Device and method for preventing welding deformation of pipelines in nuclear power plant

A welding deformation, nuclear power plant technology, applied in auxiliary devices, welding equipment, welding equipment and other directions, can solve the problems of inability to meet the construction quality, schedule and cost requirements of nuclear power plants, high maintenance costs, poor engineering quality, etc. Structure, low construction cost, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

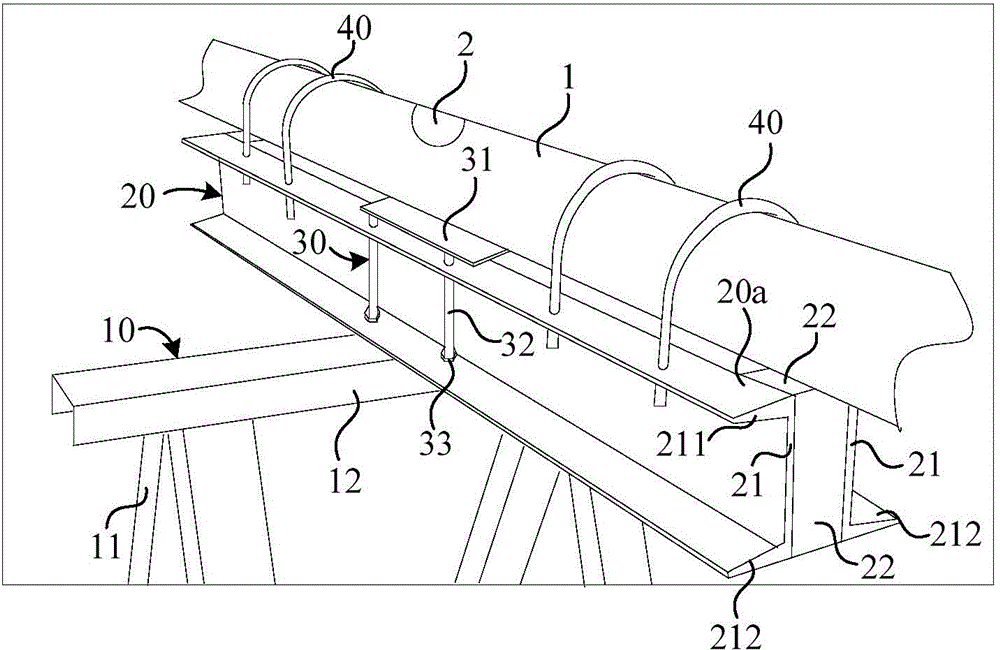

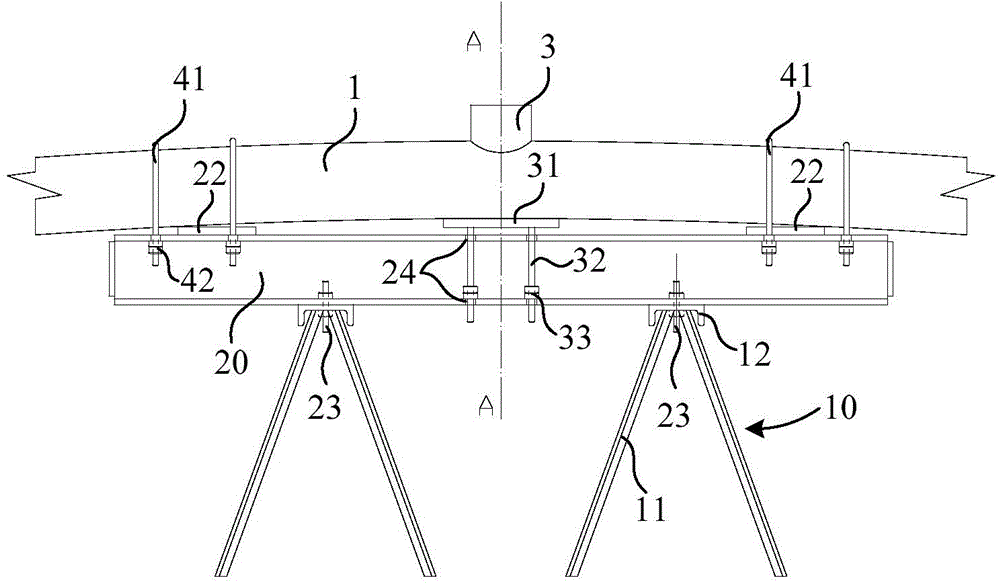

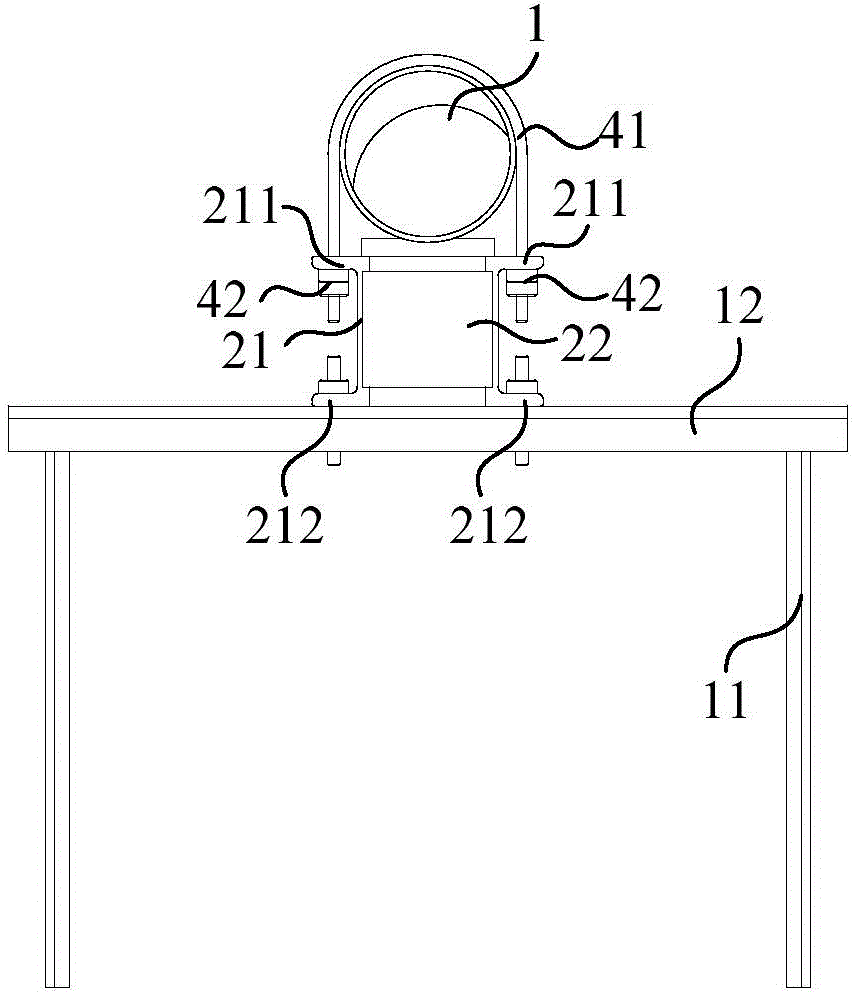

[0031] In order to solve the problem that the pipes of nuclear power plants in the prior art are prone to welding deformation when welding the sockets, the method of manually or mechanically correcting the deformation of the pipes has low efficiency, high maintenance costs, and poor engineering quality, which cannot meet the requirements for the construction quality, schedule and cost of nuclear power plants. The technical problem required, the main technical solution adopted by the present invention is: adopt a device to prevent the welding deformation of the nuclear power plant pipeline, and perform pretreatment on the pipeline before welding the connecting seat to the pipeline. The jacking mechanism that takes over the position of the seat hole enables the jacking mechanism to apply an external force equal to the welding stress and opposite in direction to the pipeline, so that the pipeline produces a pre-deformation with the same amplitude and size as the welding deformation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com