Test device for determining the quality of leather

An inspection device, leather technology, applied in the direction of measuring devices, material inspection products, raw leather/leather/fur manufacturing equipment, etc., can solve problems such as wasting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

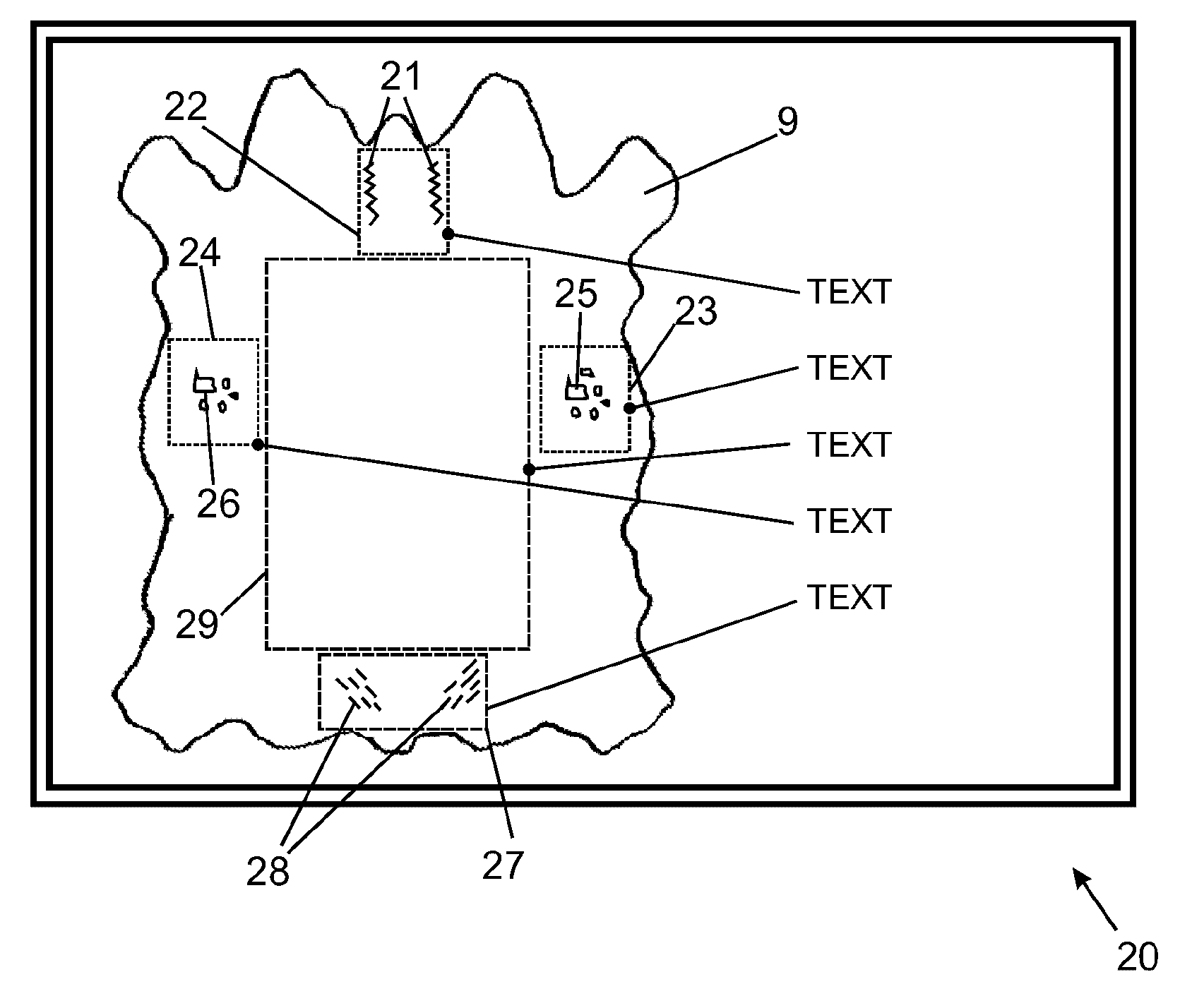

[0022] figure 1 A schematic representation of Cow 1 is shown, in which the location of a typical epidermal lesion is drawn. On the neck there are epidermal lesions 2 due to hedge and barbed wire lacerations 2 and epidermal lesions 3 due to mites. Moss in the fur causes skin damage 4, excrement site (Dungstelle) causes skin damage 5, brush damage (Striegelverletzung) causes skin damage 6, horn collision (Hornst??) causes skin damage 7 and drives away spines (Treibstachel) and Gabelstiche causes epidermal damage8.

[0023] This is only an excerpt classified in the so-called leather profile with regard to its shape (area, typical size, depth into the leather) and position.

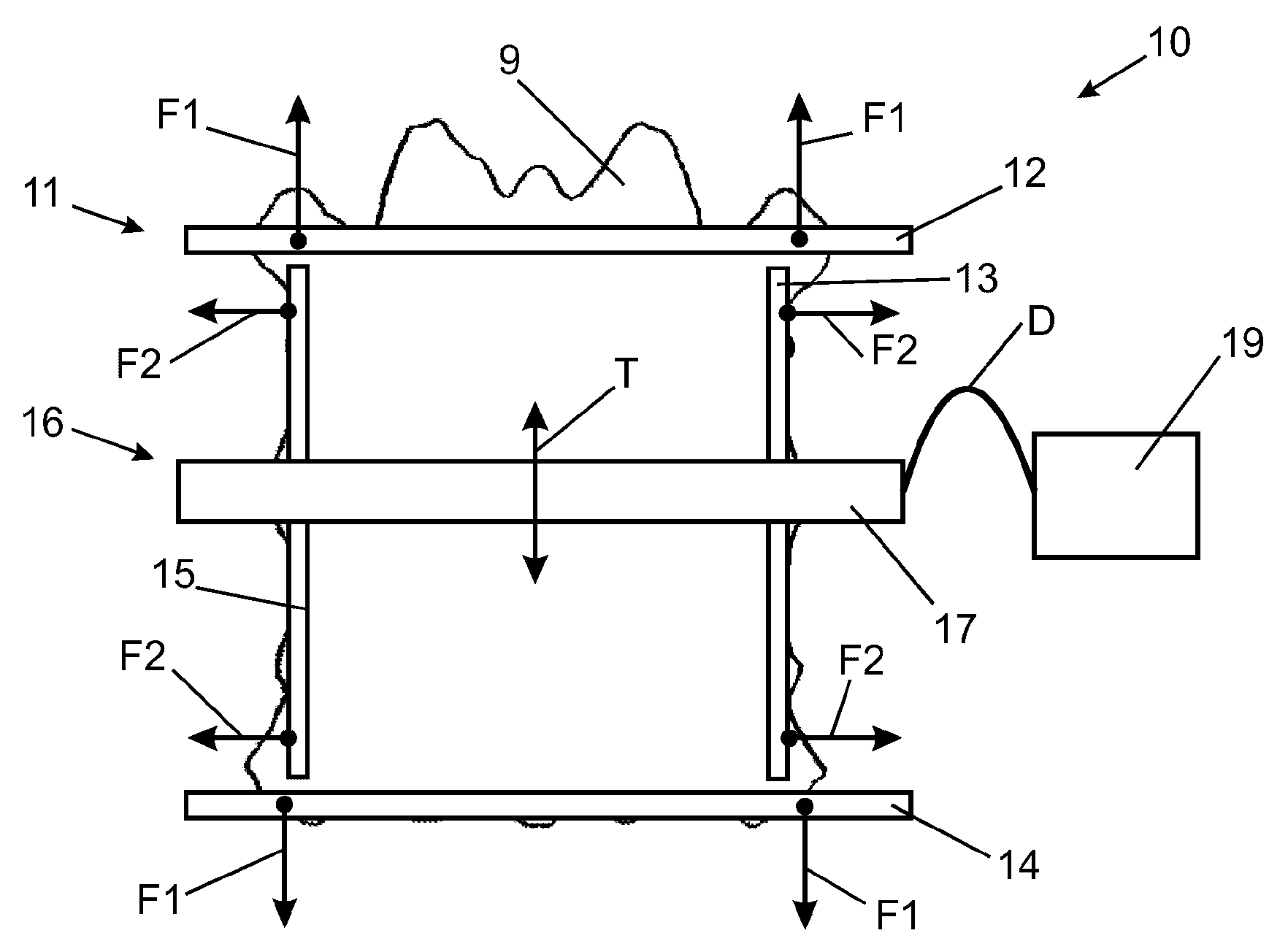

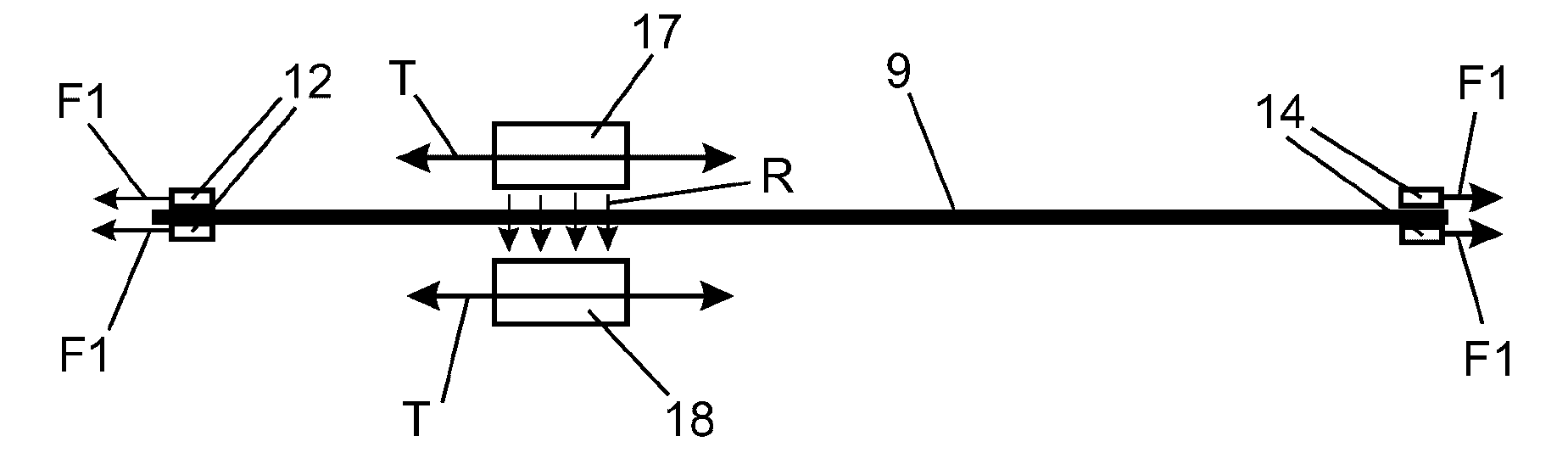

[0024] can continue to be processed in figure 2 The genuine leather 9 shown in is intended for many different uses (leather sofas, leather coats, leather steering wheels...). Different quality grades of genuine leather are processed according to the purpose of use, the expected requirements and the price...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com