Patents

Literature

32results about How to "Meet construction quality requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aerogel modified inorganic insulation mortar and use method thereof

The present invention discloses an aerogel modified inorganic insulation mortar. The aerogel composite fiber insulation material comprises and is complex processed by silicate cement, silicon dioxide aerogel particles, expanded vitreous microbeads, silica fume, redispersible latex powder, polypropylene fibers, cellulose ethers, and wood fiber. Compared with the existing inorganic insulation mortar, the aerogel modified inorganic insulation mortar has better insulation and construction performance, and can replace the existing inorganic insulation system and be widely applied in the energy saving field of building interior and exterior walls.

Owner:上海英硕聚合材料股份有限公司

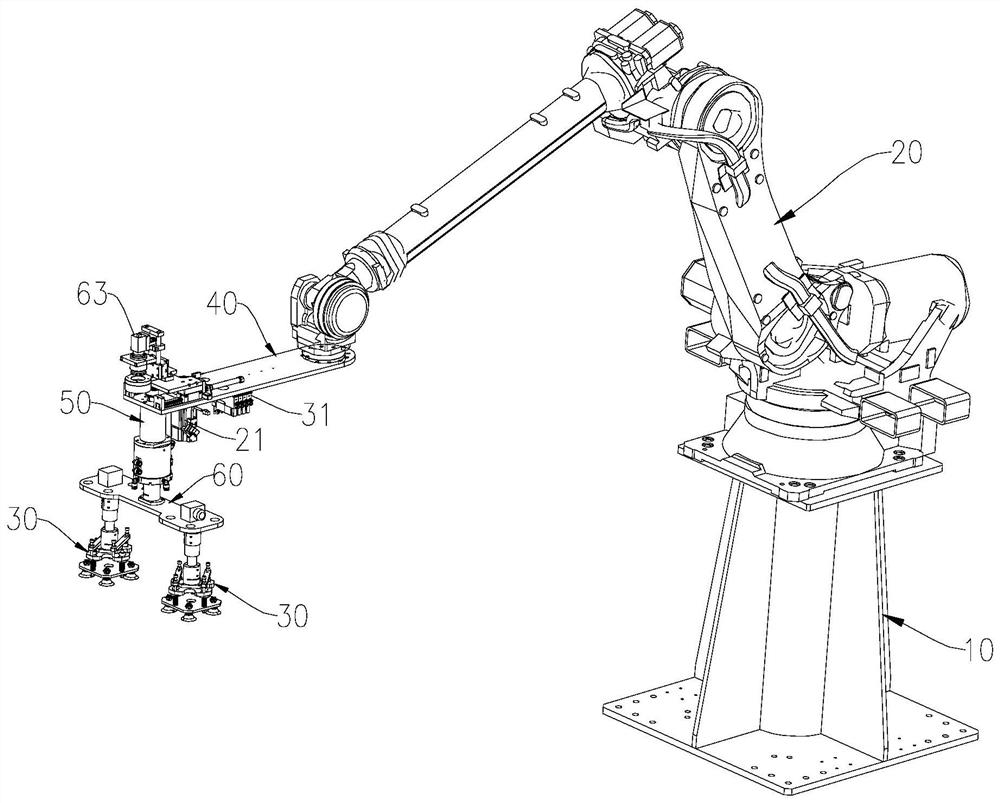

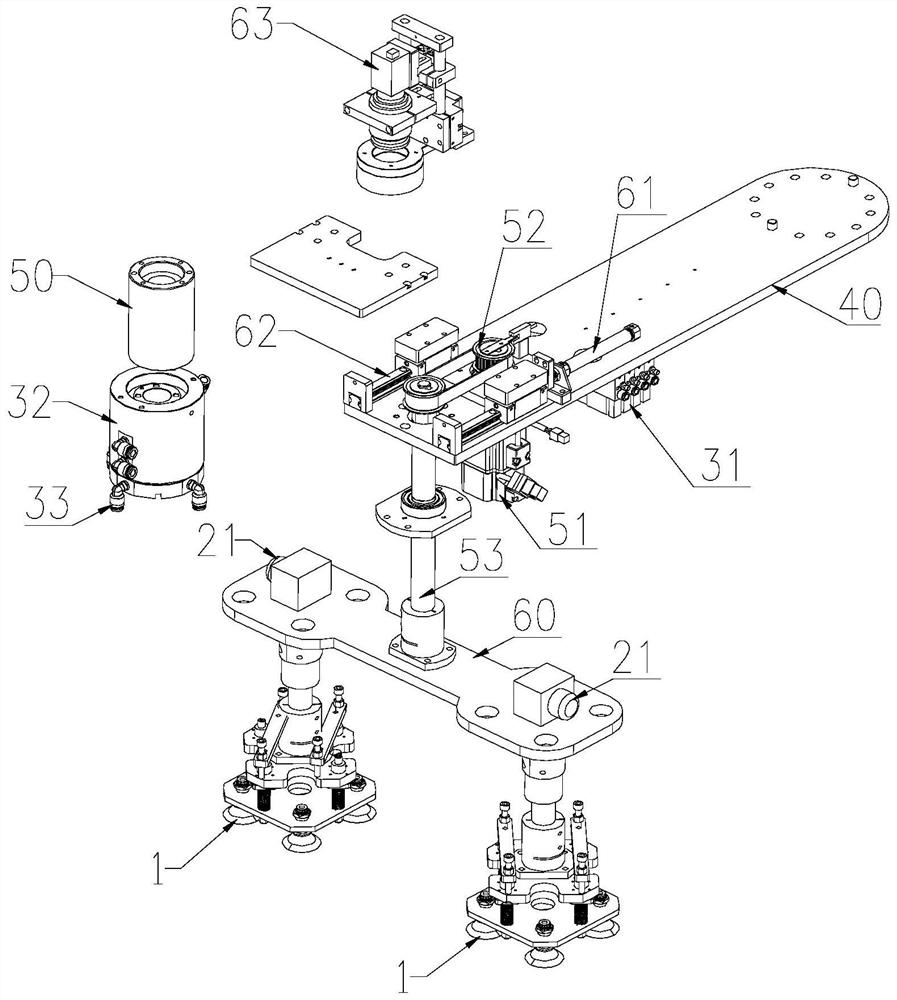

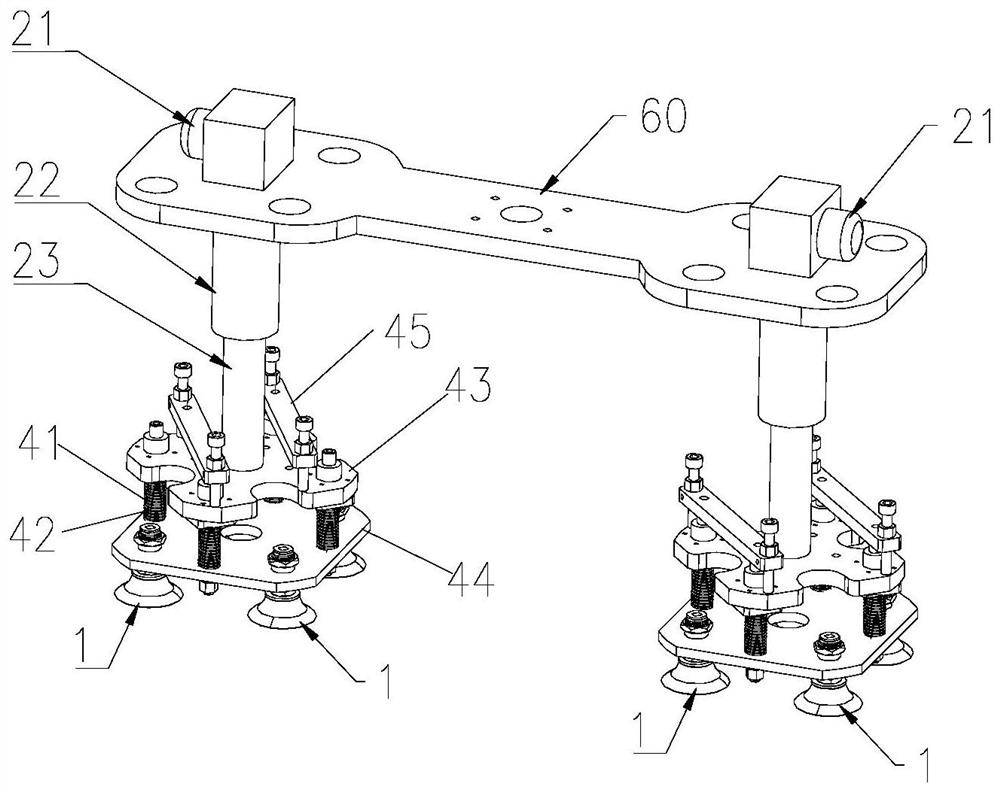

Tile sticking robot system

PendingCN111941422AUnified effectMeet construction quality requirementsProgramme-controlled manipulatorGripping headsCeramic tilesMechanical engineering

The invention provides a tile sticking robot system. The tile sticking robot system comprises a robot base, a six-axis robot, a mechanical arm and a controller; the mechanical arm comprises a sucker gripper and a detector used for detecting whether tiles exist or not; the sucker gripper comprises a vacuum sucker and a vacuum generator system; the controller controls the six-axis robot to move thevacuum sucker to the position above the tiles and controls the vacuum generator system to conduct suction, so that negative air pressure is formed in the vacuum sucker to suck the tiles; and then thesucker gripper is moved to the position above a product needing to be stuck, the vacuum generator system is controlled to inflate the vacuum sucker, zero air pressure / positive air pressure is formed in the vacuum sucker to be disengaged from the tiles, and therefore tile sticking is completed. According to the tile sticking robot system, manual tile sticking can be effectively replaced, conversionfrom building construction to industrialization is achieved, the tiled floor tile effect can be unified, and the construction quality requirement is met; and the construction efficiency can be effectively improved, the construction period is shortened and the labor cost is saved.

Owner:CHINA CONSTR SCI & TECH CO LTD

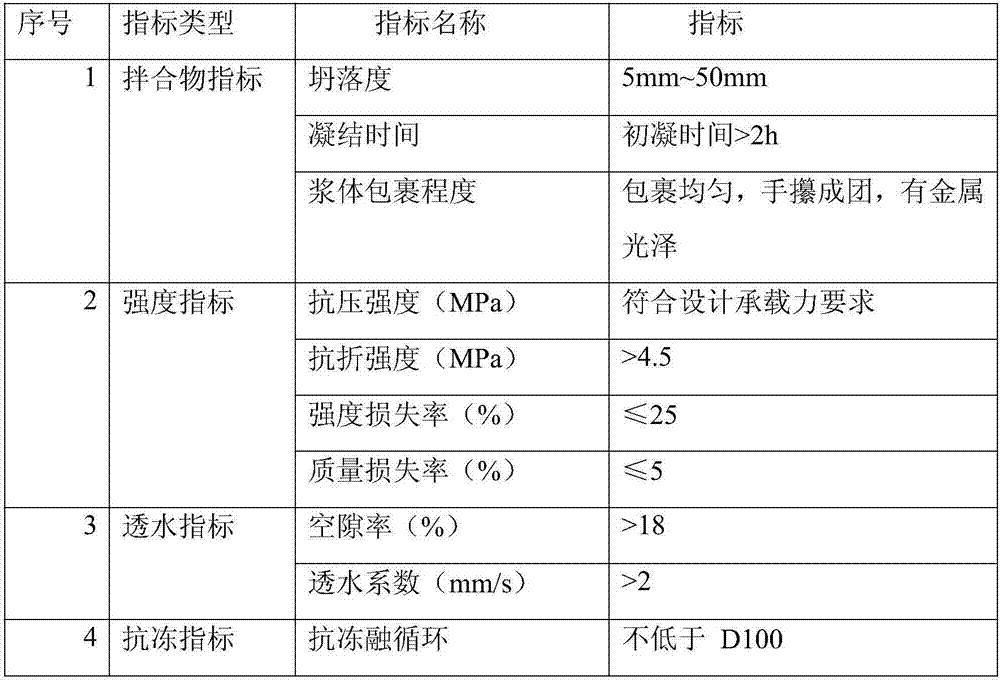

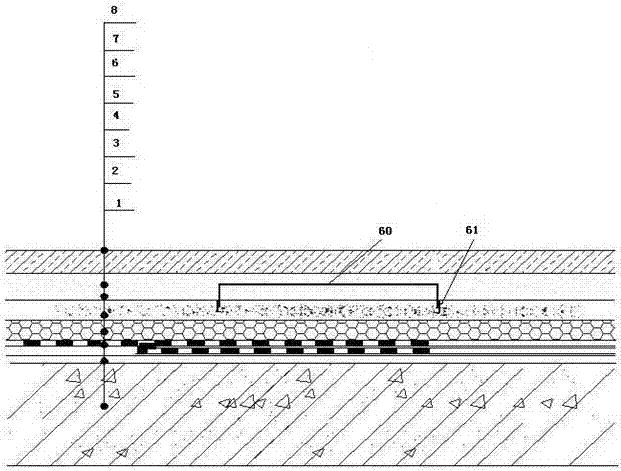

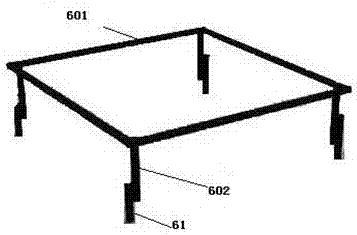

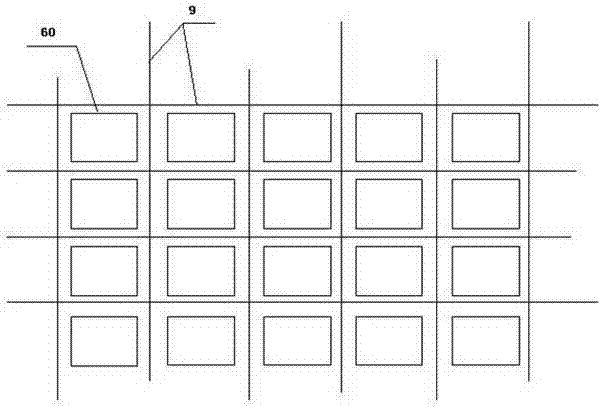

Preparation method of colored pervious concrete ground

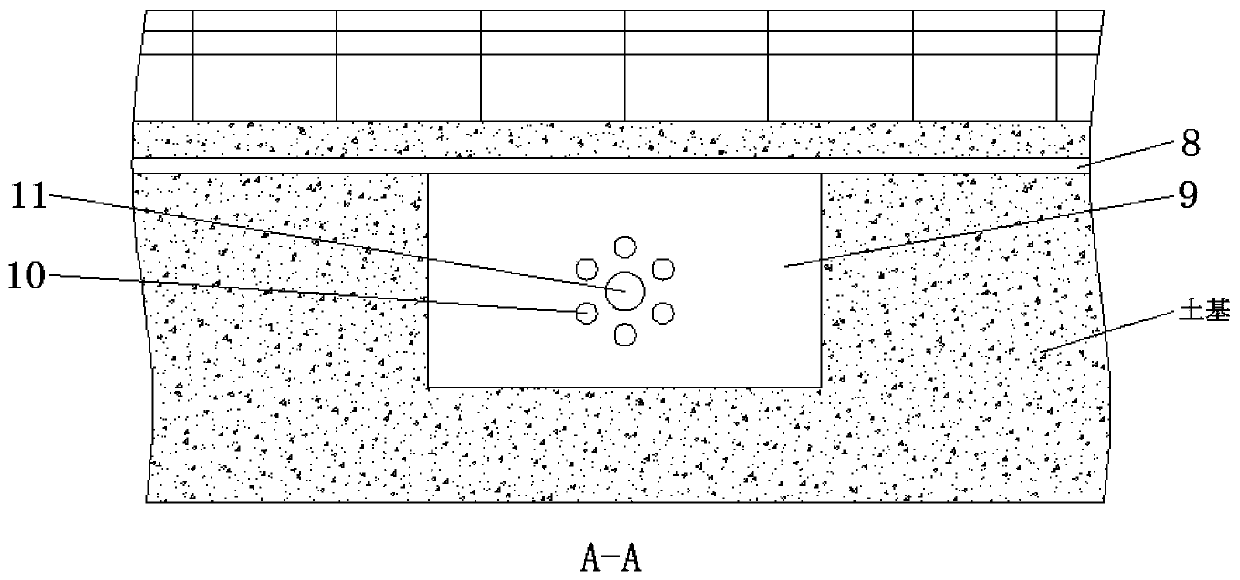

InactiveCN107217565AMeet construction quality requirementsEfficient use ofIn situ pavingsPaving gutters/kerbsSoil horizonEcological environment

The invention discloses a preparation method of a colored pervious concrete ground. According to the preparation method, by virtue of a definite mix proportion and a strict construction flow, the strength requirement and water permeability requirement of the pervious concrete ground are guaranteed; by arranging pervious geotechnical cloth, rainwater can be the purified and filtered; and by pre-burying a drain pipeline in plain soil, the infiltration amount of rainwater infiltrated into a soil layer is adjusted, so that the damage caused by excessive rainwater to a soil layer foundation is avoided, the degree of the damage caused by water infiltration to a ground structure is decreased, the service life of the pervious ground is prolonged, and the utilization of rainwater resources and the protection of an ecological environment are benefited.

Owner:POWERCHINA SEPCO1 ELECTRIC POWER CONSTR CO LTD

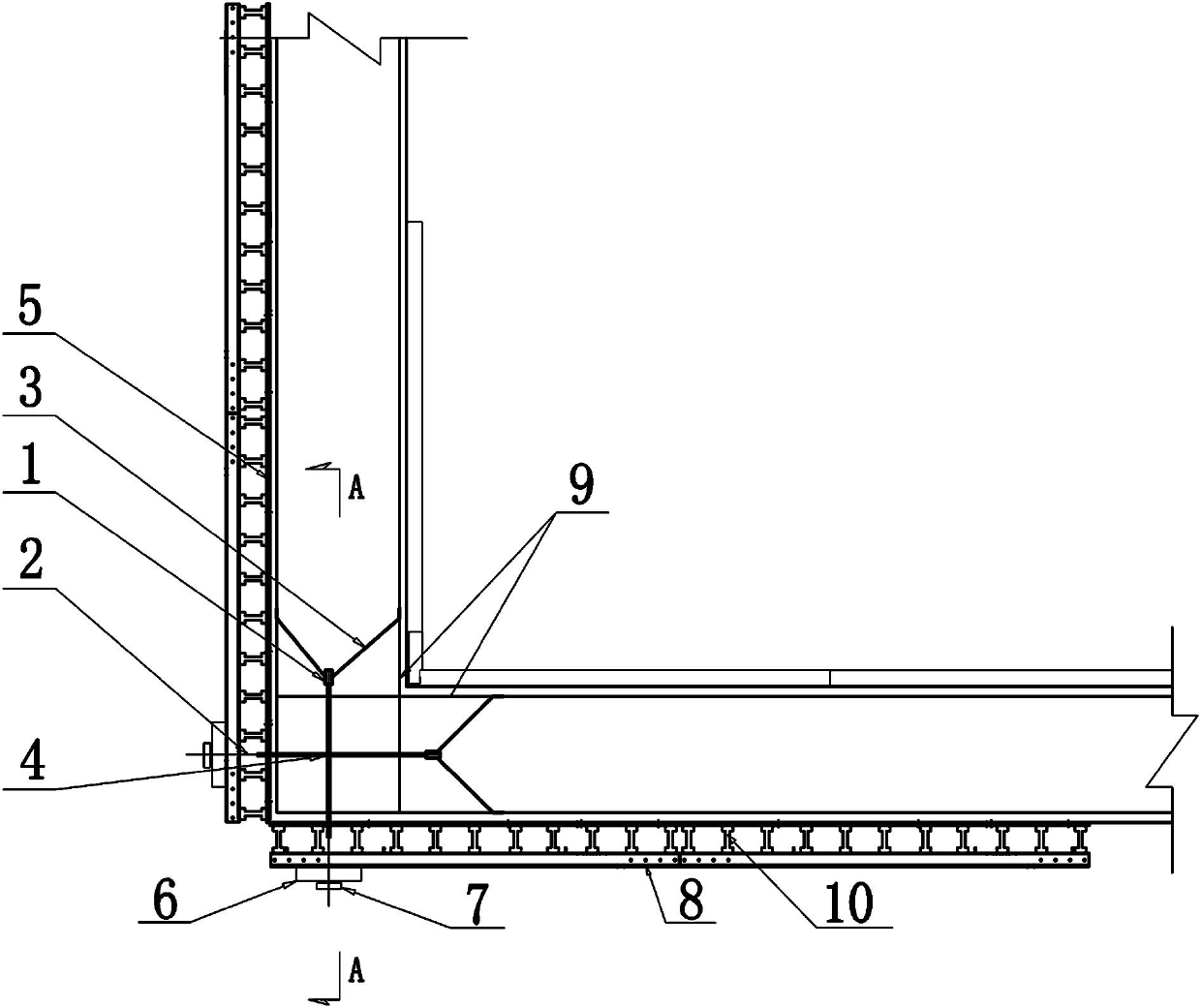

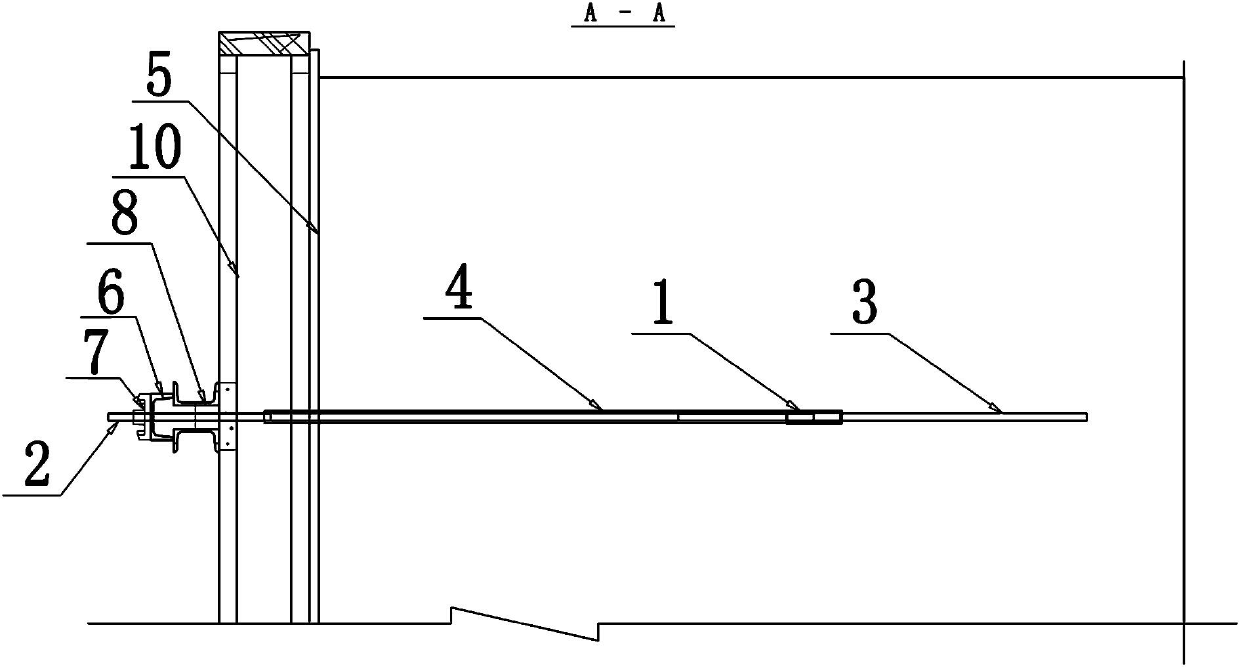

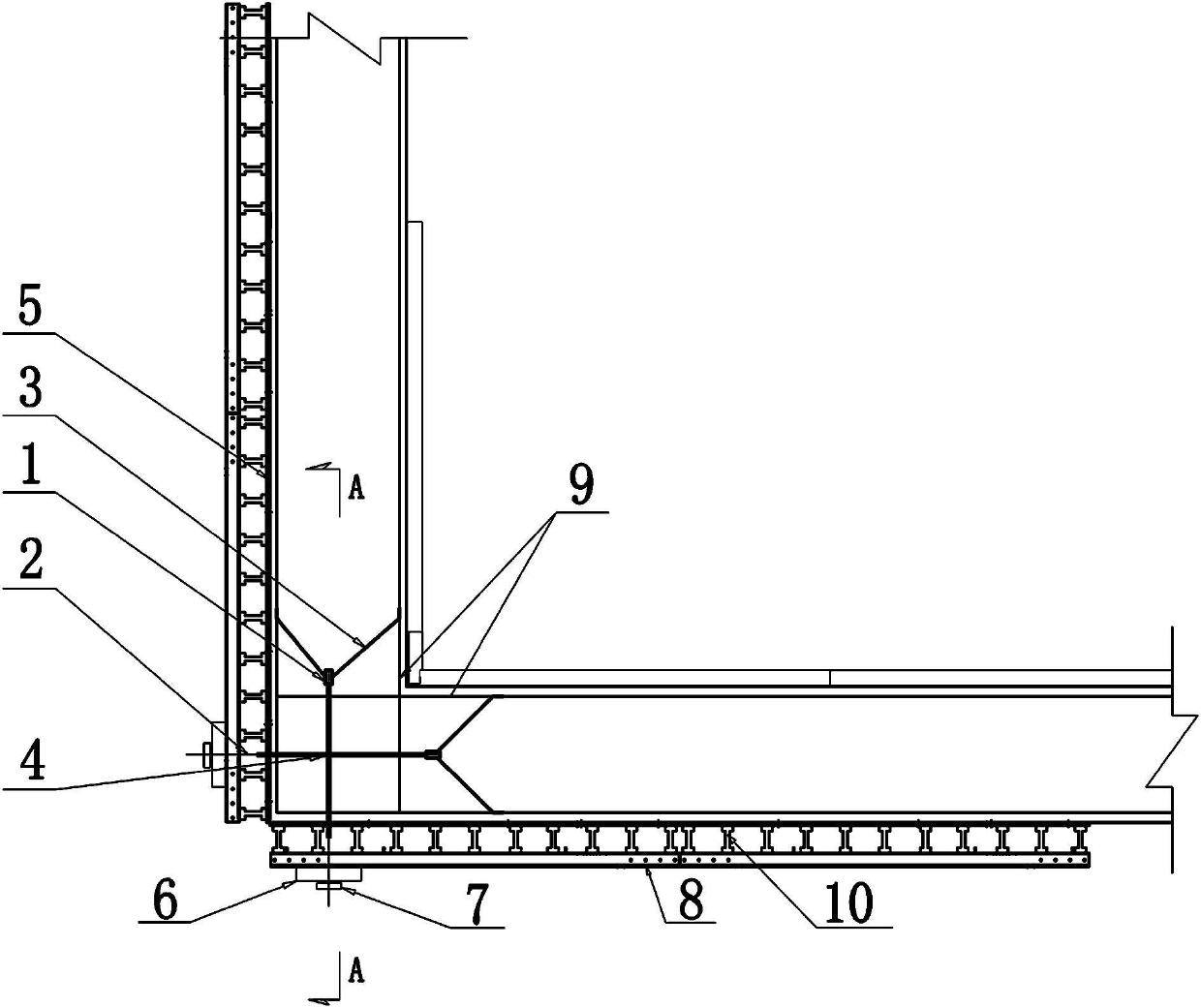

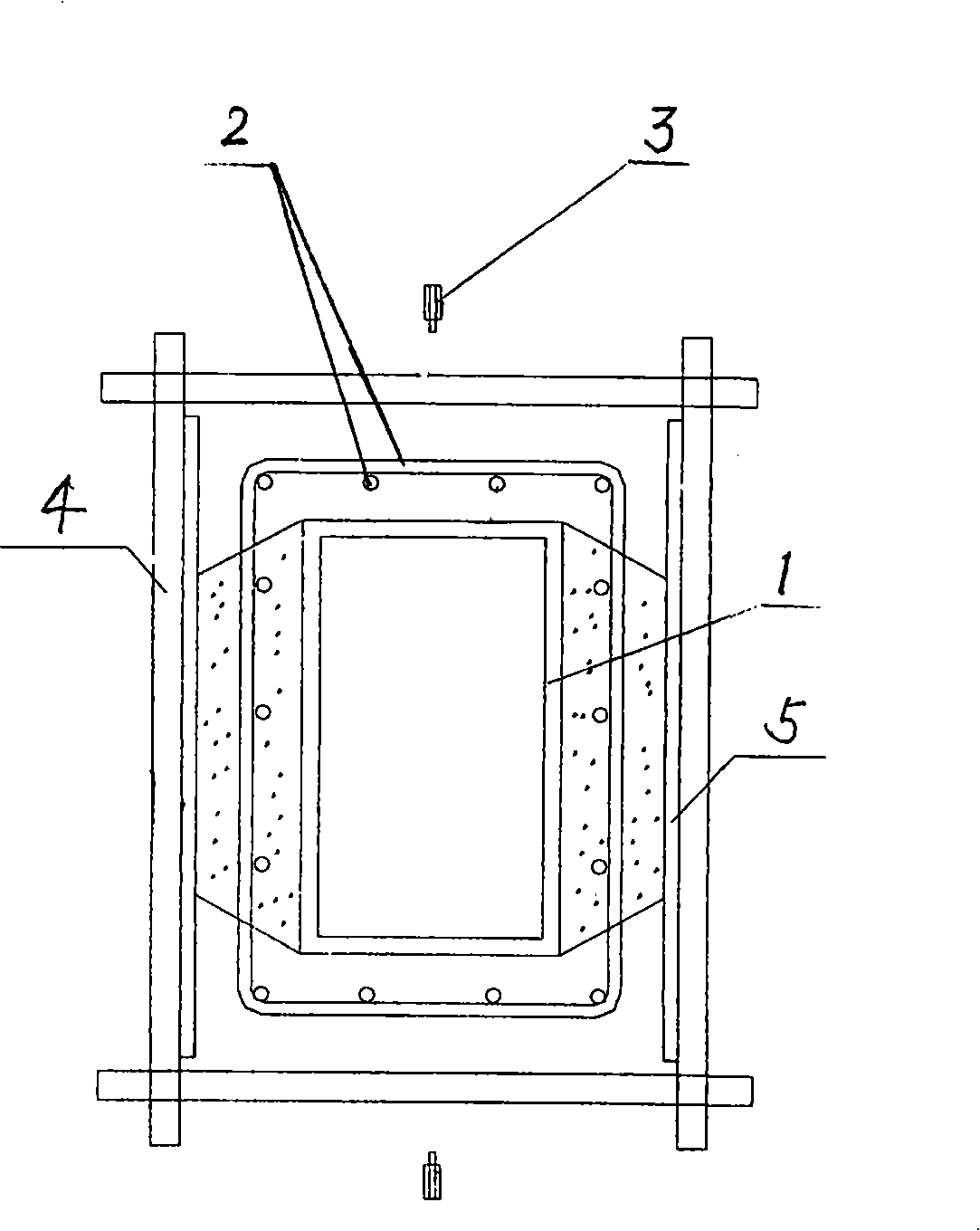

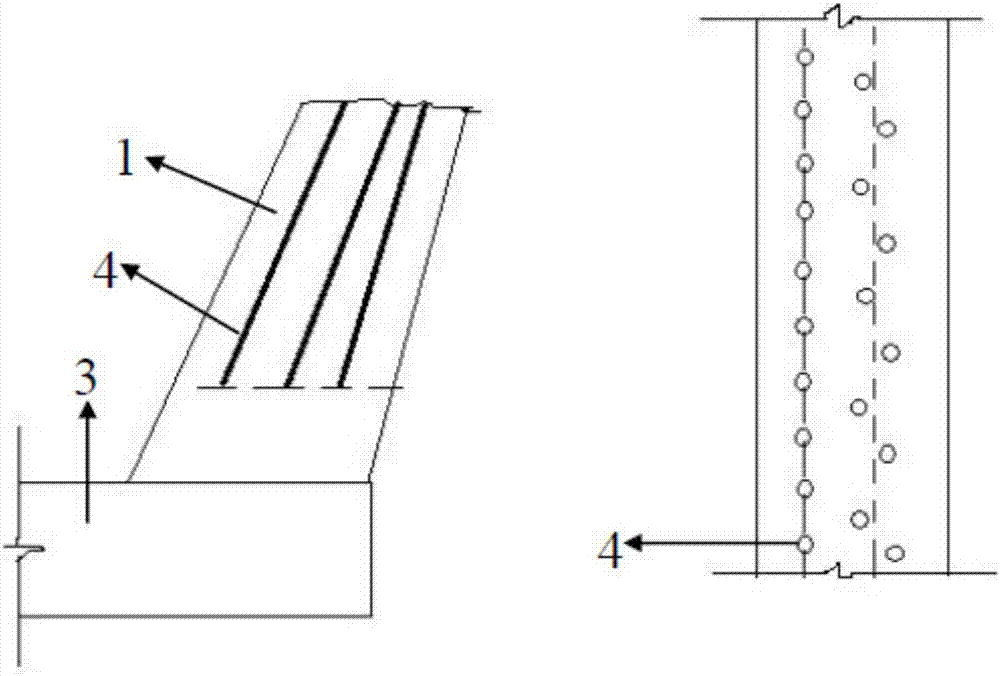

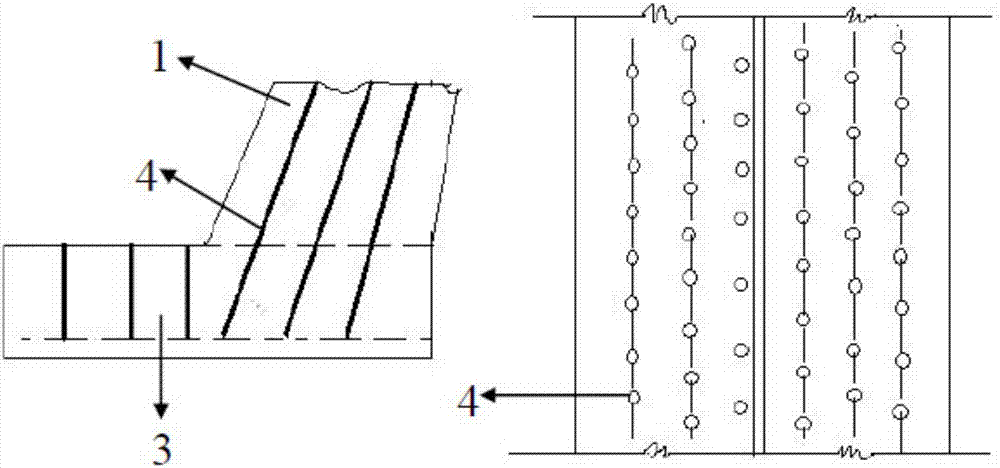

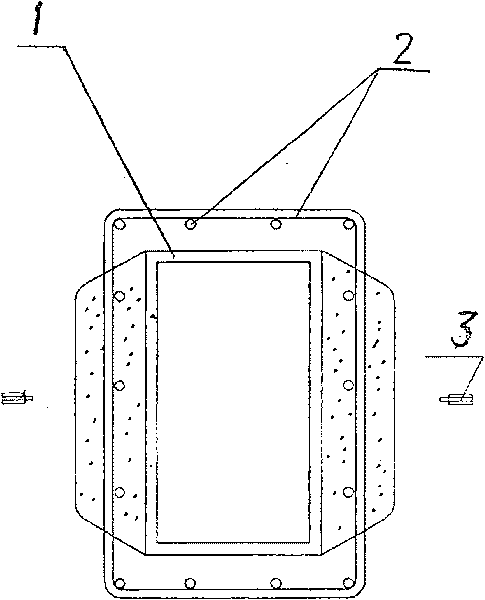

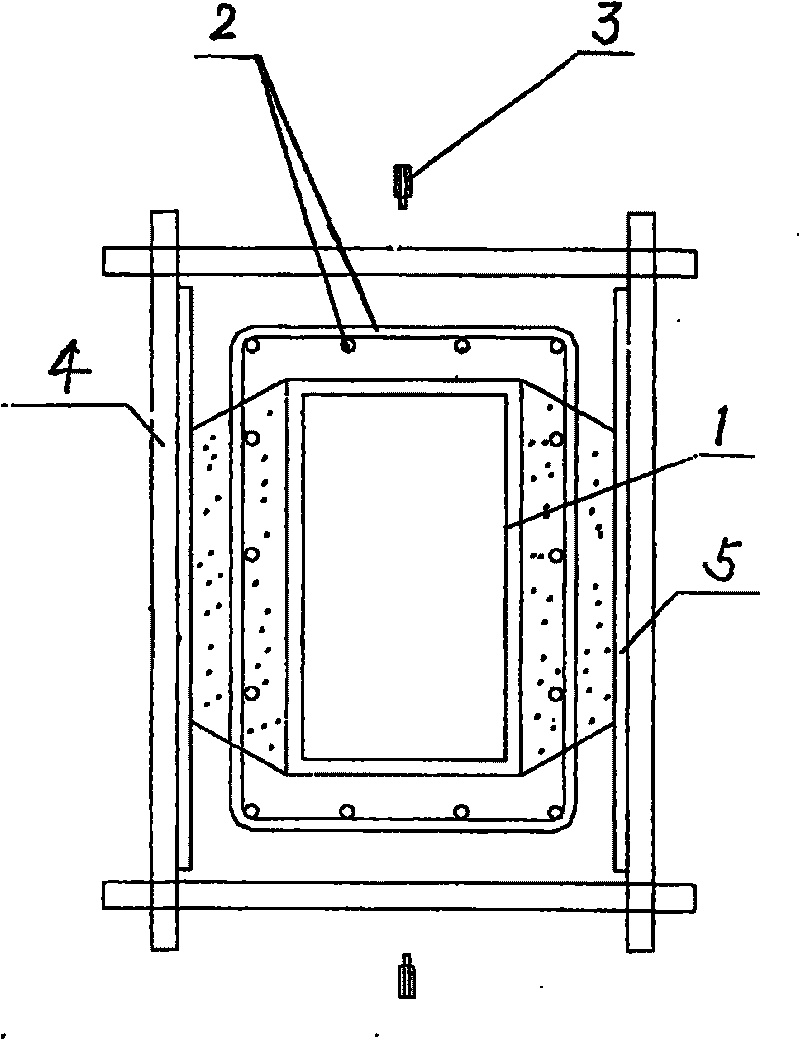

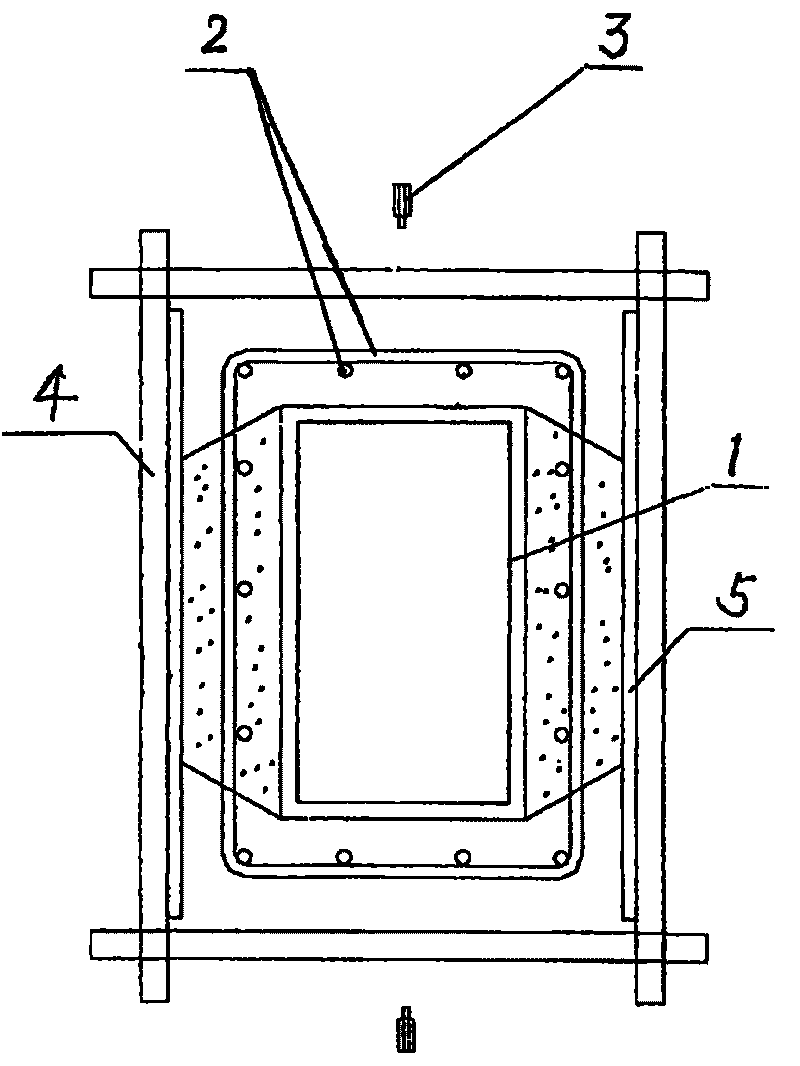

Device and method for positioning template corner

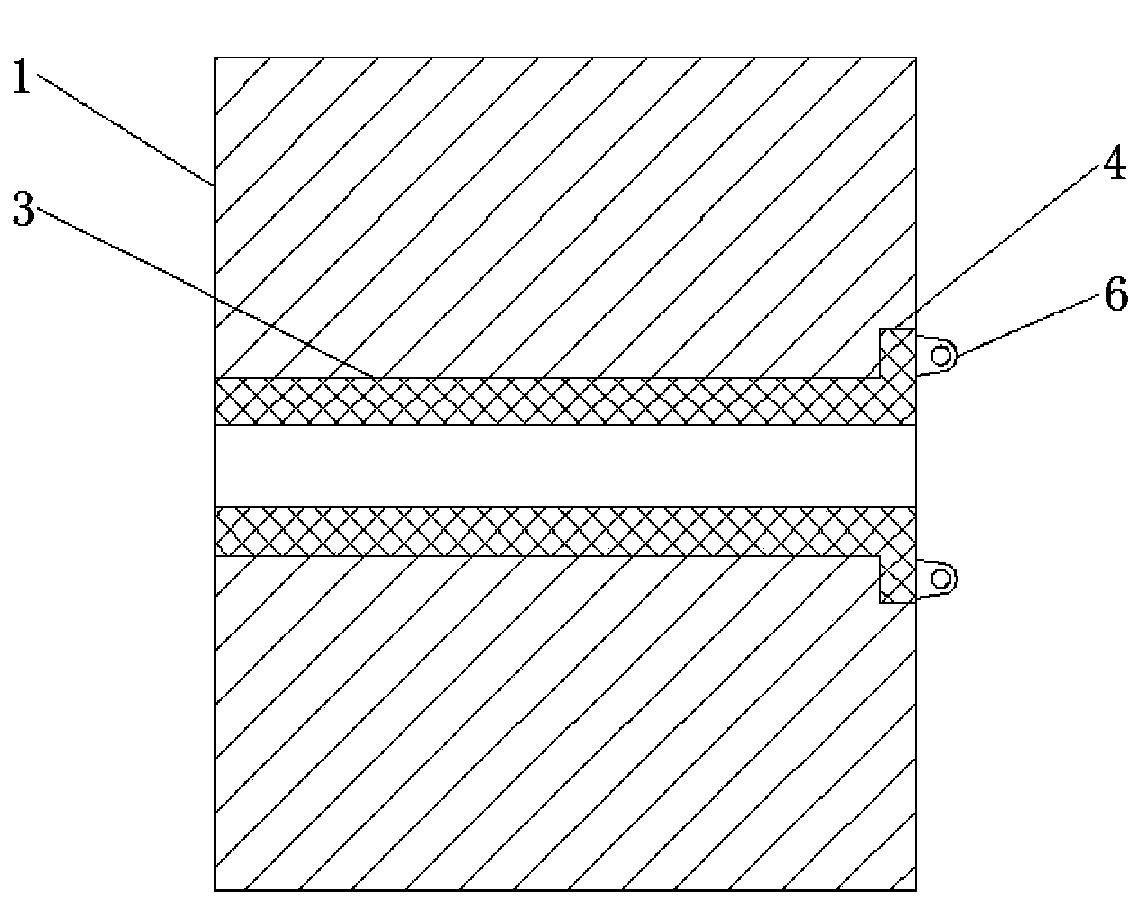

ActiveCN102383411AMeet the needs of pulling reinforcementMeet construction quality requirementsInclined ship-liftingForms/shuttering/falseworksRebarCorner angle

The invention discloses a method for positioning a template corner, which comprises a template, wherein a wailing is arranged outside the template; a lashing strip screw is arranged at the position of the template corner; one end of the lashing strip screw is connected with the template through a liner and a nut; the other end of the lashing strip screw is in threaded connection with a weldable sleeve; and the weldable sleeve is welded with steel reinforcing bars through lashing strips. A casing is arranged outside the lashing strip screw; one end of the casing penetrates out of the template; and the other end of the casing is attached to the weldable sleeve. According to the method disclosed by the invention, the weldable sleeve is welded with a general reinforced lashing strip and is also connected with a high-strength screw, so that the requirement of the template lashing strip at the corner (or T-shaped) part on diagonal pulling and reinforcing is met and the reinforced positioning of a hydraulic self-climbing template at the corner (or T-shaped) part can be ensured to meet the requirement of construction quality. The method is especially suitable for reinforcing construction of templates for tower column structural concrete of ship lifter engineering in a hydropower station under the condition that various templates at corner parts cannot form diagonal pull by using the lashing strips.

Owner:GEZHOUBA XINJIANG ENG

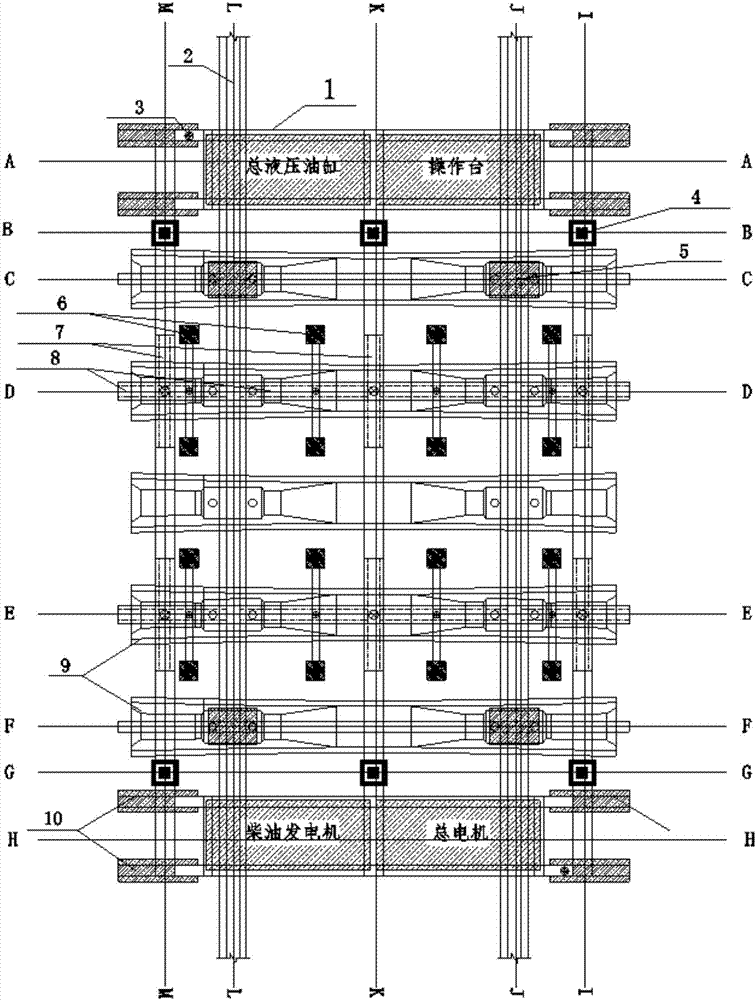

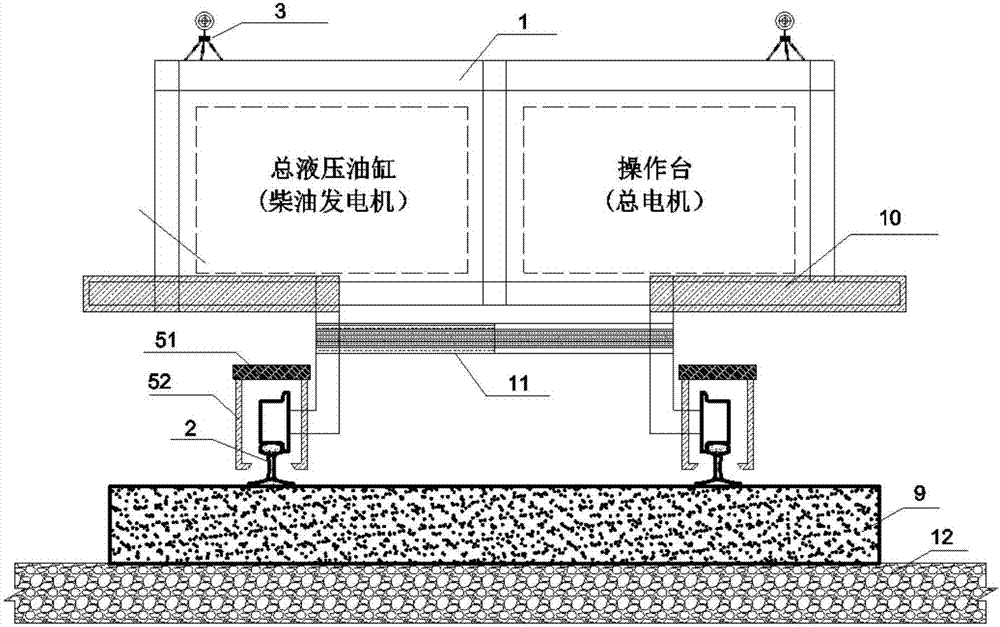

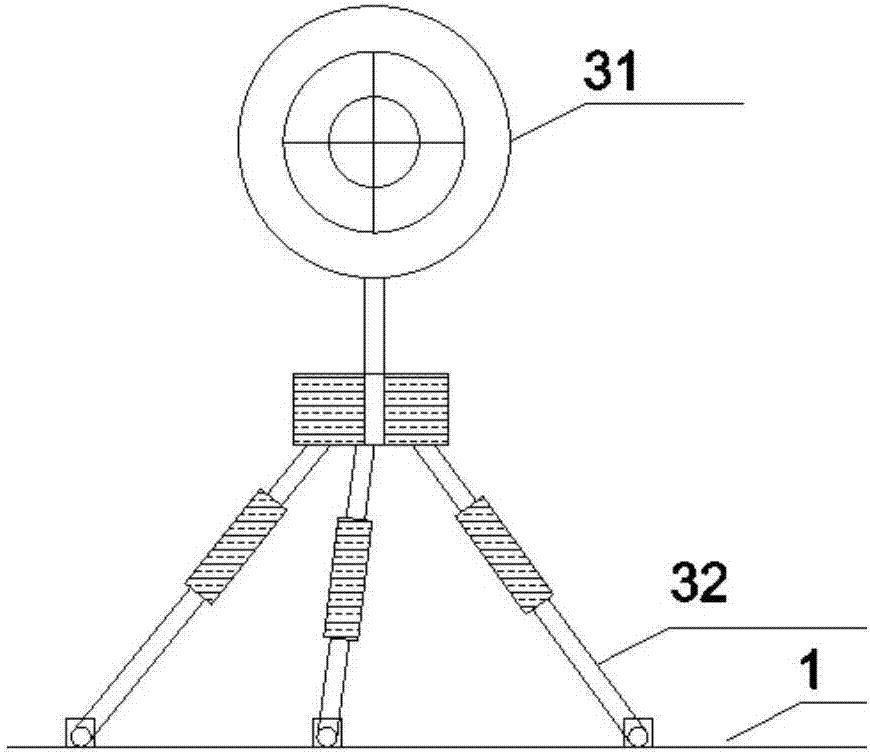

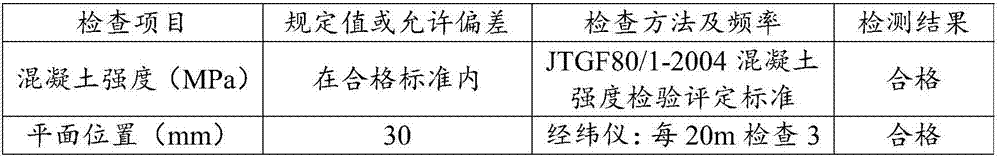

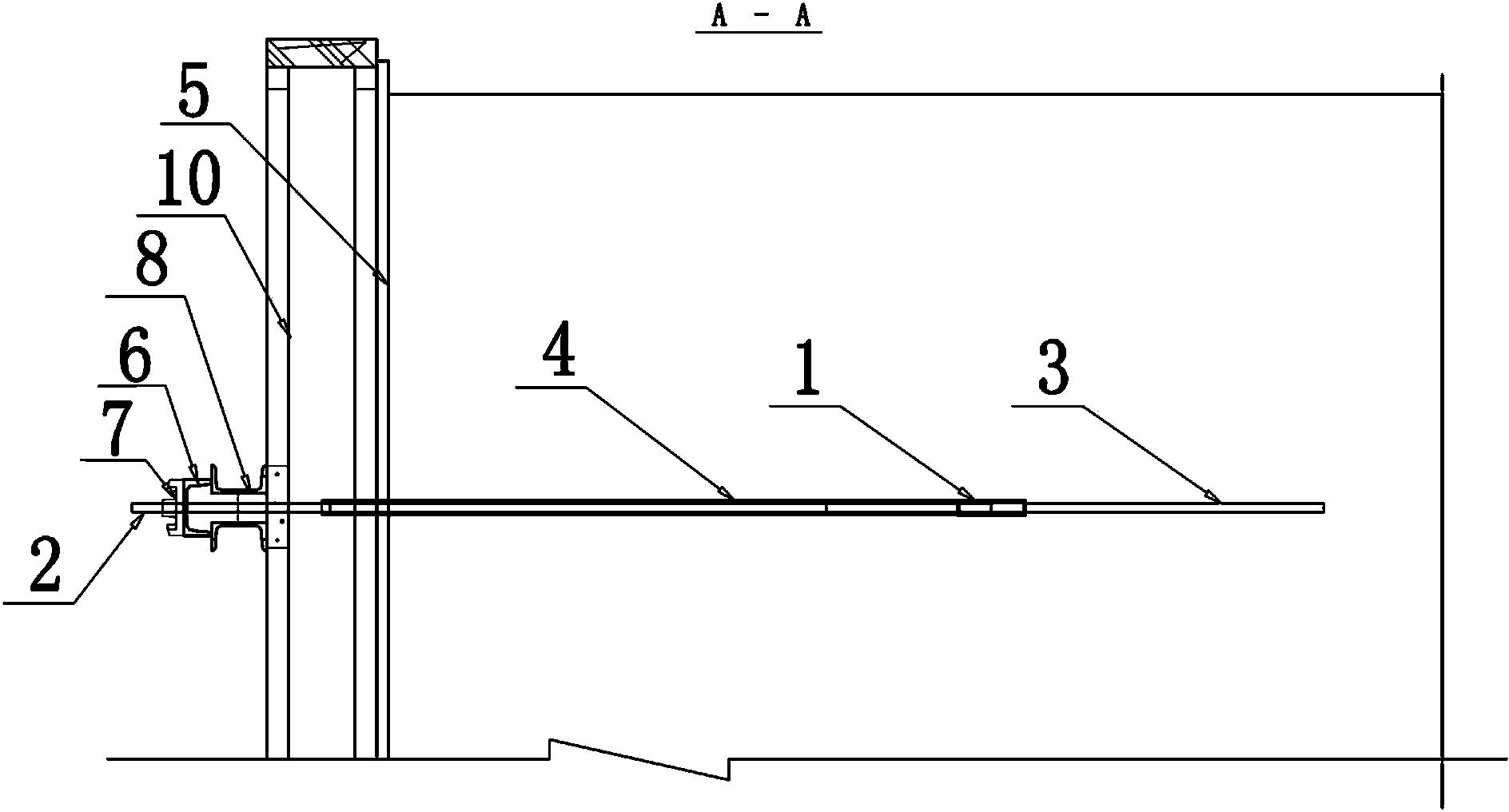

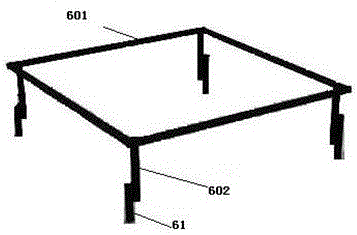

Rapid multifunctional construction equipment for ballast track

PendingCN107190597ASmall sizeFlexible constructionBallastwaySurveying instrumentsTrack bedArchitectural engineering

The invention discloses rapid multifunctional construction equipment for a ballast track. The equipment comprises a main framework, supporting frameworks, lifting combination landing legs arranged on the main framework and concrete vibrating combination devices hung on cross beams of the main framework through connecting frames; hydraulic rail clamping devices used for clamping steel rails are arranged at the bottom of the supporting framework; each lifting combination landing leg comprises a movable support rod and a landing leg hydraulic oil cylinder, each movable support rod comprises a vertical landing leg used for lifting the equipment and the steel rails upwards and integrally and diagonal bracing landing legs making the equipment and the steel rails shift left or right integrally; each concrete vibrating combination device comprises multiple tamping rods, and each connecting frame is provided with a telescopic hydraulic oil cylinder used for controlling and adjusting the depth of the corresponding tamping rod inserted into a railway ballast. Accordingly, ballast track bed construction precision measurement, track raising and lining and tamping are fused together, rapid mechanized operation is achieved, investment of personnel, materials and equipment is greatly reduced, the production efficiency is improved, the construction cost is lowered, and the ballast track bed construction quality requirement is met.

Owner:SINOHYDRO BUREAU 5

Construction method with aluminum alloy formworks as gravity type highway retaining wall formwork and retaining wall

InactiveCN107366303AMeet construction quality requirementsHigh strengthArtificial islandsUnderwater structuresForest resourceRetaining wall

The invention discloses a construction method with aluminum alloy formworks as a gravity type highway retaining wall formwork and a retaining wall and relates to the technical field of building construction. The technical problems that according to traditional formworks, the construction quality requirements of the gravity type retaining wall built at a mountain highway section adjacent to a cliff or a river cannot be meet, in addition, potential safety hazards exist, and forest resources are excessively consumed are relieved. According to the construction method with the aluminum alloy formworks as the gravity type highway retaining wall formwork, the aluminum alloy formworks are adopted to be assembled into the retaining wall formwork in a sectioned mode on a spacious site firstly, then the retaining wall formwork is hoisted to the designed position and fixed, and then concrete is poured; the construction quality requirements of the gravity type retaining wall built at the mountain highway section adjacent to the cliff or the river can be meet, besides, safety accidents can be reduced to the maximum limit, the construction speed can be also improved, and the constriction period is shortened; and meanwhile, the collapse phenomenon can be avoided, wood resources do not need to be consumed, and thus the energy-saving and environment-friendly beneficial effects are achieved. The retaining wall can take the effects of slope protection and edge protection for a long time.

Owner:江苏燕宁工程科技集团有限公司

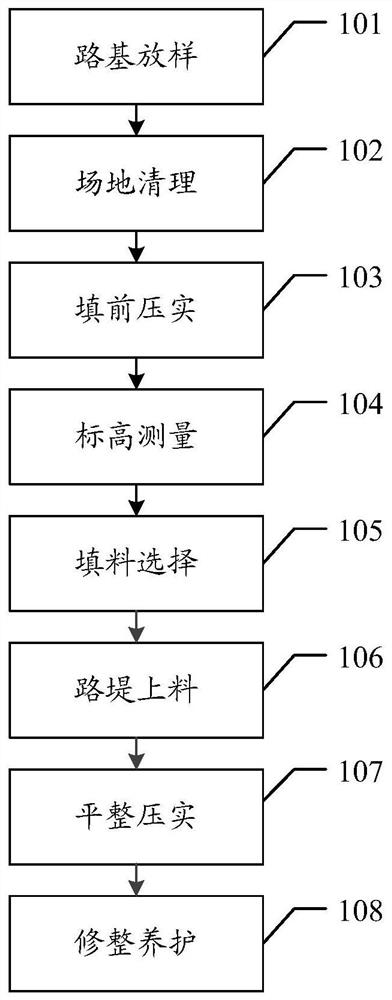

Roadbed filling construction method

InactiveCN111996854AReduce engineering costsAvoid the link of transporting materialsRoadwaysBallastwayArchitectural engineeringBuilding construction

The invention relates to the technical field of building construction, and discloses a roadbed filling construction method. The method comprises the following steps: step 1, roadbed lofting; step 2, site cleaning; step 3, compacting before filling; step 4, elevation measuring: measuring, detecting, recording and calculating the filling elevation of each layer of a compacted roadbed; step 5, fillerselecting: selecting and determining a roadbed filler; step 6, embankment feeding: carrying out layered filling treatment and paving leveling treatment on the roadbed to be fed, and carrying out filler water content detection on the roadbed subjected to watering and airing; step 7, leveling and compacting: performing layered static pressing and layered vibration pressing on the to-be-compacted roadbed according to designed filler compaction conditions to obtain a compacted roadbed; and step 8, finishing and maintaining: finishing and reinforcing a slope, a width, a height and flatness of an embankment slope and the roadbed of the compacted roadbed. Problems that an existing roadbed filling construction method is low in construction efficiency and high in construction cost are solved.

Owner:CHINA RAILWAY SIXTH GROUP +1

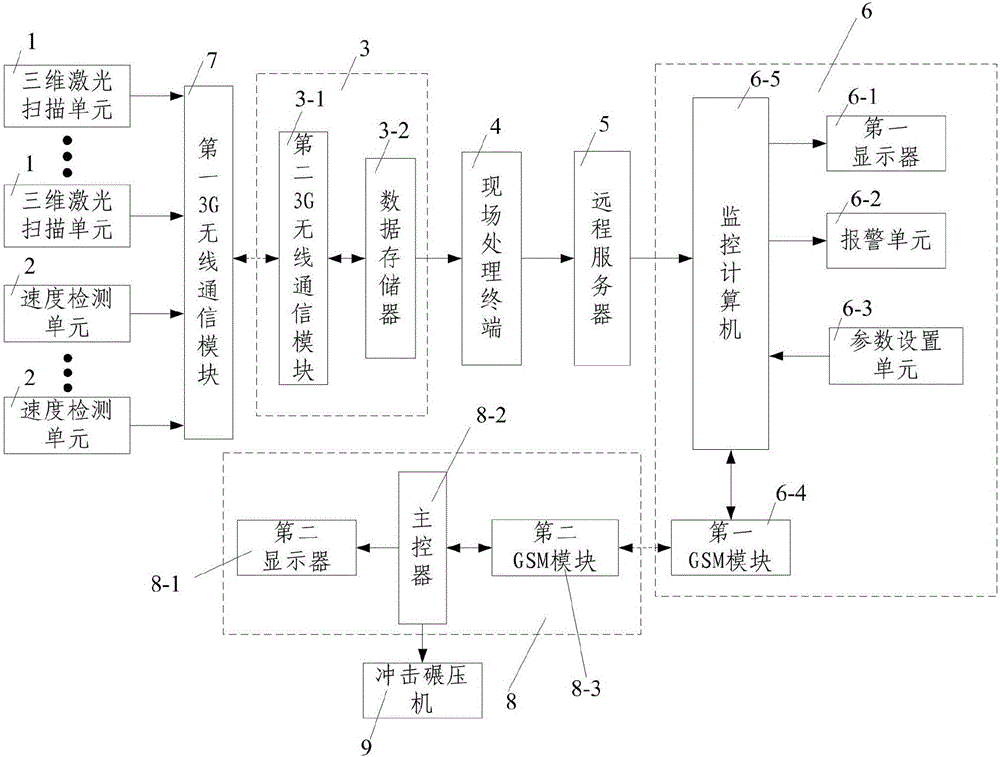

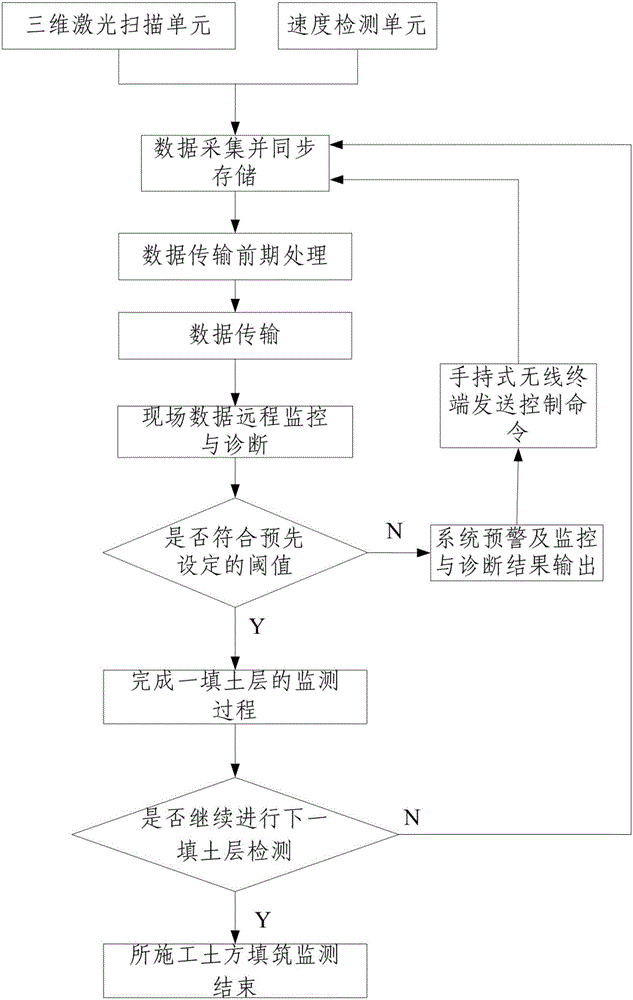

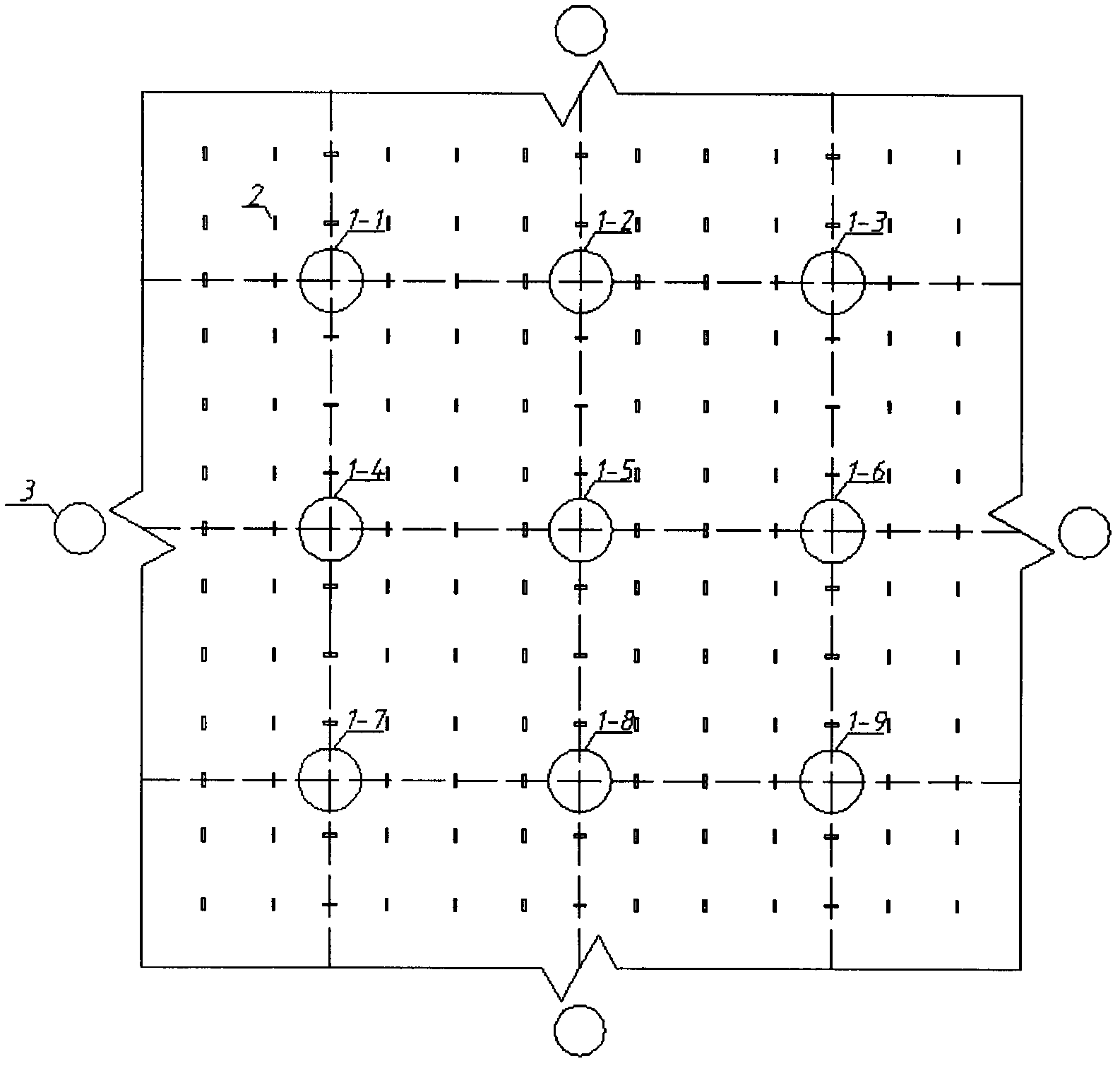

Earthwork filling monitoring device and method based on three-dimensional laser scanning

ActiveCN106774069ASimple structureReasonable designProgramme controlVolume measurement apparatus/methodsProcess moduleLaser scanning

The invention discloses an earthwork filling monitoring device and method based on three-dimensional laser scanning. The monitoring device comprises a data detecting module and a monitoring module. The monitoring module comprises a field processing module, a remote monitoring module and a handhold wireless terminal. The field processing module comprises a field server and a field processing terminal. The remote monitoring module comprises a remote server and a remote monitoring terminal. The monitoring method comprises the following steps: step one, collecting data and synchronously storing; step two, pre-processing of the data transmission; step three, the data transmission; step four, field data remote monitoring and diagnosing; and step five, repeatedly executing the step one to the step four for several times, until finishing the monitoring process of the construction earthwork filling. The monitoring device and method have the characteristics of rational design, simple and convenient operation and good using effect, and are capable of accurately monitoring the construction earthwork filling in real time, and the detection result is accurate.

Owner:CHINA JK INST OF ENG INVESTIGATION & DESIGN

Construction method for driving pre-stressed hollow pile into thick-layer soft soil

InactiveCN102535464AReduce pore water pressureGuaranteed stabilityBulkheads/pilesPre stressPre stressing

The invention discloses a construction method for driving a pre-stressed hollow pile into thick-layer soft soil, and belongs to the technical field of civil engineering pile driving. The construction method comprises the following steps: drilling a dewatering well on the edge of a pile site area; while the dewatering well is drilled, drilling and arranging water draining boards at the periphery of the pile site and other vacant positions according to rectangular arrangement; and implementing the pile driving after the water draining boards are drilled and arranged for 20-30 days by adopting an intermittent driving method and a skid driving method. The construction method disclosed by the invention has the advantages that: due to the adoption of two technologies, namely the dewatering well and the water draining boards, the pore water pressure in the soft soil can be effectively reduced and the foundation is consolidated. According to the intermittent driving method and the skid driving method, two paths for diffusing the pore water pressure are opened up, and thus the stability of driving the pre-stressed hollow pile into the thick-layer soft soil is fully ensured and the requirements for the construction quality and a bearing force can be met.

Owner:程松林

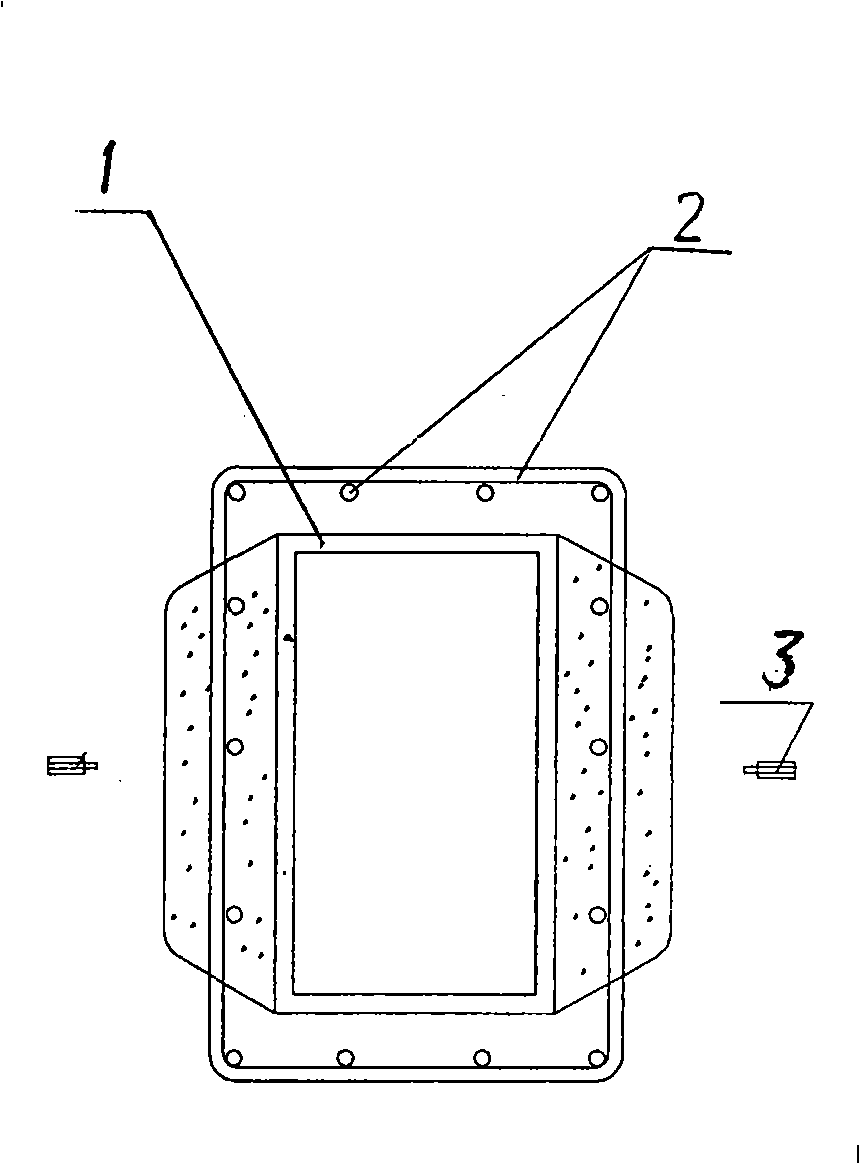

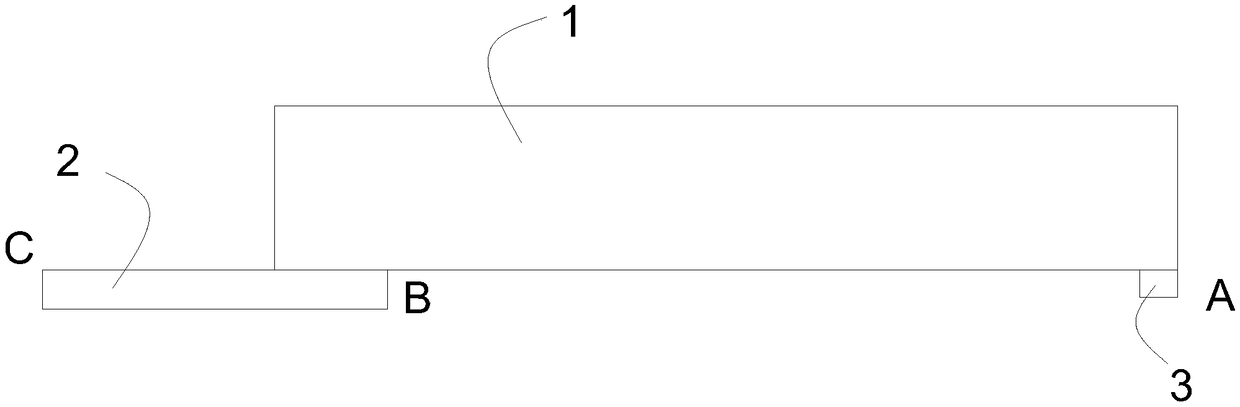

Fast in-place paving construction method for thick and heavy stone blocks

ActiveCN103031793ASimple structureEasy to manufactureSingle unit pavingsRoads maintainenceRebarCivil engineering

The invention relates to a fast in-place paving construction method for thick and heavy stone blocks. The fast in-place paving construction method comprises the following steps of: (1) manufacturing a fast in-place device, wherein the fast in-place device comprises a transverse stress part and a longitudinal stress part which are vertical to each other, the transverse stress part is of a plane framework and is used for directly supporting single stone blocks, and the longitudinal stress part is fixedly connected with one side of the plane framework and used for supporting the transverse stress part and the stone blocks thereon; (2) pre-burying a connecting steel bar which is vertically upward in the paving position of each stone block; (3) testing repeatedly to measure the virtual paving height M of mortar for paving the stone blocks, which is further used for paving the stone blocks with the same thickness and size; (4) fixedly connecting the vertical stress part of the fast in-place device with the connecting steel bars to fixedly mount the fast in-place device, and performing the paving control on the stone blocks in a wire hanging mode; (5) enabling the paid mortar to achieve the virtual paving height M; and (6) paving the stone blocks on the transverse stress part of the fast in-place device, and thrashing the stone blocks to compress the mortar which is virtually paved.

Owner:GUANGZHOU NO 1 CONSTR ENG +2

Steel component concrete encasement construction technique

InactiveCN101343912AEasy to shapeMeet construction quality requirementsStrutsPillarsRebarMaterials science

The invention discloses a construction technology of wrapping concrete outside the steel member. The construction technology adopts the procedures: firstly, concrete is prepared; secondly, the first layer of reinforcing steels are prepared outside the steel member, and the space distance between the adjacent two reinforcing steels is not less than 80 mm; thirdly, concrete is sprayed to the surface of the steel member, and the concrete thickness is controlled between 70 mm to 100 mm; fourthly, the second layers of reinforcing steels are prepared outside the concrete layer; fifthly, concrete is sprayed according to the third procedure; sixthly, according to the requirements, the fourth and fifth procedures are repeated, and the concrete is cured according to the convention. The construction technology of the invention can avoid problem existing the prior casting method for wrapping concrete outside the steel member, mould plates are not required or less mould plates are required, therefore the investment is greatly reduced and the construction period is shortened.

Owner:HEBEI CONSTR GRP

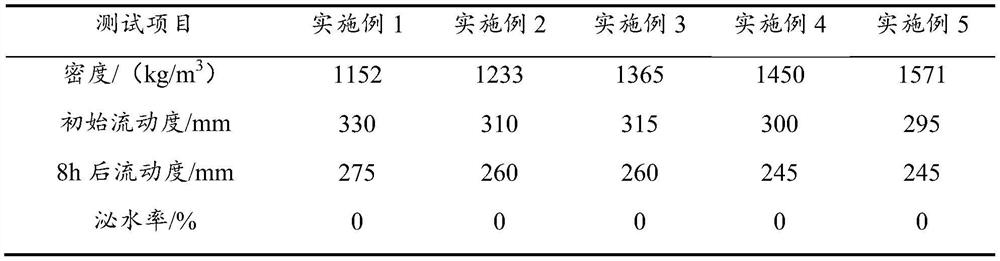

Low-density grouting material and preparation method thereof

ActiveCN112919869AGuaranteed water dispersion resistanceInhibition of segregationSolid waste managementWater dispersibleSludge

The invention discloses a low-density grouting material and a preparation method thereof. The low-density grouting material comprises 10-85 parts of cement, 5-70 parts of an admixture, 1-30 parts of lightweight aggregate, 0.1-5 parts of a thickening agent, 0.01-1 part of a water reducing agent, 0.01-1 part of an expanding agent and 50-100 parts of water. The preparation method comprises the following steps: uniformly mixing the components according to a certain ratio to form a dry mixture, adding a certain amount of water, and uniformly mixing to obtain the low-density grouting material. The density of the prepared low-density grouting material is about 1,100-1,600kg / m<3> and is slightly lower than that of sludge by selecting the lightweight aggregate and increasing the water consumption, so the sludge at the bottom of a negative pressure cylinder is prevented from being turned up in the grouting construction process, and the construction quality is ensured; in order to ensure the water dispersion resistance of the grouting material under the conditions of use of the lightweight aggregate and large water-to-material ratio and avoid segregation and floating of the lightweight aggregate, the thickening agent is added to increase the viscosity of the grouting material, so that the layering and segregation problems of the grouting material under the large water-to-material ratio are overcome, and the underwater dispersion resistance of the grouting material is improved.

Owner:CCCC SHANGHAI HARBOR ENG DESIGN & RES INST +2

Steel-concrete structure slag stop wall shallow hole loosening blasting demolition method

InactiveCN107246829AEffectively guide demolition operationsProtect personal and property safetyBlastingMaterials science

The invention discloses a shallow hole blasting demolition method for a slag retaining wall of a steel-concrete structure, which comprises the following steps: 1) cleaning the slag retaining wall of a steel-concrete structure to form a blasting free surface, 2) blasting and layering the slag retaining wall, 3 ) Rock drilling and perforation (drilling operation), 4) Setting the value of the resistance line, 5) Calculating the single-hole charge, 6) Blast hole charge and blockage, 7) Defining the initiation method and network, 8) Blasting safety Technical verification, 9) implementation of safety technical measures, 10) verification of initiation and blasting effects; shallow hole loosening blasting method is adopted for blasting demolition, combined with mechanical crushing to complete auxiliary work; blasting demolition of steel-concrete structure slag retaining wall should be top-down The next layer is carried out: the first layer blasts off the eaves and part of the main wall, the second layer mainly blasts off the main wall, and the third layer blasts off the bottom plate and the rest of the main wall. The invention is safe, efficient and has good economic benefits, and can provide reliable method support for blasting demolition of steel-concrete structure slag retaining walls such as steel slag in steel mills.

Owner:HOHAI UNIV

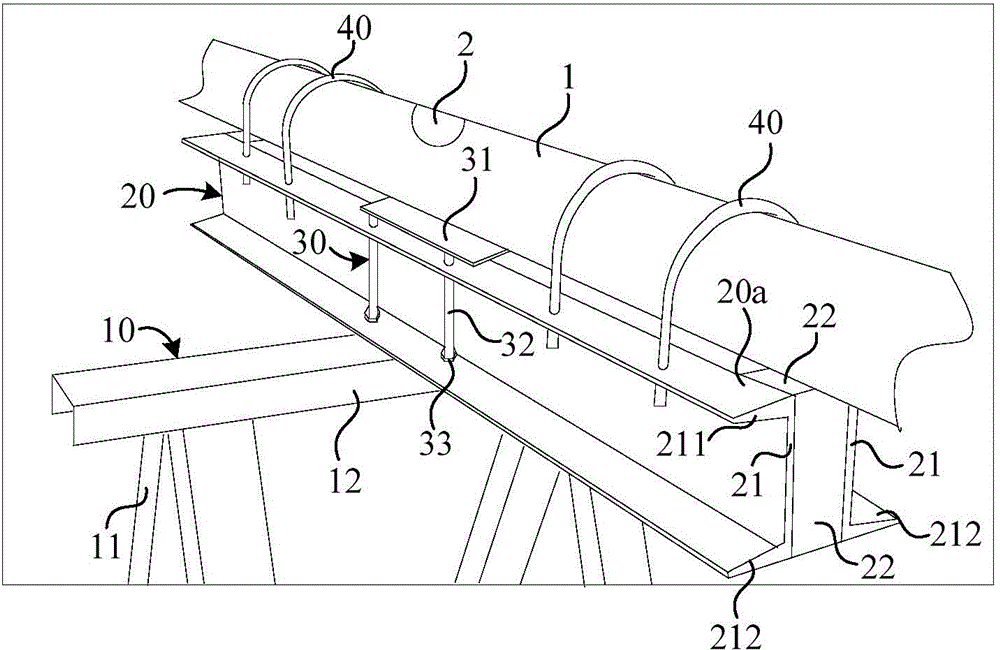

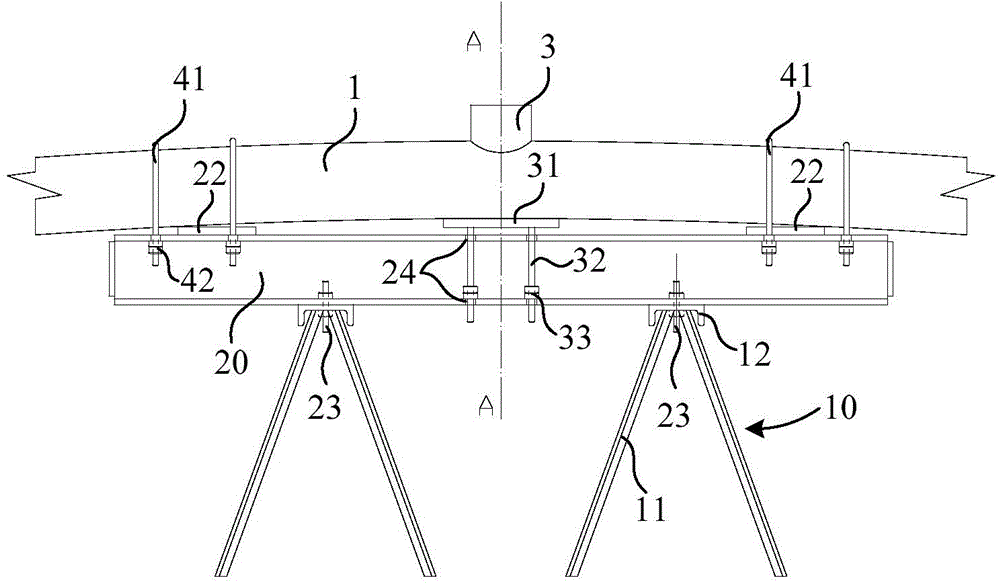

Device and method for preventing welding deformation of pipelines in nuclear power plant

ActiveCN104084725AAvoid welding deformationMeet construction quality requirementsWelding/cutting auxillary devicesAuxillary welding devicesWork periodPre deformation

The invention provides a device and method for preventing welding deformation of pipelines in a nuclear power plant. The device comprises a supporting frame, a fixed platform fixed on the supporting frame, a jacking mechanism movably connected with the fixed platform, and a clamp detachably connected with the fixed platform. Before welding, a pipeline with a connecting pipe seat hole is fixed on the fixed platform, then external force which is equal to welding stress in intensity and opposite to the welding stress in direction is exerted on the pipeline through the jacking mechanism, so that the pipeline is made to generate pre-deformation which is the same as welding deformation in amplitude and opposite to the welding deformation in direction, and welding deformation can be eliminated after a pipe connecting seat is welded on the pipeline. Accordingly, deformation correction does not need to be conducted after welding, the work period is saved, the construction efficiency is improved, meanwhile, the construction cost is lowered, the requirements for the construction quality, the schedule and the cost of the nuclear power plant are met, and therefore the technical problems that in the prior art, the method for conducting manual correction on the pipelines which are subjected to welding deformation is low in efficiency, high in maintaining cost, and poor in engineering quality are solved.

Owner:中广核工程有限公司 +1

Shallow soft foundation strong on-site solidification treatment construction method

InactiveCN112695740AHas thicknessWith uniformitySoil preservationSurface cleaningArchitectural engineering

The invention discloses a shallow soft foundation strong on-site solidification treatment construction method. The shallow soft foundation strong on-site solidification treatment construction method comprises the following specific steps of 1, surface cleaning; 2, dividing blocks; 3, blending a curing agent; 4, stirring in situ by strong stirring equipment; 5, conducting in-situ curing treatment; 6, conducting prepressing and maintaining; and 7, leveling the field. The method has the effects that the thickness, uniformity, strength, foundation bearing capacity and the like all meet the construction quality requirements, and construction is safe.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG

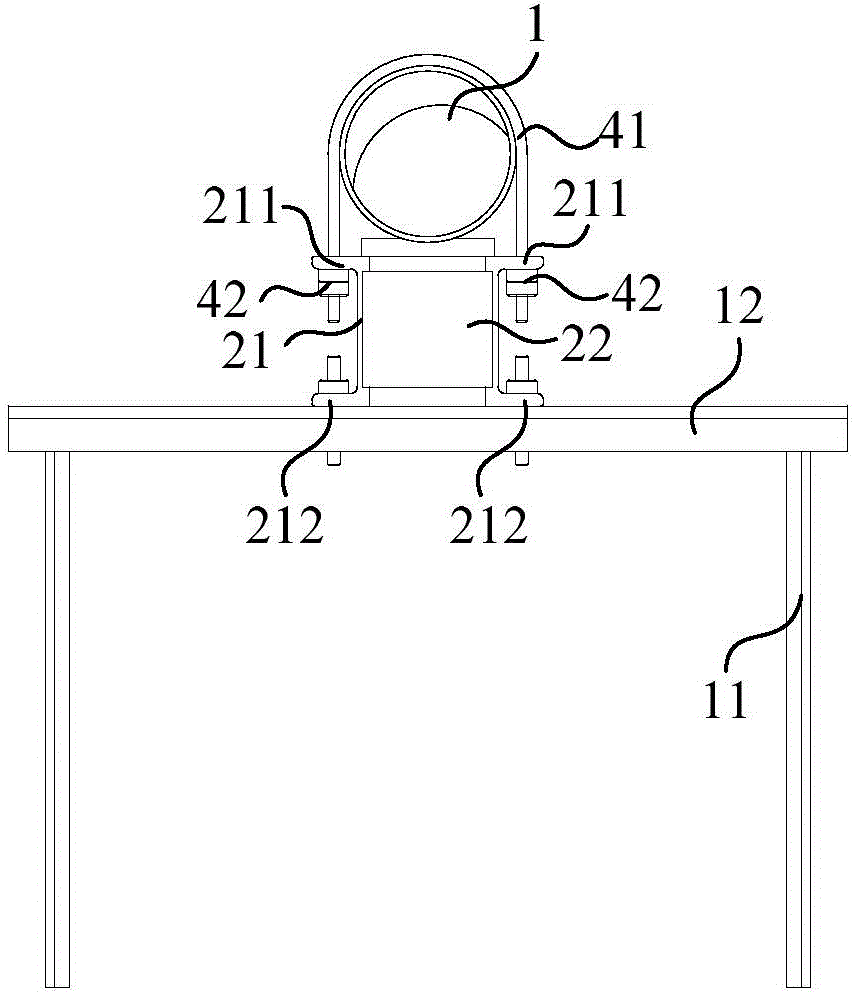

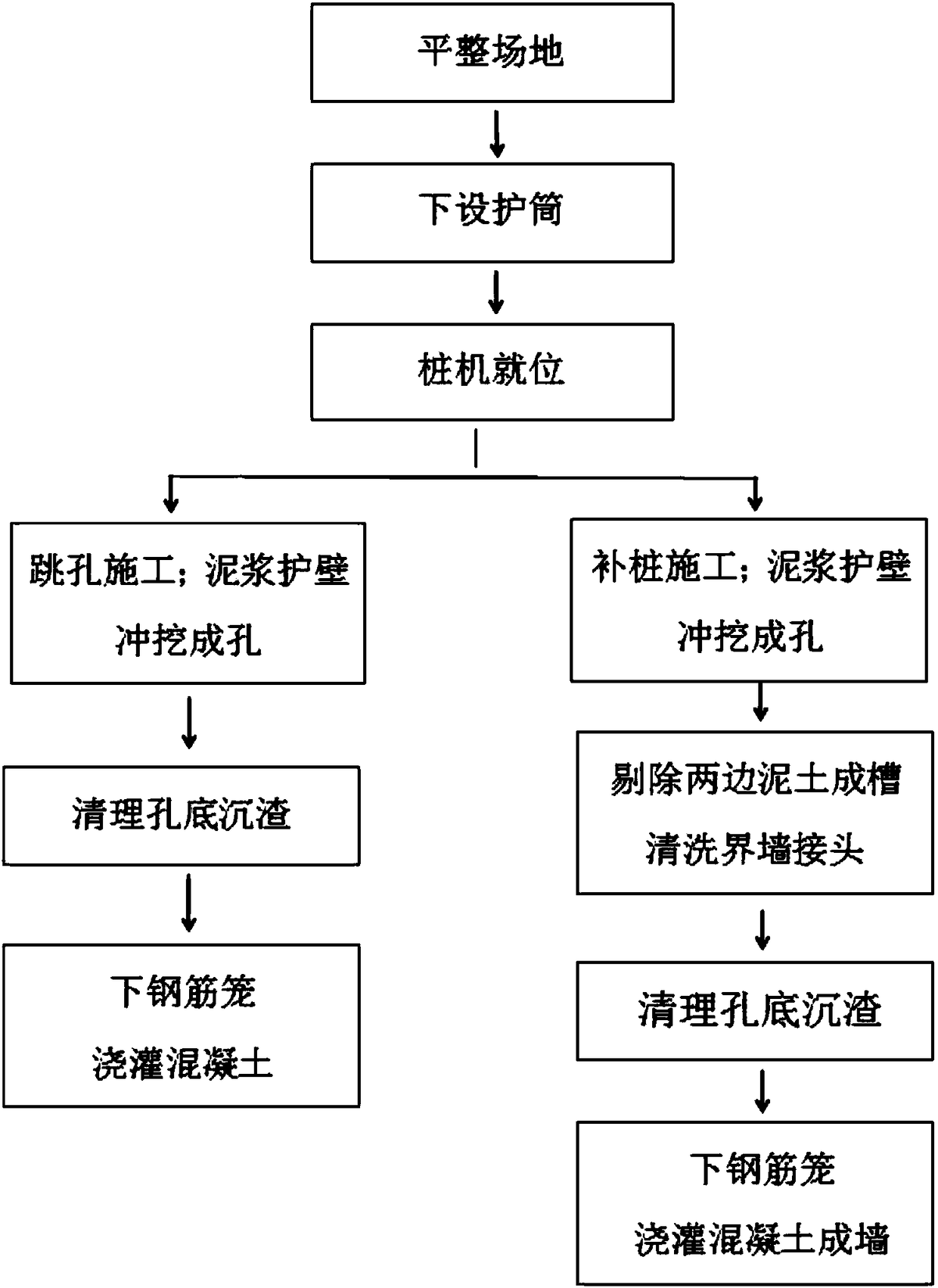

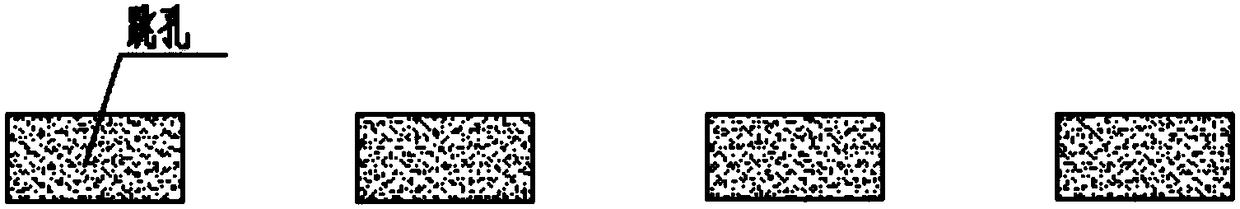

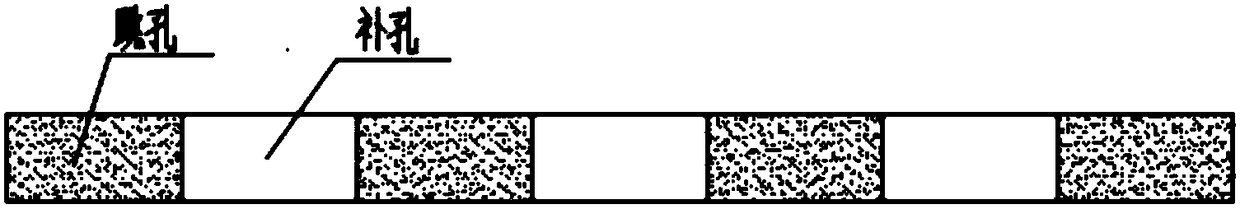

Underground pile continuous wall construction method and wall formation device for underground pile continuous wall construction method

PendingCN108442363AIncrease connection soliditySolve problems such as gaps and even water seepageSoil-shifting machines/dredgersBulkheads/pilesSlurryHigh pressure

The invention discloses an underground pile continuous wall construction method and a wall formation device for the underground pile continuous wall construction method. The underground pile continuous wall construction method is characterized by comprising the steps that S1, land is leveled; S2, a pile casing is arranged underground; S3, a pile driver is placed in position; S4, jump holes are arrayed according to pile positions for construction, and a slurry protection wall is flushed and dug to form a hole with a set depth; S5, sediment at the bottom of the hole is removed, and the slurry condensation is measured; S6, a reinforcement cage is placed downwards, concrete is poured, and thus, one jump-hole unit wall section is completed; S7, pile adding construction is conducted, and the slurry protection wall is flushed and dug to form another hole; S8, mud in two boundary walls is removed, high-pressure spray heads move up and down along guide rods, and thus, joints of the two boundarywalls are flushed, cut and cleaned with water slurry; S9, sediment at the bottom of the hole is removed, and the slurry concentration is measured; and S10, a reinforcement cage is placed downwards, and concrete is poured to form a wall body. By adoption of the construction method, firstly, mud between the joints of the wall bodies is removed, so that the connection firmness between the wall bodies are improved, and the quality problems such as gaps and water seepage between the wall bodies caused by mud between the wall bodies can be effectively solved; secondly, sediment at the bottoms of the holes is mechanically removed, so that the work efficiency is high, sediment is completely removed, the effect is good, and a traditional floating removal method is changed; and thirdly, hole formation based on flushing and digging is practical under complex geological conditions such as a sandy gravel condition and a backfill miscellaneous stone condition, grooves can be formed in rocks, and thus, the construction quality requirement is met.

Owner:连云港市云达建设工程有限公司

A kind of filling material and its construction method for the expansion joints of the concrete face of the rockfill dam

ActiveCN107043545BIncrease elasticityImprove adhesionMarine site engineeringBuilding insulationsKeroseneArchitectural engineering

The invention relates to the technical field of hydraulic construction and particularly relates to a packing material for an expansion joint of a concrete facing rockfill dam and a construction method of the packing material. The packing material is prepared from the following components in parts by weight: 100 parts of petroleum asphalt, 50-60 parts of kerosene, 70-80 parts of asbestos mud and 45-50 parts of rubber powder. The packing material has the advantages of being available in materials and wide in application range, has good elasticity, cohesiveness and plasticity, and is capable of uniformly bestrewing the whole concrete surface; and the material has good adhesive force and can meet the construction quality requirements of a vertical construction joint.

Owner:ZHEJIANG PROVINCIAL NO 1 WATER CONSERVANCY & ELECTRIC POWER CONSTR GRP HLDG

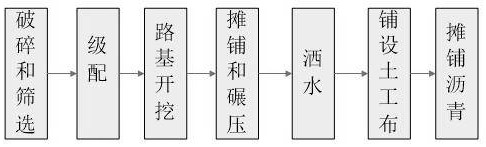

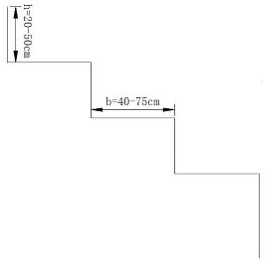

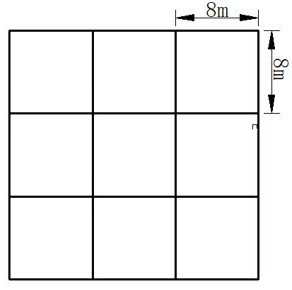

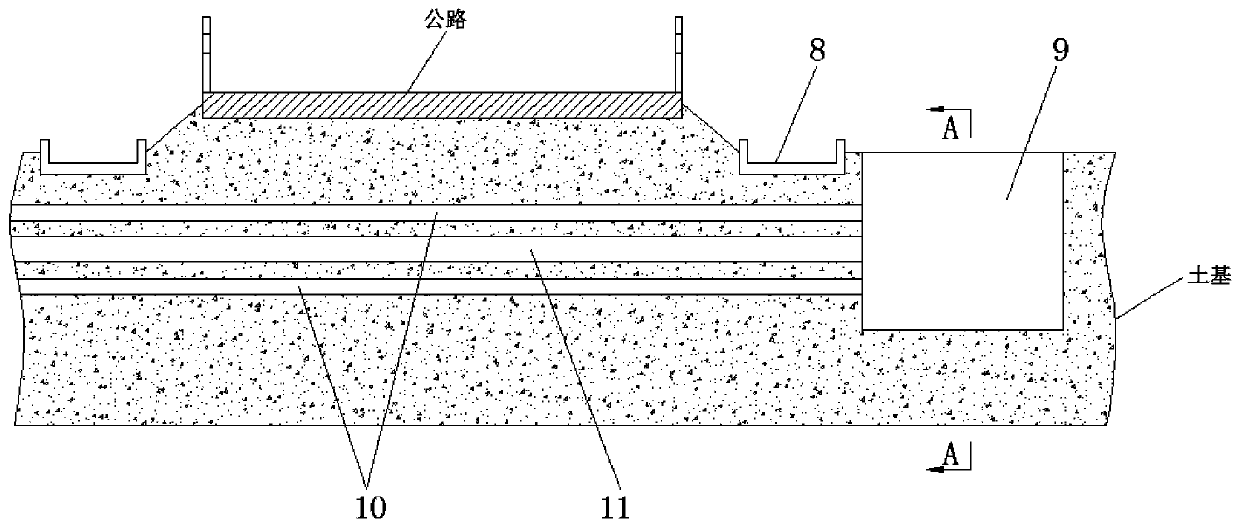

Application process of construction waste roadbed filling aggregate

PendingCN113818299AAvoid pollutionReduce investmentIn situ pavingsSolid waste managementSocial benefitsArchitectural engineering

The invention discloses an application process of construction waste roadbed filling aggregate. The application process comprises the following steps: step 1, selecting raw materials; step 2, preparing a roadbed filling material; step 3, excavating a roadbed;step 4, paving and rolling the roadbed; step 5, laying steel-plastic grating; step 6, performing watering; and step 7, pouring asphalt. The construction waste filling aggregate is used for filling the roadbed, the application problem of the construction waste in roadbed engineering is solved, the utilization rate of the construction waste is increased, a reliable choice is provided for roadbed filling materials and methods, and huge economic benefits and social benefits are brought.

Owner:SHANDONG UNIV OF SCI & TECH +2

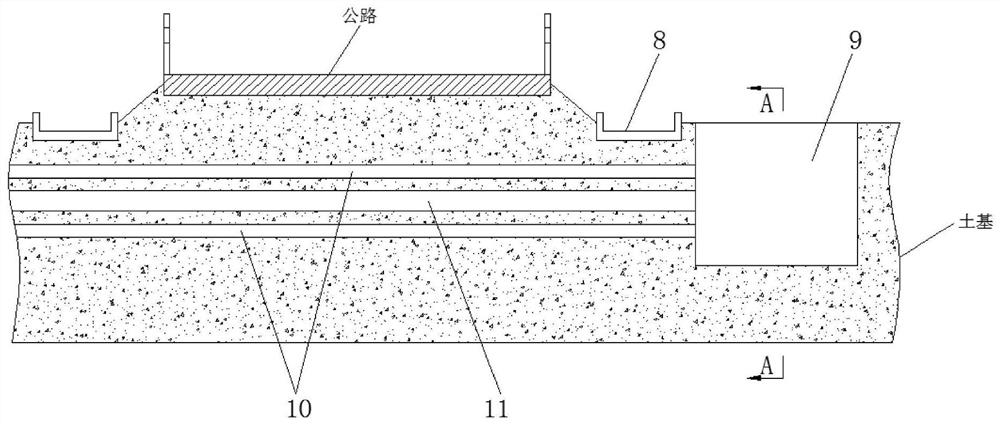

Drilling method of earth below highway ditches

ActiveCN109797733AImprove molding qualityFreezing stabilityRoadwaysSoil preservationCement groutHighway drainage

The invention discloses a drilling method of earth below highway ditches and relates to the technical field of highway drainage engineering. The drilling method herein comprises the steps of digging afoundation pit on one side of a ditch, drilling a plurality of circularly arrayed and evenly distributed reinforcing holes in the lateral side of the foundation pit in the foundation pit through guide piers and a drilling apparatus in a sequence of from top to bottom, after the reinforcing holes of same height are made, draining the reinforcing holes until the water level drops below the reinforcing holes, grouting the reinforcing holes, after cement grout in the reinforcing holes sets, removing earth bases at the bottom of the guide piers until the heights of the guide piers decrease to a suitable level, drilling reinforcing holes of next height through the guide piers, repeatedly the operation above to drain and grout the reinforcing holes of the height, and after the cement grout in the reinforcing holes of the smallest height sets, and drilling a drain hole in the center of a circular array formed by the reinforcing holes. The drilling method herein has the advantages that construction is reasonable and the drain holes can prevent pavement sinking.

Owner:CHINA MCC5 GROUP CORP +1

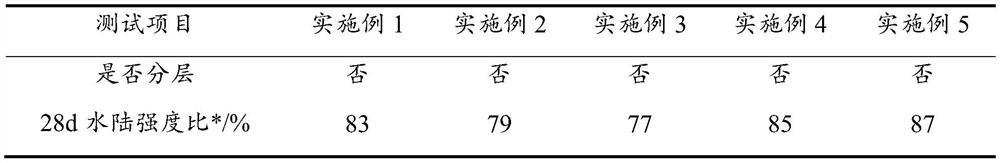

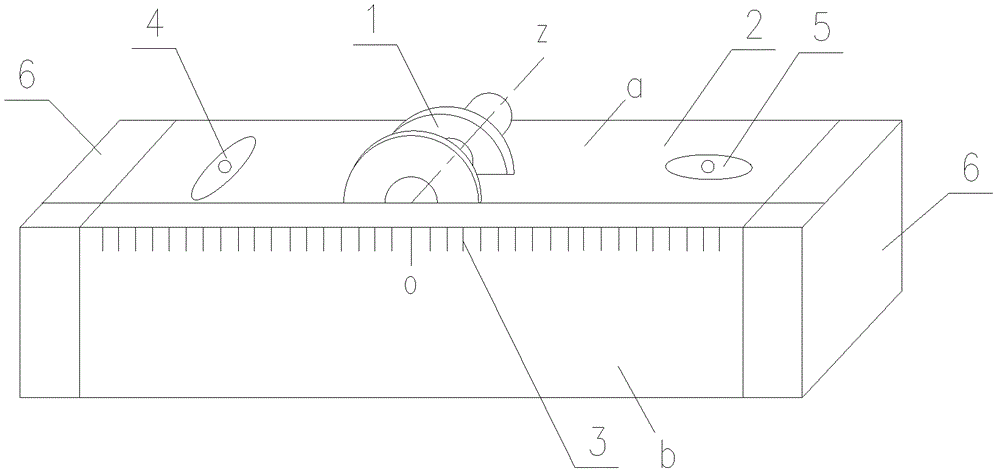

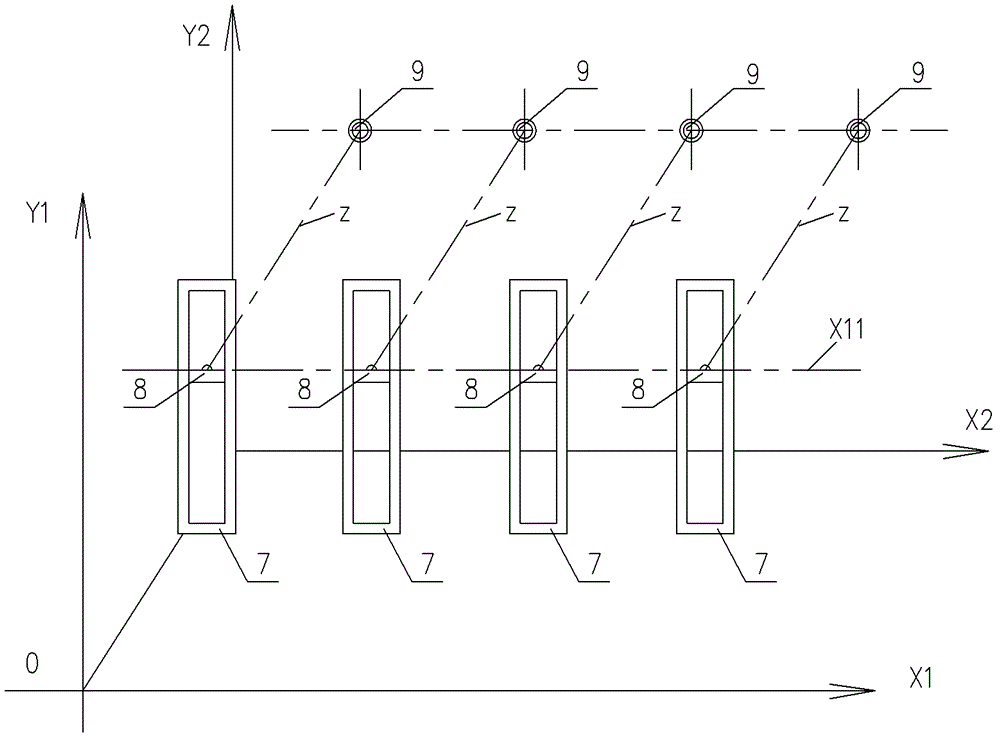

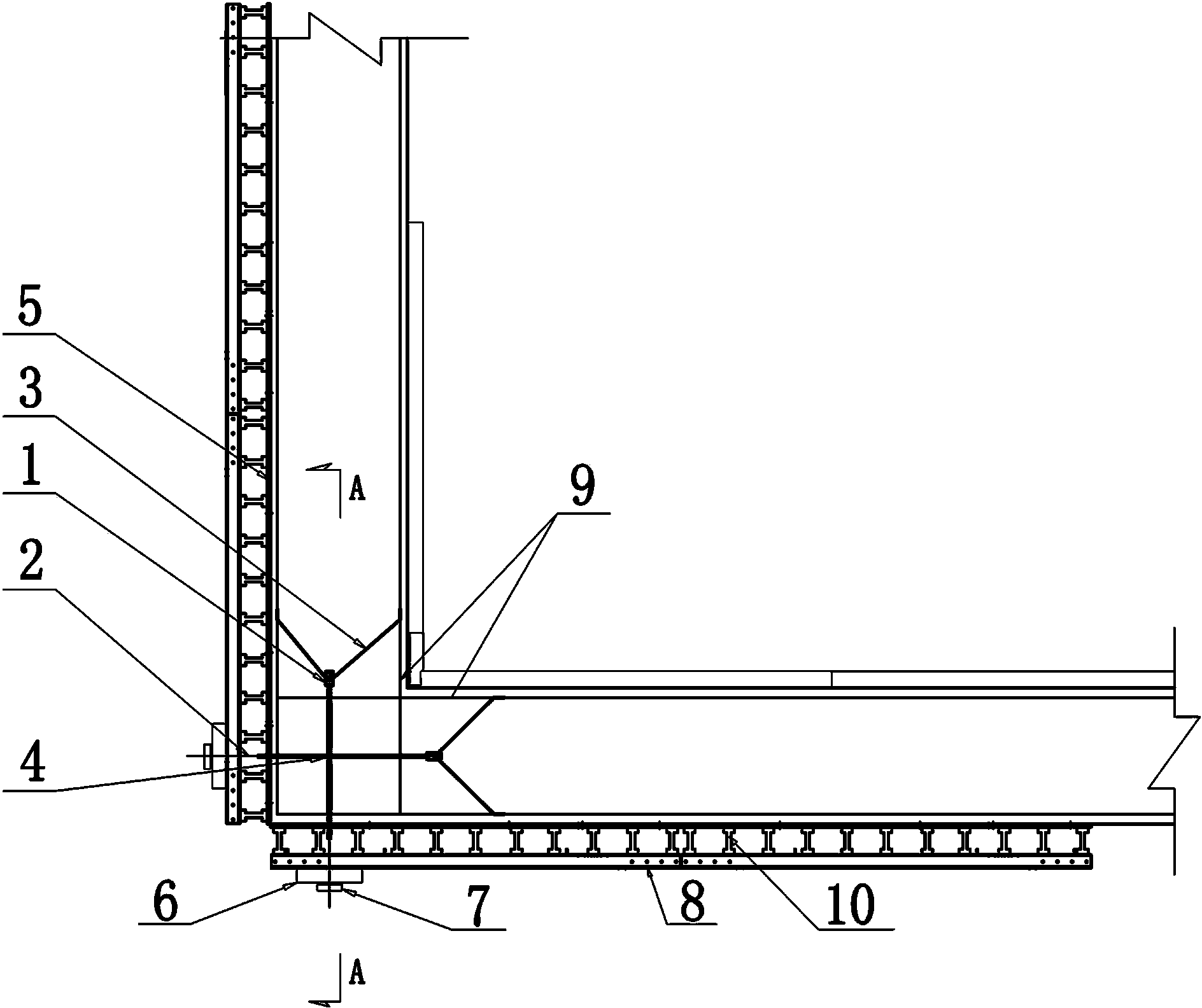

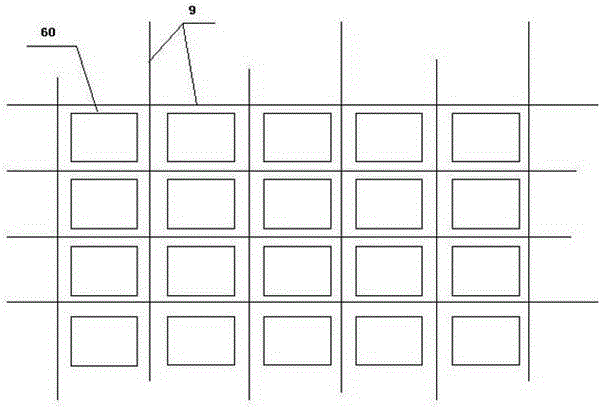

Point location installation method for foot support of thermal radiation tube

ActiveCN103090857BReduce measurement and calculation workloadImprove positioning accuracySurveying instrumentsRectangular coordinatesContinuous annealing

The invention relates to the field of industrial installation technology of vertical type continuous annealing furnace, and particularly relates to a point location installation method for a foot support of a thermal radiation tube. The point location installation method is characterized by comprising the following operational steps of 1) determining a pay-off height datum line X11 on installation reference rectangular windows; 2) center-placing a combined laser pay-off instrument on a flange of each rectangular window horizontally, forming a central cross projection point since laser beams Z projects on wall board planes in a furnace shell; 3) welding a temporary positioning elevation angle iron; 4) repeating the steps of 2) and 3), and thus the installation positioning centers of all the foot supports of the thermal radiation tube can be positioned. Compared with a conventional method, the point location installation method has the beneficial effects that the step of establishing a three-dimensional rectangular coordinate system for coordinate central points of a structure installation part so as to measure and mark is omitted, the position can be fixed at one time directly and quickly, measurement calculation workload can be reduced, positioning accuracy is high and meets the requirement of construction quality, the qualified rate of installation reaches 100%, and construction efficiency is increased by three times.

Owner:ANGANG CONSTR CONSORTIUM

Steel component concrete encasement construction technique

InactiveCN101343912BEasy to shapeMeet construction quality requirementsStrutsPillarsSteel barMaterials science

Owner:HEBEI CONSTR GRP

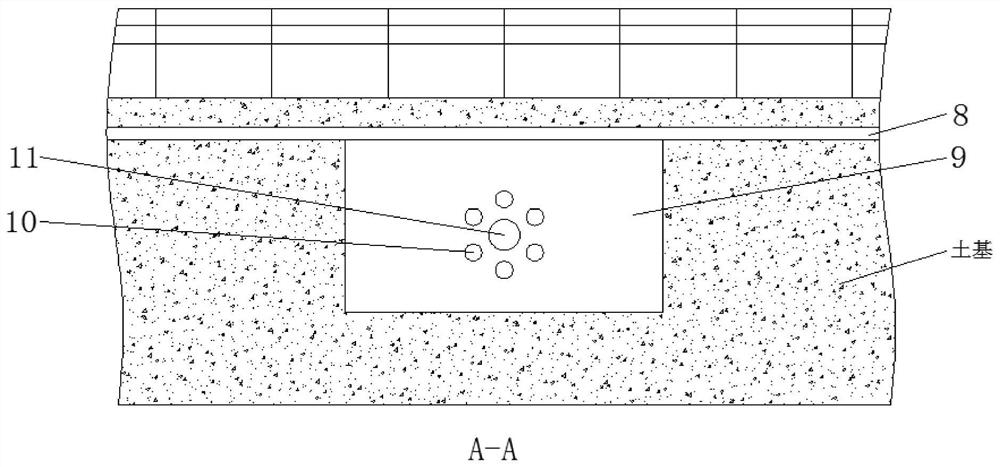

Method for positioning template corner

ActiveCN102383411BMeet the needs of pulling reinforcementMeet construction quality requirementsInclined ship-liftingForms/shuttering/falseworksEngineeringRebar

A framework corner positioning device comprises a framework (5). Wailings (8, 10) are disposed outside the framework (5). A brace screw (2) is mounted at a corner of the framework (5). One end of the brace screw (2) is connected to the framework (5) through a gasket (6) and a nut (7), and the other end of the brace screw (2) is connected to a weldable sleeve (1) through threads. The weldable sleeve (1) is connected to rebar (9) through a brace (3) in a welding manner. A casing pipe (4) is disposed outside the brace screw (2). One end of the casing pipe (4) penetrates out of the framework (5), and the other end of the casing pipe (4) is close to the weldable sleeve (1). The brace (3) is made of common rebar, and the brace screw (2) is made of manganese steel with high strength. The weldable sleeve (1) is welded to the brace (3), and the weldable sleeve (1) is also connected to the brace screw (2), thereby satisfying the requirement for counter bracing reinforcement of the framework and the brace at the corner, and being applicable to various kinds of framework reinforcement construction in the case that the framework using the brace at the corner fails to achieve counter bracing.

Owner:GEZHOUBA XINJIANG ENG

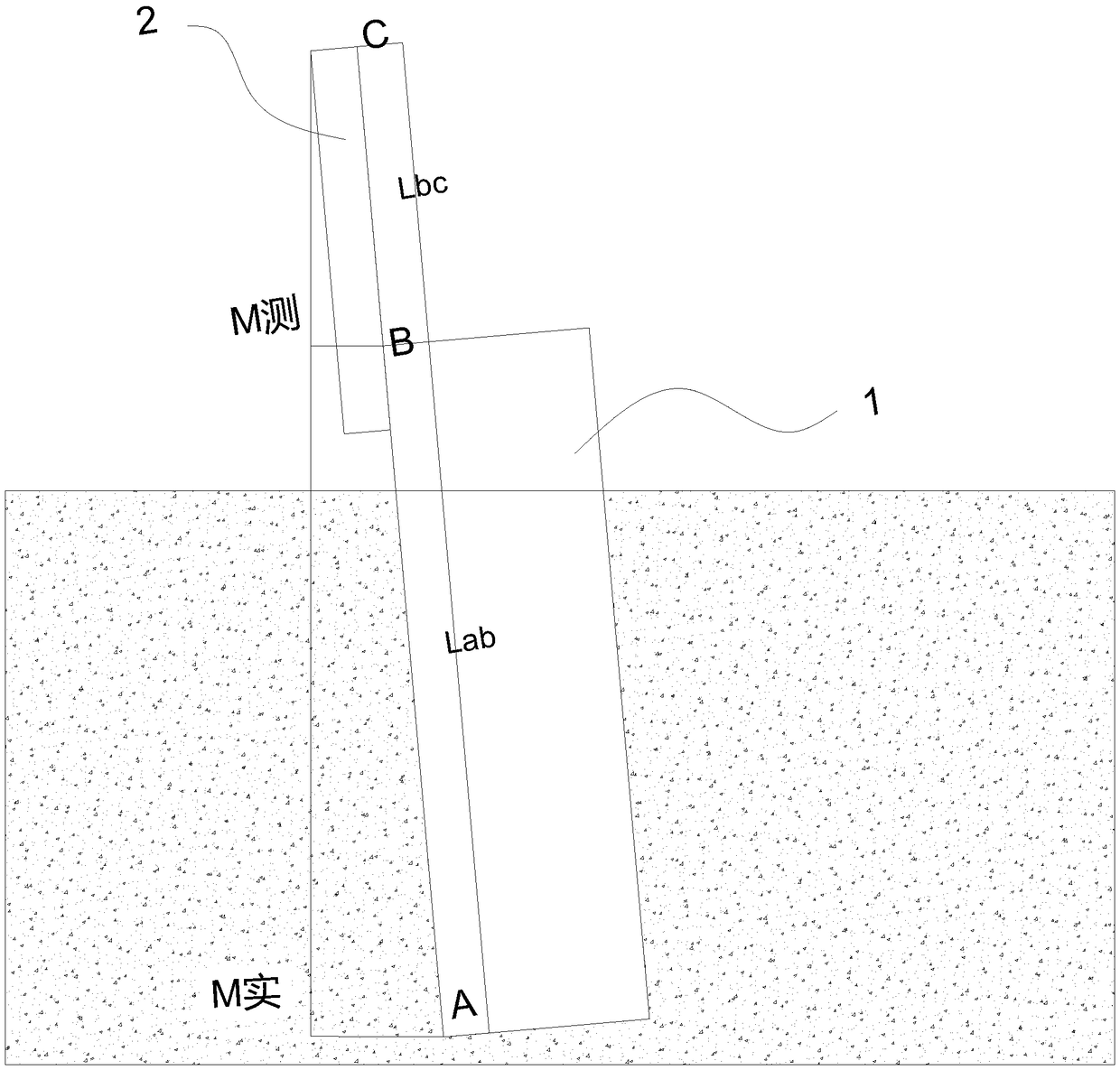

Verticality control method in construction process of lattice column

InactiveCN109025328AEasy to findMeet construction quality requirementsBuilding material handlingArchitectural engineeringUltimate tensile strength

The invention discloses a verticality control method in the construction process of a lattice column, and belongs to the technical field of building construction. The method is to set a verticality detecting steel plate for welding on a lattice column, detect the verticality of the verticality detecting steel plate at any time during the construction process, and obtain the verticality deviation of the lattice column by proportional conversion. The construction is simple and convenient, the construction progress can be effectively guaranteed, and the lattice column can be corrected at any timefor the found verticality deviation. In this way, the construction quality requirements of the column pile are met, the labor and other comprehensive costs are reduced, the labor intensity of construction workers are lowered, the labor productivity is improved, and the practicality is high.

Owner:CHINA MCC17 GRP

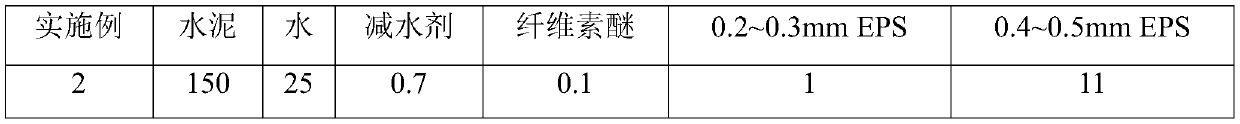

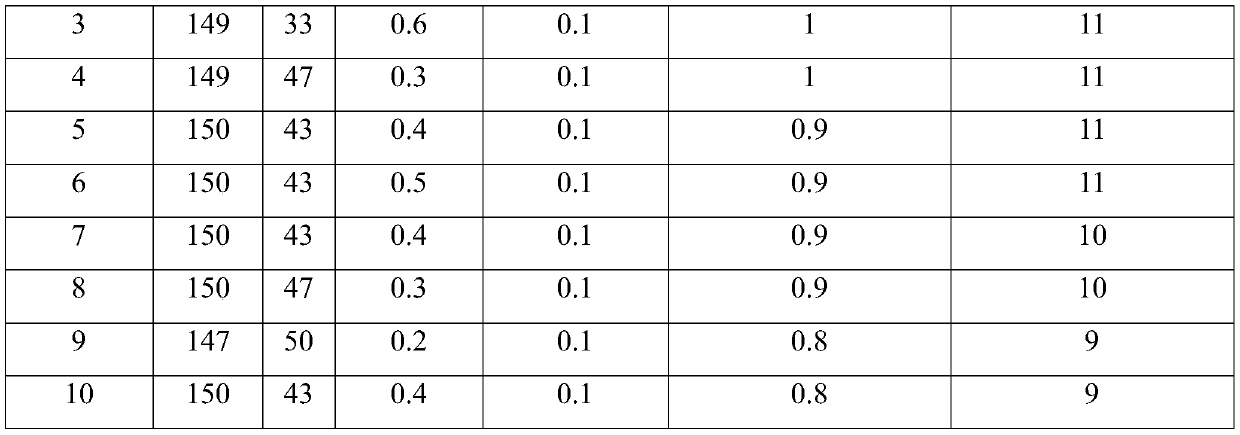

A kind of interface reinforced lightweight concrete and its preparation method

The invention relates to the field of light concrete materials and in particular to interface reinforced light concrete. The interface reinforced light concrete is prepared from the following raw materials in parts by weight: 147-150 parts of cement, 25-50 parts of water, 0.2-0.7 part of a water reducer, 0.1-0.7 part of cellulose ether and 6-12 parts of organosilicone emulsion coupled and modified expandable polystyrene (modified EPS). According to the interface reinforced light concrete provided by the invention, by adding the granularly graded modified EPS, the filling arte of the modified EPS and the specific surface area of the modified EPS granules in a cement matrix can be increased. The adhesive strength of the coupled EPS and the cement slurry is improved, so that the weight of the concrete is greatly alleviated and the two are tightly combined; the cellulose ether is added, so that the slurry viscosity is increased; the EPS granules are unlikely to float upward and are more uniformly distributed.

Owner:WUHAN UNIV OF TECH

A construction method for drilling holes in earthwork below highway drainage ditches

ActiveCN109797733BPrevent subsidenceImprove protectionRoadwaysSoil preservationCement groutRoad surface

The invention discloses a drilling method of earth below highway ditches and relates to the technical field of highway drainage engineering. The drilling method herein comprises the steps of digging afoundation pit on one side of a ditch, drilling a plurality of circularly arrayed and evenly distributed reinforcing holes in the lateral side of the foundation pit in the foundation pit through guide piers and a drilling apparatus in a sequence of from top to bottom, after the reinforcing holes of same height are made, draining the reinforcing holes until the water level drops below the reinforcing holes, grouting the reinforcing holes, after cement grout in the reinforcing holes sets, removing earth bases at the bottom of the guide piers until the heights of the guide piers decrease to a suitable level, drilling reinforcing holes of next height through the guide piers, repeatedly the operation above to drain and grout the reinforcing holes of the height, and after the cement grout in the reinforcing holes of the smallest height sets, and drilling a drain hole in the center of a circular array formed by the reinforcing holes. The drilling method herein has the advantages that construction is reasonable and the drain holes can prevent pavement sinking.

Owner:CHINA MCC5 GROUP CORP +1

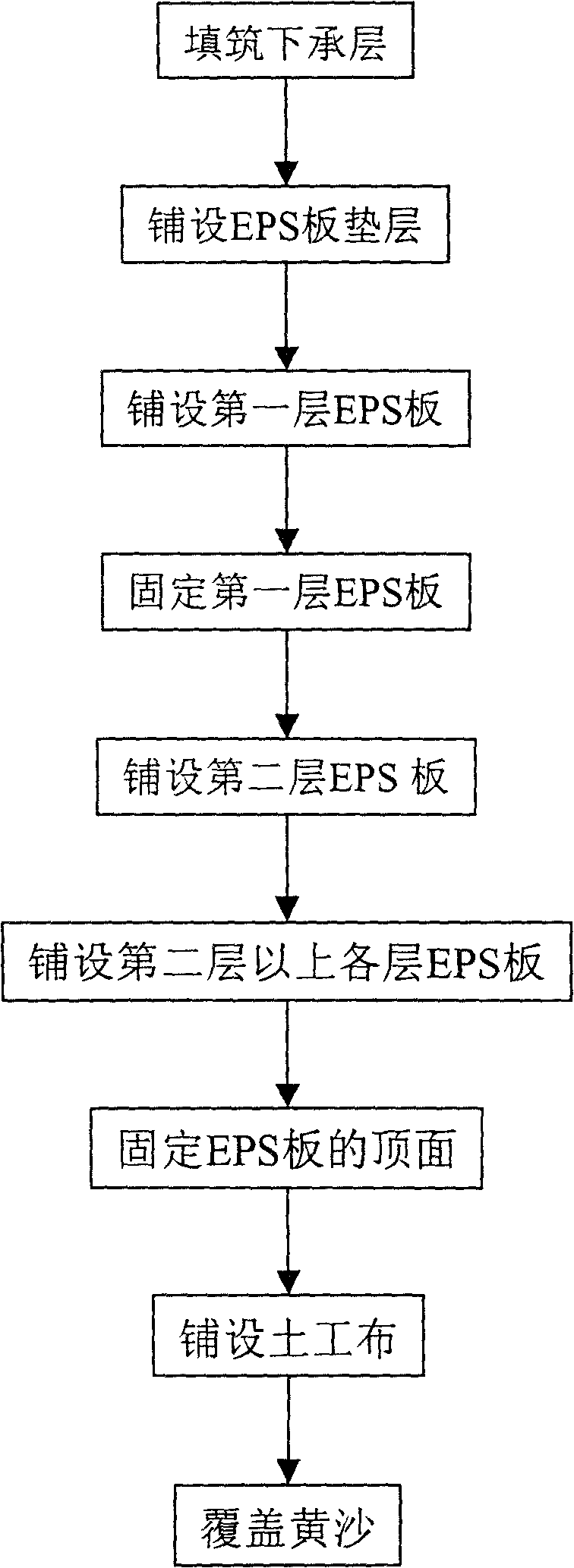

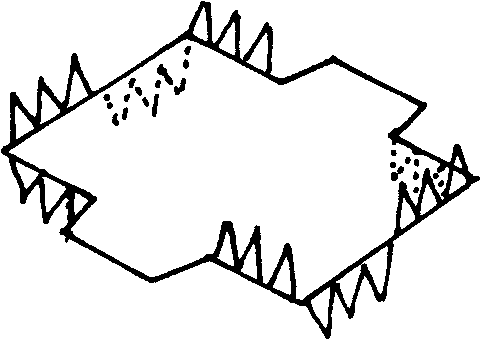

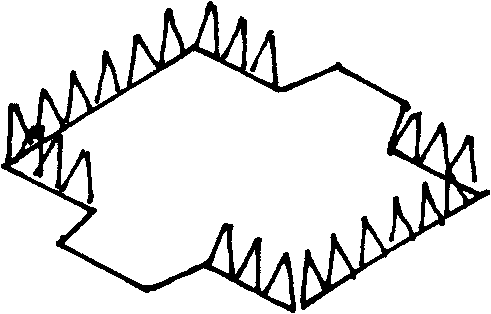

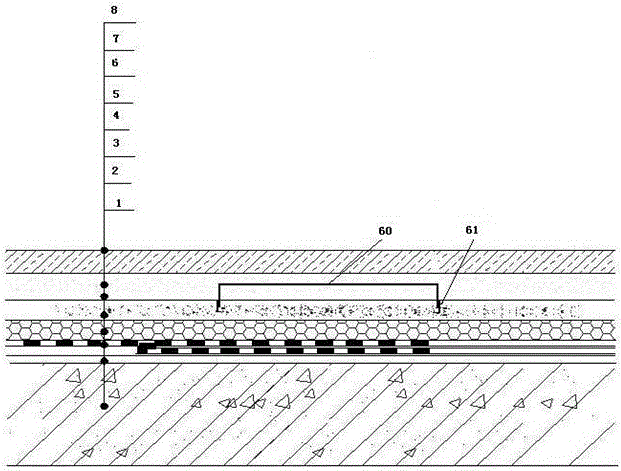

Method for landfilling roadbed in high earth fill on groundwork of soft soil

The present invention provides a high-fill roadbed reclamation method on soft soil foundation. Said method uses polystyrene foam plate as main filling material and includes the following steps: reclaiming lower bearing layer, laying polystyrene foam plate bedding layer, laying first layer of polystyrene foam plate, laying second layer of polystyrene foam plate, laying other layers of polystyrene foam plate on the second layer, fixing top surface of polystyrene foam plate, laying geotextile and covering the geotextile with yellow sand.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

Construction method of fast pavement in place with thick and heavy stones

ActiveCN103031793BSimple structureEasy to manufactureSingle unit pavingsRoads maintainenceRebarBuilding construction

Owner:GUANGZHOU NO 1 CONSTR ENG +2

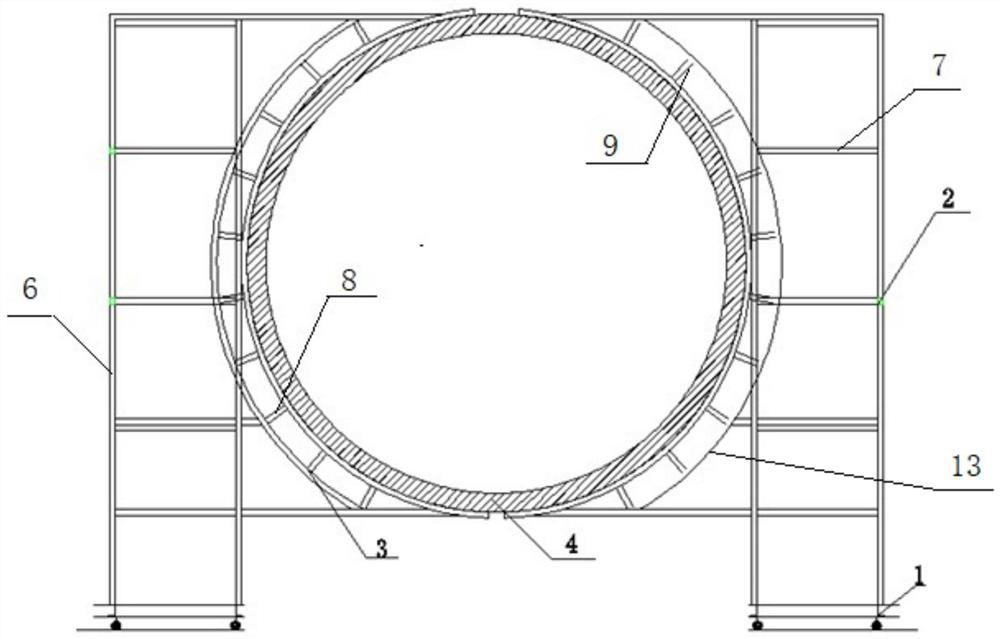

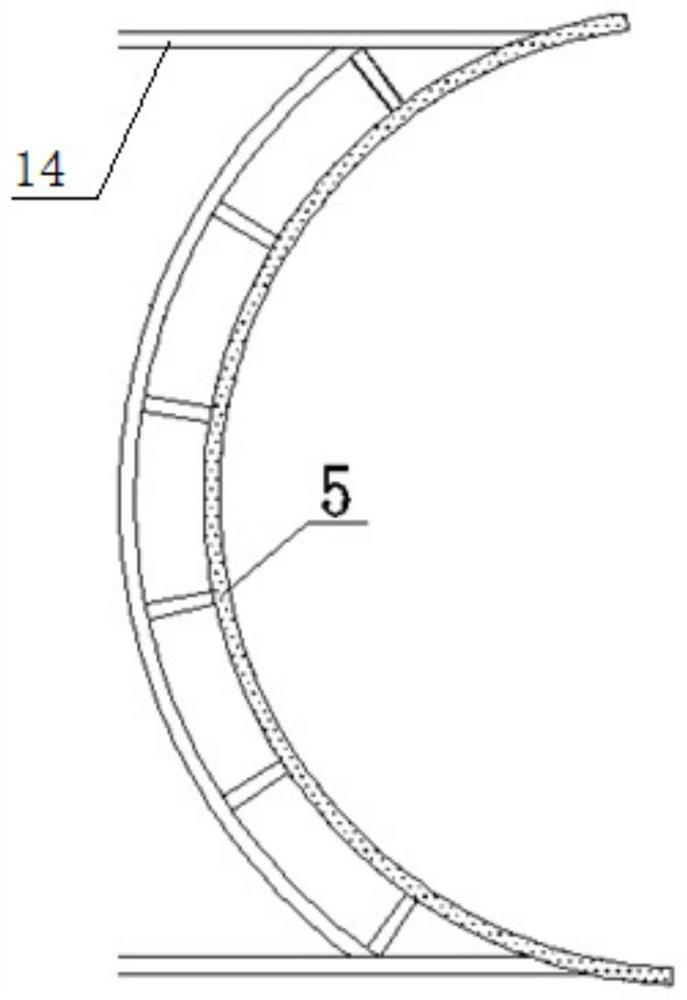

Auxiliary device for preheating and heat preservation of weld joint of pressure steel pipe and construction method

PendingCN113263283AGuarantee the efficiency of welding constructionReduce manufacturing costWelding/cutting auxillary devicesAuxillary welding devicesButt jointPipe

The invention discloses an auxiliary device for preheating and heat preservation of a weld joint of a pressure steel pipe and a construction method. The auxiliary device comprises a first stand column, a second stand column, a first semicircular bracket and a second semicircular bracket, the first semicircular bracket is fixed in the height direction of the first stand column, and the second semicircular bracket is fixed in the height direction of the second stand column; semicircular heating plates are arranged on the inner arc wall surface of the first semicircular bracket and the inner arc wall surface of the second semicircular bracket, supporting devices are arranged at the bottoms of the first stand column and the second stand column, and the supporting devices are supported on the ground; and when the weld joint of the pressure steel pipe is preheated or insulated, the two ends of the first semicircular bracket and the two ends of the second semicircular bracket are in one-to-one butt joint, and the semicircular heating plate of the first semicircular bracket and the semicircular heating plate of the second semicircular bracket wrap a pipe body of the pressure steel pipe. The safety and stability of heating operation are improved.

Owner:中国葛洲坝集团第三工程有限公司

Pre-sulfurizing rubber lining and its production

The invention is concerned with a kind of advance vulcanization rubber liner and its produce method. Extrude the rubber piece using for liner through the extruding machine and spread adhesive on the surface of rubber piece and dry. Carry the vulcanization disposal to the rubber piece with vulcanization machine to get the advance vulcanization rubber liner. Stick this rubber liner on surface of metal or pipe directly without using existing method to dispose the liner. It leaves out the vulcanization equipment on locale, reduces the cost and solves the difficult disposal of vulcanization on locale to keep the quality. It also increases the work efficiency by predigesting process and cutting work time limit. The most importance thing is adjusting the vulcanization disposal process to rubber liner and keeps the quality of advance vulcanization rubber liner to fit for the demand of construct.

Owner:云南阿斯泰克科工贸有限公司

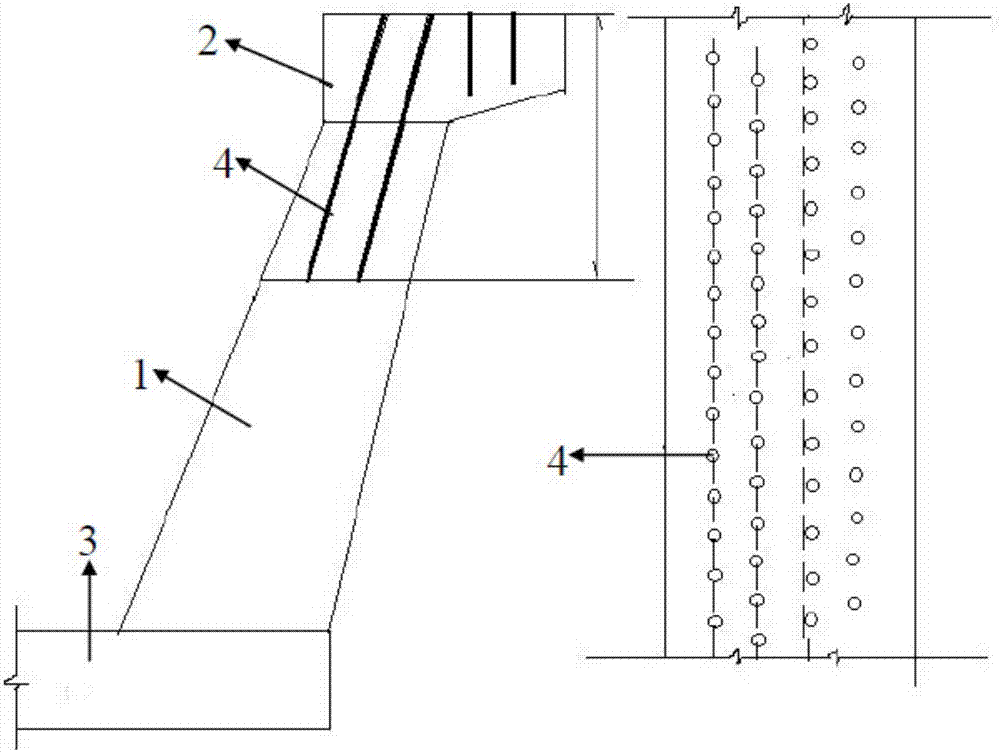

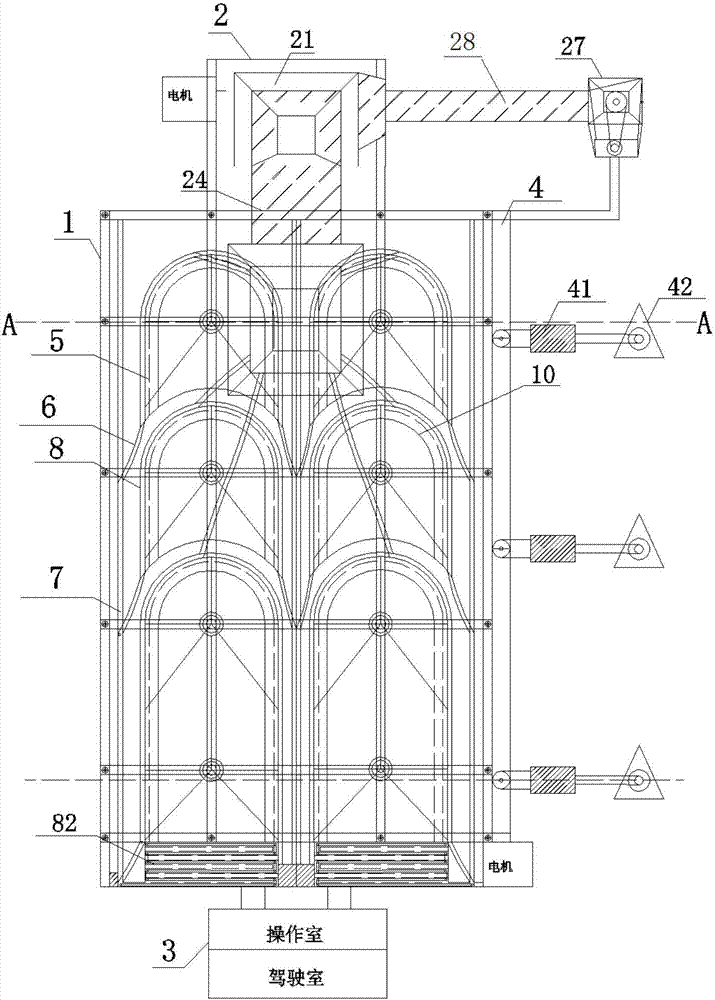

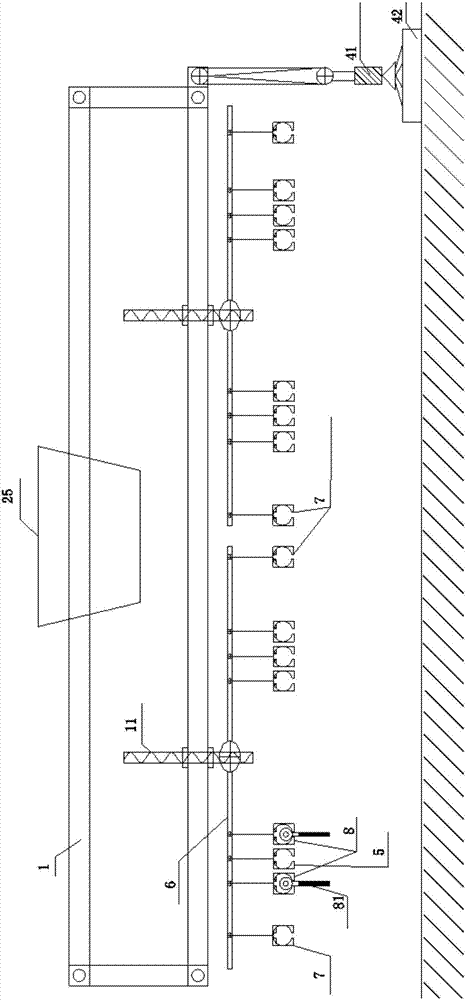

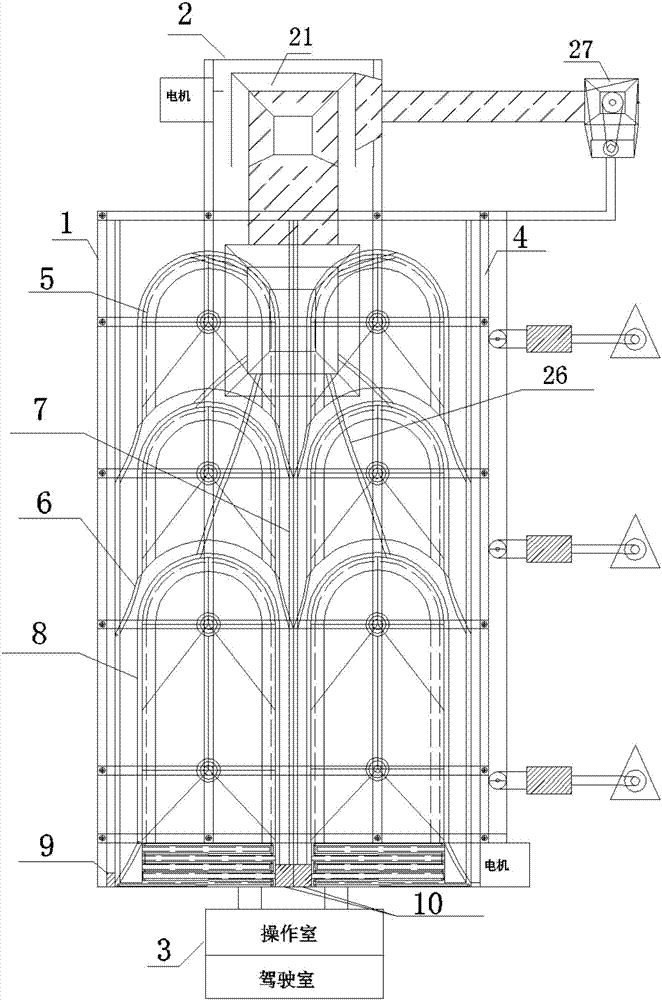

An integrated device for slope concrete protection

ActiveCN106193069BAchieve the effect of one-time pouring and moldingReach reviewExcavationsControl systemDistribution system

The invention discloses integrated equipment for side slope concrete protection. The integrated equipment is composed of a main framework system, an operation room, a power system, a walking system, an excavation system, a formwork system, a concrete distribution system, a vibrating (flattening and finishing) system, a curing system, a monitoring system, a hydraulic system and an automated control system. Trench excavation, framework mounting and checking, concrete pouring and forming including material distribution, vibrating, flattening, finishing, grinding and leveling and framework disassembly of slide slope concrete protection can be integrally conducted, and subgrade side slope concrete protection and pouring and forming can be achieved at a time; and the structure is simple, operation is safe and reliable, construction is convenient, production efficiency is improved, the construction cost is lowered, and the quality requirements of concrete construction are met effectively.

Owner:SINOHYDRO BUREAU 5

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com