Roadbed filling construction method

A construction method and subgrade filling technology, applied in the directions of roads, roads, buildings, etc., can solve the problems of low construction efficiency and high construction cost, and achieve the effect of solving high construction cost, shortening construction period and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manners of the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

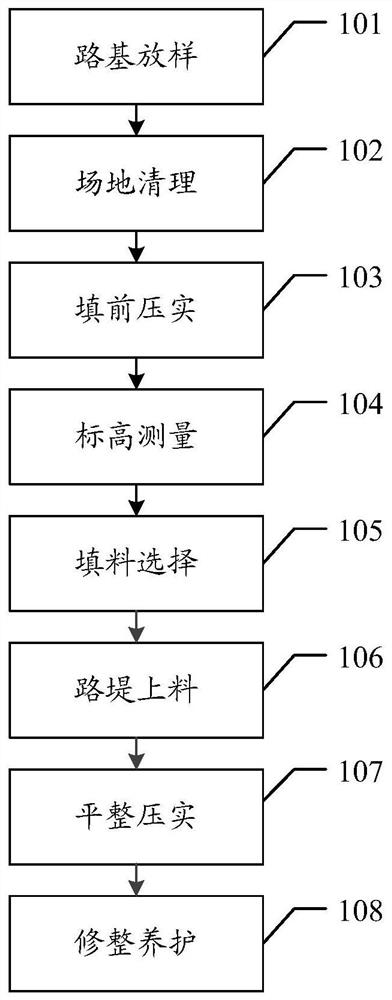

[0039] refer to figure 1 , figure 1 It is a schematic flow chart of an embodiment of the roadbed filling construction method of the present invention, and the method comprises the following steps:

[0040] 101. Subgrade stakeout: carry out the stakeout process on the gravel road section of the roadbed side piles and side slopes, and obtain the staked out subgrade;

[0041] According to the designed subgrade center coordinate value and the polar coordinate method, stake out the pile center point on the ground of the gravel road section to obtain the subgrade center pile point. According to the slope ratio, subgrade width and c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com