Large-scale prefabricated enclosure structure and construction method for deep foundation pit

A construction method and a technology for retaining structures, which are applied in foundation structure engineering, excavation, sheet pile walls, etc., can solve problems such as difficult building quality, slow construction speed, economic loss, etc., and achieve reliable pile quality and high pile speed. Fast, Controllable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below in conjunction with accompanying drawing, the present invention is continued to describe in detail:

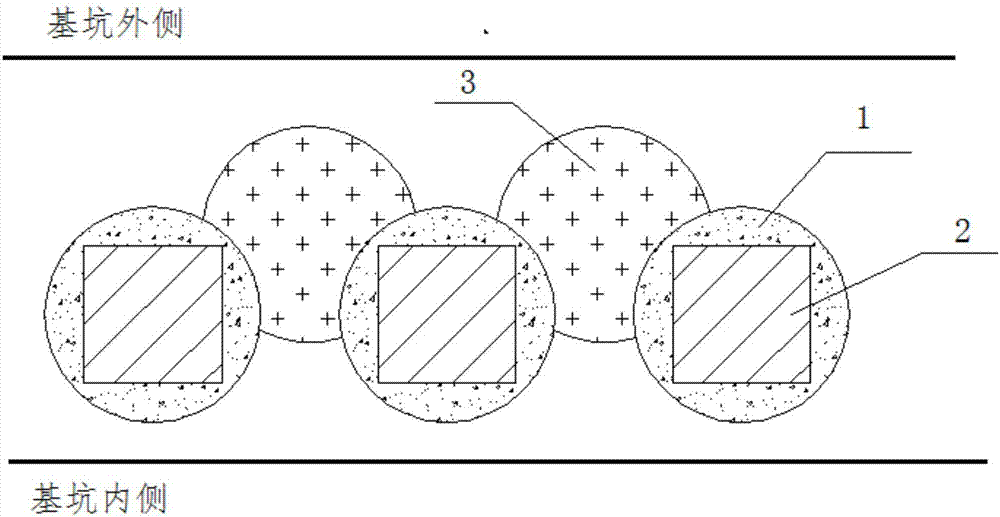

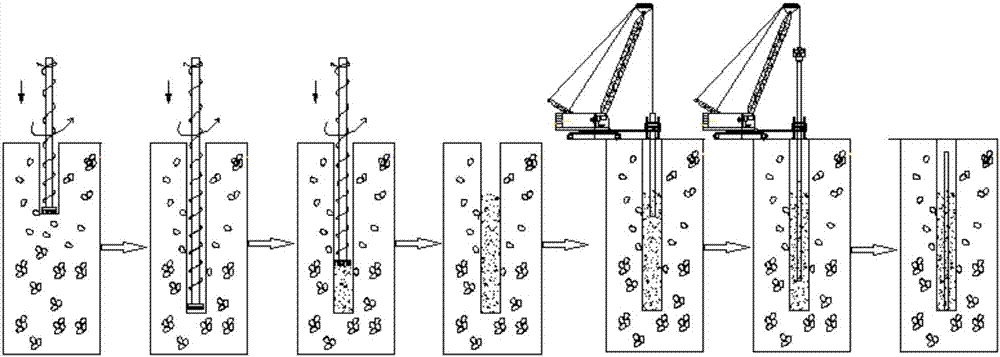

[0052] The present invention aims at the problems and deficiencies in the background technology, and aims to provide a large-scale prefabricated enclosure structure and construction method for deep foundation pits. The enclosure structure has dual functions of soil retaining and water-stopping; the soil-retaining function is realized by a composite pile, the composite pile has a circular hole, and prefabricated piles are implanted in the hole, and the gap is filled with cement soil; the water-stopping function is achieved through the cement soil and composite pile Inter-pile jet grouting piles or mixing piles are occluded. This invention introduces the prefabricated piles in the pile foundation engineering into the enclosure structure of the deep foundation pit engineering, and the variable-squeezed soil piles are low-squeezed soil piles, which expands the applica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com