Method for landfilling roadbed in high earth fill on groundwork of soft soil

A soft soil foundation, high fill technology, applied in fill, roads, roads and other directions, can solve the problems of not perfecting EPS road control standards and specification requirements, and not perfecting methods, etc., to achieve strong thermal insulation and light density. , the effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

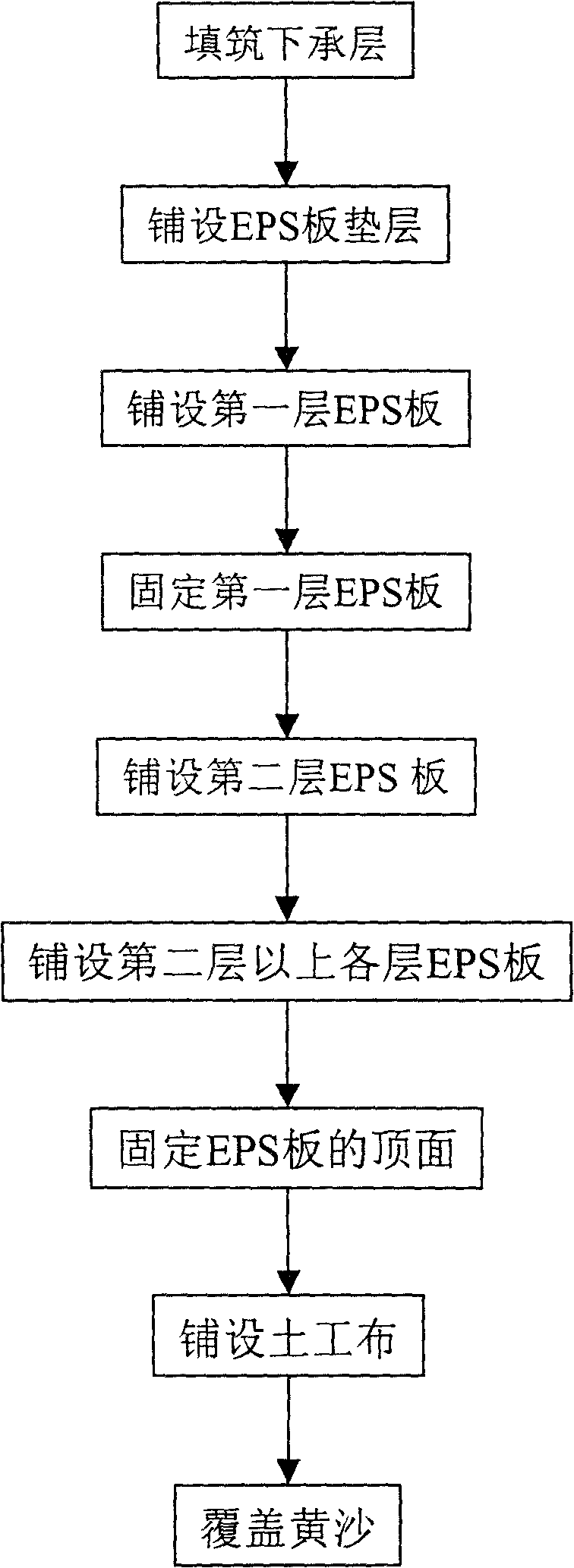

[0035] The filling method of the high filling subgrade on the soft soil foundation of the present invention can be combined figure 1 Further explanation is as follows:

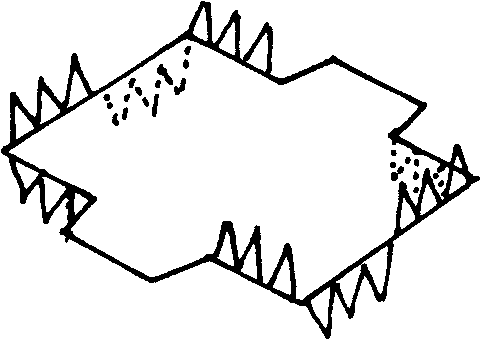

[0036] First, reinforce the foundation with square piles, and lay a 25cm thick lower gravel drainage layer, a 30cm thick lime soil layer, a 25cm thick upper gravel drainage layer, and a 100cm thick fly ash layer from bottom to top. Bearing layer. After the acceptance is passed, a blind ditch will be excavated every 10m on the underlying layer. Each blind ditch is 30cm wide and 30cm deep. Fill the blind ditch with gravel wrapped with geotextile to facilitate drainage during the construction period. Then set out the construction control line of the first layer of polystyrene foam board. According to the design drawings, use a total station to accurately place the vertices of the inner and outer edge lines of the polystyrene foam board, and set every ten columns on the line connecting the vertices of the inner and o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com