Heat exchanger tube box welding structure and manufacturing method

A technology for welding structures and heat exchanger tubes, which is applied in the direction of heat exchanger shells, heat exchange equipment, lighting and heating equipment, etc., and can solve the difficulties of splicing welding seam blanking and welding of baffle plates and oval heads, Solve problems such as weld failure, achieve the effect of improving processing capacity and heat exchange efficiency, simplifying operation, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

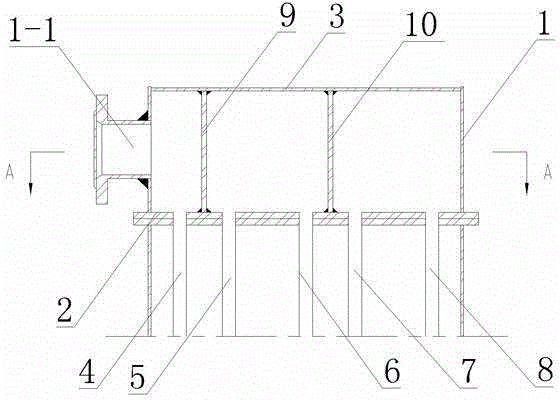

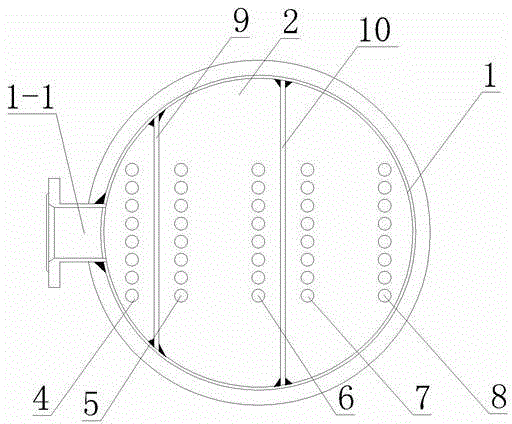

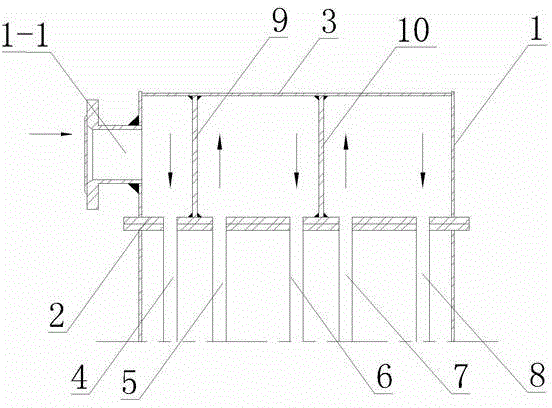

[0019] Embodiment: The welded structure of the heat exchanger tube box of this embodiment is as follows figure 1 and figure 2 As shown, it includes a vertical cylindrical cylinder 1, on the side wall of the cylinder 1, there is a feed port 1-1 for inputting the material to be processed, and a flat-bottomed head 3 is also welded on the top of the cylinder 1, A tube plate 2 is welded at the bottom of the cylinder body 1, and the bottom of the tube plate 2 is connected with the first heating tube 4, the second heating tube 5, the third heating tube 6, the fourth heating tube 7 and the fifth heating tube Tube 8 is connected. In order to facilitate segmental manufacturing and splicing installation, the edge of the tube plate 2 extends to the outside of the cylinder 1 and forms a flange.

[0020] There are vertical rectangular first baffles 8 and second baffles 9 welded inside the cylinder 1, the sides of which are connected to the vertical inner wall of the cylinder 1, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com