Construction process for lifting leg pile of offshore living platform

A living and platform technology, applied in the field of leg pile construction, can solve the problems of lack of rack and plate welding process steps, poor leg support and stability, welding deformation welds, etc., to improve support and stability, reduce Construction cost, the effect of avoiding welding distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

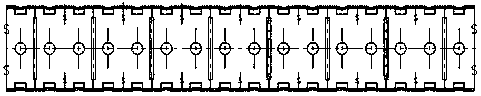

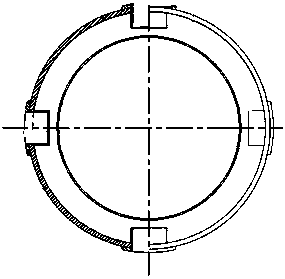

[0053] Such as figure 1 and figure 2 The construction process of lifting leg piles for a marine living platform is shown, including joint pipe making, unit segment butt joint, segmental butt joint, T-shaped frame welding, external web welding, and hole making and sealing on the curved surface of the leg cylinder , sandblasting coating and piling assembly; the specific manufacturing process is as follows:

[0054] S1: Sectional pipe production: The steel plate after blanking including bevel cutting is rolled into a single-section cylinder by a large hydraulic press and plate rolling machine, and the longitudinal seam welding is completed and tested to form a single section pipe part;

[0055] S2: Unit segment docking: 3-4 segmented pipes are docked with the tire frame and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com