Tube box welded structure and manufacturing method

A technology of welding structure and manufacturing method, applied in the field of welding structure and manufacturing of tube box, can solve the problems of failure of welding seam, splicing welding seam of baffle plate and elliptical head and difficulty in welding and blanking, and achieves simplified operation, The effect of improving processing capacity and heat exchange efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

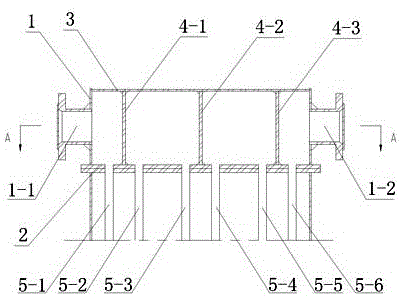

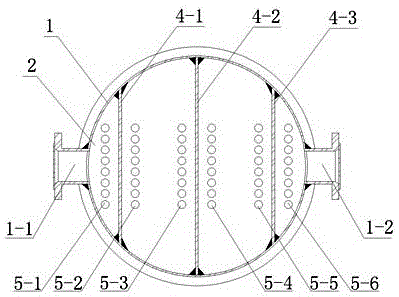

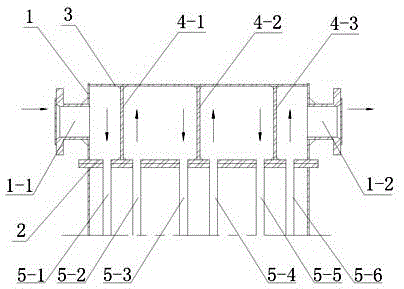

[0019] Embodiment: the pipe box welding structure of the present embodiment is as figure 1 and figure 2 As shown, it includes a vertical cylindrical barrel 1, and a feed port 1-1 for inputting materials to be processed and a discharge port 1-2 for discharging processed materials are provided on the side wall of the barrel 1, A flat-bottomed head 3 is also welded on the top of the cylinder 1, and a tube plate 2 is welded on the bottom of the cylinder 1, and the bottom of the tube plate 2 is connected to the first heating array tube 5-1, the second heating array tube 5-2, The third heating tube 5-3, the fourth heating tube 5-5, and the sixth heating tube 5-6 are in communication. In order to facilitate segmental manufacturing and splicing installation, the edge of the tube plate 2 extends to the outside of the cylinder 1 and forms a flange.

[0020] A first baffle plate 4-1, a second baffle plate 4-2 and a third baffle plate 4-3 parallel to each other are welded in the cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com