Preparation method of colored pervious concrete ground

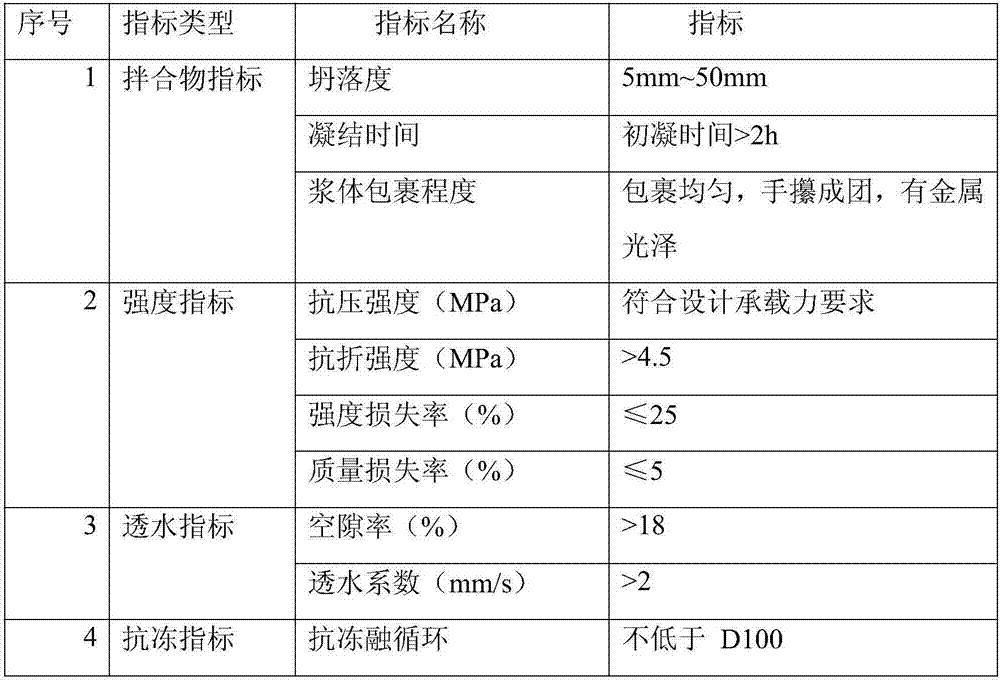

A technology of permeable concrete and permeable geotextile, which is applied to the coagulation pavement, pavement details, roads and other directions of on-site paving, can solve problems such as uninvolved safety, and achieve the effect of easy-to-use method, good effect and simple construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

[0031] The application provides a method for preparing a colored permeable concrete floor, comprising the following steps:

[0032] 1) Plain soil is compacted to obtain a plain soil compaction layer;

[0033] 2) laying graded crushed stones on the plain soil compacted layer obtained in said step 1), to obtain a graded crushed stone layer;

[0034] 3) Laying a permeable geotextile on the graded crushed stone layer prepared in the step 2) to obtain a permeable geotextile layer;

[0035] 4) laying C25 permeable concrete on the permeable geotextile layer prepared in the step 3) to obtain a permeable concrete base;

[0036] 5) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Seam width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com