Verticality control method in construction process of lattice column

A control method and verticality technology, applied in building construction, construction, building material processing and other directions, can solve the problems of failing to meet construction requirements, affecting construction quality, and high verticality deviation requirements, and meeting construction quality requirements, Improve labor productivity and ensure the effect of construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

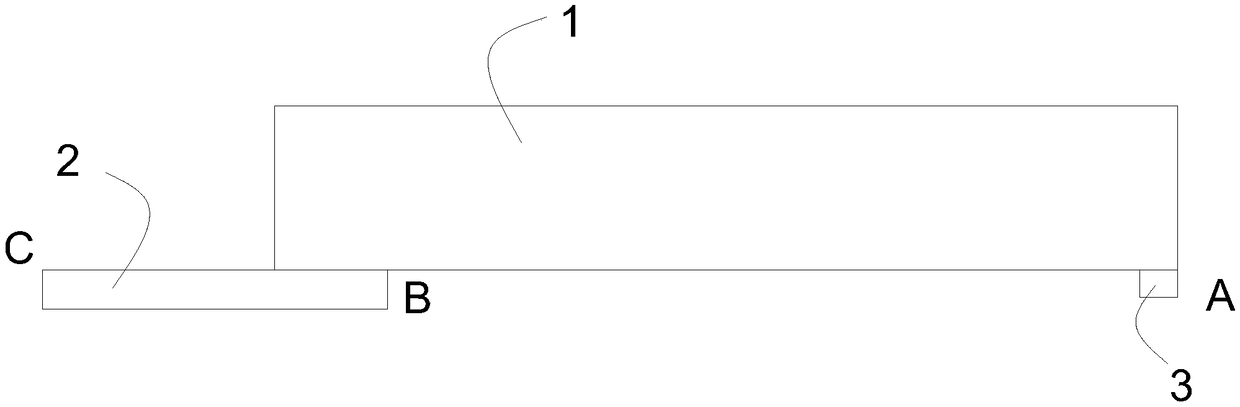

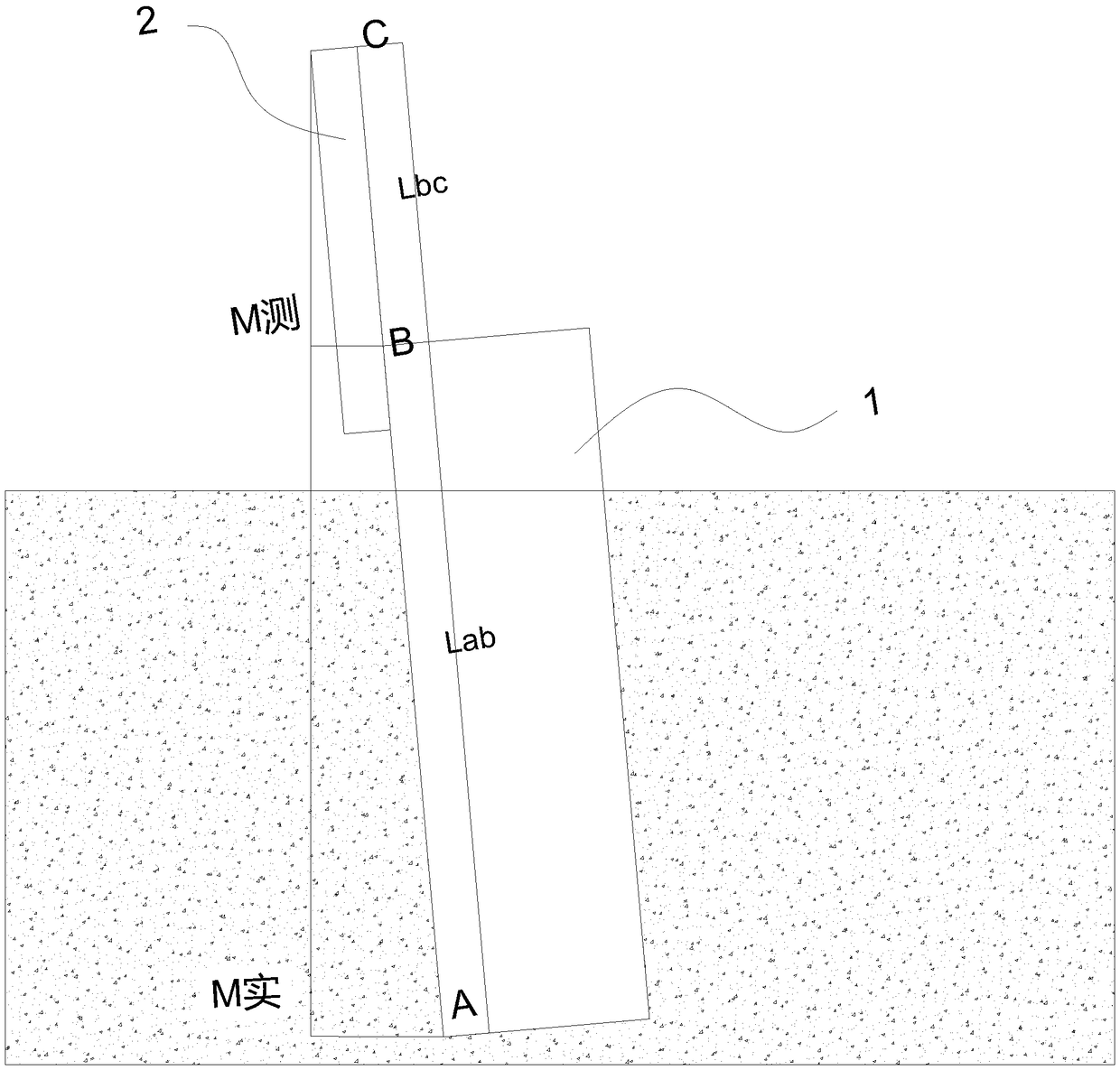

[0019] Such as figure 1 and figure 2 As shown in the present invention, a verticality control method in the construction process of a lattice column, the bottom end of the lattice column 1 is provided with a column foot positioning ear plate 3, and the method includes the following steps:

[0020] Step 1. Weld the verticality detection steel plate 2 on the upper part of the lattice column 1, set the position of the positioning lug 3 of the column foot as point A, the top of the lattice column 1 as point B, and the top of the verticality detection steel plate 2 as point C, The length between point A and point B is Lab, the length between point B and point C is Lbc, and M is measured as the verticality deviation measured from point B to point C on the verticality detection steel plate 2, and M is actually lattice The actual verticality deviation of column 1;

[0021] Step 2, construct the welded integral lattice column 1 and the verticality detection steel plate 2, and measur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com