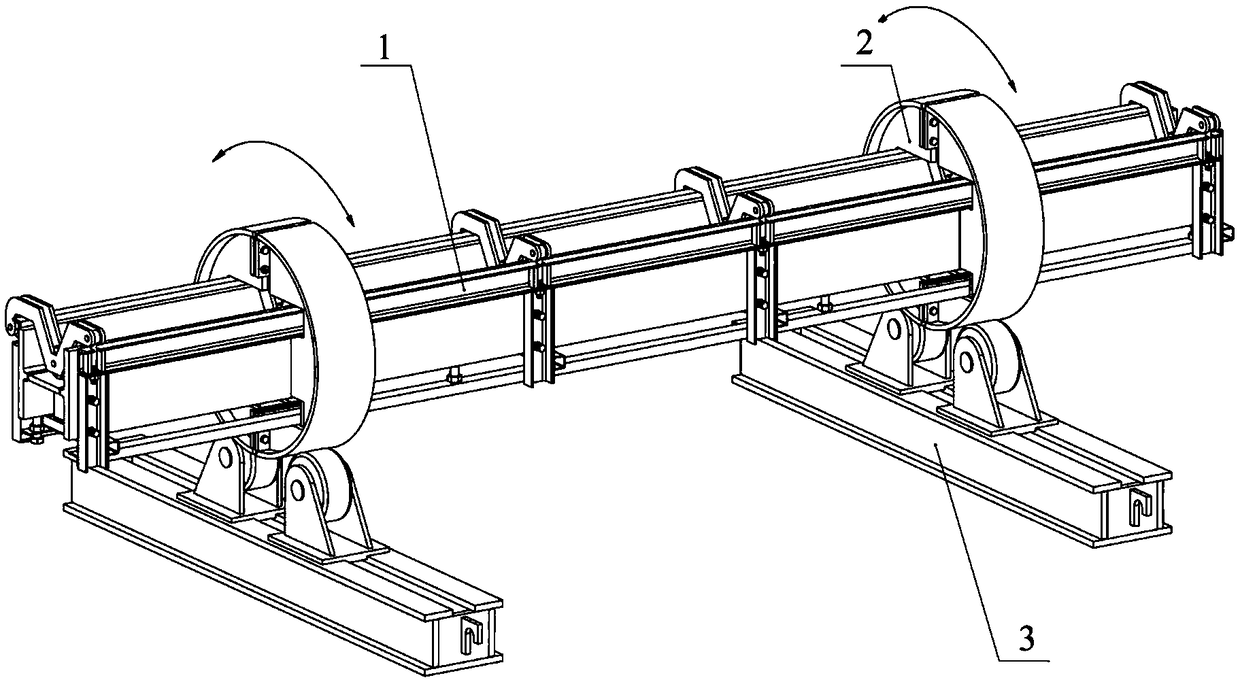

Large austenite welding H-shaped steel assembly and rotation welding device

A welding device and H-shaped steel technology, which is applied in the field of nuclear power, can solve problems such as controlling the verticality and position of the H-shaped steel plate within the required range, high linear expansion coefficient of stainless steel, and deformation of H-shaped steel, etc., to achieve novel structure and easy Operation and prevention of welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

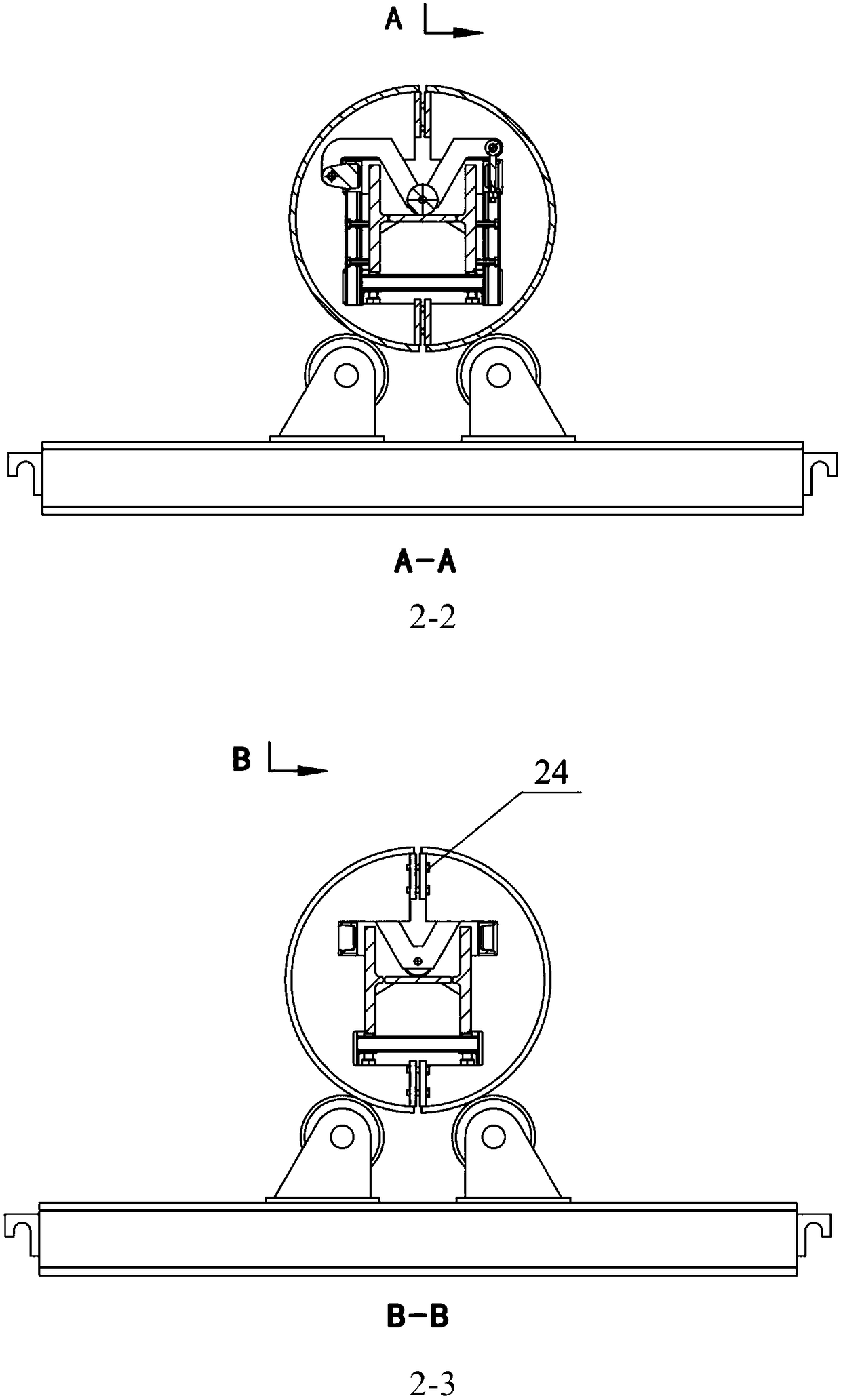

[0094] According to a preferred embodiment of the present invention, the adjustment frame 11 further includes a positioning plate 111 disposed inside it, and the positioning plate 111 is used for positioning the position of the welded H-shaped steel plate.

[0095] In a further preferred embodiment, the positioning plate 111 is arranged on the upper surface of the bottom beam 114 , and the surface of the positioning plate is perpendicular to the bottom beam 114 .

[0096] In a further preferred embodiment, there are multiple positioning plates 111, which are evenly distributed inside the adjustment frame 1,

[0097] Preferably, the distance between the adjacent positioning plates 111 is 0.8-1.0m.

[0098] Wherein, the distribution position of the positioning plate on the bottom beam corresponds to the distribution position of the side beam on the bottom beam, preferably, the bottom edge of the positioning plate abuts against the side edge of the side beam.

[0099] According ...

Embodiment 1

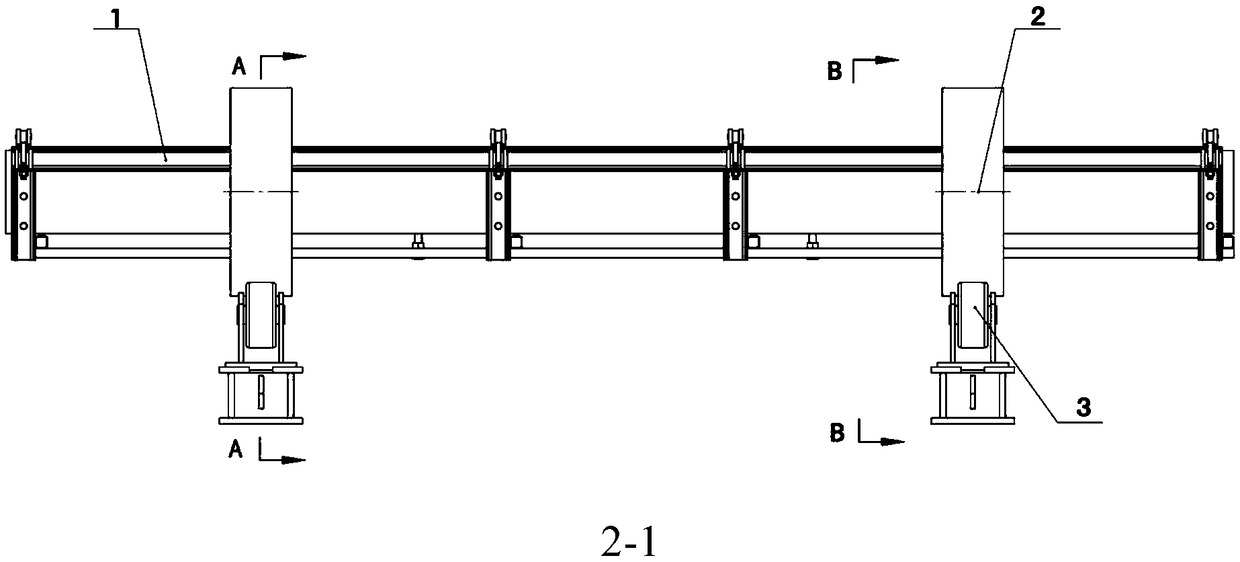

[0165] Weld the large stainless steel H-beam with the specification of WH280×280×18×28, using Figure 1 to Figure 9 The shown welding device comprises the following steps:

[0166] (1) Adjust the top surfaces of multiple positioning plates to be in the same horizontal plane, and the sides are coplanar and parallel to the sides of the adjustment frame, then place the adjustment frame on two horizontal pads, and then lock and press several The block is fixed on the adjustment frame through the rotating shaft to form a pair frame;

[0167](2) Place the web horizontally on the top surface of the positioning plate, place the two wing plates on both sides of the positioning plate respectively; The welding groove of the web is at the same height; then pre-tighten the flange to fix the top wire, so that the inner side of the flange is close to the side of the positioning plate;

[0168] (3) Adjust the welding gap between the web plate and the fixed wing plate to 4mm, make the fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com