A dual-circuit washing and desulfurization device for ship exhaust gas combined with seawater and fresh water

A desulfurization device and double-loop technology, applied to the separation of dispersed particles, chemical instruments and methods, and the use of liquid separation agents, etc., can solve problems that affect the uniform distribution of exhaust gas, are not conducive to exhaust gas desulfurization, and the structure of the scrubber is complicated, so as to achieve environmental protection and energy saving Effects of detergent usage, increased operational stability, and reduced fresh water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

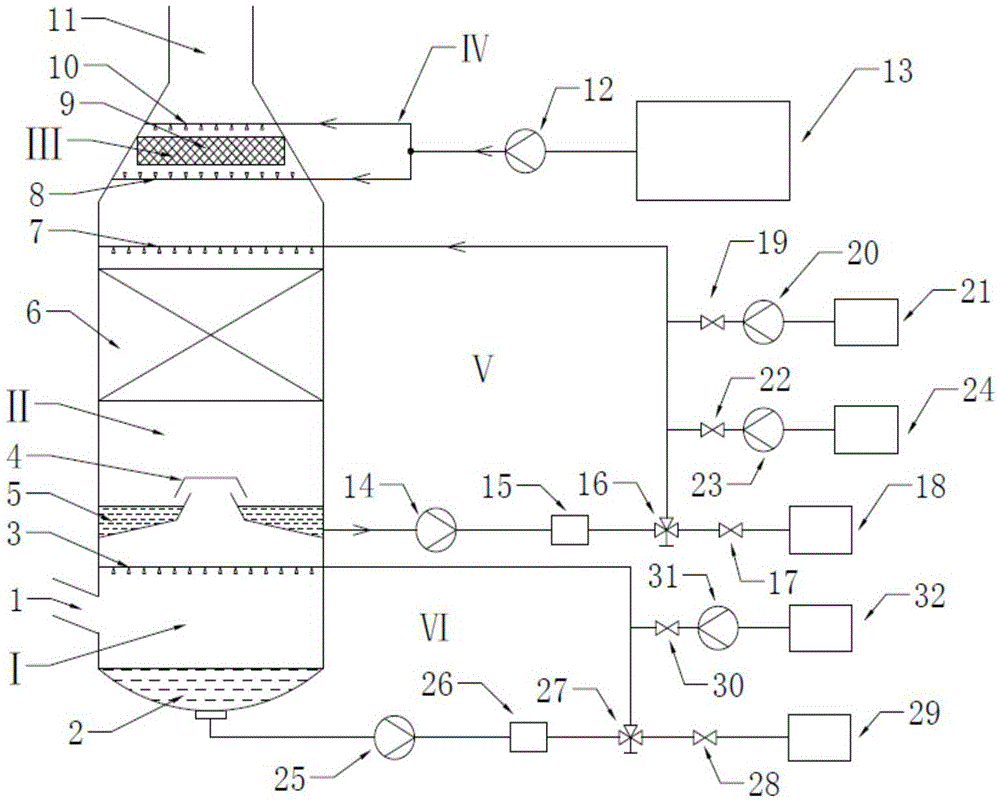

[0025] combine figure 1 , the present invention includes seawater absorption liquid spray area I, fresh water alkaline absorption liquid spray area II, demister area III, demister cleaning pipeline IV, fresh water alkaline absorption liquid circuit V, seawater absorption liquid circuit VI, waste gas Inlet 1, liquid collection tank 2, liquid collection tank 5, seawater absorption liquid spray device 3, waste gas cover 4, packing 6, fresh water alkaline absorption liquid spray device 7, demister cleaning device 8, 10, demister 9. Exhaust gas outlet 11, water pump 12, 14, 20, 23, 25, 31, one-way valve 17, 19, 22, 28, 30, fresh water tank 13, three-way valve 16, 27, monitoring unit 15, 26, fresh water Supply unit 21 , alkaline additive supply unit 24 , seawater supply unit 32 , washing fresh water treatment unit 18 , and washing seawater treatment uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com