Manufacturing method of PCC (Cast-in-Place Concrete Large-Diameter Pipe Pile) underground storage well in soft soil region

A technology of underground storage and manufacturing method is applied in the field of making underground storage wells of PCC piles in soft soil areas, which can solve the problems of lack of sealing, and achieve the effects of high construction efficiency, strong engineering practicability and fast construction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

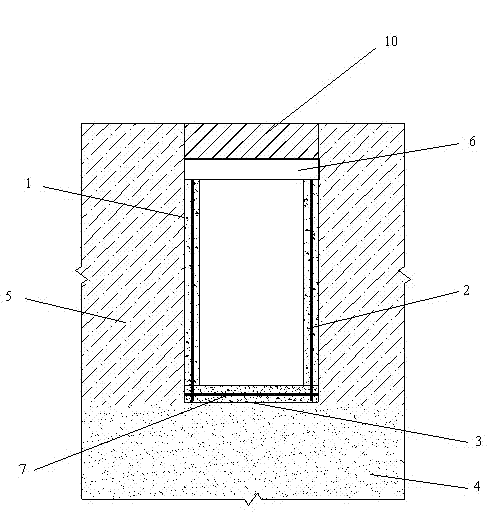

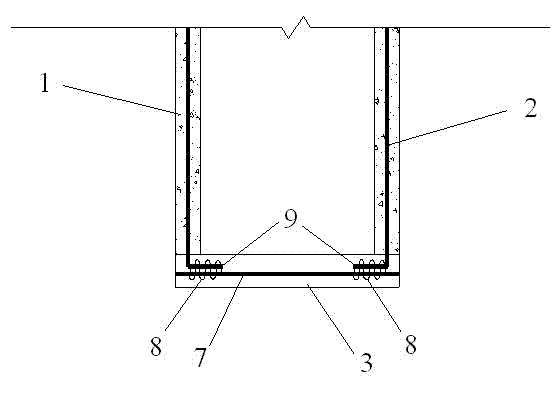

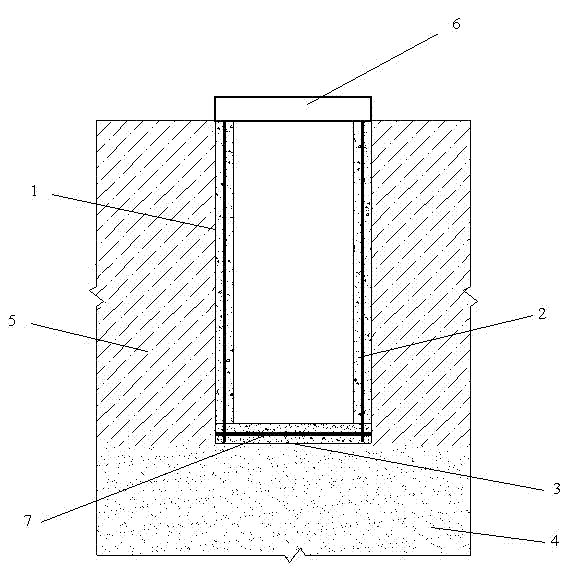

[0032] Such as Figure 1~Figure 4 Shown, a kind of PCC pile underground storage well manufacturing method in soft soil area, concrete steps are:

[0033] (1) The PCC pile driver is in place, and the valve pile tip is aligned with the pile position.

[0034] (2) Static pressure assisted vibrating immersed tube. At the beginning, the pile formwork can be pressed into the foundation to a certain depth with the help of mechanical self-weight. When the pile formwork is subjected to great resistance and sinking is difficult, the vibrating head is turned on, and the pile formwork is driven into the foundation design depth by means of vibrating sinking tubes.

[0035] (3) Remove the vibrating head, lower the reinforcement cage and then connect the vibrating head to the top of the pile formwork.

[0036] (4) Concrete is poured, and the pipe is pulled out by vibration to form a pile. In order to ensure the concrete strength of the pile top and its lower part, the pulling speed should...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com