Chlorohydrination reaction system and reaction method

A reaction system, chlorohydrinization technology, applied in the direction of organic chemistry, the introduction of hydroxyl and halogen preparation, etc., can solve the problems of reducing by-products, unable to increase the yield of chlorohydrins, etc., and achieve the effect of large operating flexibility, small investment, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

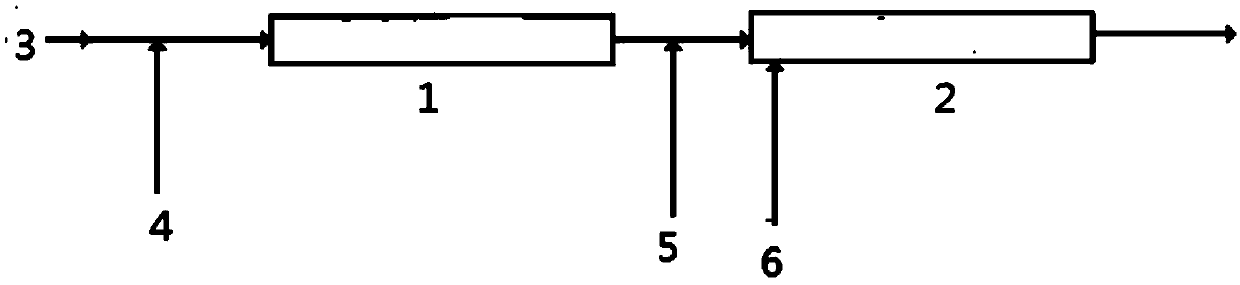

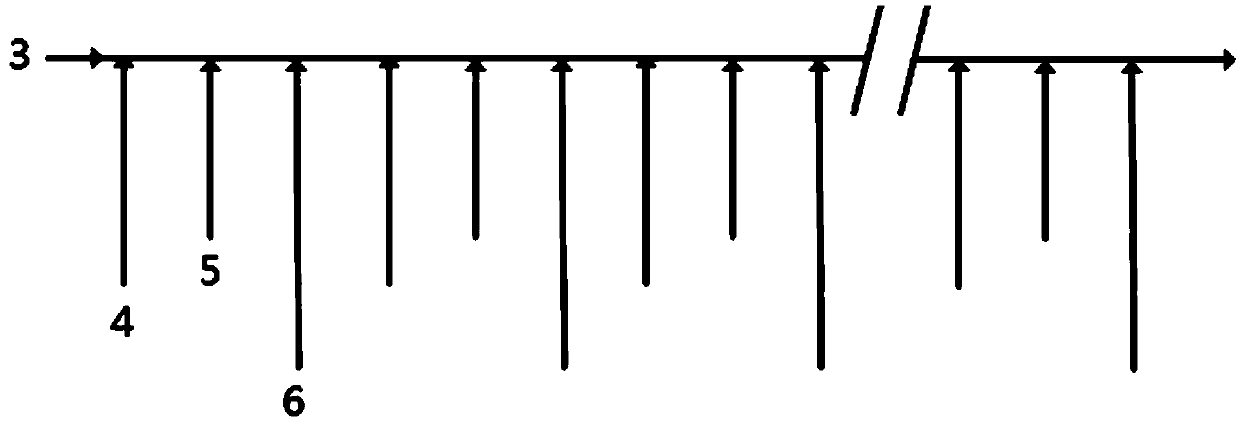

[0049] Such as figure 1 and image 3 Shown, a kind of chlorohydrination reaction system. The system comprises: 50 chlorine dissolving sections and chlorohydrinization reaction sections connected in sequence; the water inlet pipeline is connected to the inlet pipeline of the first chlorine dissolving section; the chlorine gas inlet pipeline is connected to the inlet pipeline of each chlorine dissolving section; the chlorine dissolving section outlet is connected to the chlorine The inlet of the alcoholization reaction section is connected, the outlet of the chlorohydrination reaction section is connected to the inlet of the next chlorine gas dissolution section; the propylene inlet pipeline is connected to the inlet pipeline of each section of the chlorohydrination reaction section; the alkali liquor inlet pipeline is connected to each section of the chlorohydrination reaction section; The outlet is connected to the chloropropanol outlet line.

[0050] The chlorine gas dissol...

Embodiment 2

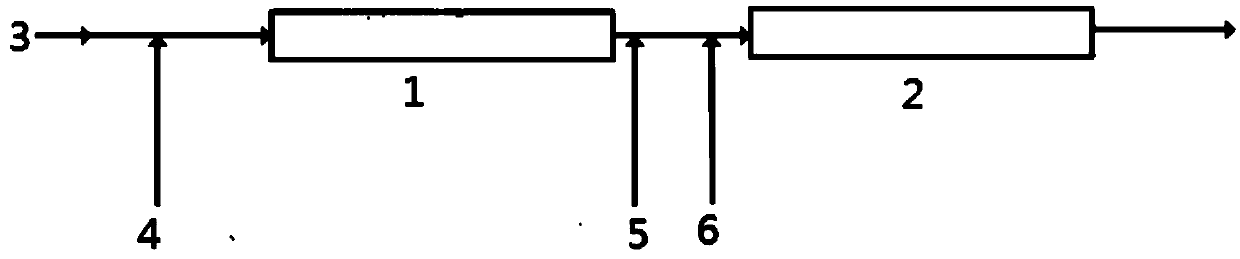

[0056] Such as figure 2 and image 3 Shown, a kind of chlorohydrination reaction system. The system comprises: 30 chlorine dissolving sections and chlorohydrinization reaction sections connected in sequence; the water inlet pipeline is connected to the inlet pipeline of the first chlorine dissolving section; the chlorine gas inlet pipeline is connected to the inlet pipeline of each chlorine dissolving section; the chlorine dissolving section outlet is connected to the chlorine The inlet of the alcoholization reaction section is connected, and the outlet of the chlorohydrination reaction section is connected to the inlet of the next chlorine gas dissolution section; the propylene inlet pipeline is connected to the inlet pipeline of each chlorohydrination reaction section; the lye inlet pipeline is connected to the inlet pipeline of each chlorohydrination reaction section; The outlet of the reaction section is connected with the outlet pipeline of chloropropanol.

[0057] The...

Embodiment 3

[0063] Same as embodiment 2, the only difference is that N is 80 segments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com