Point location installation method for foot support of thermal radiation tube

A technology of a heat radiation tube and an installation method, which is applied to measurement devices, instruments, surveying and mapping, and navigation, etc., can solve problems such as large measurement workload, achieve high positioning accuracy, improve construction efficiency, and reduce measurement and calculation workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

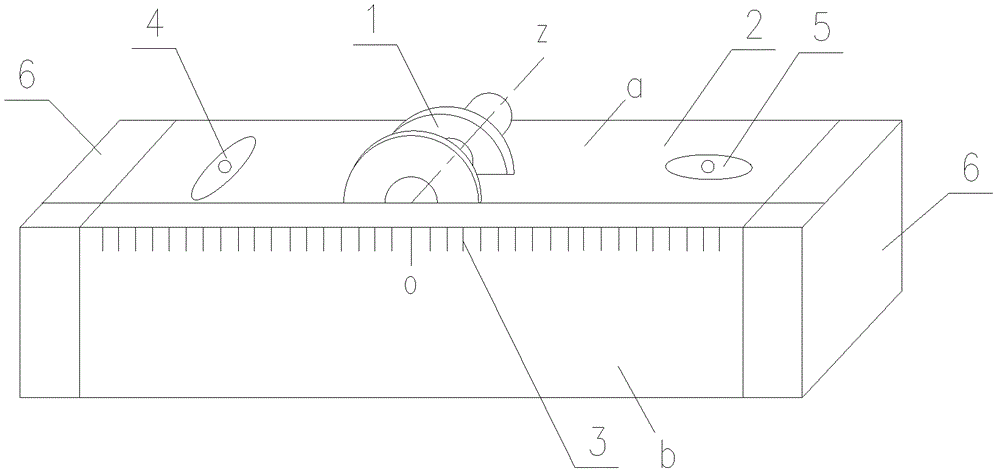

[0018] See figure 1 , is a structural schematic diagram of an embodiment of a combined laser unloading instrument of the present invention, including a laser emitting head 1, a horizontal bubble 4, a horizontal bubble 2 5 and a square bracket 2, the laser beam emitting axis z of the laser emitting head 1 and the square bracket The central position of the scale scale 3 of the frame 2 corresponds to and is parallel to the upper plane a of the square bracket 2, and perpendicular to the front side b of the square bracket 2. The upper plane a of the square bracket 2 is also provided with a horizontal bubble 4 and a horizontal bubble 2 5 , the length direction of horizontal bubble 1 4 is parallel to the width direction of plane a on the square bracket 2, the length direction of horizontal bubble 2 5 is parallel to the length direction of plane a on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com