A kind of sulfur recovery process of Claus plus Hov tail gas treatment

A technology for sulfur recovery and tail gas treatment, which is applied in the direction of sulfur preparation/purification, separation of dispersed particles, chemical instruments and methods, etc. It can solve the problems of high operating costs, difficult hydrogenation reduction process, high energy consumption, etc., to ensure work The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the present invention more comprehensible, preferred embodiments are described in detail below with accompanying drawings.

[0021] The invention provides a sulfur recovery process for Claus plus HOV tail gas treatment, the steps of which are:

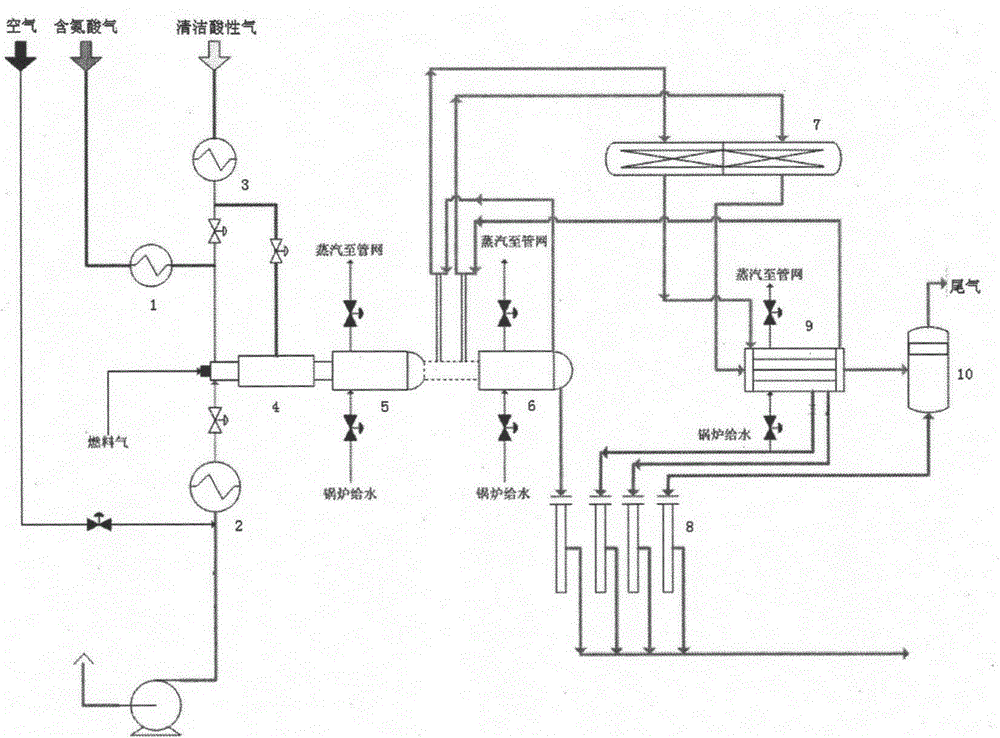

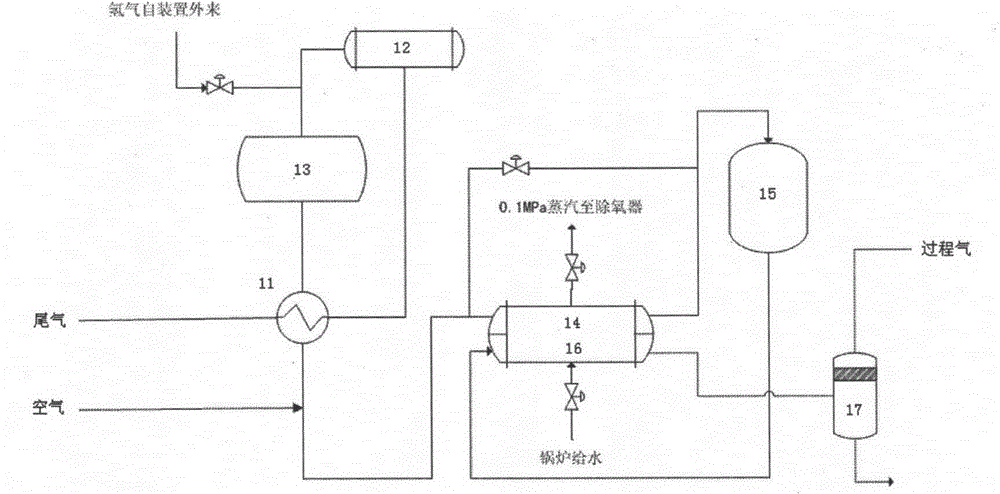

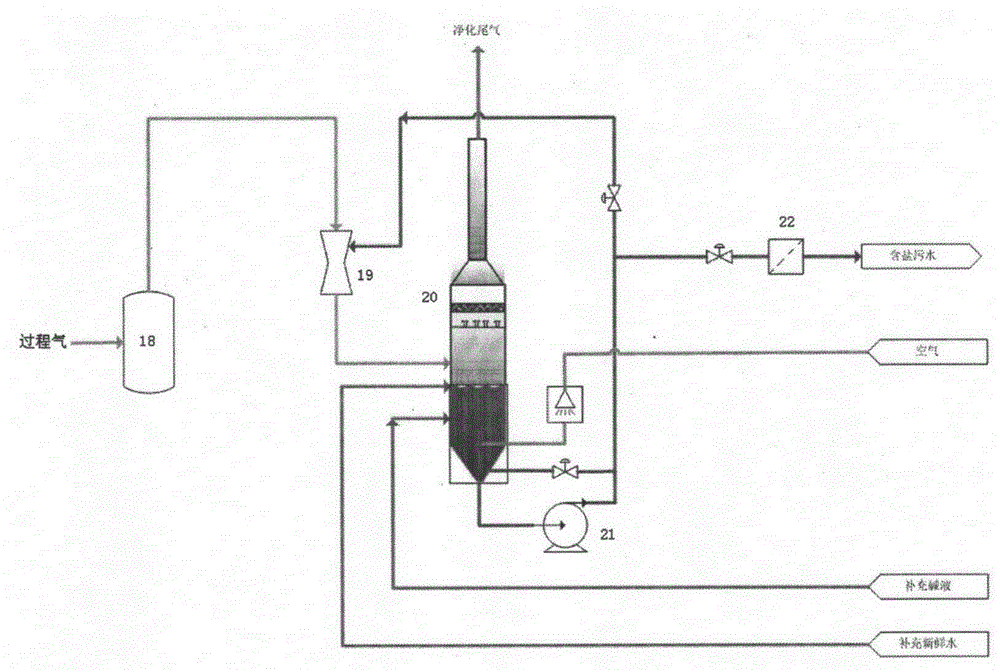

[0022] First step, two-level Claus part: Combining figure 1 , similar to the conventional Claus process, containing H 2 The acid-containing exhaust gas of S, stoichiometric air or oxygen-enriched air and clean acid gas are respectively heated by the acid-containing exhaust gas heater, the air heater and the clean acid gas, and then mixed and then enter the sulfur production combustion furnace 4 for combustion. In the combustion furnace 4 for sulfur production, containing H 2 Ammonia, hydrocarbons, etc. in the acid-containing exhaust gas of S are completely decomposed, and about 30% of H 2 S to SO 2 , the resulting SO 2 Continue to react with the rest of H2S to generate elemental sulfur through high-temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com