Mercaptans removal apparatus for light oil and mercaptans removal method thereof

A light oil and input pipe technology, applied in the field of oil refining and chemical industry, can solve the problems of increasing refining operation intensity and energy consumption, doctor's test does not meet the requirements, affecting gasoline sweetening effect, etc., and achieves good oil-alkali separation effect and saves energy The required amount of lye and good oil-alkali separation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

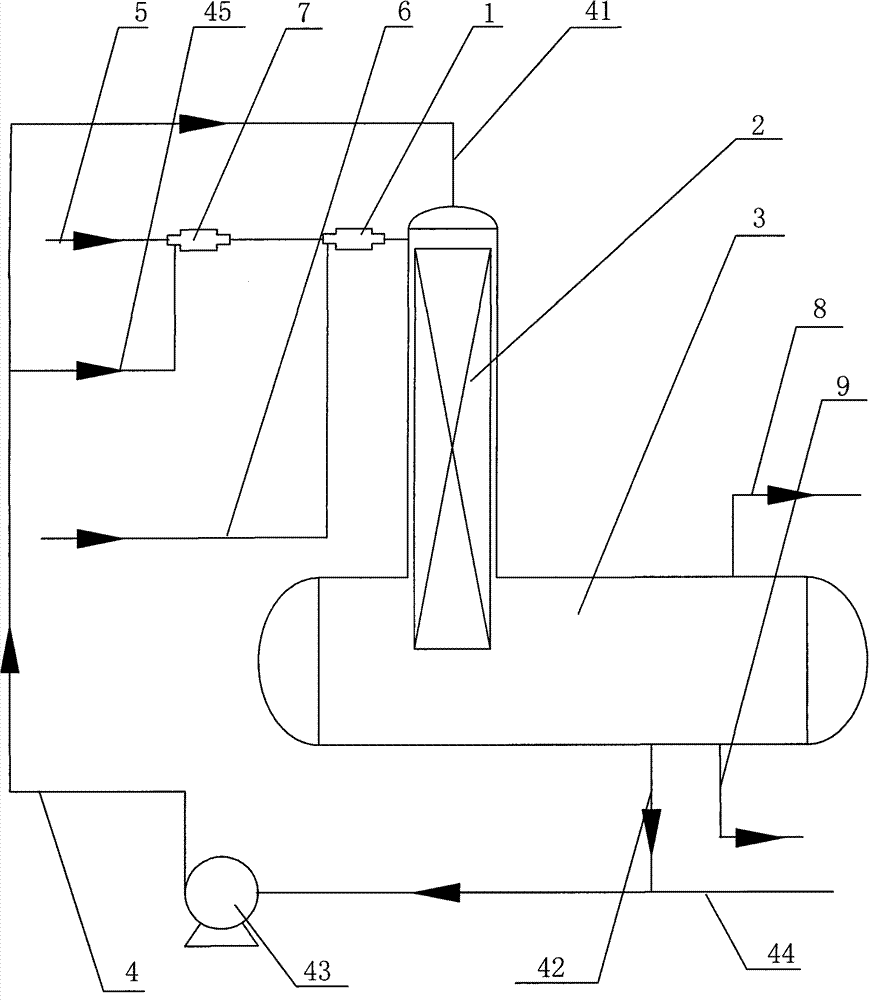

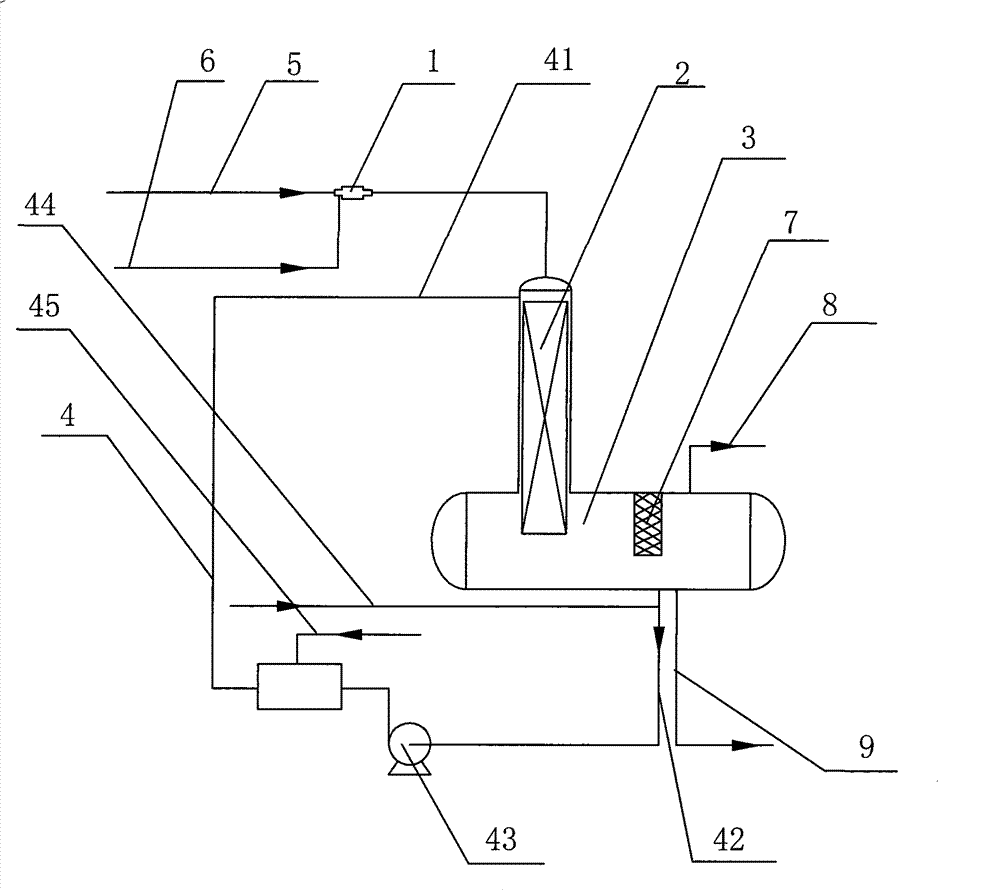

[0041] 1. If figure 1 The sweetening device for a light oil product shown includes a first mixer 1, a separation tank 3 and an alkali liquor circulation system 4, the front end of the first mixer 1 is provided with a raw material input pipe 5 and a vent pipe 6, and the alkali The lye circulation system 4 comprises the first input pipe 41 of the circulating lye, the output pipe 42 of the lye circulation and the lye circulation pump 43, the lye circulation system 4 is connected with the fresh lye input pipe 44, which can be added and supplemented with fresh lye at any time and catalyzer, the separation tank 3 is provided with a refined light oil output pipe 8 and an alkali slag output pipe 9, and the circulating lye output pipe 42 is connected with the separation tank 3, and a second mixer 7 is arranged on the raw material input pipe 5. The front end of the second mixer 7 is provided with the second input pipe 45 of circulating lye, and the top of the separation tank 3 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com