Zigzag prefabricated beam and its preparation method and installation construction method

A construction method and technology of prefabricated beams, applied to bridges, bridge parts, bridge construction, etc., can solve problems such as inconvenient inspection and maintenance, easy floating of inner molds, difficulty in pouring diaphragms, etc., to achieve convenient construction, convenient quality inspection, The effect of ensuring durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

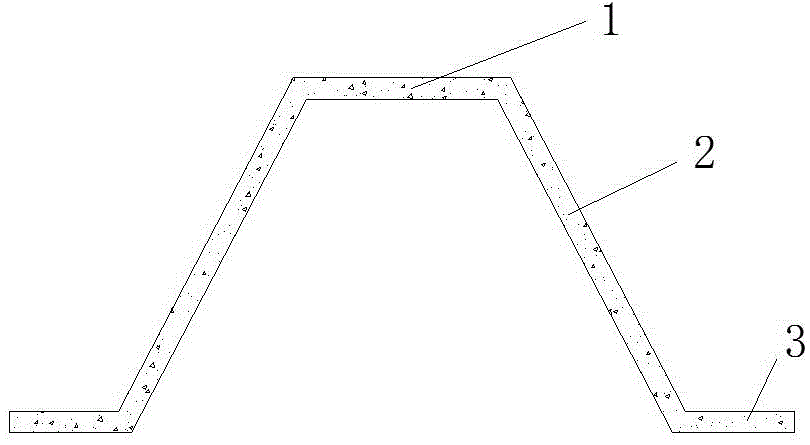

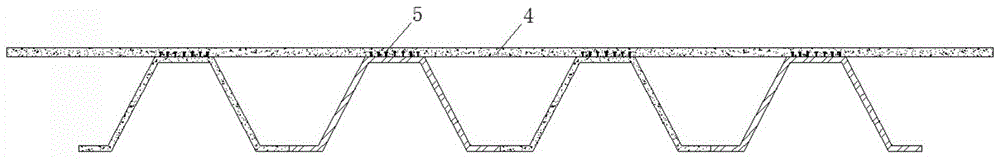

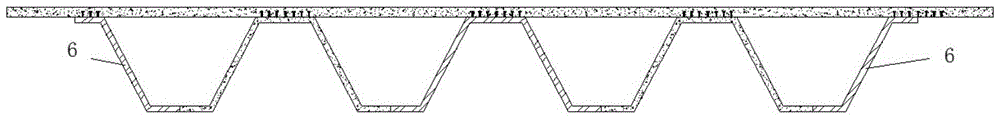

[0025] The first embodiment provided by the present invention is a type of prefabricated girder with a cross-section in the middle of the span as shown in Figure 7 , the figure shows the top plate (1), web plate (2), and lower flange plate (3) of the zigzag prefabricated beam. The angle between the web (2) and the horizontal plane is 60°. The thickness of the top plate (1) is 200mm, the thickness of the web (2) is 150mm at the mid-span, and 300mm at the end, and the thickness of the web from the end to the eighth span varies linearly. The prefabricated beam has 5 transverse diaphragms at the end, one-eighth span from the end, and mid-span. The thickness of the diaphragm is 200mm, and there is a gap on the outer side of the diaphragm on the outer side of the web. After the bridge is completed, the adjacent diaphragms of the prefabricated girders are connected to form a manhole. The prefabricated beam lower flange plate (3) is equipped with internal prestressed tendons.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com