Alkali desulfurization method and device for lime kiln flue gas

A lime kiln and desulfurization device technology, applied in separation methods, chemical instruments and methods, furnaces, etc., can solve the problems of complex flue gas conditions, large fluctuations in the concentration of target substances to be removed, and large fluctuations in flue gas volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

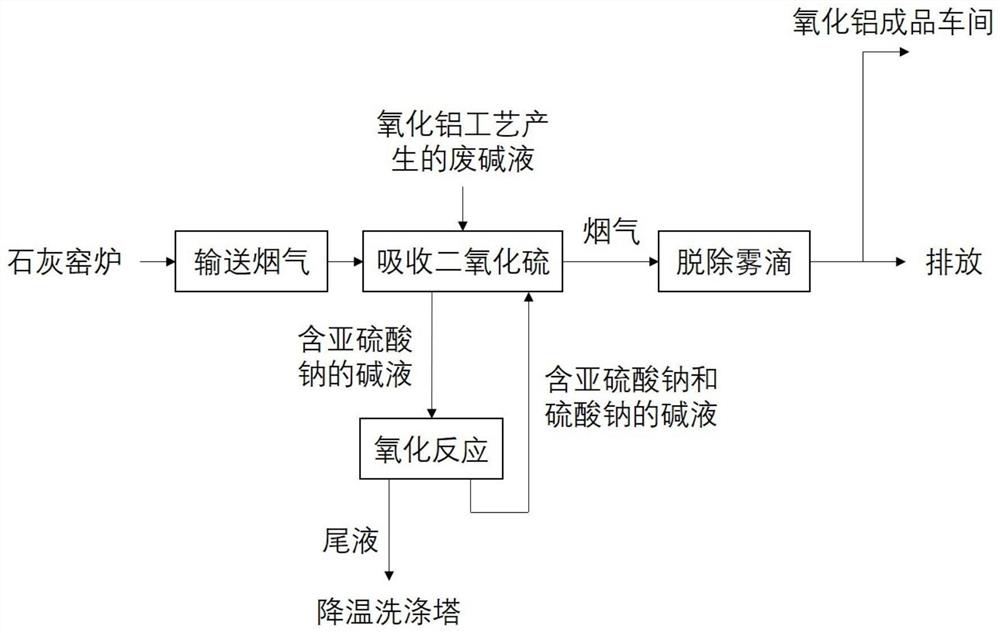

[0056] Attached figure 1 The shown lime kiln flue gas alkali desulfurization method, such as figure 1 As shown, the method includes the following steps:

[0057] Step 1) Conveying flue gas: the lime kiln flue gas after dedusting is pressurized and passed through the lower part of the desulfurization device. The initial sulfur dioxide concentration in the lime kiln flue gas is about 480mg / Nm 3 , the desulfurization device includes a desulfurization absorption tower, and the lower part of the desulfurization device includes the bottom of the desulfurization absorption tower;

[0058] Step 2) Absorption of sulfur dioxide: the lime kiln flue gas entering the desulfurization device passes through the absorption area from bottom to top, the lye is sprayed downward from the upper part of the absorption area, and passes through the absorption area from top to bottom, and the lime kiln flue gas and lye are in the absorption area Fully contacted, the sulfur dioxide in the lime kiln fl...

Embodiment 2

[0061] Attached figure 2 The shown lime kiln flue gas alkali desulfurization method, such as figure 2 As shown, the method includes the following steps:

[0062] Step 1) Conveying flue gas: The lime kiln flue gas after dedusting is pressurized and passed through the lower part of the desulfurization device. The initial sulfur dioxide concentration in the lime kiln flue gas is about 490mg / Nm 3 , the desulfurization device includes a desulfurization absorption tower, and the lower part of the desulfurization device includes the bottom of the desulfurization absorption tower;

[0063] Step 2) Absorption of sulfur dioxide: the lime kiln flue gas entering the desulfurization device passes through the absorption area from bottom to top, and the lye is sprayed downward from the upper part of the absorption area. Realized, the coverage rate of the spray layer is about 260%, passing through the absorption area from top to bottom, the lime kiln flue gas and lye are in full contact i...

Embodiment 3

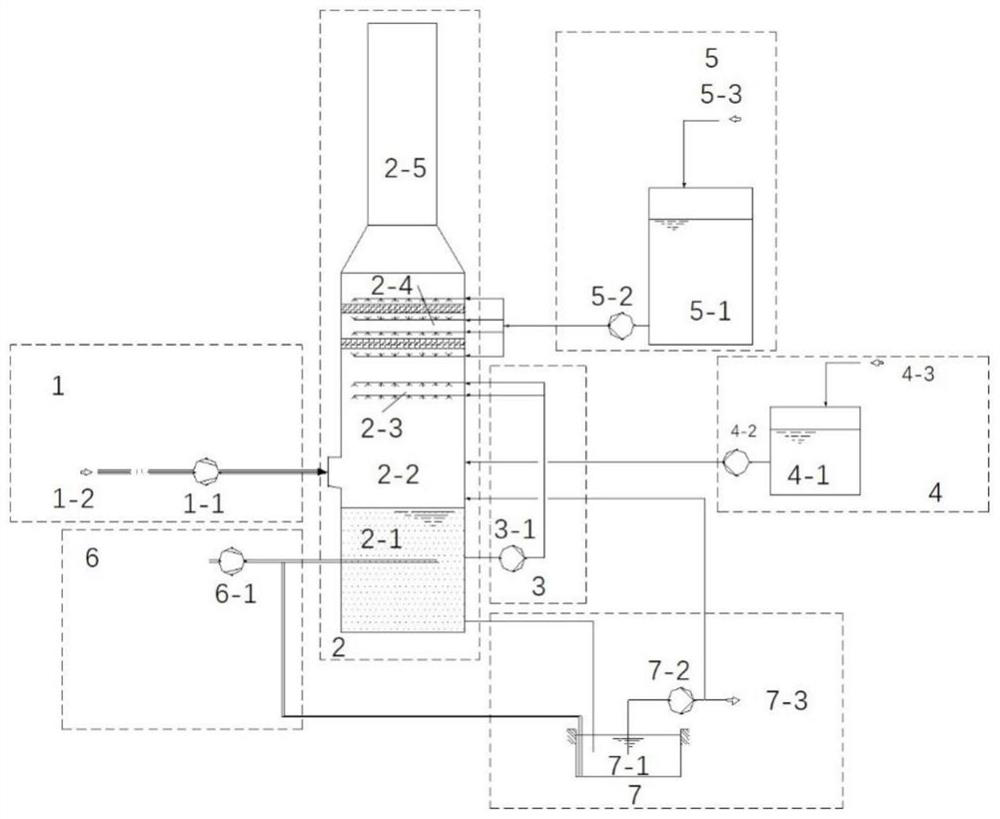

[0068] This embodiment discloses a lime kiln flue gas alkali desulfurization device, such as figure 1 As shown, it mainly includes lime kiln flue gas delivery unit 1, desulfurization unit 2, lye circulation unit 3, lye delivery unit 4, process water delivery unit 5, oxidation wind delivery unit 6 and tail liquid discharge unit 7. The inlet of the lime kiln flue gas delivery unit 1 is connected to the inlet of the desulfurization absorption tower of the desulfurization unit 2. The lime kiln flue gas delivery unit 1 is located below the desulfurization absorption tower of the desulfurization unit 2. The desulfurization absorption tower is equipped with an oxidation reaction from bottom to top. Zone 2-1, absorption zone 2-2, spray layer 2-3, droplet trapping zone 2-4, external chimney 2-5, lye circulation unit 3 circulation pump inlet pipeline connected to desulfurization absorption tower for reaction area, the lye circulation unit 3 circulation pump outlet pipe is connected to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cover factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com