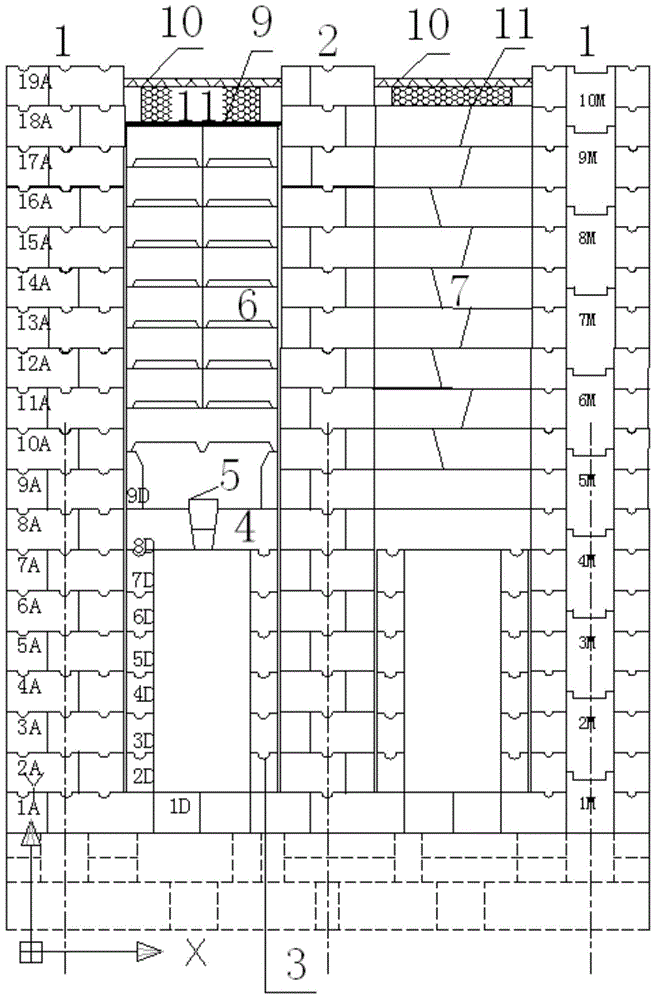

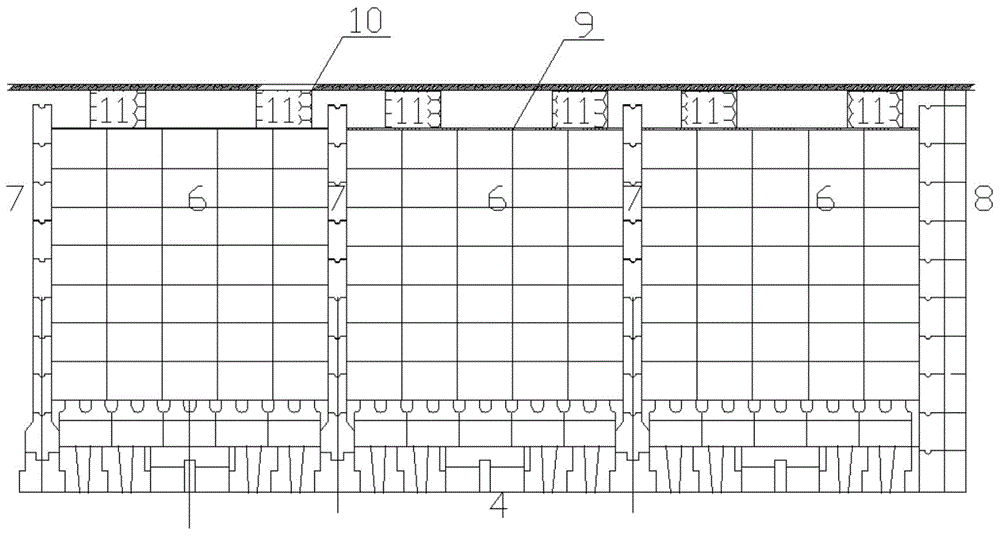

Down-adjusted 7m coke oven regenerative chamber constructing method

A regenerator and masonry technology, which is applied to coke oven bricklaying operations and other directions, can solve the problems of narrow construction work area, poor working environment for workers, inconvenient quality inspection, etc., to expand the construction work area, ensure the quality of masonry, Ease of quality inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A method for building a lower-adjustable 7m coke oven regenerator, the steps of which are as follows:

[0023] a. 1-3A layer main wall and single wall construction section masonry, each masonry team is responsible for three main walls and single walls, which will be built in three days, and a main wall and a single wall adjacent to each other will be built every day. Clean joints after laying, check and accept;

[0024] b. Masonry construction of the main wall and single wall construction section of the 4-7A layer, the operation is the same as a;

[0025] c.1 Masonry for the lining brick construction section of the 1-7D layer of the small flue, each masonry team is responsible for 6 holes, and the masonry is divided into three days, and two adjacent holes are built every day, the joints are clean, and the inspection is accepted;

[0026] d. Masonry construction of the main wall and single wall construction section of the 8-10A layer, the operation is the same as a;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com