Patents

Literature

30results about How to "Easy QA" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

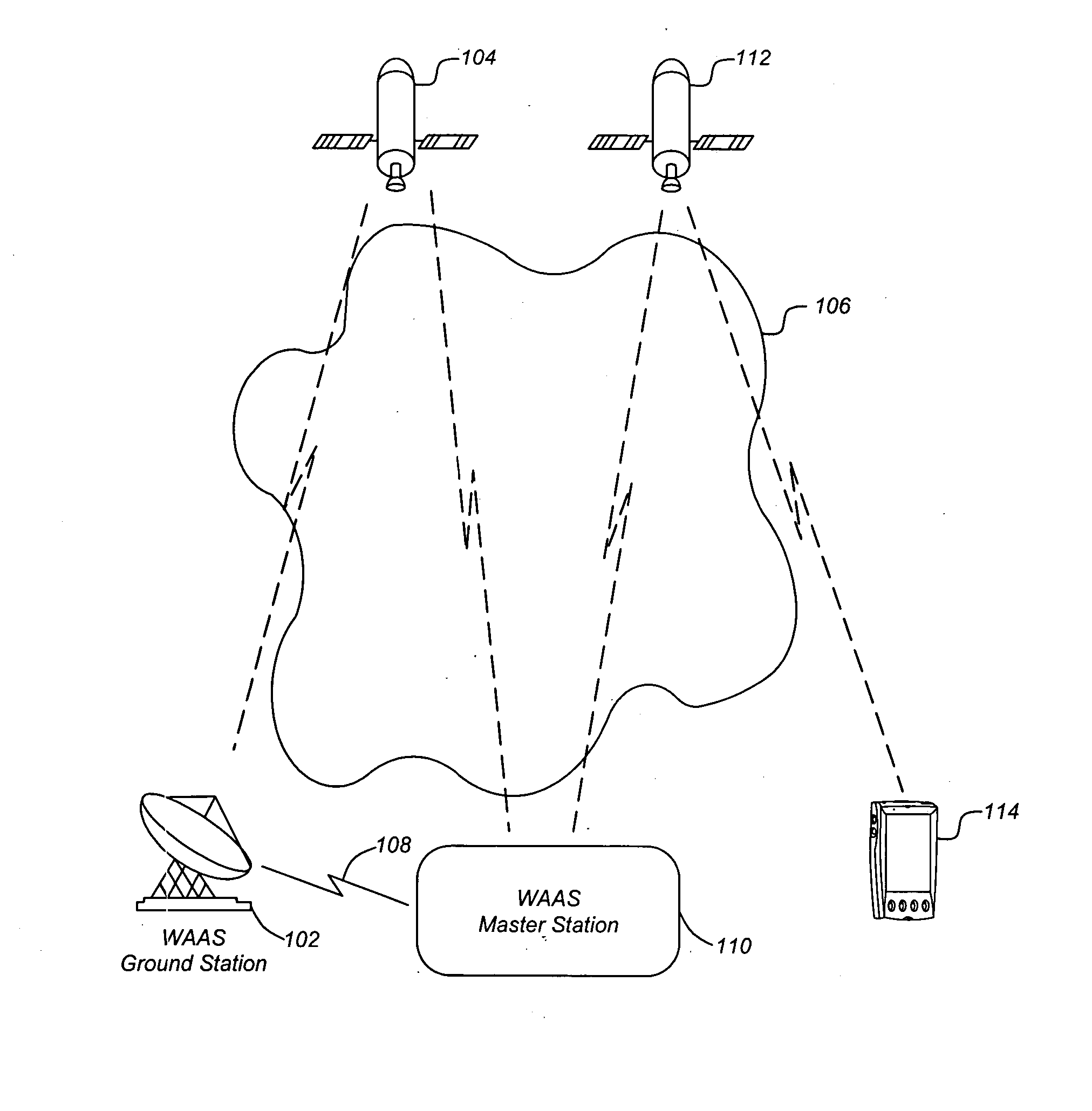

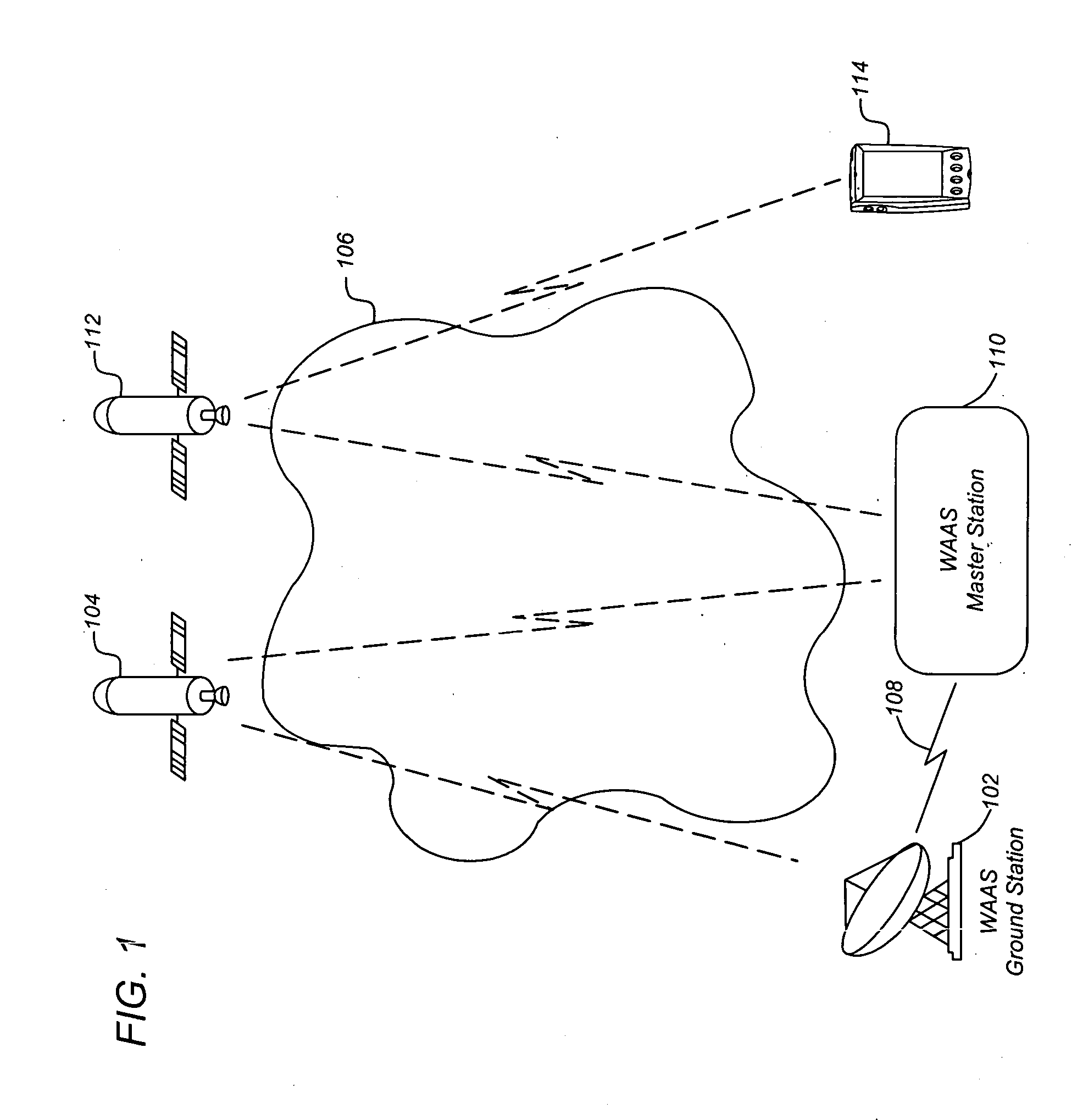

Generating high precision ionospheric ground-truth measurements

ActiveUS20060017610A1More data volumeEasy QAPosition fixationSatellite radio beaconingGround truthWide area

A method, apparatus and article of manufacture provide ionospheric ground-truth measurements for use in a wide-area augmentation system (WAAS). Ionospheric pseudorange / code and carrier phase data as primary observables is received by a WAAS receiver. A polynomial fit is performed on the phase data that is examined to identify any cycle slips in the phase data. The phase data is then leveled. Satellite and receiver biases are obtained and applied to the leveled phase data to obtain unbiased phase-leveled ionospheric measurements that are used in a WAAS system. In addition, one of several measurements may be selected and data is output that provides information on the quality of the measurements that are used to determine corrective messages as part of the WAAS system.

Owner:CALIFORNIA INST OF TECH

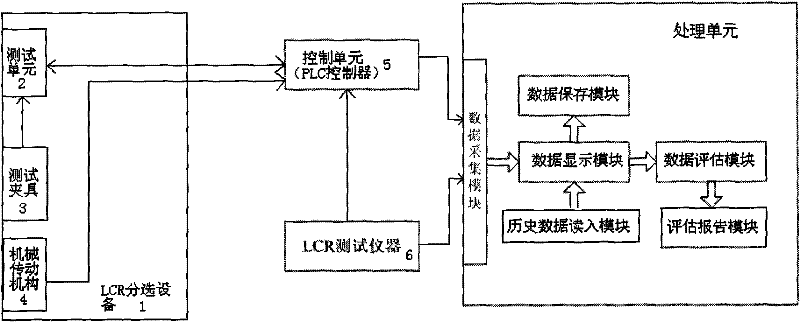

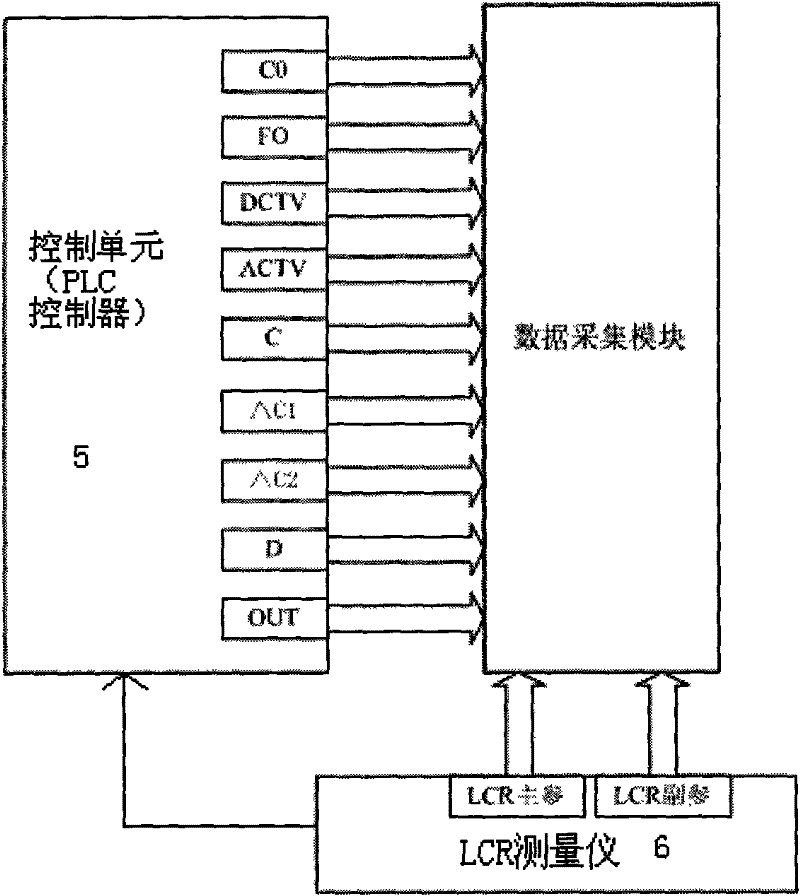

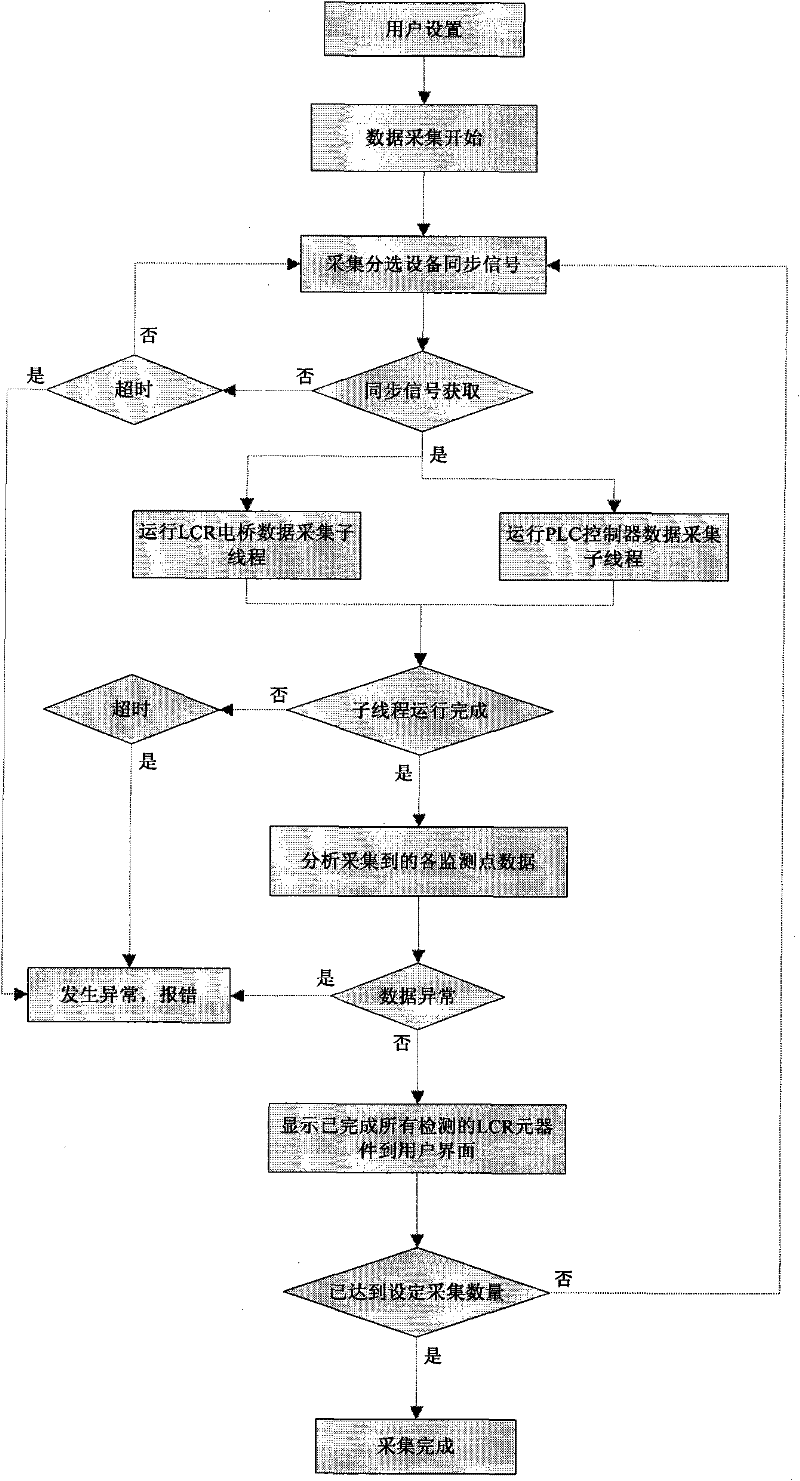

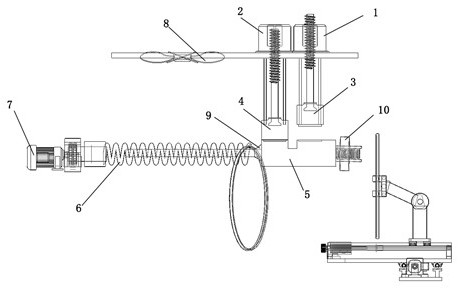

Automatic sorting, detecting and evaluating system for impedance elements

InactiveCN102193035AEasy QAEasy to trackTesting dielectric strengthResistance/reactance/impedenceCapacitanceGraphics

The invention discloses an automatic sorting, detecting and evaluating system for impedance elements. The system comprises an automatic sorting and detecting part for the impedance elements and a processing unit, wherein the processing unit is used for acquiring and combining measured impedance element parameters on an inductance, capacitance, resistance (LCR) measuring meter and data output by a control unit, and processing the parameters and the data through a data model to obtain a quality evaluation report; and the processing unit is provided with a data acquisition module, a historical data read module, a display module, a storage module, and an evaluation report module, wherein the data acquisition module is used for acquiring the data of the measured impedance elements; the historical data read module is used for reading the stored data; the display module is used for displaying the data of the measured impedance elements and a data processing result; the storage module is used for storing the data of the measured impedance elements; the data evaluation module is used for processing the parameters of the measured impedance elements through the data model; and the evaluation report module is used for outputting the data processed by the data evaluation module in a graph form. The system analyses and processes detection parameters of the impedance elements so as to form the evaluation report for a user to directly evaluate the quality of the impedance elements.

Owner:SHANGHAI INSTR RES INST

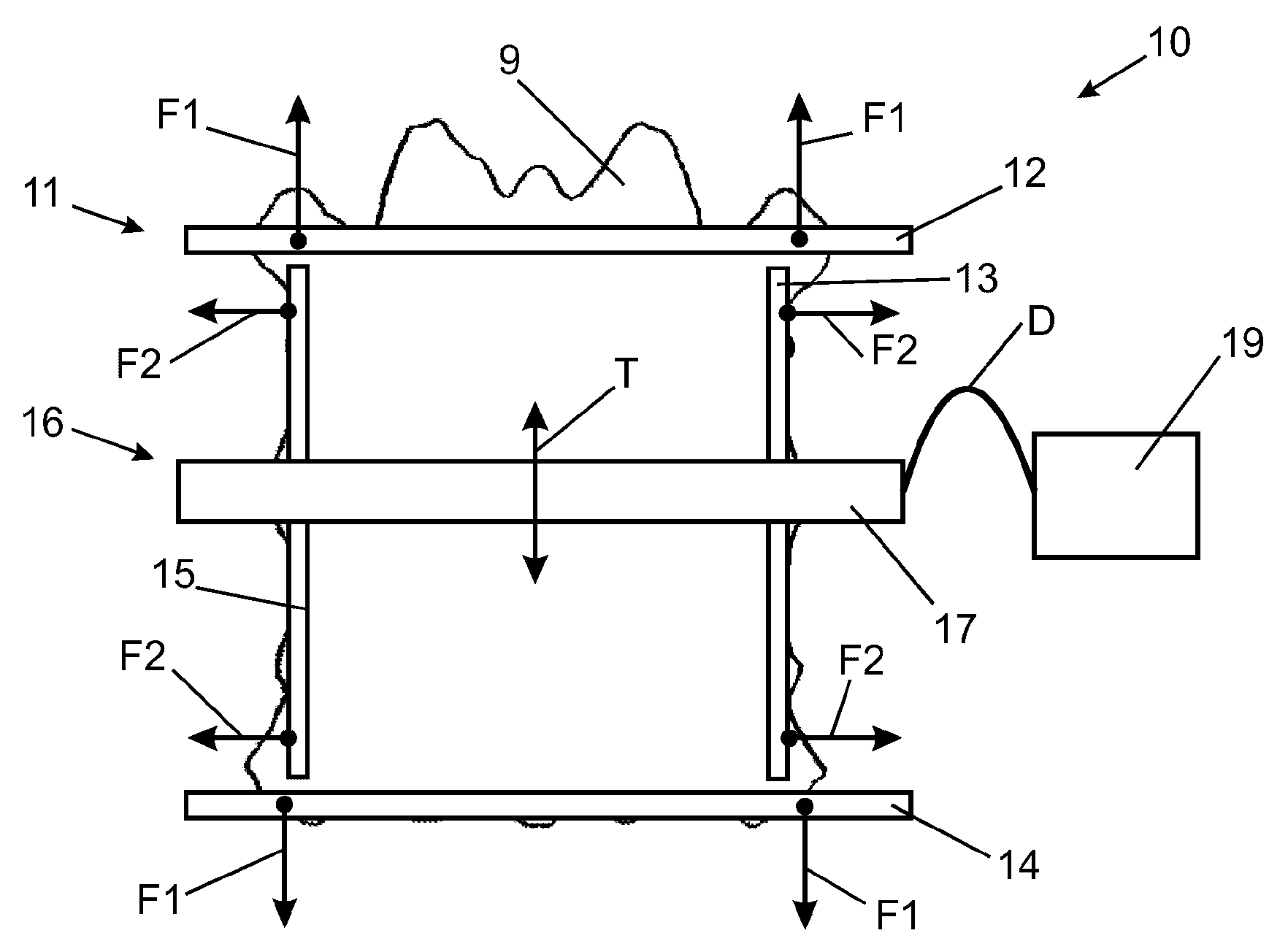

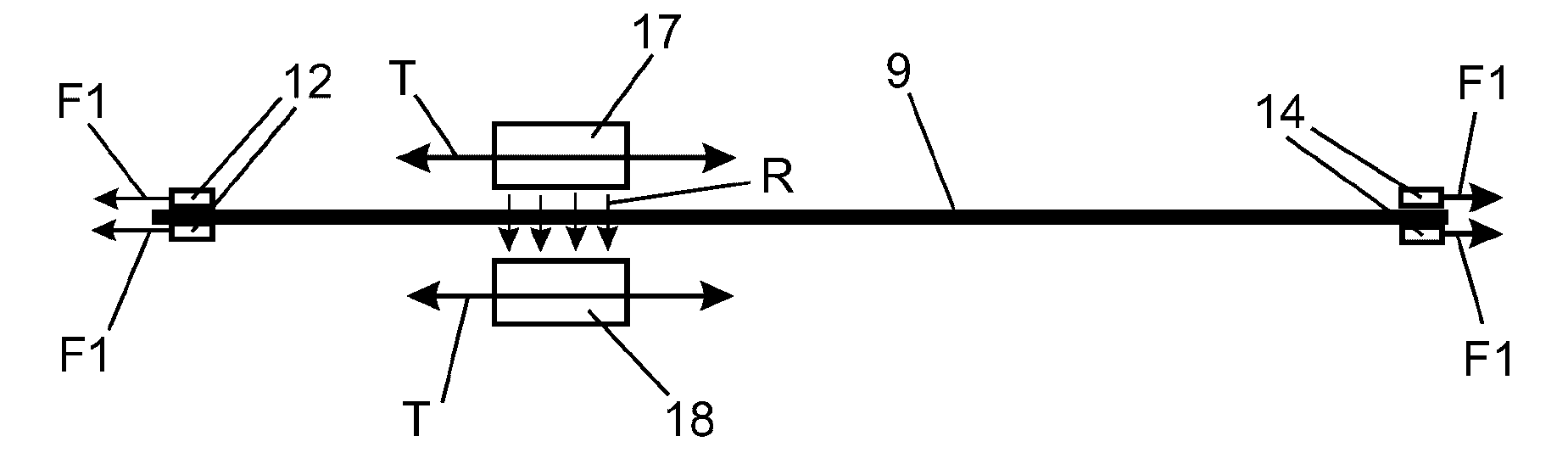

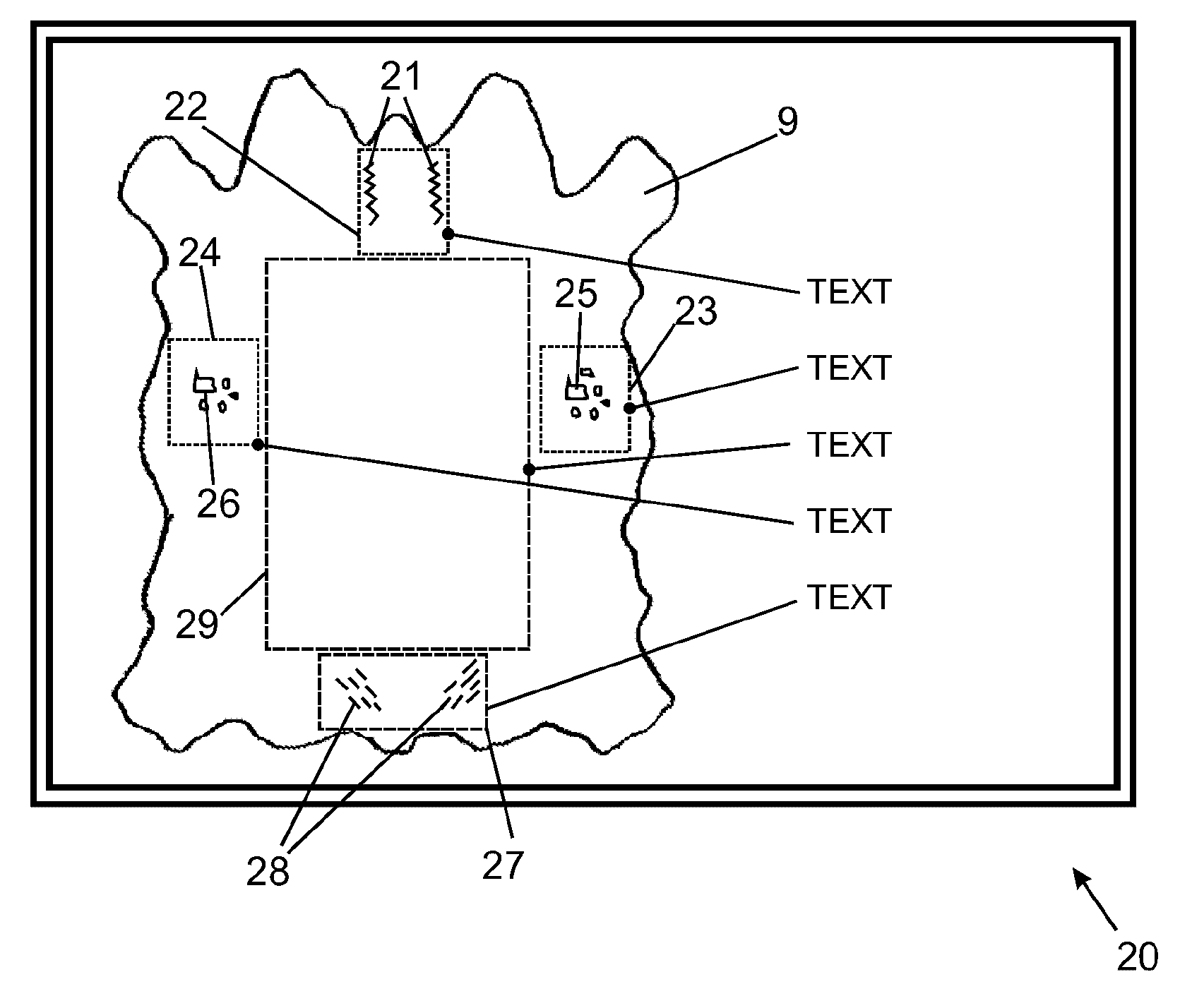

Test device for determining the quality of leather

InactiveCN102725627AEfficient use ofPixel Defect EliminationSkins/hides/leather/fur manufacturing apparatusMaterial testing goodsSkin damageFluoroscopy

The invention relates to a test device (10) for determining the quality of leather (9) in leather production, wherein the test device (10) is designed for testing a quality category of the leather (9) and for outputting a quality value identifying the leather (9) with respect to the quality category, wherein the test device (10) comprises fluoroscopy equipment (16) for testing the homogeneity of the leather (9), by means of which at least partial areas (22, 23, 24, 27, 29) of the leather (9) can be fluoroscopically examined and that are designed for outputting fluoroscopy data (D) to analysis means (19), and the analysis means (19) are designed for comparing the fluoroscopy data (D) to characteristic data typical for skin damage or inhomogeneity in leather (9) and for categorizing detected skin damage of tested partial areas (22, 23, 24, 27, 29) of the leather, and display means (20), and are designed for displaying the categorized skin damage or the quality value of the leather (9), preferably for each partial area (22, 23, 24, 27, 29) of the leather (9).

Owner:WOLLSDORF LEDER SCHMIDT & GES

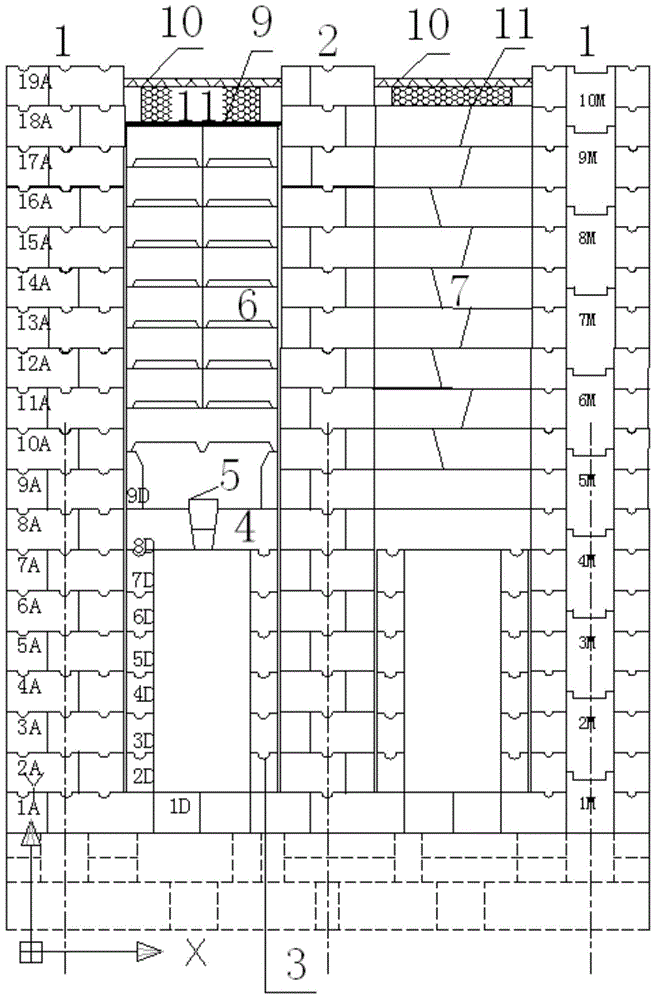

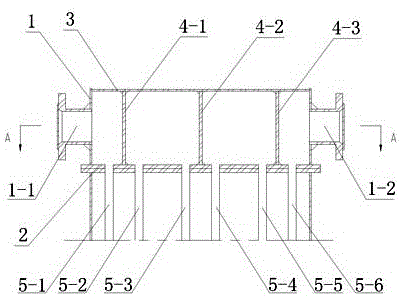

Down-adjusted 7m coke oven regenerative chamber constructing method

InactiveCN104927882AImprove working environmentCreate pollutionCoke oven brickworkBrickArchitectural engineering

The invention discloses a down-adjusted 7m coke oven regenerative chamber constructing method. The method comprises the following steps: firstly, alternately constructing main wall, single wall, small flue lining bricks and grating bricks of a small flue construction section according to construction section and construction order; and then, alternately constructing main wall, single wall, down-adjusted hole adjusting bricks, checker bricks, partition and enclosing wall of a regenerative chamber construction section according to construction section and construction order until reaching the top of a regenerative chamber. Therefore, the constructing method can expand a construction working surface, guarantee constructing quality, facilitate quality inspection, improve working efficiency, improve the working environment of workers and avoid dust pollution to the environment.

Owner:MCC TIANGONG GROUP

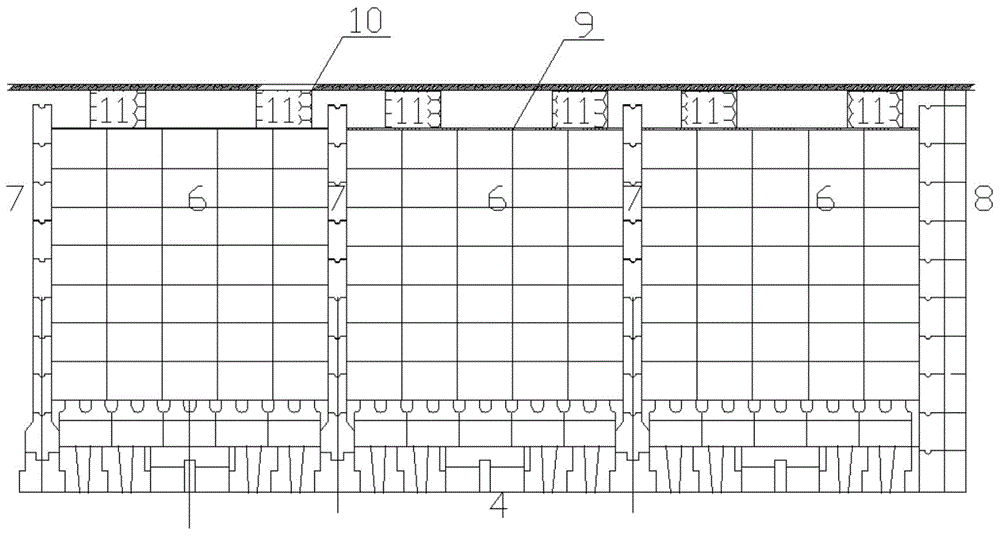

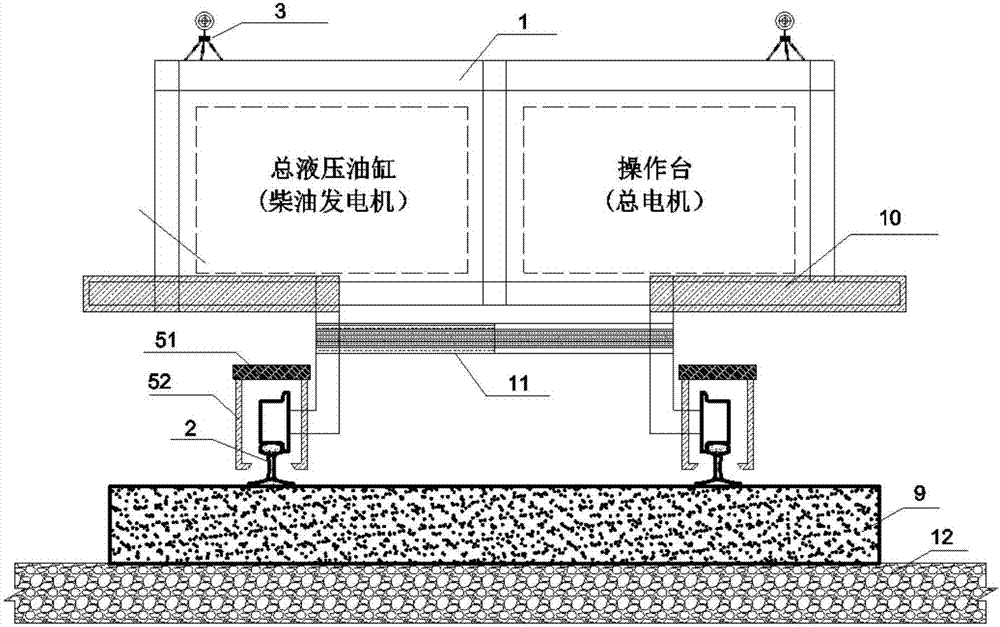

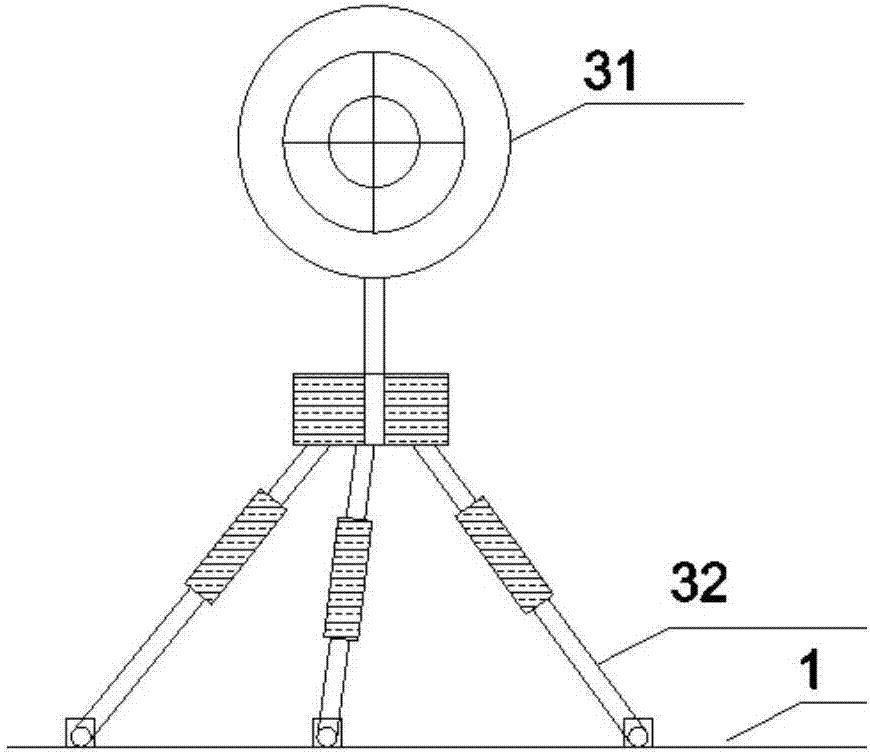

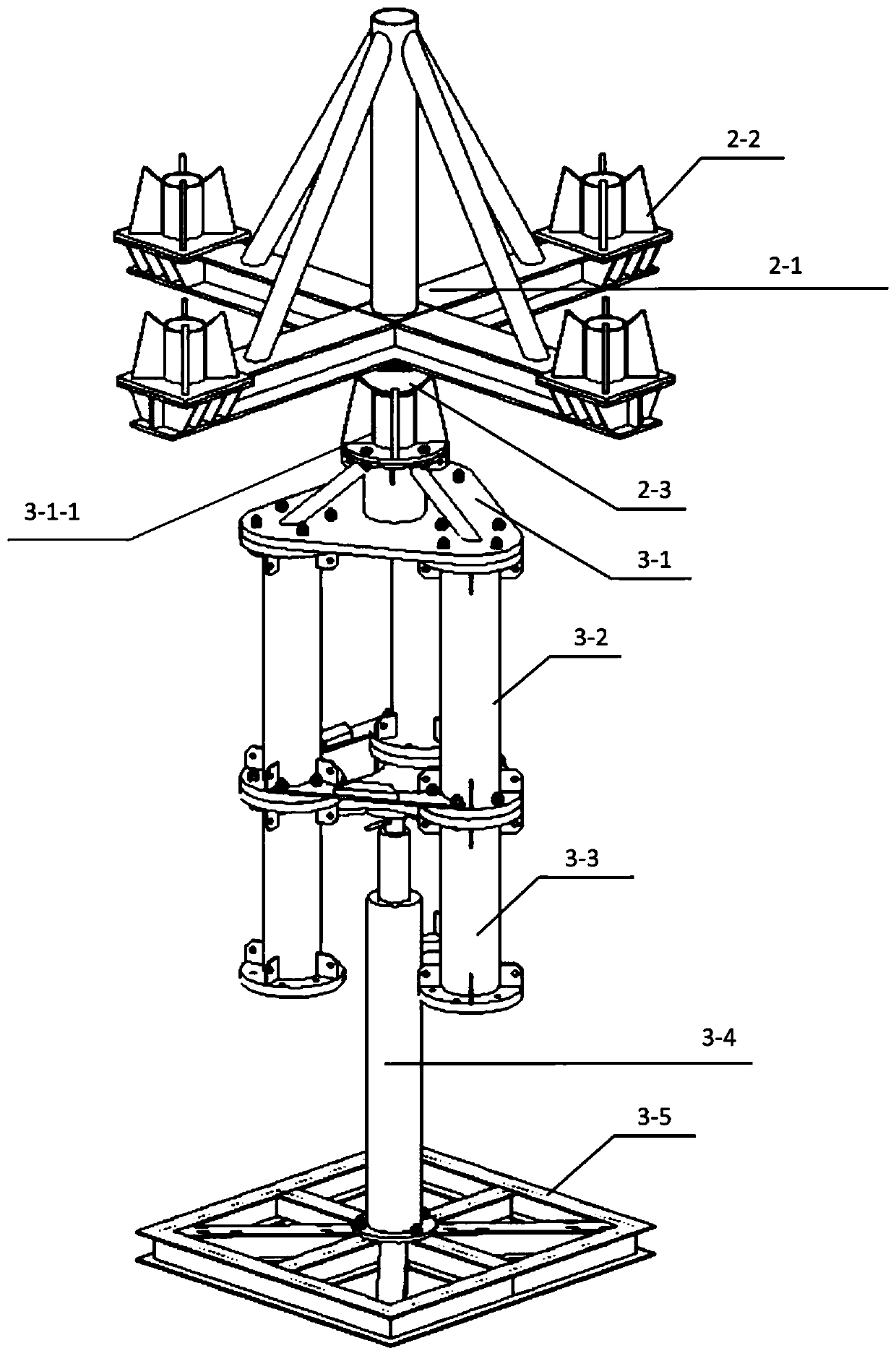

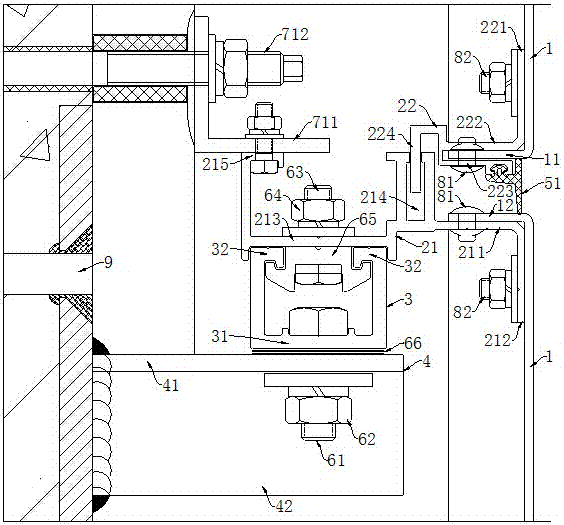

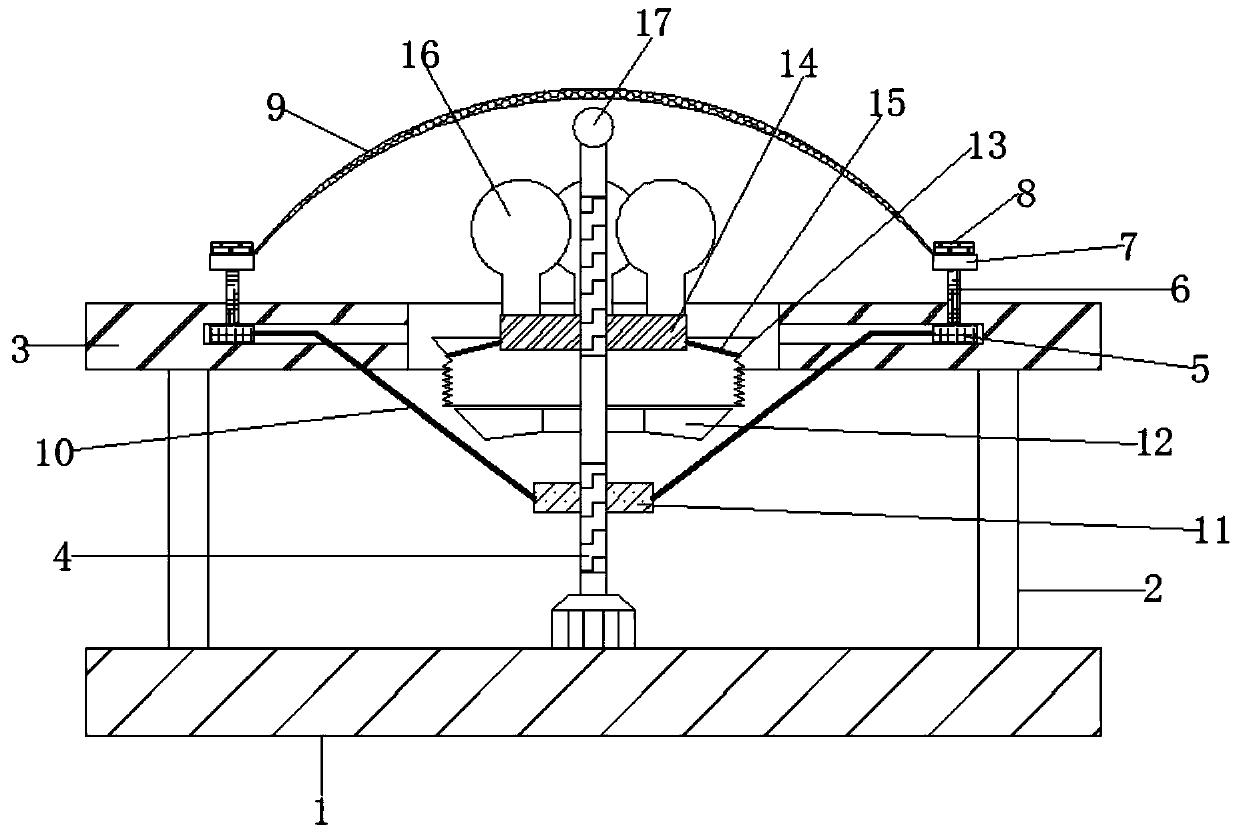

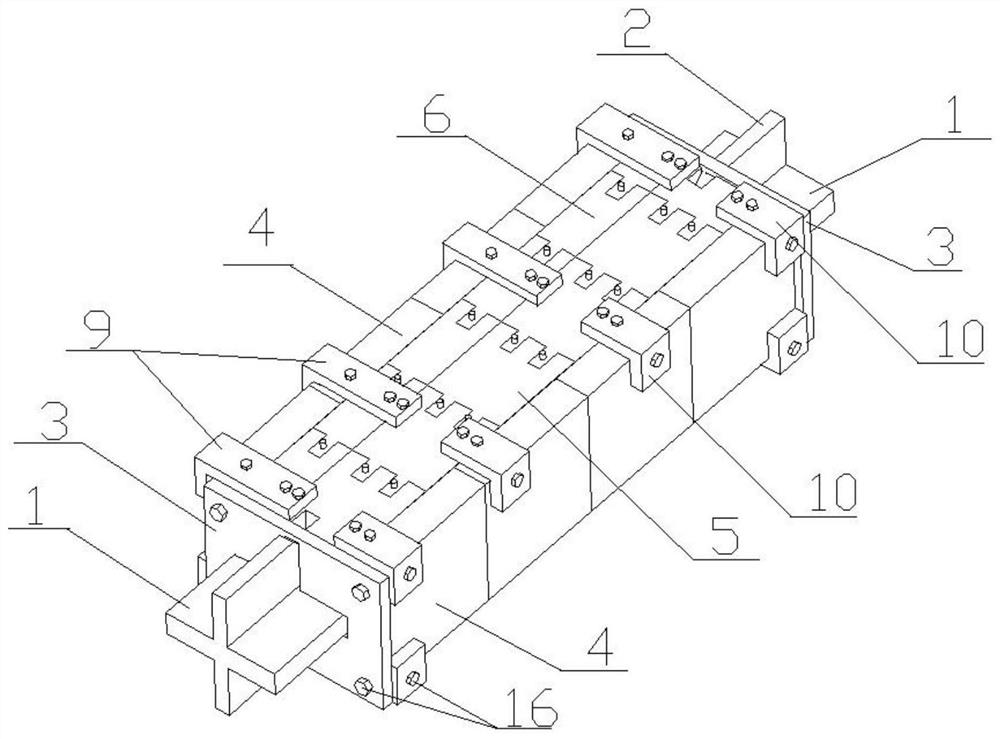

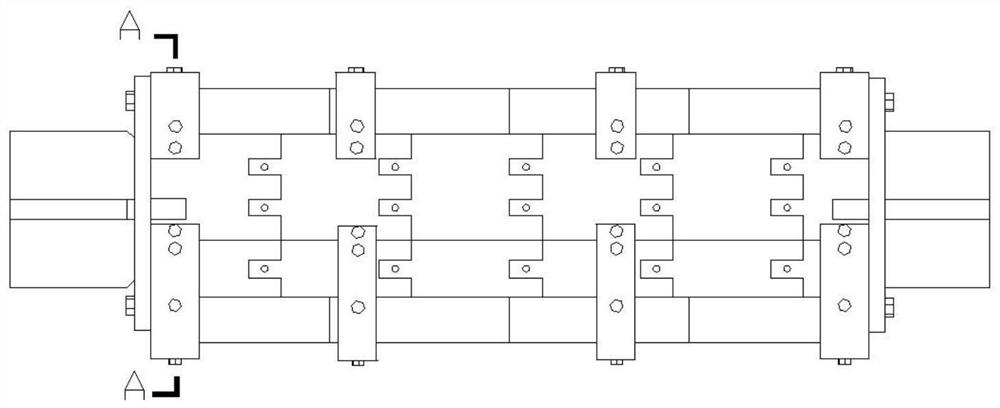

Rapid multifunctional construction equipment for ballast track

PendingCN107190597ASmall sizeFlexible constructionBallastwaySurveying instrumentsTrack bedArchitectural engineering

The invention discloses rapid multifunctional construction equipment for a ballast track. The equipment comprises a main framework, supporting frameworks, lifting combination landing legs arranged on the main framework and concrete vibrating combination devices hung on cross beams of the main framework through connecting frames; hydraulic rail clamping devices used for clamping steel rails are arranged at the bottom of the supporting framework; each lifting combination landing leg comprises a movable support rod and a landing leg hydraulic oil cylinder, each movable support rod comprises a vertical landing leg used for lifting the equipment and the steel rails upwards and integrally and diagonal bracing landing legs making the equipment and the steel rails shift left or right integrally; each concrete vibrating combination device comprises multiple tamping rods, and each connecting frame is provided with a telescopic hydraulic oil cylinder used for controlling and adjusting the depth of the corresponding tamping rod inserted into a railway ballast. Accordingly, ballast track bed construction precision measurement, track raising and lining and tamping are fused together, rapid mechanized operation is achieved, investment of personnel, materials and equipment is greatly reduced, the production efficiency is improved, the construction cost is lowered, and the ballast track bed construction quality requirement is met.

Owner:SINOHYDRO BUREAU 5

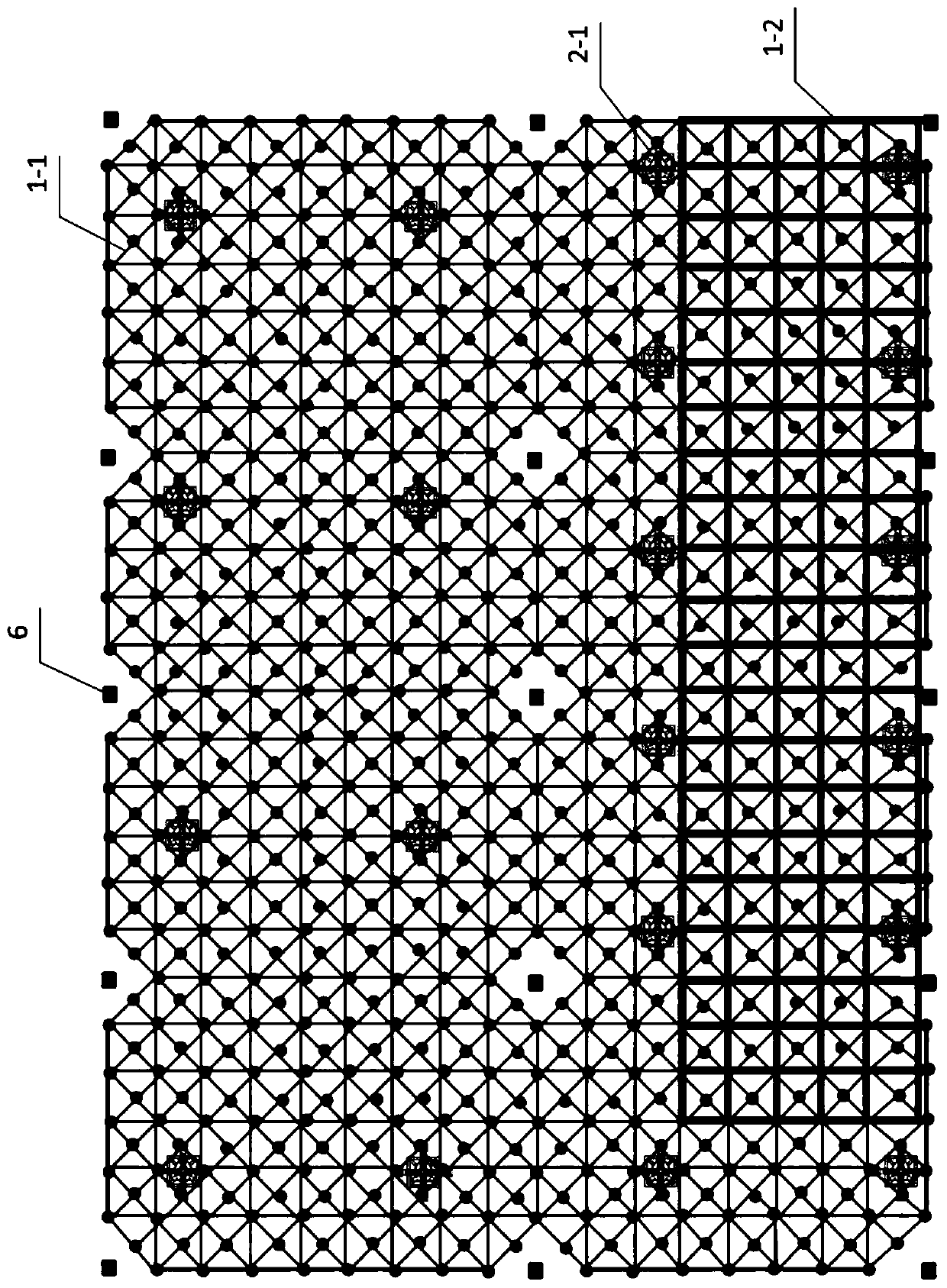

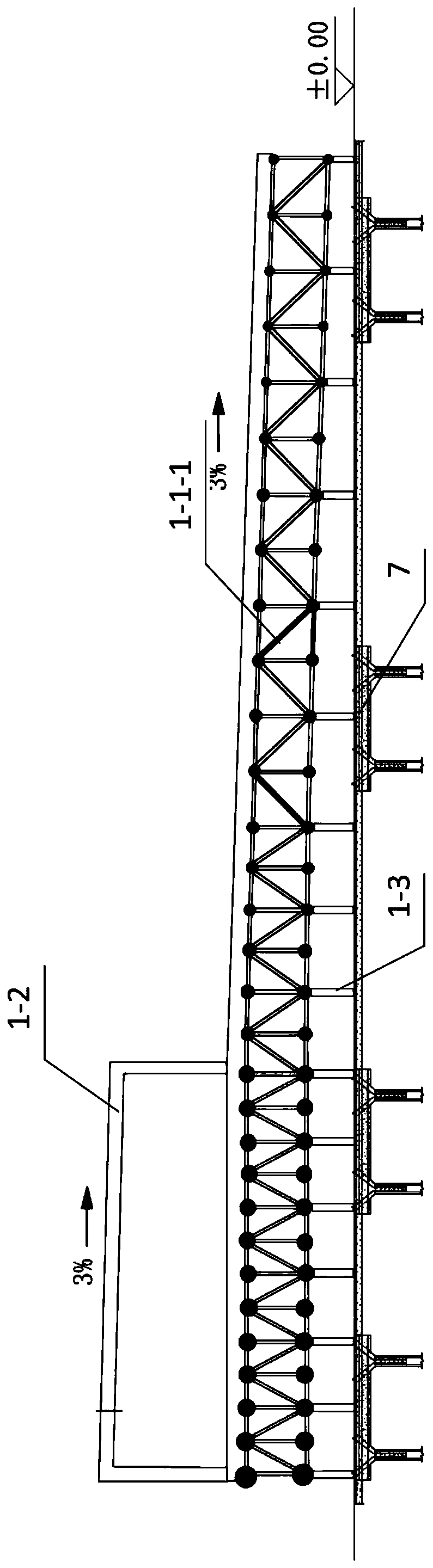

Large-span combined type overload eccentric slope angle steel structure integrated synchronous jacking construction method

ActiveCN110820950AReduced ground assembly heightGuaranteed installation qualityLifting framesBuilding constructionsButtressArchitectural engineering

The invention discloses a large-span combined type overload eccentric slope angle steel structure integrated synchronous jacking construction method. The method comprises the following steps that 1, acorresponding number of jacking foundations are constructed on a terrace according to a plurality of set jacking point locations; 2, after the terrace is hardened, ground splicing and acceptance inspection of combined steel structures are performed; 3, jacking equipment is installed, and jacking is performed; 3.1, ground assembling of crossed joists is performed on the multiple set jacking pointlocations; 3.2, the crossed joists are lifted to the positions of net rack upper chord balls; 3.3, hemispherical hinged supports are concentrically welded to the bottoms of the crossed joists; 3.4, the combined steel structures achieve supporting conversion from net rack lower chord balls supported by buttresses to the net rack upper chord balls supported by jacking frames through a jack; 3.5, synchronous jacking is performed; 3.6, supplementing and splicing installing of net rack support position balls and connecting rod pieces thereof can be performed, and then the whole structure falls backin position. Overhead operation can be greatly reduced, and safety and reliability are achieved.

Owner:中建六局第一建设有限公司 +1

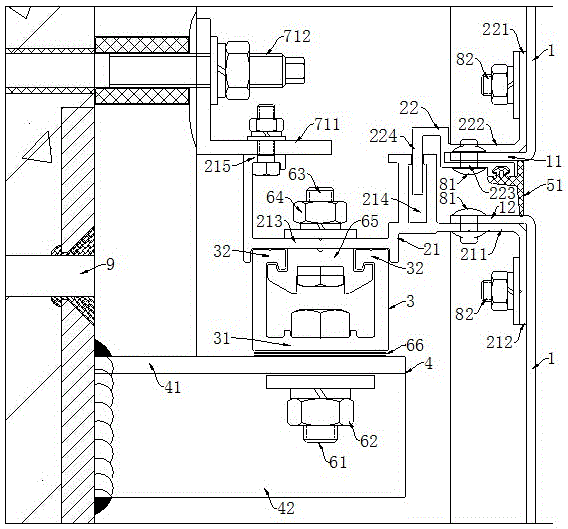

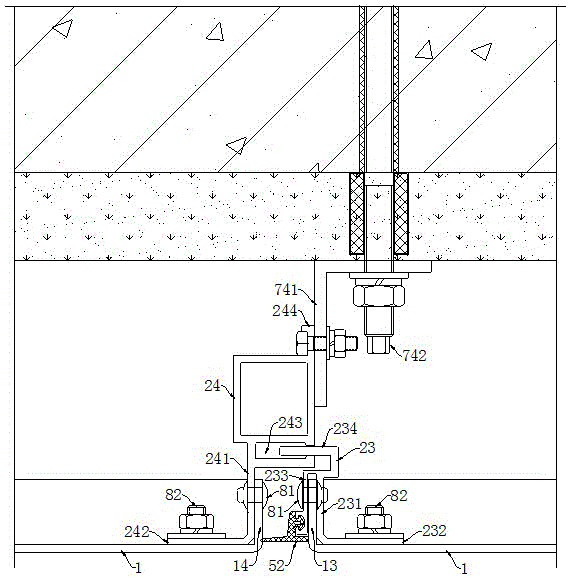

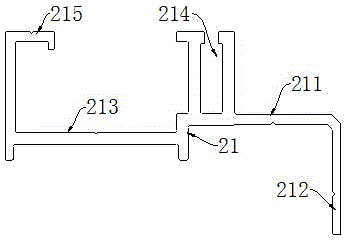

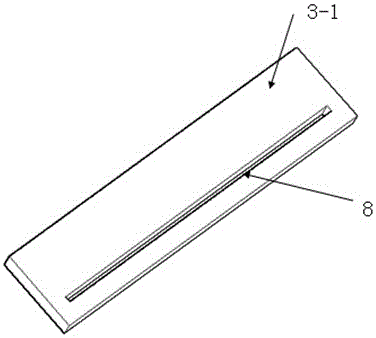

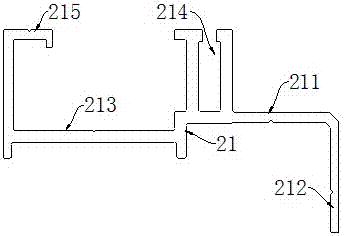

Unit-type metal curtain wall

The invention discloses a unit-type metal curtain wall which comprises a plurality of rectangular metal plates in transverse-vertical splicing connection, through connection members, and shielding members used for shielding dividing joints between each two adjacent metal plates. Each through connection member comprises a vertical reinforcing side rib used for being connected with a vertical free side on the right side, a vertical connecting side rib used for being connected with a vertical free side on the left side, a transverse connecting side rib used for being connected with a transverse free side at the bottom, a transverse reinforcing side rib used for being connected with and supporting a transverse suspending side at the top, a transverse through connection groove used for being connected with and supporting a transverse reinforcing side rib, and channel steel used for being connected with and supporting the transverse through connection groove. Deformation of the metal plates of the curtain wall caused by temperature changing can be eliminated effectively, convex faces or concave faces of the metal plates are prevented, and a curtain wall framework is not needed.

Owner:苏州市鑫泰建筑装璜有限公司

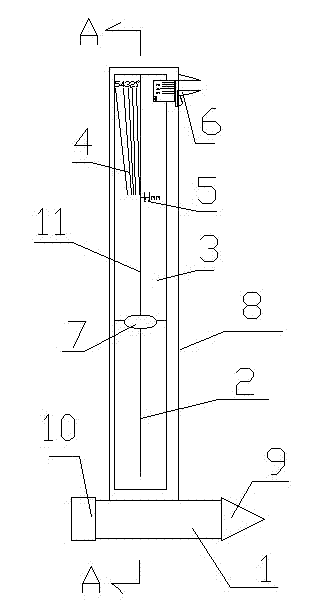

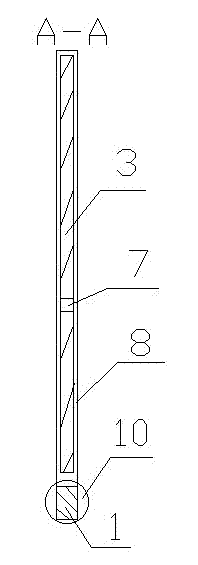

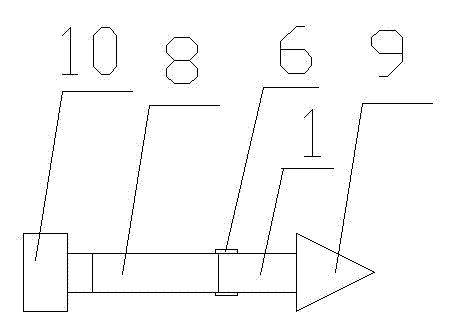

Electric slag pressure welding appearance quality measuring device and using method thereof

InactiveCN103090763AOn-site quality inspection is convenientEasy QAAngles/taper measurementsElectricitySlag

An electric slag pressure welding appearance quality measuring device and a using method thereof comprise a measuring ruler and an iron hammer. The measuring ruler is provided with an electric slag pressure welding package placing hole, a steel bar axis reference line is engraved at the up-down center position of the measuring ruler, the measuring ruler is provided with a welding package height measurement caliper, an up-down steel bar joint bending angle index dial engraved with a welding package and a steel bar axis offset index dial. A protruded electric slag pressure welding package is sleeved inside the electric slag pressure welding package placing hole, a welding package lower steel bar axis aims at a lower reference line of the steel bar axis the measuring ruler, an upper reference line of the steel bar axis of the measuring ruler is used as the comparison reference of an upper steel bar, the welding package height measurement caliper on the upper right corner is moved in a sliding mode to enable the electric slag pressure welding package to be clamped up and down, and the height of the welding package is measured out through the index dial of the welding height measuring caliper. According to the electric slag pressure welding appearance quality measuring device, by manufacturing of a factory, field quality check is convenient, data are accurate, effective control to the quality of electric slag pressure welding in a construction site can be achieved, and the electric slag pressure welding appearance quality measuring device is economic and suitable for being used.

Owner:CHINA MCC17 GRP

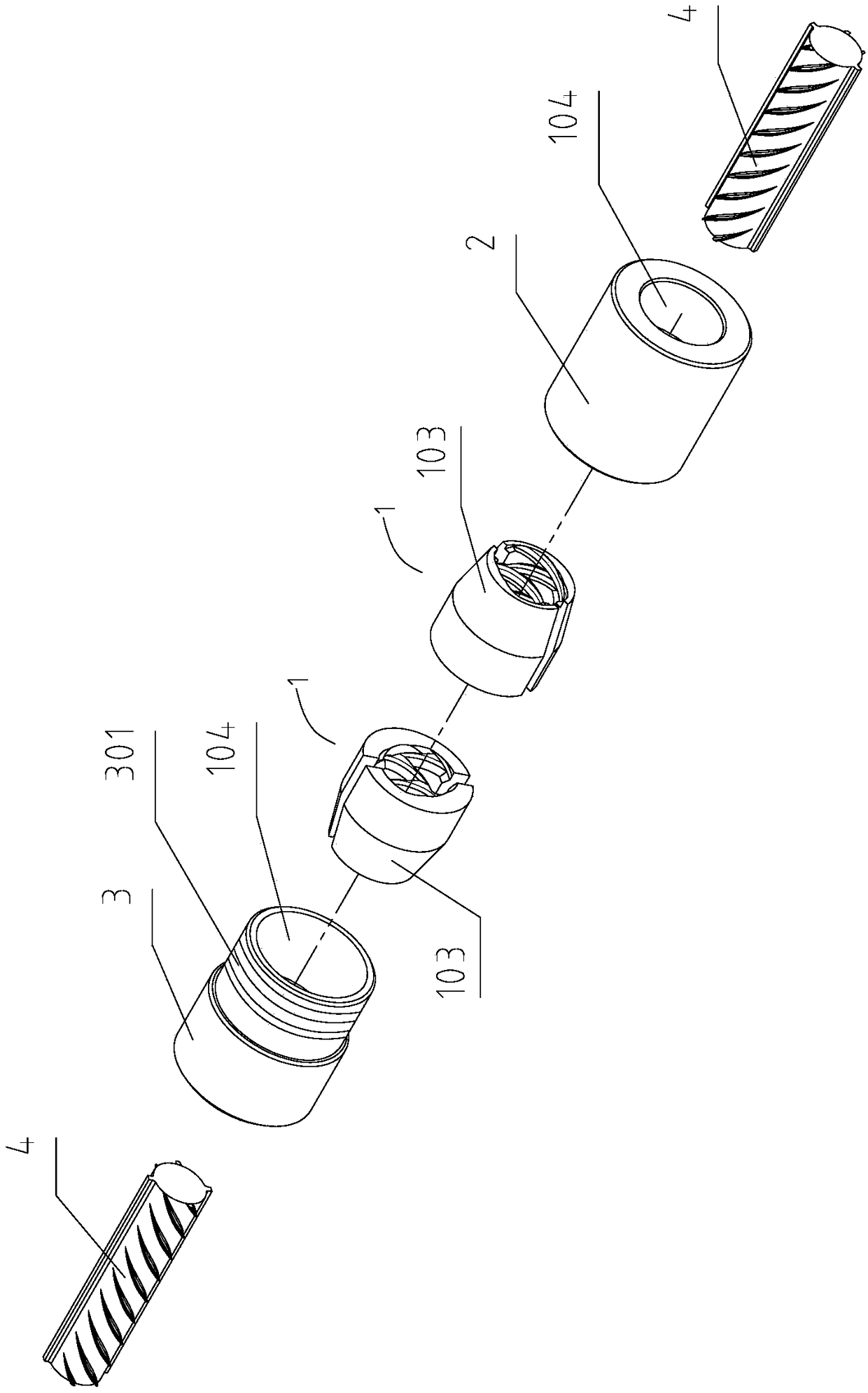

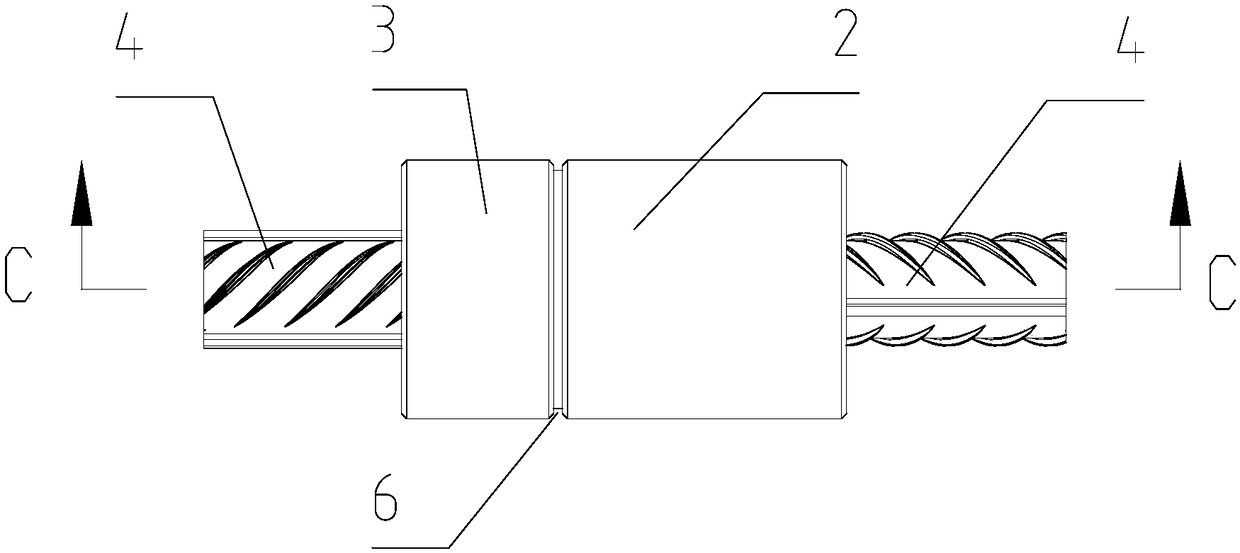

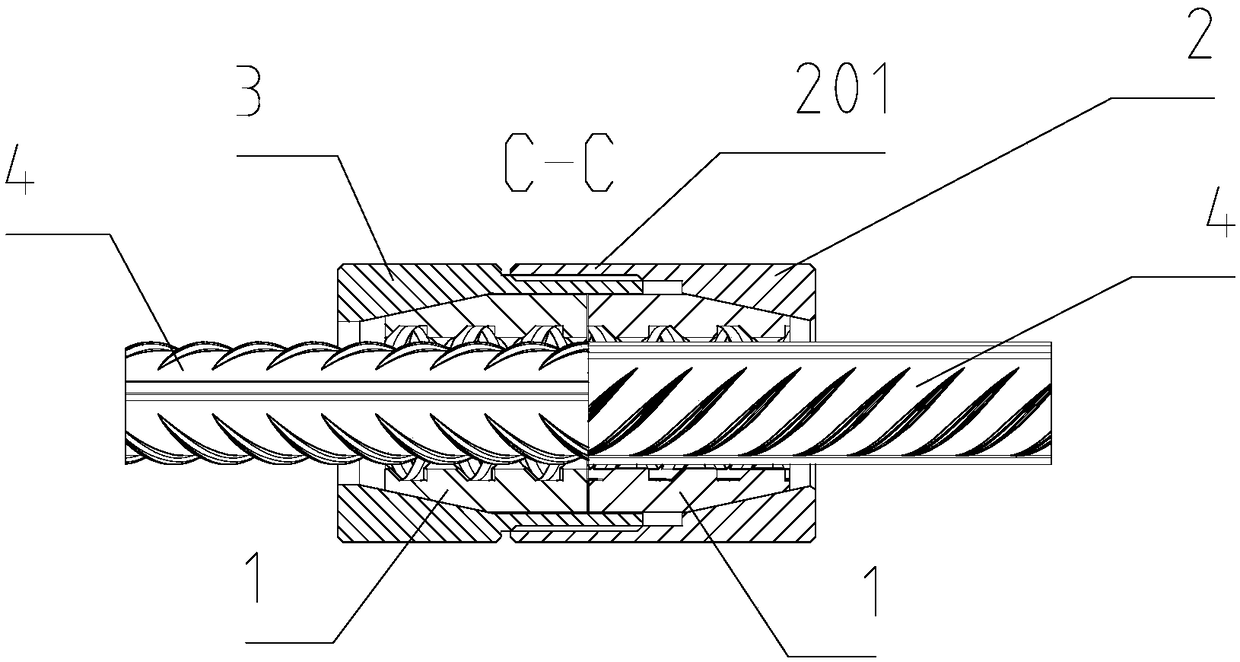

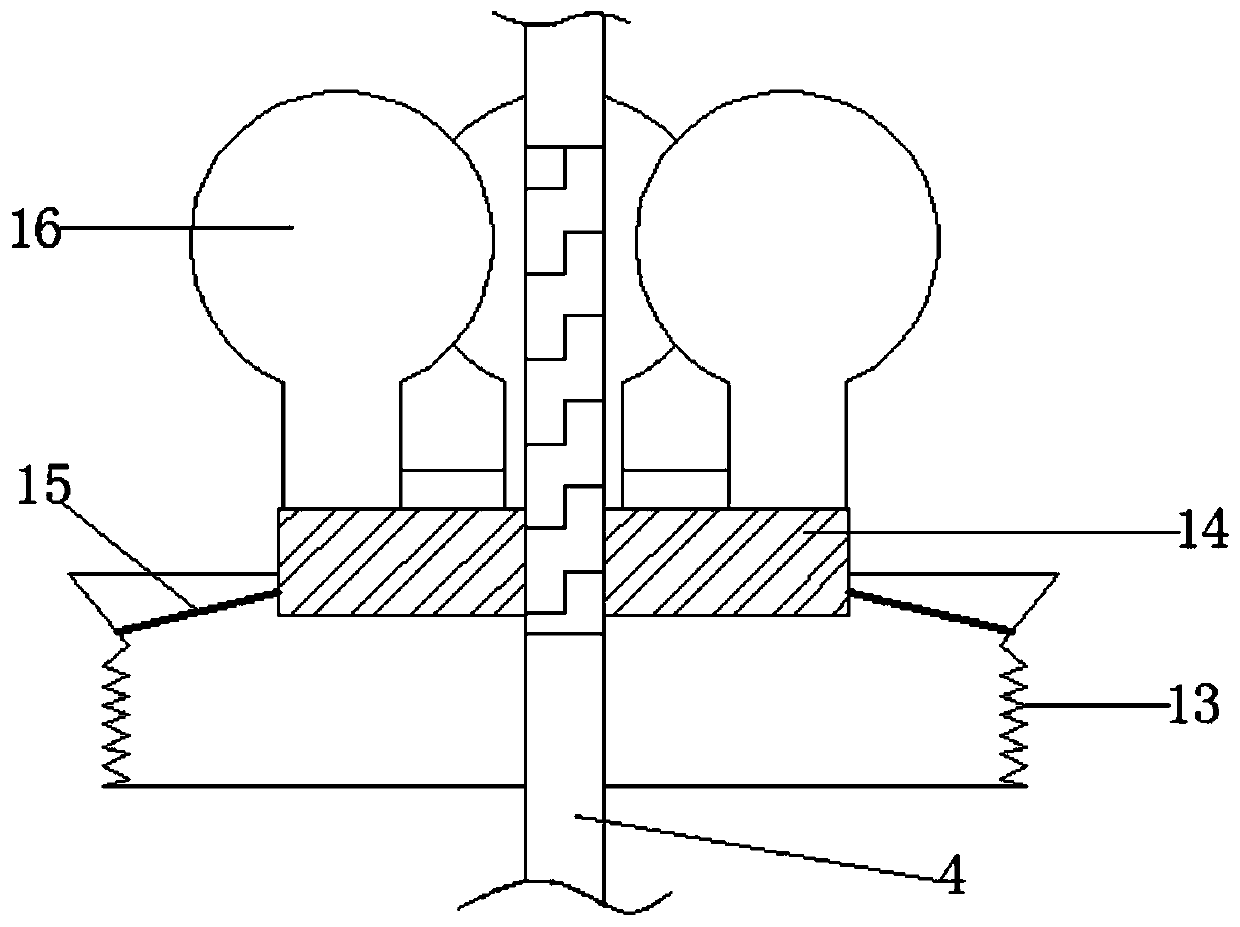

Steel bar mechanical connecting piece and steel bar mechanical connecting method

InactiveCN108756075AFacilitate axial clamping forceNo quality problemsBuilding reinforcementsArchitectural engineeringSteel bar

The invention relates to a steel bar mechanical connecting piece and a steel bar mechanical connecting method. According to the steel bar mechanical connecting piece and the steel bar mechanical connecting method, the technical problems that existing steel bar connecting is unreliable in quality and cumbersome in operation are solved. The steel bar mechanical connecting piece is provided with twoembracing clamping hoops which are located on the left side and the right side correspondingly, embracing inner cavities are formed in the embracing clamping hoops, and steel bars can be embraced in the embracing inner cavities through the embracing clamping hoops; and locking outer conical surfaces are arranged at the tails of the embracing clamping hoops, anti-sliding buckling devices are arranged on the inner surfaces of the embracing inner cavities, anti-sliding buckling clamping grooves serve as the anti-sliding buckling devices, and the direction of the anti-sliding buckling clamping grooves is consistent with the direction of protruding patterns on the outer surfaces of the steel bars. The steel bar mechanical connecting piece can be widely used for mechanical connection of the building steel bars.

Owner:于洋

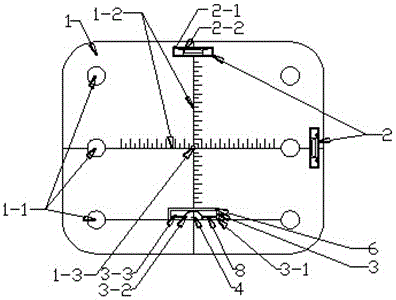

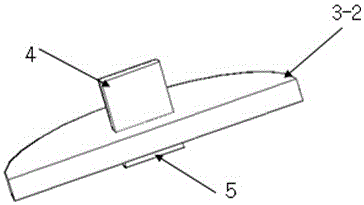

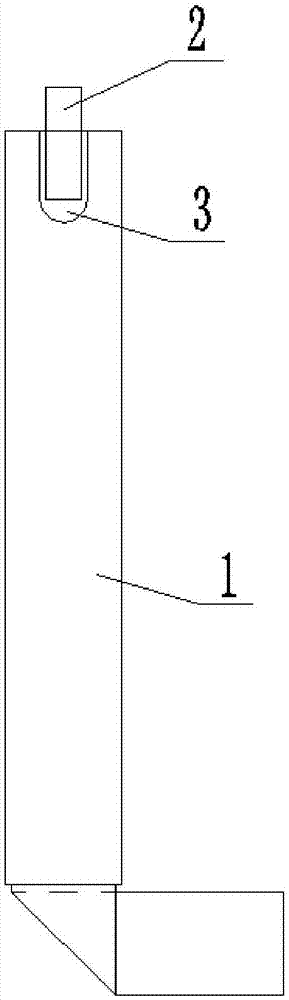

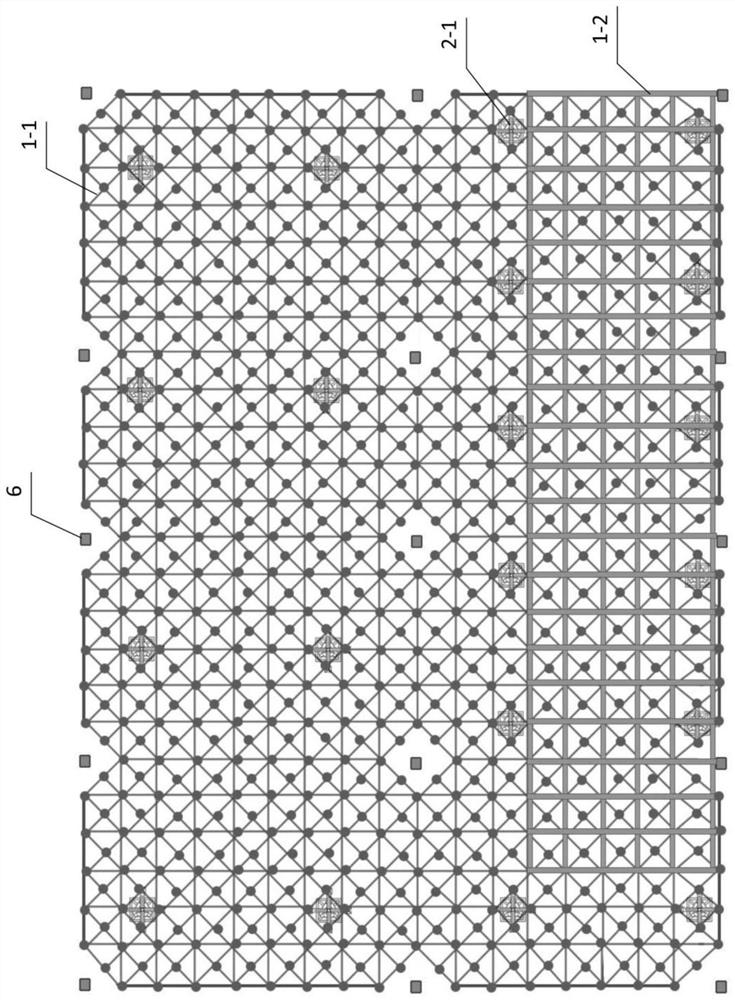

Tool plate for embedded bolt assembly installation and checking

InactiveCN106352776AImprove installation accuracyImprove installation efficiencyAngles/taper measurementsMechanical clearance measurementsProtractorEaves

The invention discloses a tool plate for embedded bolt assembly installation and checking. The tool plate is made of hard transparent plastics, and comprises a tool plate body (1), a horizontal device (2) and a built-in movable protractor (3), wherein a target bolt hole (1-1), a cross graduation graduated scale (1-2), a centering hole (1-3), a horizontal pipe preserved hole (2-1) and a protractor moving cavity (3-3) are formed in the tool plate body (1); a high-precision horizontal plate (2-2) is implanted in the horizontal pipe preserved hole (2-1) to form the horizontal device (2); a bulge 5 of a purpose-made angle disc (3-2) is embedded into a chute 7; a push-pull handle 4 passes through a chute 8; an angle measuring cover plate (3-1) is bonded with a cover plate eave edge 6, so that the built-in movable protractor (3) is formed. When the tool plate is used for embedded bolt installation and checking process, each installation index of a bolt assembly can be precisely and efficiently detected; basis is provided for installation; a reliable measure is provided for checking.

Owner:CHINA RAILWAY NO 5 ENG GRP +1

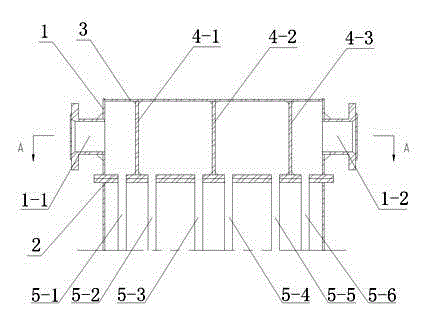

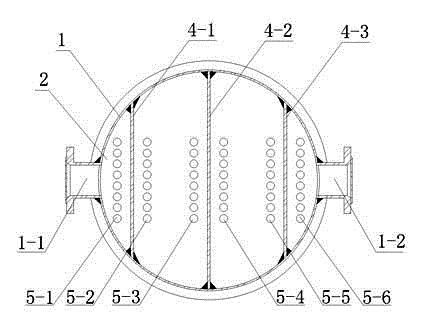

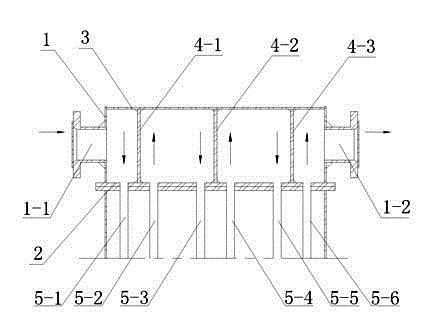

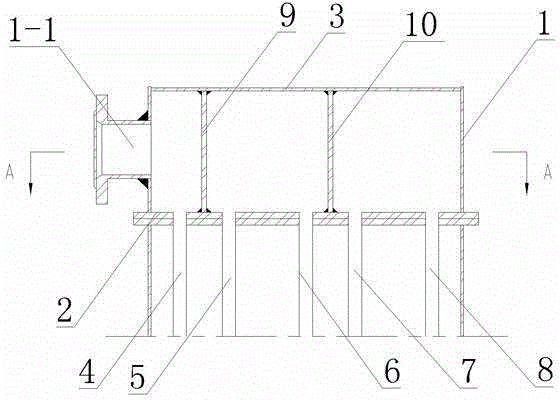

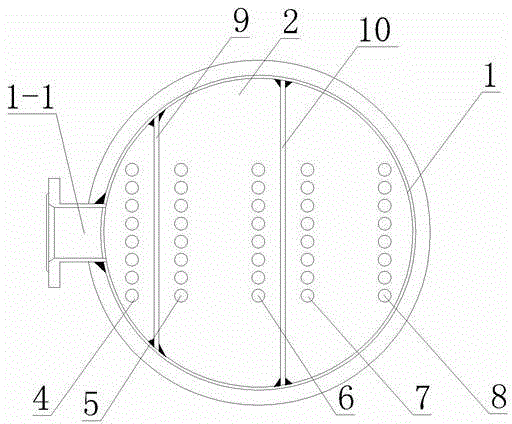

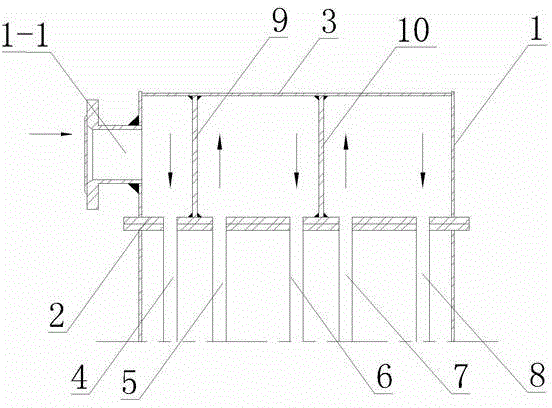

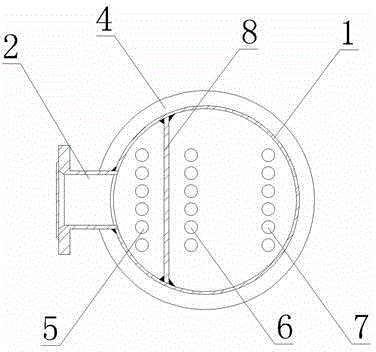

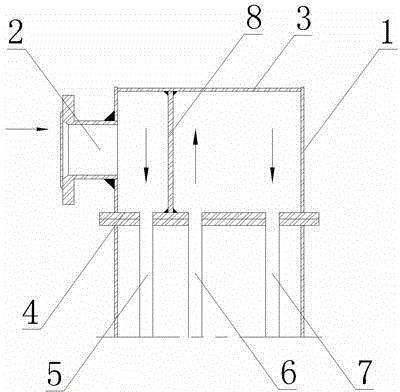

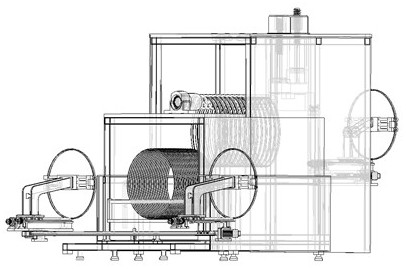

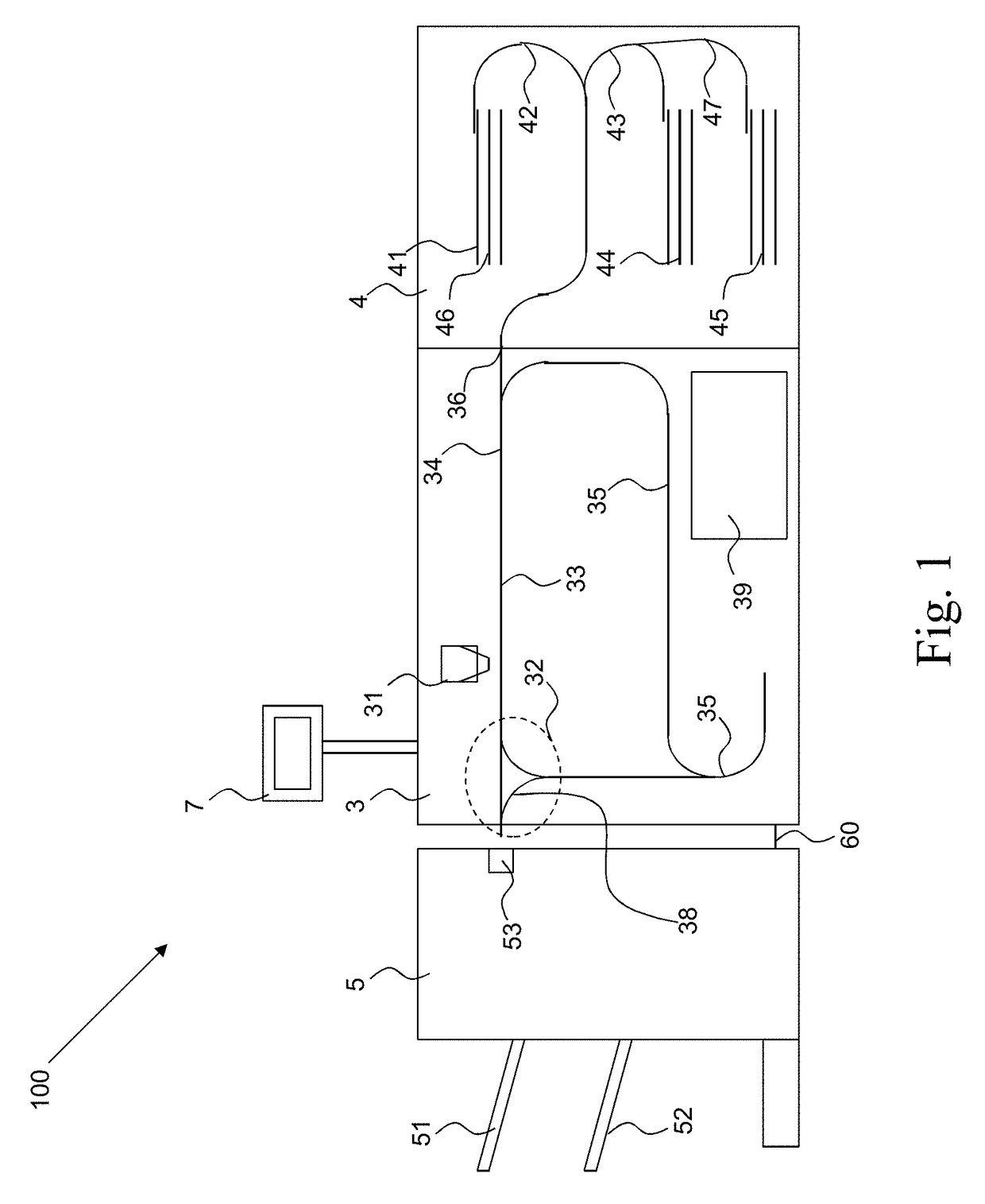

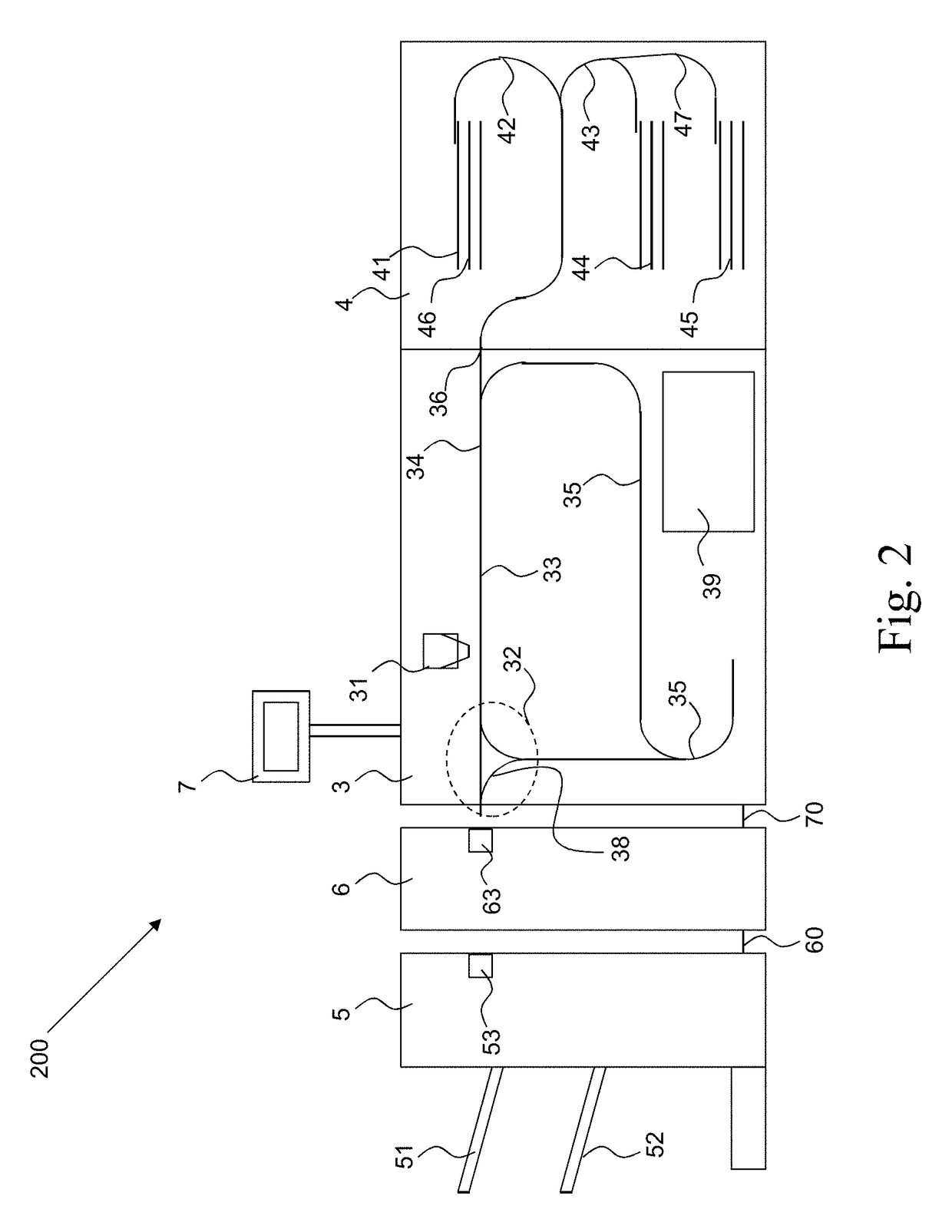

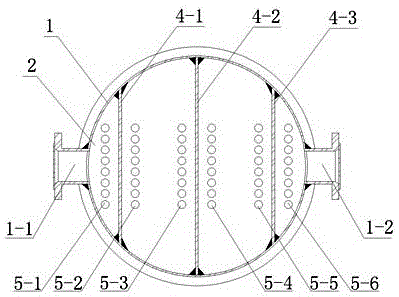

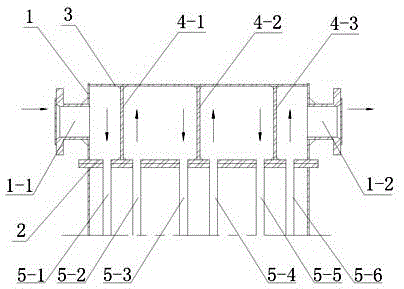

Tube box welding structure and manufacturing method

The invention discloses a tube box welding structure and a manufacturing method. The tube box welding structure comprises a barrel, wherein the side walls of the barrel are provided with a feed inlet and a discharge outlet respectively, a flat base end socket and a tube plate are welded to the two ends of the barrel respectively, the lower portion of the tube plate is communicated with six heating tubes, two baffle plates in the barrel divides the barrel into four chambers, the first chamber enables the feed inlet to be communicated with the first heating tube, the second chamber enables the second heating tube to be communicated with the third heating tube, the third chamber enables the fourth heating tube to be communicated with the fifth heating tube, and the sixth chamber enables the second heating tube to be communicated with the discharge outlet. The manufacturing method includes the steps of welding the barrel, the tube plate, the baffle plates and the flat base end socket in sequence. The tube box welding structure and the manufacturing method facilitate shaping of a tube box, enable welding operation to be more convenient, and better facilitate spacing distribution after baffling is completed.

Owner:JIANGSU JIATAI EVAPORATION CRYSTALLIZATION EQUIP

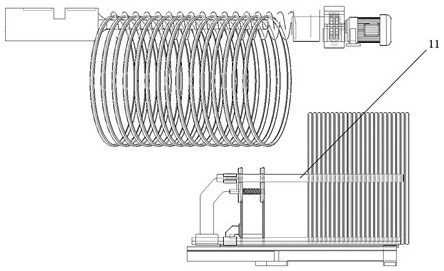

Heat exchanger tube box welding structure and manufacturing method

InactiveCN104019692AEasy to handleImprove heat transfer efficiencyHeat exchanger casingsEngineeringHeat exchanger

The invention discloses a heat exchanger tube box welding structure and a manufacturing method. The structure comprises a barrel, wherein one side wall of the barrel is provided with a feed inlet, a flat base end socket and a tube plate are welded to the two ends of the barrel respectively, the lower portion of the tube plate is communicated with five heating tubes, two baffle plates in the barrel divides the barrel into three chambers, the first chamber enables the feed inlet to be communicate with the first heating tube, the second chamber enables the second heating tube to be communicated with the third heating tube, and the third chamber enables the fourth heating tube to be communicated with the fifth heating tube. The manufacturing method includes the steps of welding the barrel, the tube plate, the baffle plates and the flat base end socket in sequence. The heat exchanger tube box welding structure and the manufacturing method facilitate shaping of a tube box, enable welding operation to be more convenient, and better facilitate spacing distribution after baffling is completed.

Owner:JIANGSU JIATAI EVAPORATION CRYSTALLIZATION EQUIP

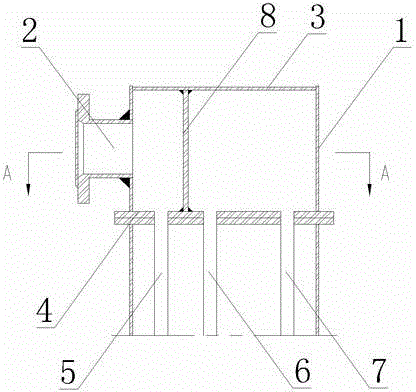

Evaporator heat exchanger tube box welding structure and manufacturing method

InactiveCN104014150AEasy to handleImprove heat transfer efficiencyEvaporator accessoriesEngineeringHeat exchanger

The invention discloses an evaporator heat exchanger tube box welding structure and a manufacturing method. The structure comprises a barrel with a feeding hole in the side wall, wherein a flat bottom head and a tube plate are welded at the two ends of the barrel respectively; a first heating tube, a second heating tube and a third heating tube are communicated below the tube plate; a baffle plate in the barrel separates the barrel into a first chamber and a second chamber; the first chamber is communicated with the feeding hole and the first heating tube; the second chamber is communicated with the second and third heating tubes. The manufacturing method comprises the step of welding the barrel, the tube plate, the baffle plate and the flat bottom head in sequence. The evaporator heat exchanger tube box welding structure and the manufacturing method are beneficial for forming a tube box, are more convenient for welding and are more beneficial for space distribution after baffling.

Owner:JIANGSU JIATAI EVAPORATION CRYSTALLIZATION EQUIP

Quality control method for cleaning liquor and its derivative formulation for female

ActiveCN1839985AQuality improvementEasy QAHydroxy compound active ingredientsComponent separationLotionAuthentication

The invention discloses a quality control method for women's washing lotion and its derivating agents including bougie, vaginal gelling agent, vaginal tablet and effervescent tablet, characterized in that a process of thin-layer authentication for pomegranate bark and borneo camphor is added, and a high performance liquid phase chromatographic method is employed to control the quality of the medicament.

Owner:江西康美医药保健品有限公司

Unitized Metal Curtain Wall

Owner:苏州市鑫泰建筑装璜有限公司

Capacitor lead wire connecting structure and manufacturing method thereof

The invention relates to a capacitor lead wire connecting structure and a manufacturing method thereof. The capacitor lead wire connecting structure comprises a core lead-out connecting piece and a copper stranded wire. The end face of the core lead-out connecting piece is provided with a fixing groove. The copper stranded wire is arranged inside the fixing groove. The manufacturing method comprises the following steps: 1, punching the fixing groove at one end of the core lead-out connecting piece by using a mold; 2, placing the capacitor bushing copper stranded wire into the fixing groove atone end of the core lead-out connecting piece; 3, melting a tin bar into tin water by using electric soldering iron, causing the tin water to slowly penetrates gaps between the copper stranded wire and the fixing groove, repeating the soldering three times until the tin water completely fills the fixing groove, and covering the copper stranded wire with three tin layers; and 4, removing the residual tin with the high-temperature electric soldering iron. The capacitor lead wire connecting structure completely avoids the influences of manmade omitted pressing and virtual pressing, improves connection reliability, greatly reduces the contact resistance at the joint, and can withstand high-strength and high-current impulse discharge.

Owner:WUXI SUNKING POWER CAPACITOR CO LTD

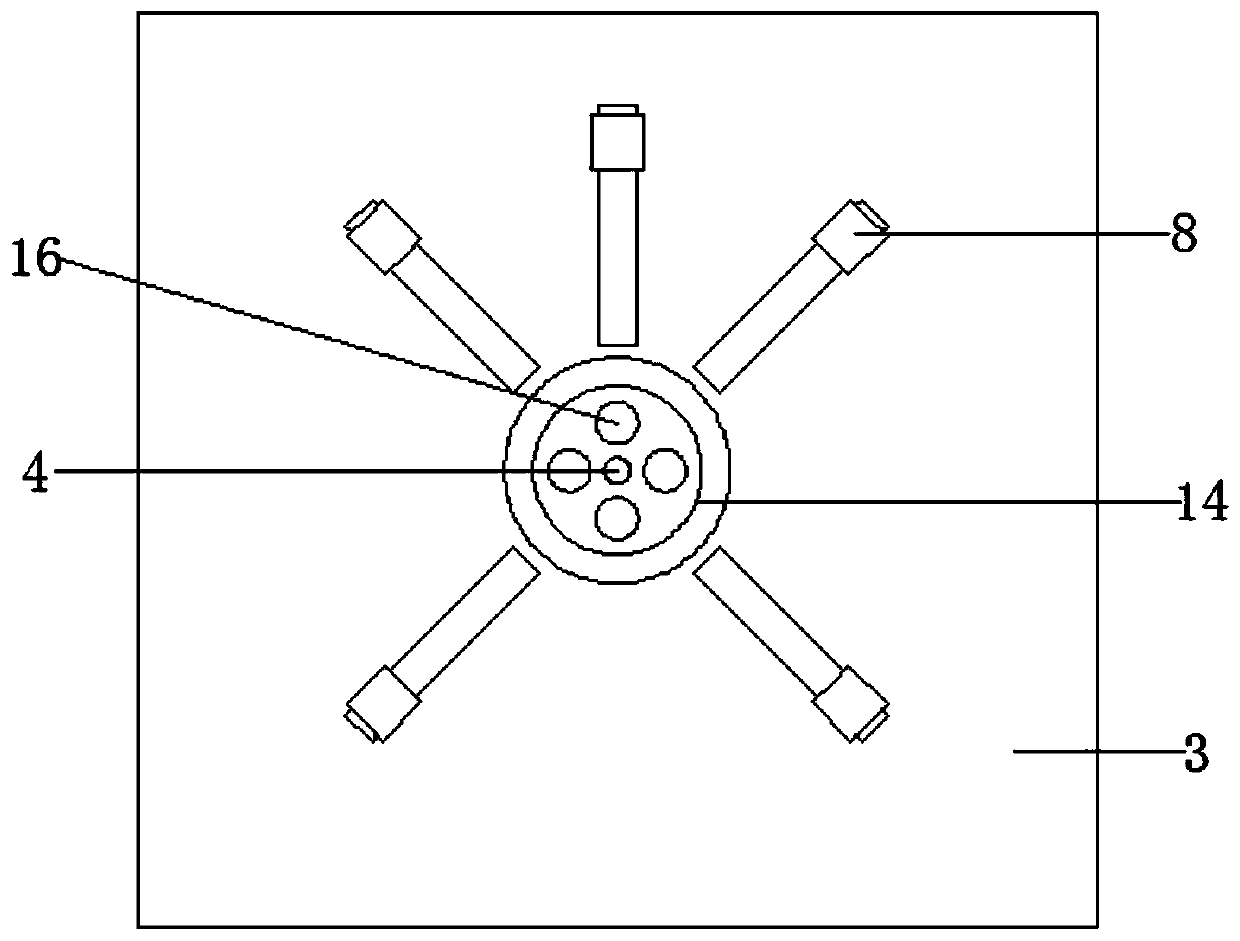

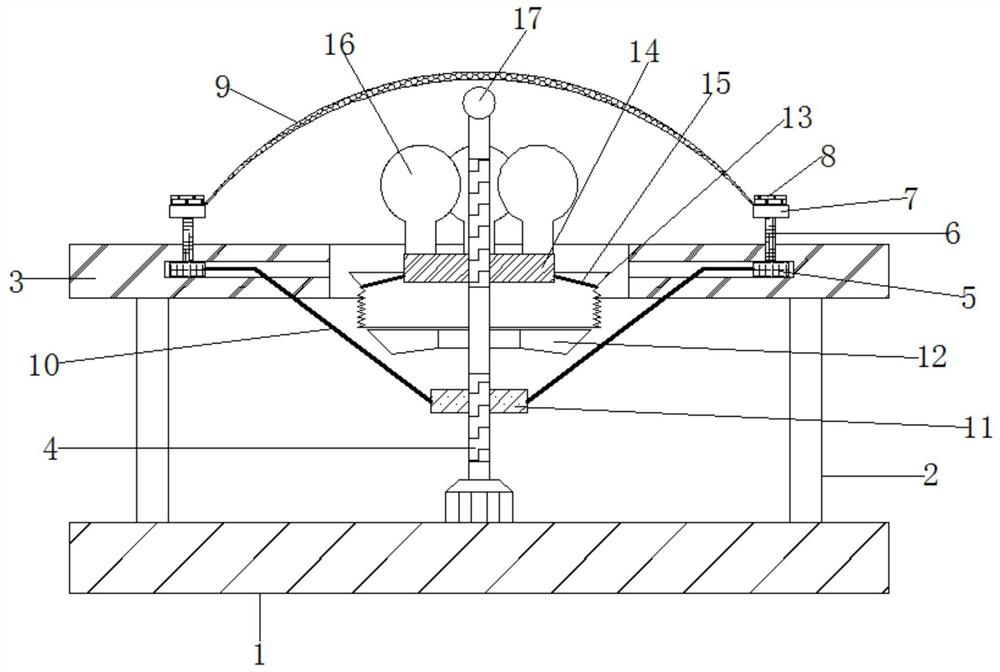

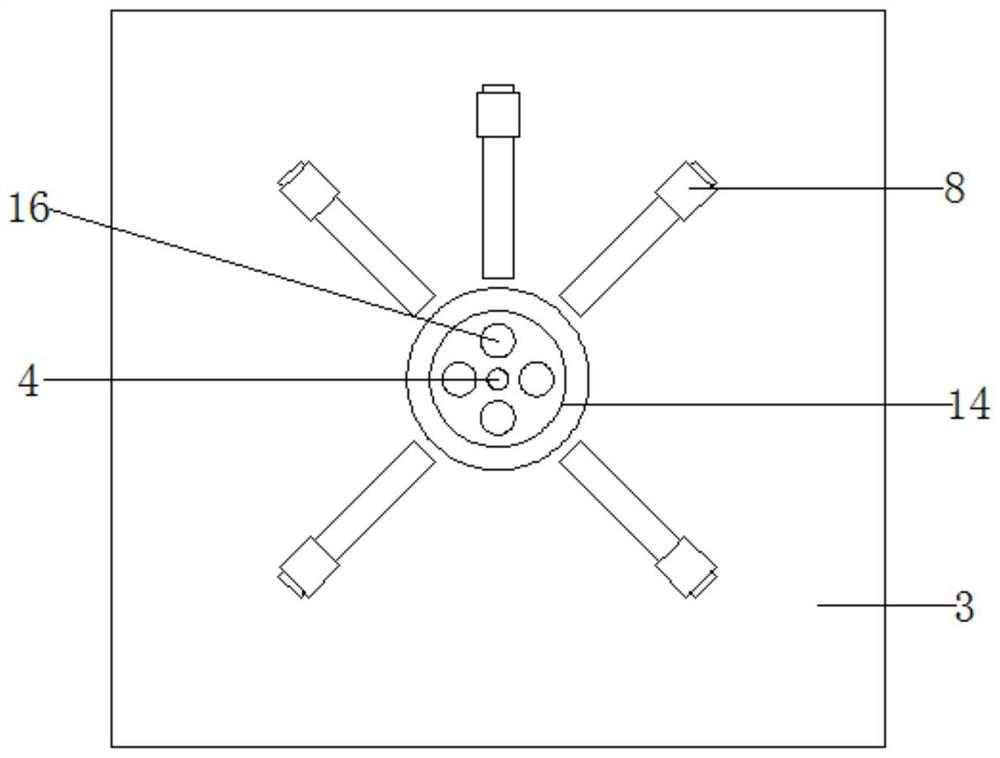

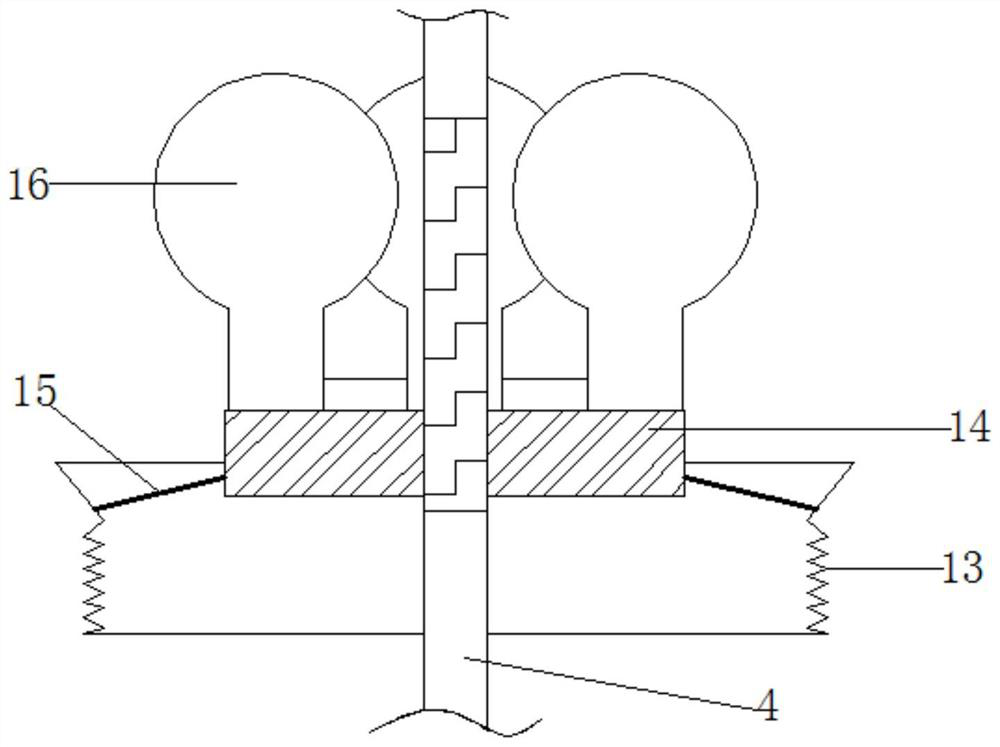

Quality inspection device for diaphragm structure installation

ActiveCN110609044AEasy QAEasy to checkOptically investigating flaws/contaminationDiaphragm structureEngineering

The invention, which relates to the technical field of diaphragm structure detection, discloses a quality inspection device for diaphragm structure installation. The device comprises a bottom plate and a supporting plate. A rotating shaft is arranged above the bottom plate. A movable block is arranged in the supporting plate; a fixed magnetic block and a movable magnetic block are arranged above the movable block; and a diaphragm is arranged between the movable magnetic block and the fixed magnetic block. A first rope is fixedly connected to the side face of the movable block; one end of the first rope is fixedly connected with a screw block arranged at the lower portion of a rotating shaft; fan blades are fixedly connected to the middle of the rotating shaft; and a folding air pipe is fixedly connected to the rotating shaft above the fan blades. A lamp holder is connected to the upper portion of the rotating shaft. According to the quality inspection device, the diaphragm can be bulged and unfolded and the bulged diaphragm can be checked rapidly and observably by cooperating with a light source. The diaphragm can be unfolded to realize observation conveniently; and the diaphragm can be rapidly and comprehensively inspected.

Owner:山东瑞谱检测技术有限公司

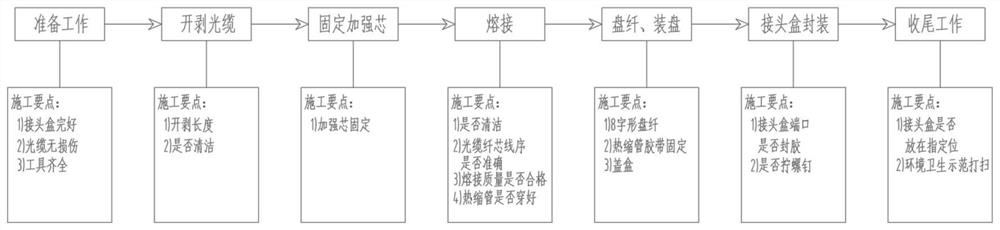

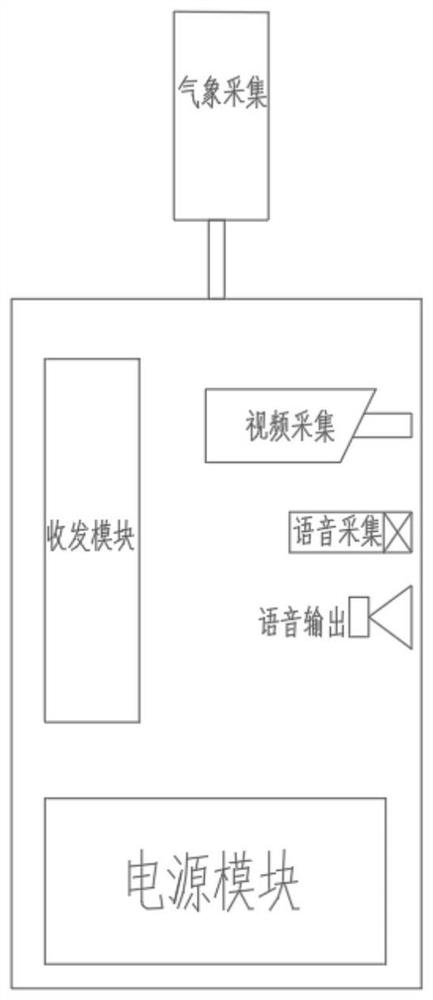

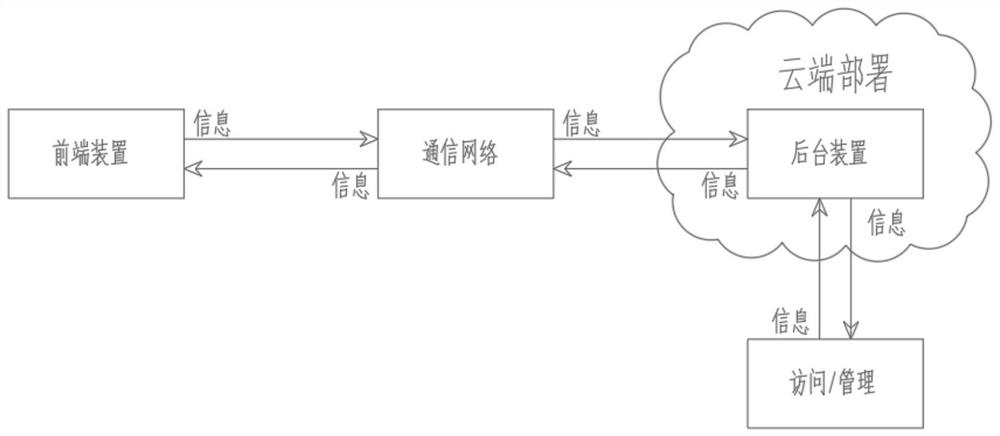

Communication optical cable engineering joint quality intelligent management and control method

PendingCN114139993AReduce labor costsImprove project qualityResourcesConstruction managementDigital data

The invention discloses a communication optical cable engineering joint quality intelligent management and control method. According to the invention, the data transmitted by the front-end device is cleaned, converted and stored according to a standard data format, and the data is subjected to model analysis, so that whether a constructor in a communication optical cable joint construction site performs optical cable connection according to the required steps of the standard specification and whether the quality is qualified in the connection process are automatically judged; and the result is pushed to on-site construction managers and background full-time quality officers through the background device, and the cloud quality officers are arranged to replace on-site actual full-time quality officers, so that the labor cost is reduced, the project quality is improved, and the management efficiency is improved. By performing standardized management on optical cable joint quality records, single text data can be upgraded to three-dimensional digital data records of automatically recorded videos, voices and analysis results, so that the storage and retrieval are convenient, and the quality inspection and quality problem tracing are more convenient.

Owner:中国通信建设北京工程局有限公司

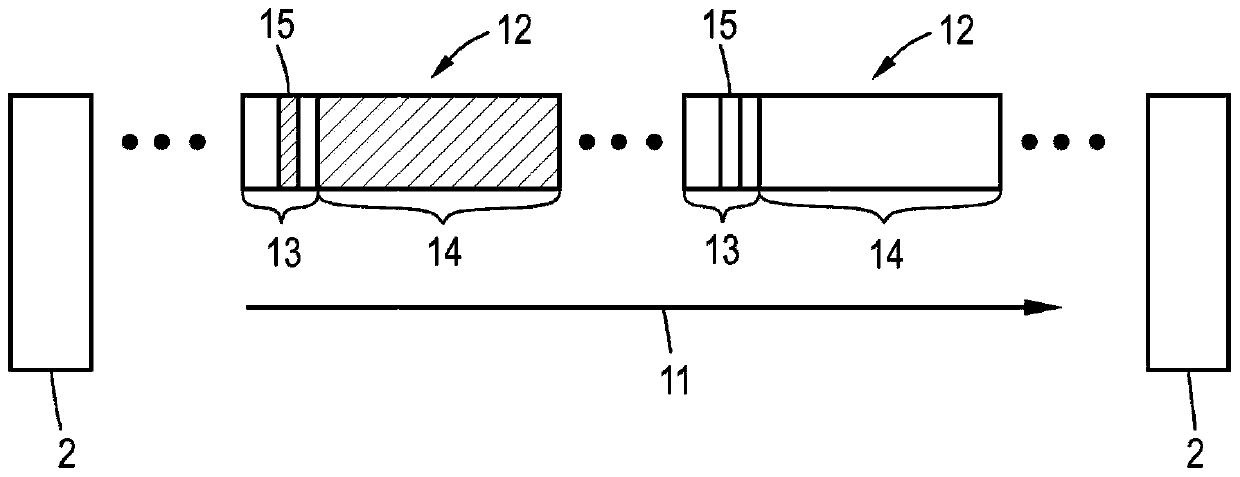

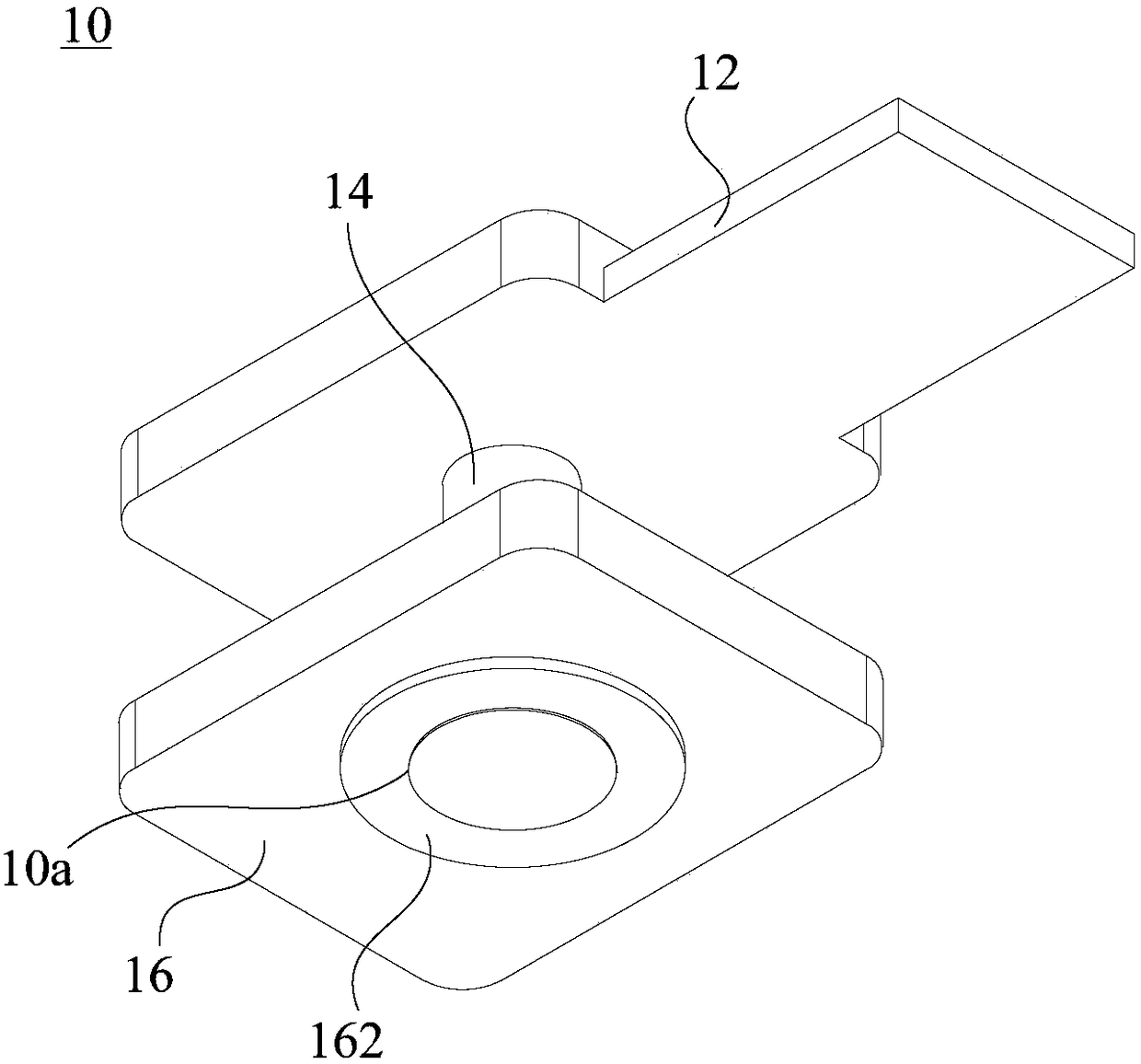

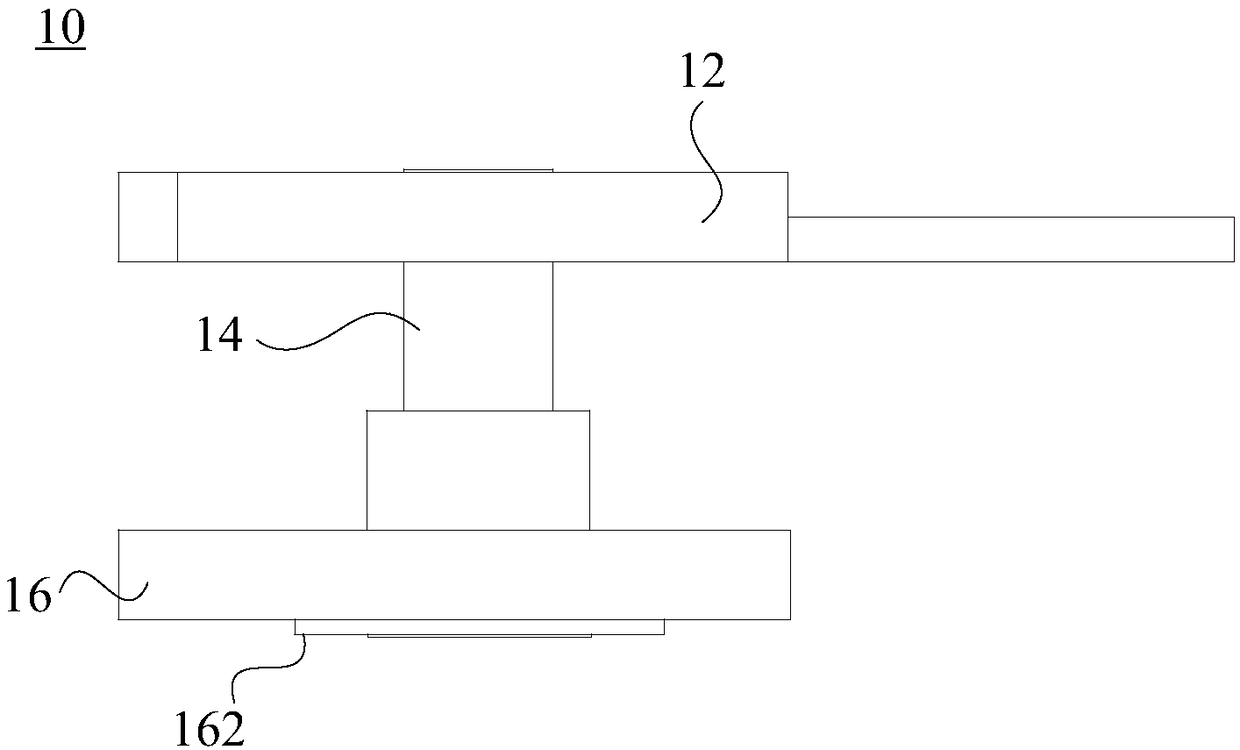

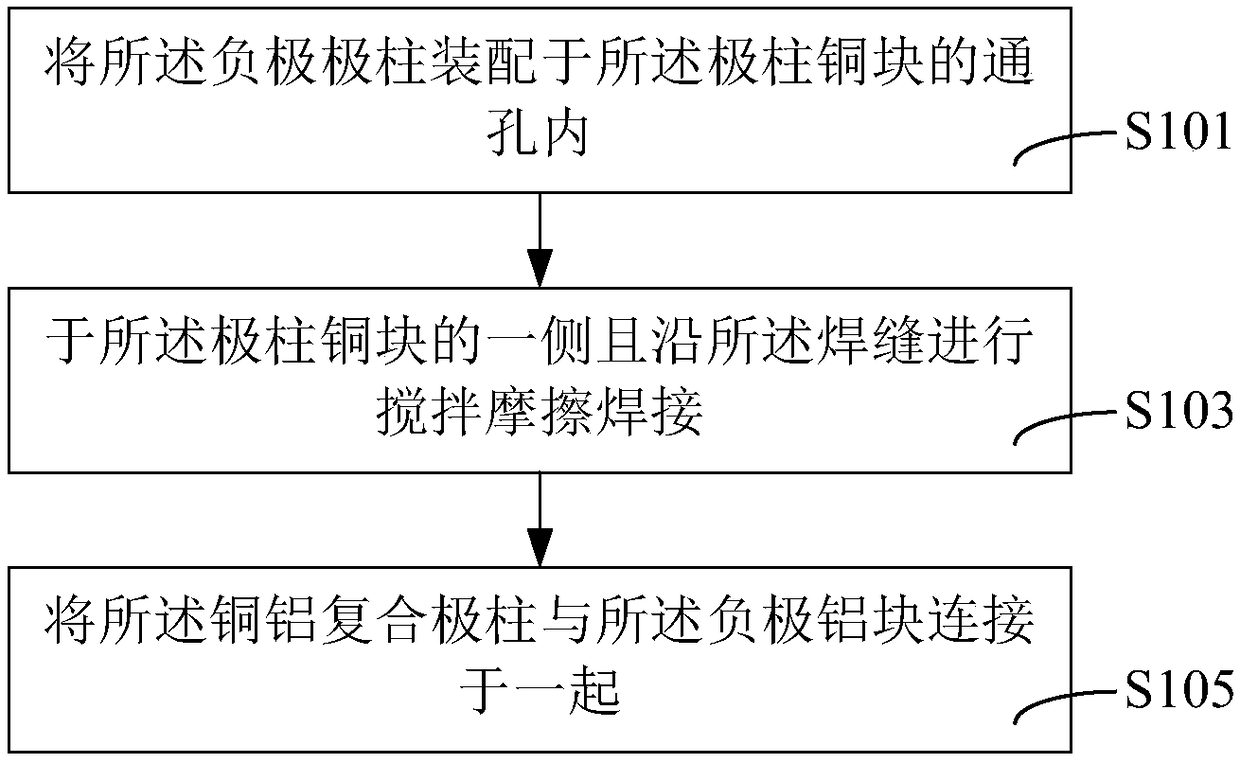

Power battery, top cover negative electrode structure and welding method thereof

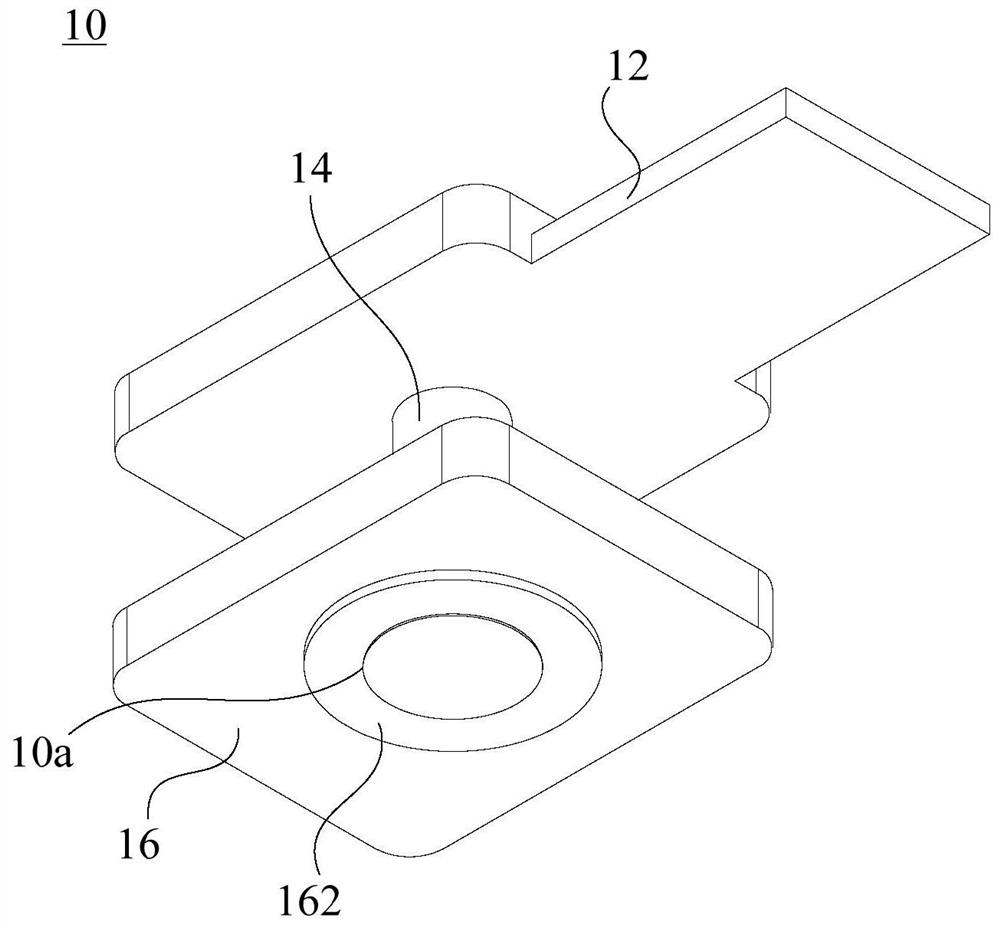

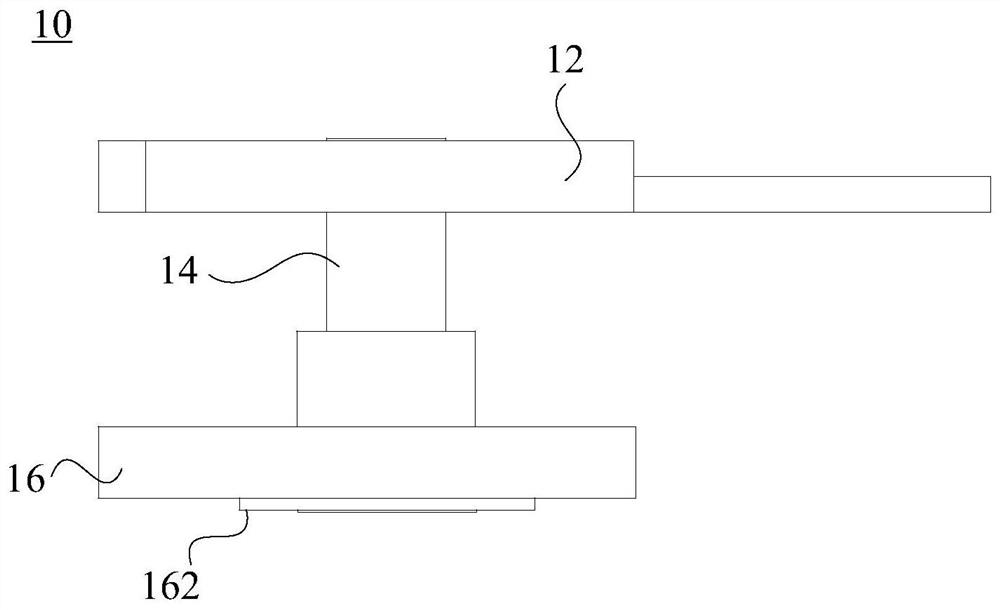

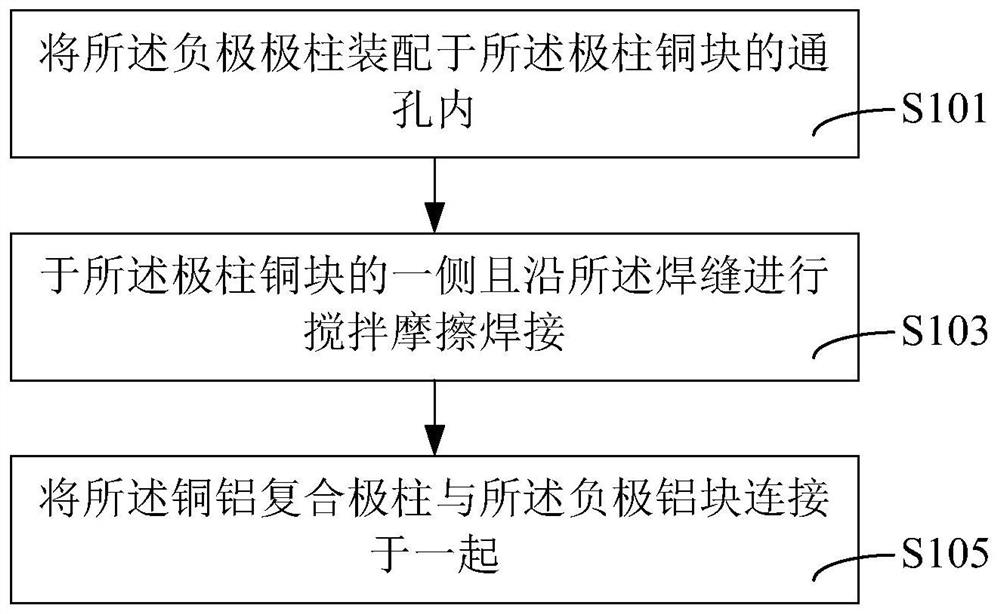

ActiveCN108544083BSolve low production efficiencyAvoid safety hazardsCell lids/coversNon-electric welding apparatusPower batteryEngineering

The invention relates to a power battery, a top cover negative electrode structure and a welding method thereof. The above-mentioned welding method of the top cover negative electrode structure, the top cover negative electrode structure includes a negative electrode aluminum block, a negative electrode pole and a pole copper block, and the welding method of the top cover negative electrode structure includes: assembling the negative pole pole to the through hole of the pole copper block Inside, the gap between the pole copper block and the negative pole is matched to form a weld; friction stir welding is performed on one side of the pole copper block and along the weld to form a copper-aluminum composite pole; the copper-aluminum composite pole It is connected with the negative aluminum block to form a top cover negative electrode structure; wherein, the negative aluminum block is located on the other side of the pole copper block. Since the position of the friction stir welding is located on the side of the pole copper block away from the negative aluminum block, rather than between the negative aluminum block and the pole copper block, the quality of the weld between the pole copper block and the negative pole It is more convenient to check, and avoids potential safety hazards in the negative electrode mechanism of the top cover.

Owner:深圳市大族锂电智能装备有限公司

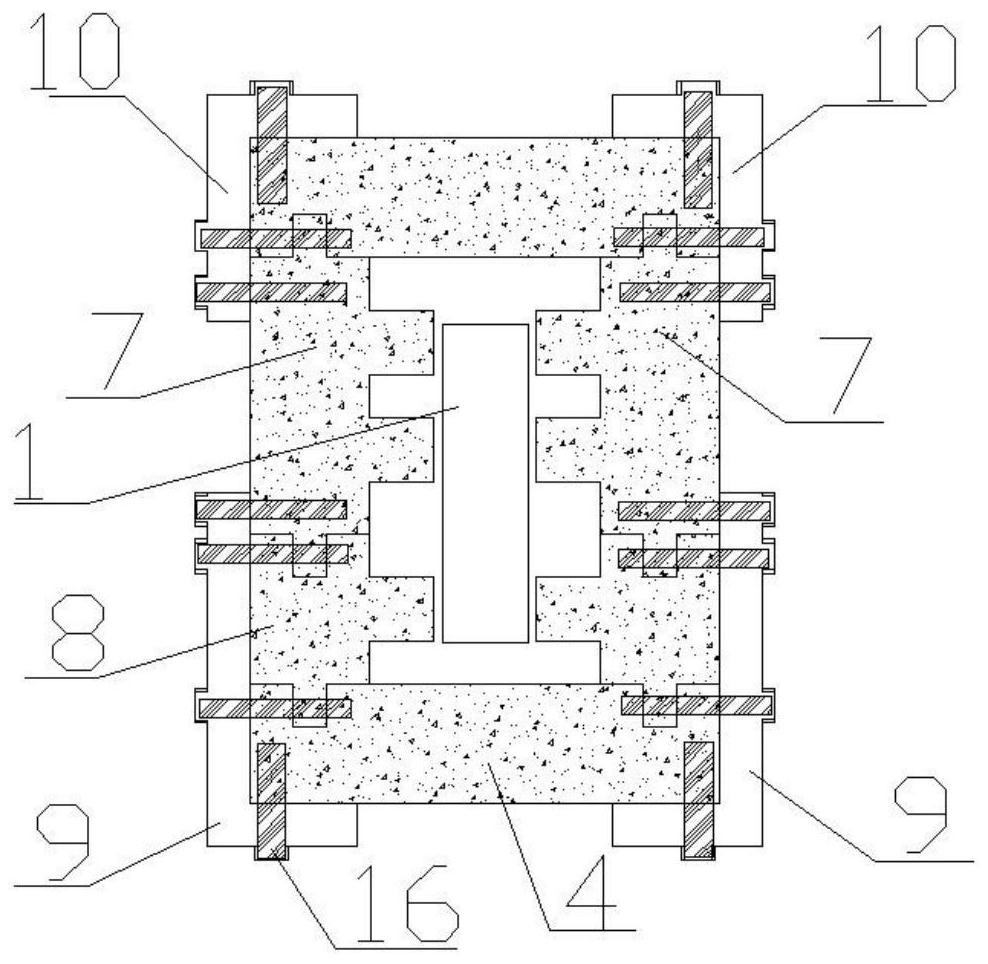

Self-locking assembly type buckling-restrained brace for nuclear island structure

PendingCN112695910AEasy to disassembleEasy QAProtective buildings/sheltersShock proofingPipeSteel tube

The invention discloses a self-locking assembly type buckling-restrained brace for a nuclear island structure. The self-locking assembly type buckling-restrained brace comprises a core plate and stiffening ribs, wherein the core plate is sleeved with a sleeve; the sleeve comprises a plurality of steel pipe concrete blocks; each piece of steel pipe concrete is provided with concave-convex blocks which can be matched with each other; the sleeve is formed by splicing and assembling multiple pieces of steel pipe concrete; the multiple pieces of steel pipe concrete are restrained and fixed through self-locking devices; and the steel pipe concrete block a and the other steel pipe concrete blocks are fixed through long angle steel or short angle steel. The self-locking assembly type buckling-restrained brace has the advantages that the supporting outer sleeve is formed by assembling the multiple steel pipe concrete blocks, the multiple steel pipe concrete blocks are restrained and fixed through the self-locking devices and the angle steel, and the self-locking devices are ingeniously provided with knob switches capable of controlling lock catches to stretch out and draw back, so that the sleeve is convenient to disassemble and the quality inspection of the core plate in the using process is facilitated.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

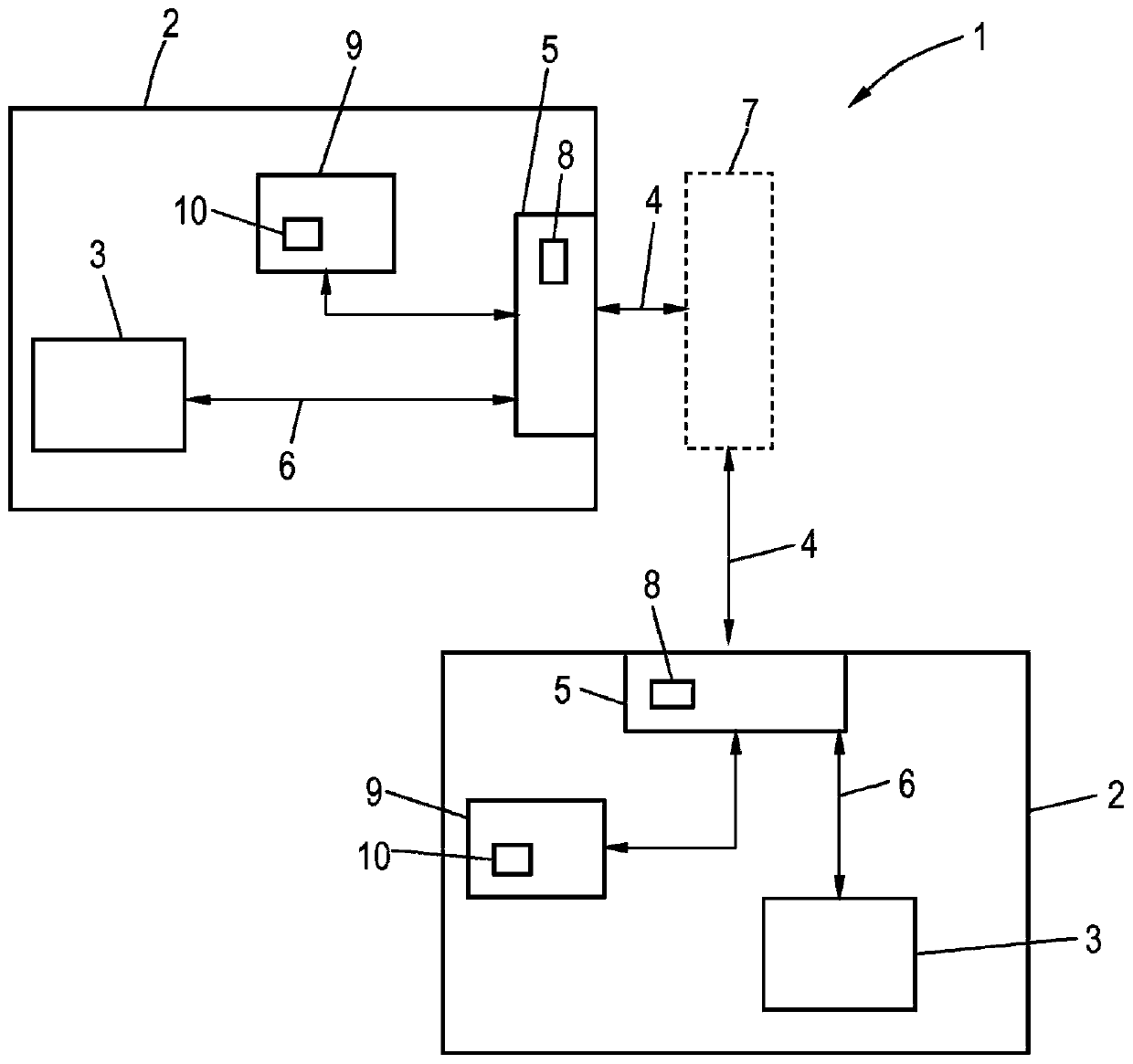

Whole apparatus having an authentication arrangement, and method for authentication

PendingCN110520814AEasy QAProtection against tampering and attacksDigital data protectionInternal/peripheral component protectionData transmissionData processing

Whole apparatus (1) having an authentication arrangement for a communication connection (4), using a communication protocol, between two data processing devices (2) of the whole apparatus (1), whereinthe data processing devices (2) each have an interface unit (5) for the communication connection (4) and a computation unit (3), wherein the interface units (5) each have an encryption / decryption means (8), at least partially produced by hardware, for encrypting at least some of the user data (14) to be transmitted via the communication connection (4) as part of the authentication arrangement, said encryption / decryption means being applied in a communication layer of the communication protocol to the user data (14) prepared for the physical user data transmission or to the physically receiveduser data (14), wherein each data processing device (2) has a security unit (9), implemented as dedicated hardware that the computation unit (3) cannot access and / or in a manner logically isolated from the computation unit, and producing a trusted execution environment, of the authentication arrangement with in each case at least one piece of hardware-encoded key information (10), on the basis ofwhich the user data (14) are encrypted by the encryption / decryption means (8).

Owner:AUDI AG

Power battery, top cover cathode structure and welding method of top cover cathode structure

ActiveCN108544083ASolve low production efficiencyAvoid safety hazardsCell lids/coversNon-electric welding apparatusAluminum compositesElectrical battery

The invention relates to a power battery, a top cover cathode structure and a welding method of the top cover cathode structure. The top cover cathode structure comprises a cathode aluminum block, a cathode pole post and a pole post copper block. The welding method of the top cover cathode structure includes the steps that the cathode pole post is assembled in a through hole of the pole post copper block, the pole post copper block and the cathode pole post are in clearance fit, and a weld joint is formed between the pole post copper block and the cathode pole post; friction-stir welding is carried out on one side of the pole post copper block along the weld joint, and a copper-aluminum composite pole post is formed; and the copper-aluminum composite pole post and the cathode aluminum block are connected together, and the top cover cathode structure is formed, wherein the cathode aluminum block is located on the other side of the pole post copper block. Due to the fact that the position of the friction-stir welding is located on the side, deviating from the cathode aluminum block, of the pole post copper block instead of being located between the cathode aluminum block and the polepost copper block, quality inspection of the weld joint between the pole post copper block and the cathode pole post is convenient, and potential safety hazards of the top cover cathode mechanism areavoided.

Owner:深圳市大族锂电智能装备有限公司

Automatic transport air-drying cache device for viscous ring parts

InactiveCN110893987BQuality improvementReduction rate and costConveyorsDrying solid materials with heatTire beadControl engineering

Owner:HARBIN UNIV OF SCI & TECH

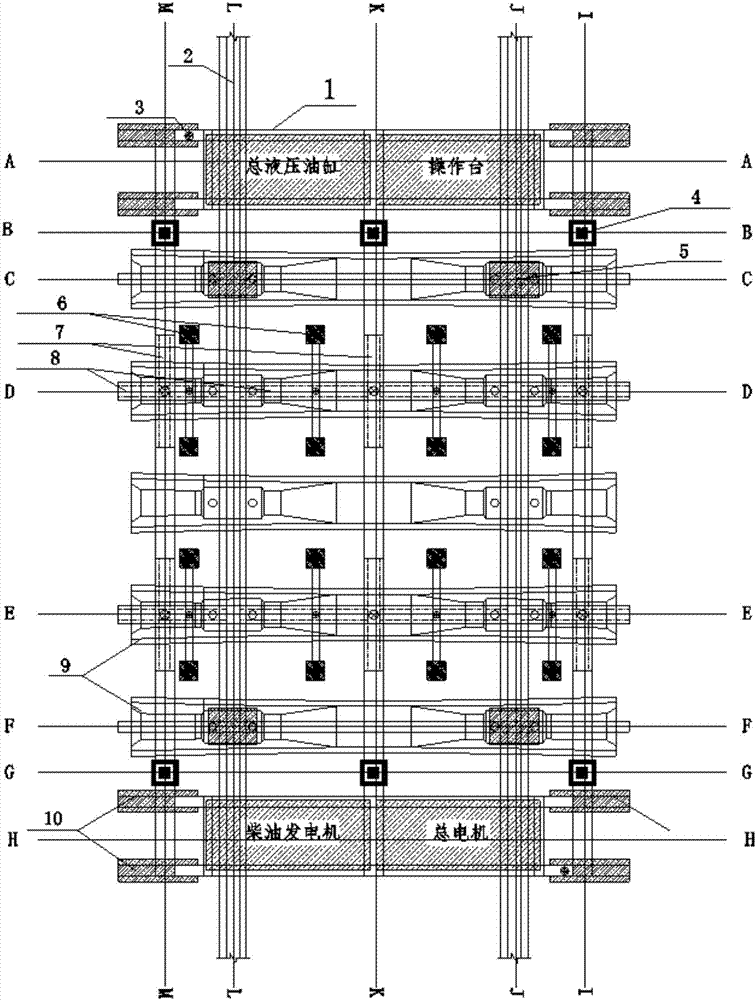

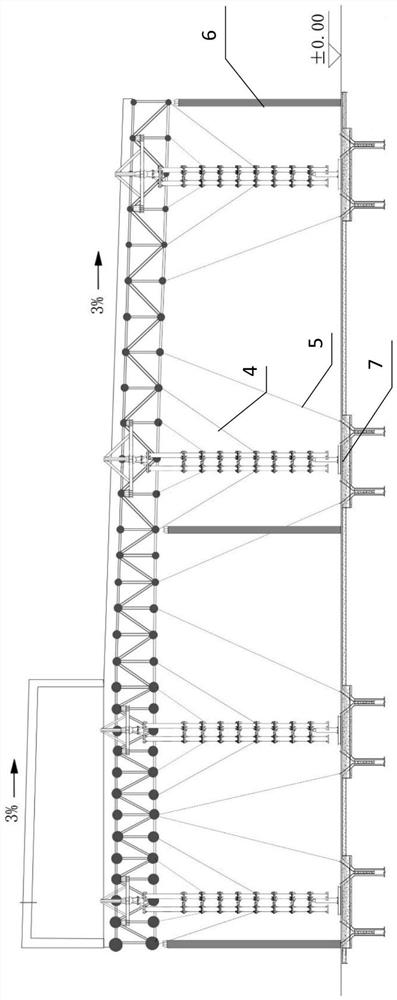

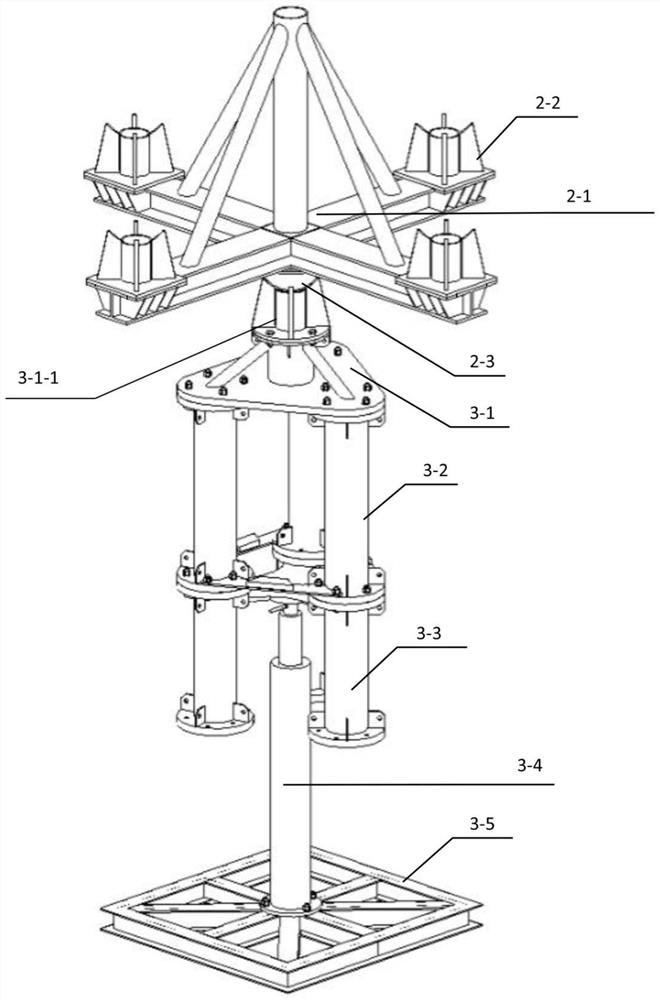

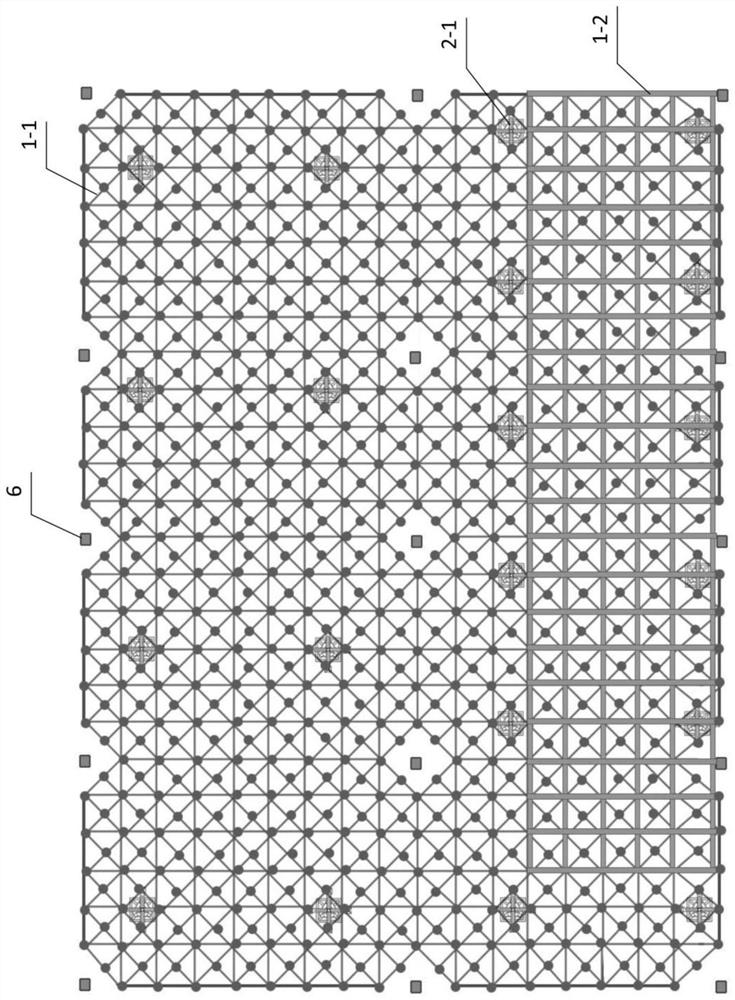

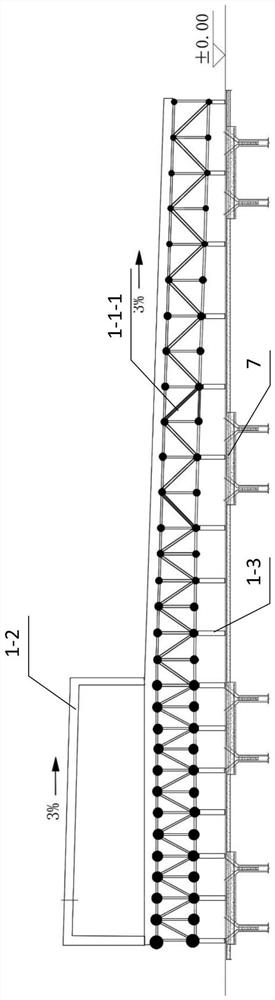

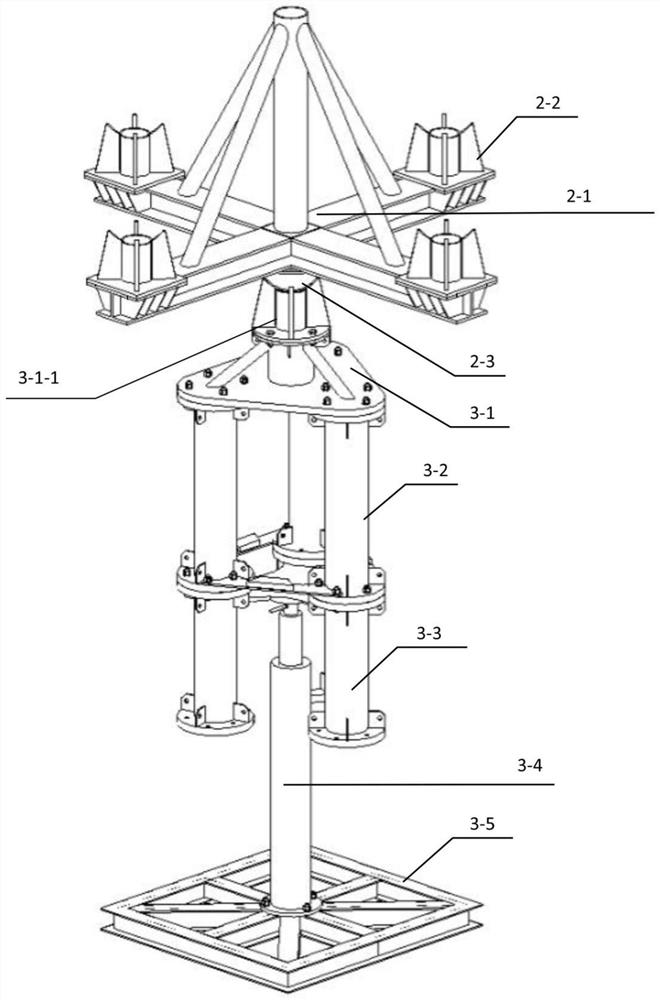

Large-span combined super-heavy eccentric slope angle steel structure overall synchronous jacking equipment

ActiveCN110792265BReduced ground assembly heightGuaranteed installation qualityLifting devicesBuilding material handlingArchitectural engineeringJoist

The invention discloses a large-span combined overweight eccentric slope angle steel structure overall synchronous jacking device, which includes a plurality of jacking units, and each jacking unit includes cross joists and jacking units coaxially arranged sequentially from top to bottom. The jacking frame is lifted by a jack; the jacking frame includes a jacking bracket, an initial section, a multi-level standard section and a base arranged coaxially from top to bottom; The bottom of the joist is equipped with a hemispherical hinge support that coincides with the jacking ball holder, and the top string ball holder of the grid frame is fixed above the cantilever end of the cross joist; the bottom surface of the initial section of the jacking frame of all jacking units The height from the ground is the same, and the top surface is leveled along the slope of the grid; the jacking frame is tied with the combined steel structure through the inverted cable wind rope, and the combined steel structure is tied with the jacking foundation through the in-place cable wind rope. The invention can safely and reliably realize the overall synchronous jacking of the combined steel structure, and can greatly reduce high-altitude operations.

Owner:中建六局第一建设有限公司 +1

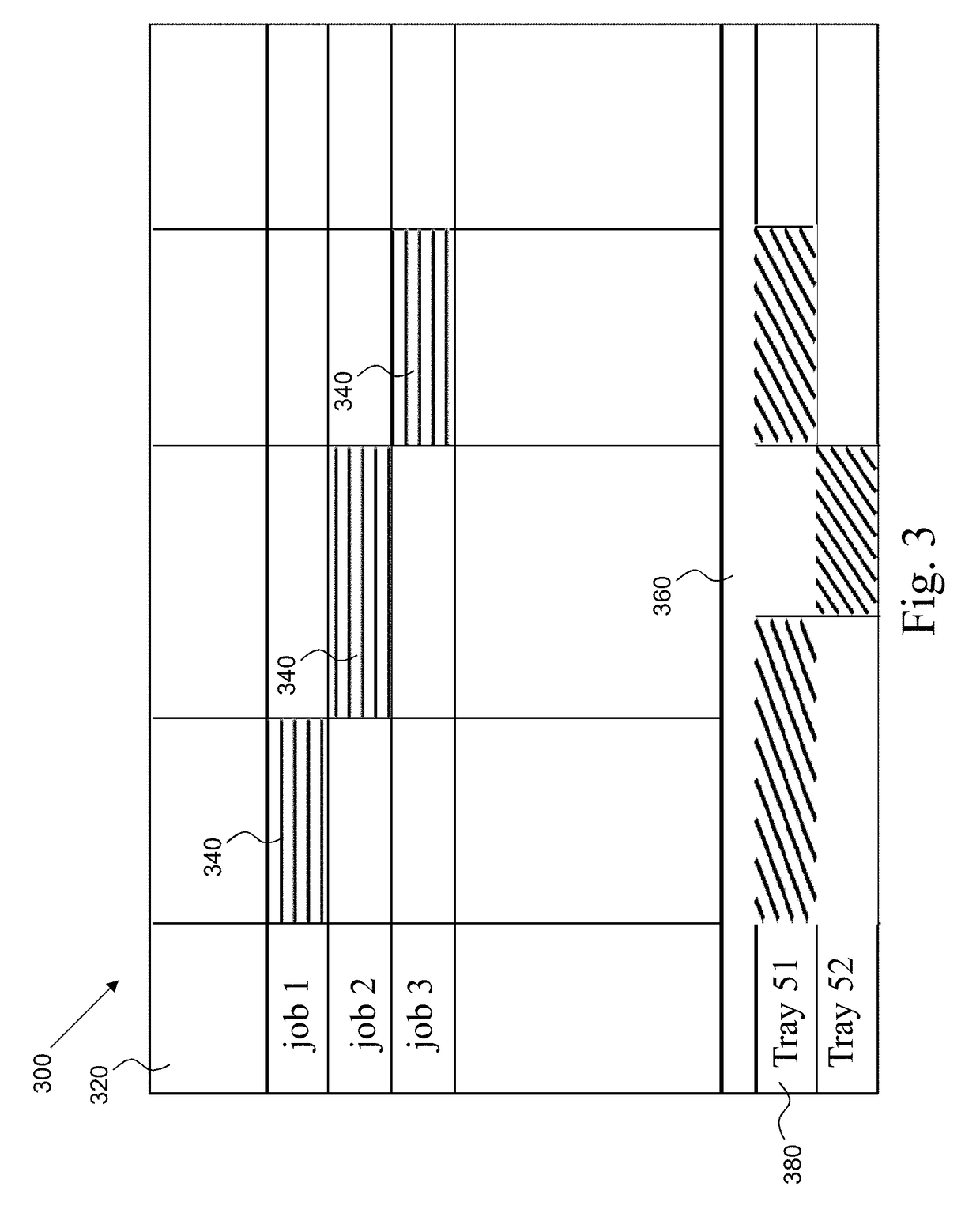

Method of printing a print job with digital finishing visualization images

ActiveUS10220610B2Easy QAEasily identifiableVisual presentation using printersElectrographic process apparatusComputer graphics (images)Digital image

The present invention relates to a method of printing a print job by an image reproduction system. The print job specifies a printing step on an image receiving medium and a finishing step in or on the image receiving medium. The method comprises the steps of receiving the print job by the image reproduction system and receiving a trigger by a controller of the image reproduction system that the finishing step is not to be performed. In such a case for a digital image comprised in print job data of the print job, at least one digital finishing visualization image of a predetermined visual appearance of a result of the finishing step in or on the image receiving medium is obtained as well as a position of the digital image for merging the obtained at least one digital finishing visualization image with the digital image. The digital image is updated by merging the obtained at least one digital finishing visualization image with the digital image at the obtained position. The updated digital image is printed by the image reproduction system.

Owner:OCE HLDG BV

Construction method of overall synchronous jacking up of large-span combined super-heavy eccentric slope angle steel structure

ActiveCN110820950BReduced ground assembly heightGuaranteed installation qualityLifting framesBuilding constructionsButtressArchitectural engineering

The invention discloses a large-span combined overweight eccentric slope angle steel structure overall synchronous jacking construction method, which adopts the following steps: 1) constructing a corresponding number of jacking foundations on the floor according to a plurality of set jacking points; 2) After the floor is hardened, assemble and check the combined steel structure ground; 3) Install jacking equipment and implement jacking; 3.1) Carry out ground assembly of cross joists at multiple jacking points set; 3.2 ) Hoist the cross joist to the upper string ball of the net frame; 3.3) Concentrically weld the hemispherical hinge support at the bottom of the cross joist; 3.4) The combined steel structure is realized by the jack supporting the lower string ball of the grid frame to the net supported by the jacking frame 3.5) Implement synchronous jacking; 3.6) Carry out the supplementary installation of the grid support position ball and its connecting rods, and then fall back into place as a whole. The invention can greatly reduce high-altitude operations, and is safe and reliable.

Owner:中建六局第一建设有限公司 +1

A quality inspection device for diaphragm structure installation

ActiveCN110609044BEasy QAEasy to checkOptically investigating flaws/contaminationDiaphragm structureStructural engineering

The invention relates to the technical field of diaphragm structure detection, and discloses a quality inspection device for diaphragm structure installation, which includes a bottom plate and a support plate, a rotating shaft is arranged above the bottom plate, and a movable block is arranged in the support plate. A fixed magnetic block and a movable magnetic block are arranged above the block, a diaphragm is arranged between the movable magnetic block and the fixed magnetic block, the side of the movable block is fixedly connected with a first rope, and one end of the first rope is connected to the screw block at the bottom of the rotating shaft. It is fixedly connected, the middle part of the rotating shaft is fixedly connected with the fan blade, the folding air duct is fixedly connected above the fan blade on the rotating shaft, and the upper part of the rotating shaft is connected with the lamp holder. The quality inspection device used for the installation of the diaphragm structure can make the diaphragm bulge and expand, and the bulging diaphragm can be quickly and conspicuously checked with the light source, and the diaphragm can be unfolded for easy observation. And it can quickly and comprehensively inspect the diaphragm.

Owner:山东瑞谱检测技术有限公司

Tube box welded structure and manufacturing method

ActiveCN104019693BEasy to handleImprove heat transfer efficiencyHeat exchanger casingsEngineeringWelding

Owner:JIANGSU JIATAI EVAPORATION CRYSTALLIZATION EQUIP

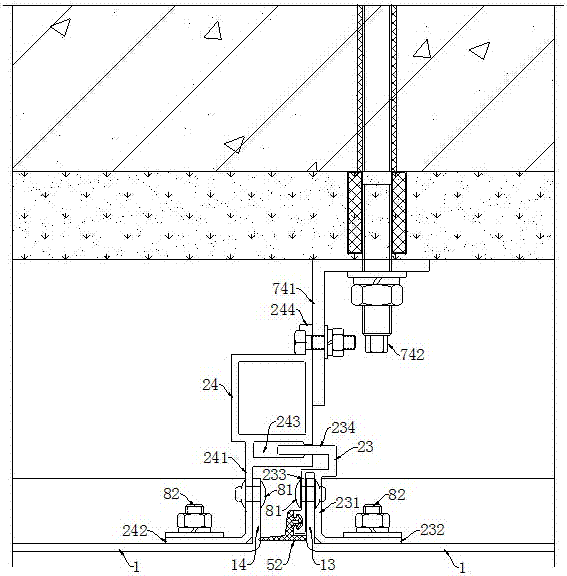

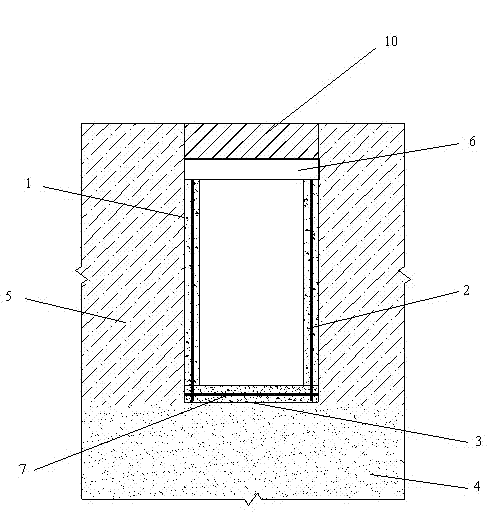

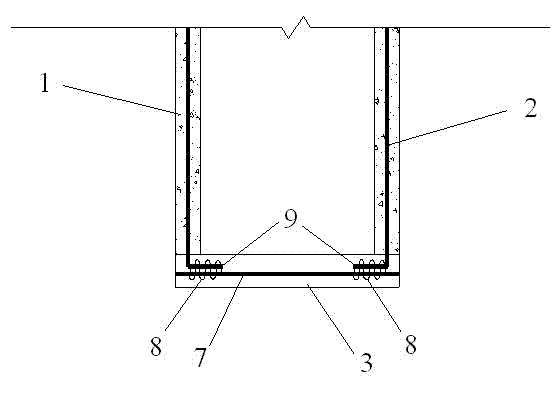

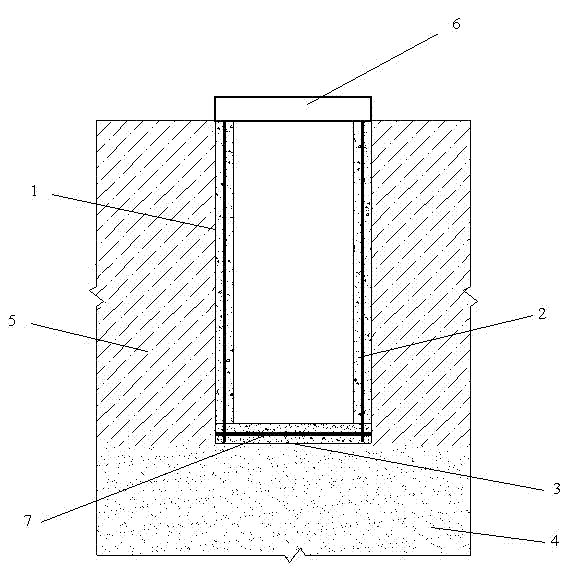

Manufacturing method of PCC (Cast-in-Place Concrete Large-Diameter Pipe Pile) underground storage well in soft soil region

ActiveCN102296632BPile fastNo construction technical difficultiesArtificial islandsUnderwater structuresRebarBuilding construction

The invention discloses a manufacturing method of a (Cast-in-Place Concrete Large-Diameter Pipe Pile) underground storage well in a soft soil region, which comprises the following technical steps of: constructing a PCC; curing concrete; dewatering a construction site; digging pile core soil; gouging for removing partial pile bottom concrete so that a 20-30cm reinforcing steel bar is exposed from the pile head to be used as a connecting reinforcing steel bar or punching the pile wall, and exposing a reinforcement cage; putting a bottom plate reinforcing steel bar and connecting with a pile endconnecting reinforcing steel bar or connecting with a pile wall reinforcement cage; pouring a concrete bottom plate for back sealing; manufacturing a pile head cover plate; and earthing on a cover plate to form the underground storage well. The storage well has a depth of 10-30m, an internal diameter of 1.5-4m, and a maximum capacity of reaching 370cm<3>. The movable cover plate is adopted in thestorage well and can be fixed with the pile head together, and a conveying pipeline can be arranged according to the demands. The manufacturing method has the advantages of matured technology, safety, economy, convenience for quality inspection, high construction efficiency and strong engineering practical applicability, and effective solving of the problem of the construction of the underground storage well in the soft soil region.

Owner:HOHAI UNIV

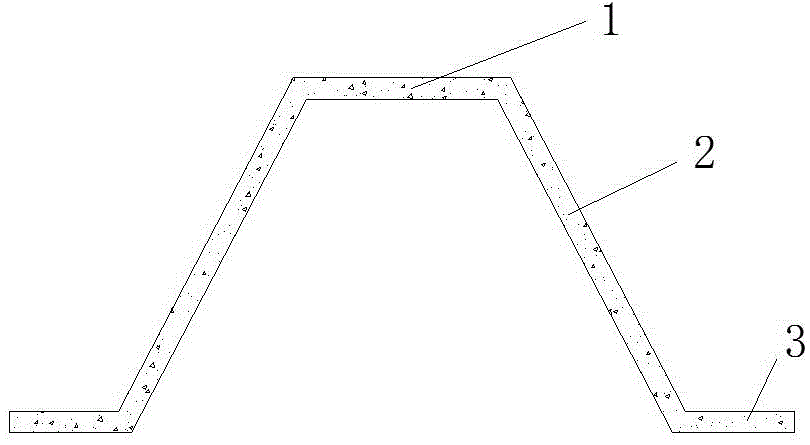

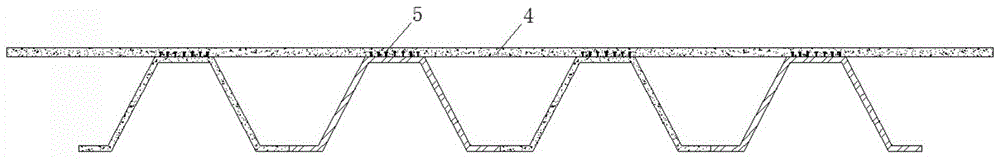

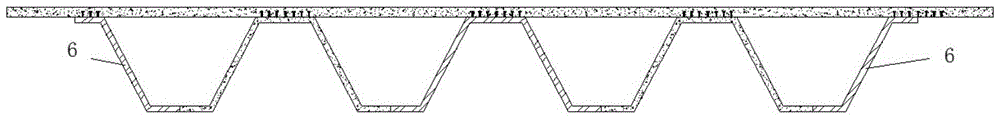

Zigzag prefabricated beam and its preparation method and installation construction method

ActiveCN105019349BWell formedGuaranteed integrityBridge structural detailsBridge erection/assemblyBridge deckBox girder

The invention relates to a Pi-shaped precast beam and a preparation method thereof as well as mounting and a construction method of the precast beam, which belong to the field of constructional engineering. The cross section of the Pi-shaped precast beam is shaped like Pi; the Pi-shaped precast beam comprises a top plate, web plates and separated bottom flange plates, wherein the web plates are arranged on the two sides. During assembling on the construction site, the bottom flange plates on the adjacent sides of the two parallel Pi-shaped precast beams are connected with each other to form a box shape; and the appearance of the whole bridge is as same as that of the traditional small box girder bridge. End transverse diaphragms are precast at the two ends of the Pi-shaped precast beams; and middle transverse diaphragms are precast in the middle of the Pi-shaped precast beams. Shear connectors are embedded in the top plates of the Pi-shaped precast beams; after assembling on the construction site, the shear connectors are connected with precast bridge deck slabs or cast-in-place bridge deck slabs. The thickness of the top plates can be more than 15cm; the bridge deck slabs do not need to be arranged on the top plates; and after a permanent formwork is mounted between the top plates, concrete is poured between the permanent formwork and the top plates to connect the permanent formwork with the top plates. The Pi-shaped precast beam provided by the invention is advantaged in that a problem that an internal mold is difficult to locate and detach in the process of pre-casting the traditional small box girder is solved; the quality of a precast piece is convenient to visually check; the precast pieces are convenient to precast, transport and assemble; the construction qualities of the transverse diaphragms after the precast pieces are assembled are guaranteed; and the integrity and durability of the whole bridge are more reliable.

Owner:南通际铨建筑科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com