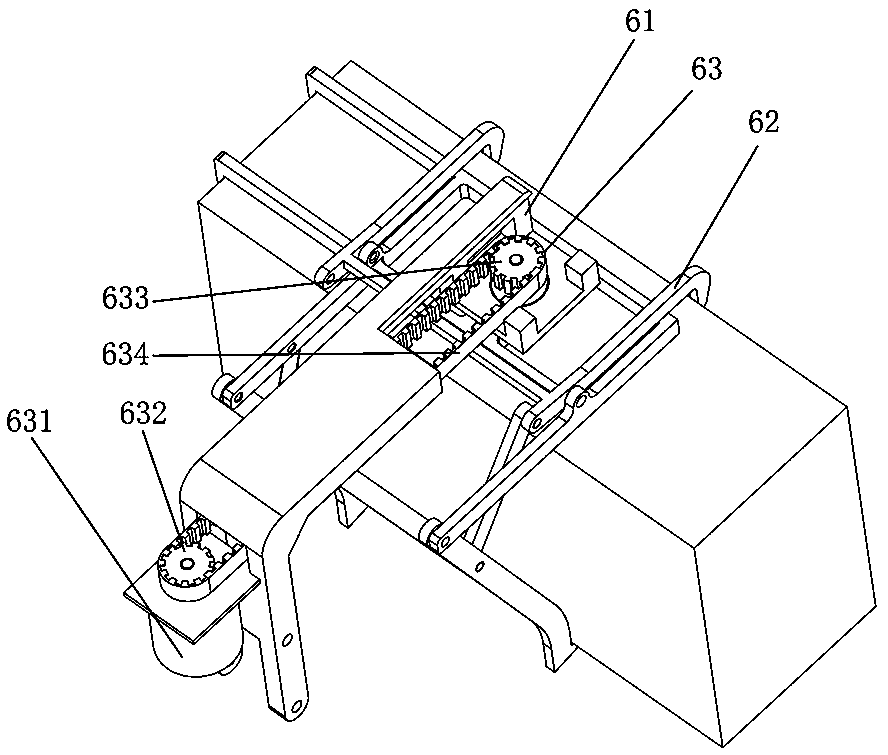

[0034] Figure 1 to Figure 3 Shown is an embodiment of an automatic stacker of the present invention, the automatic stacker includes a chassis 1, a support 3, a luffing telescopic mechanism 4, a linear telescopic mechanism 5, a gripper mechanism 6 and a mechanism for keeping the gripper mechanism 6 horizontal The jaw horizontal holding mechanism 7, the bracket 3 is installed on the chassis 1, one end of the linear telescopic mechanism 5 is hinged with the upper end of the bracket 3, the other end is connected with the jaw mechanism 6 through the jaw horizontal holding mechanism 7, and the luffing telescopic mechanism 4 is at one end It is hinged with the bracket 3, and the other end is hinged at the middle part of the linear telescopic mechanism 5. The automatic stacking machine of the present invention has a simple and reliable structure. One end of the linear telescopic mechanism 5 is hinged to the upper end of the bracket 3, and the other end is connected to the jaw mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com