Girder machining method and girder machining device for crane and crane span collecting-mounting method

A processing method and processing device technology, applied in the direction of metal processing, metal processing equipment, workbench, etc., can solve the problems of inability to realize modularization, batch production, wheel gnawing rails, long assembly cycle, etc., and achieve easy interchangeability Assembly and modular production, eliminating welding deformation, and ensuring the quality of assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

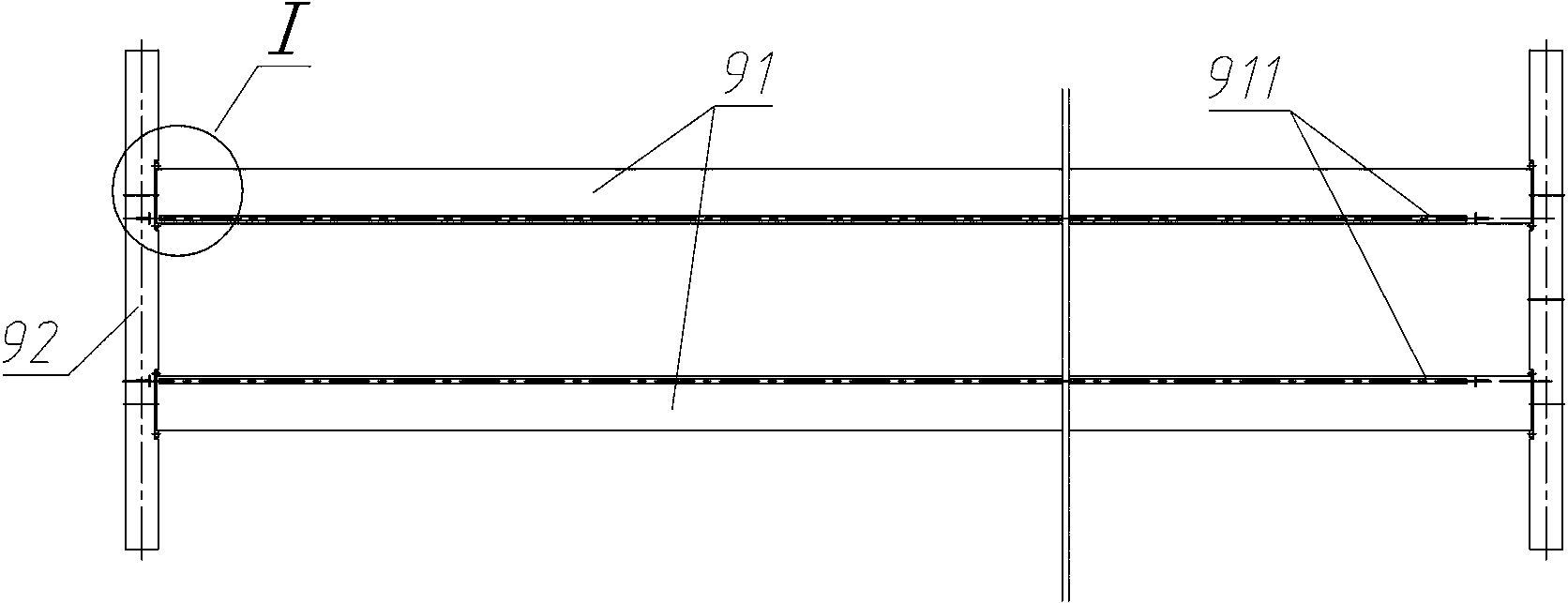

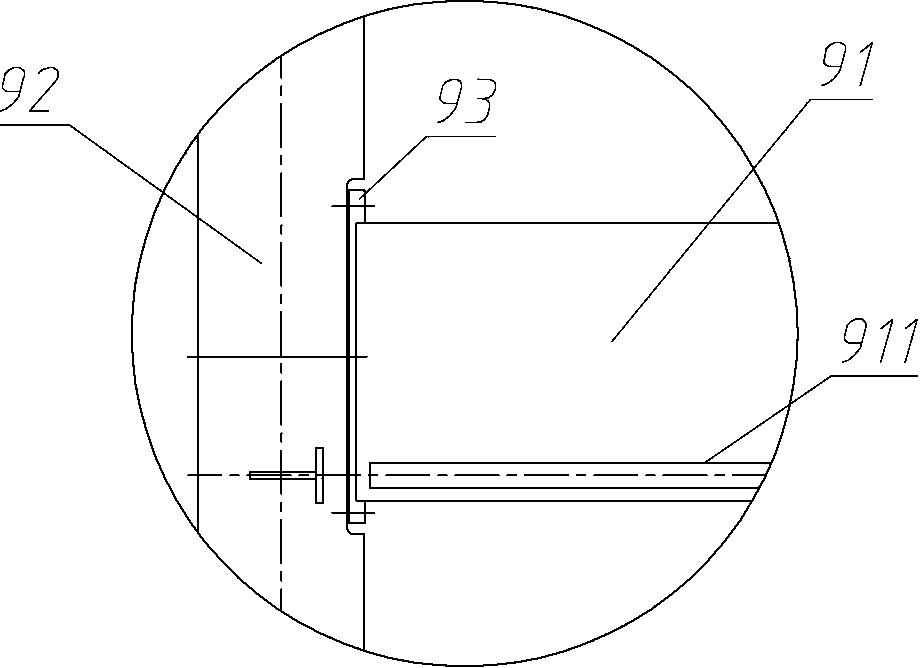

[0036] An embodiment of the crane main beam processing device in the present invention Figure 4~Figure 18 As shown, it includes two support tables 7 arranged side by side at intervals and a mobile boring and milling machine 11 arranged on the outside of the support table 7 in the width direction. Both ends of the main beam 1 in the length direction can be supported on the support tables 7 respectively.

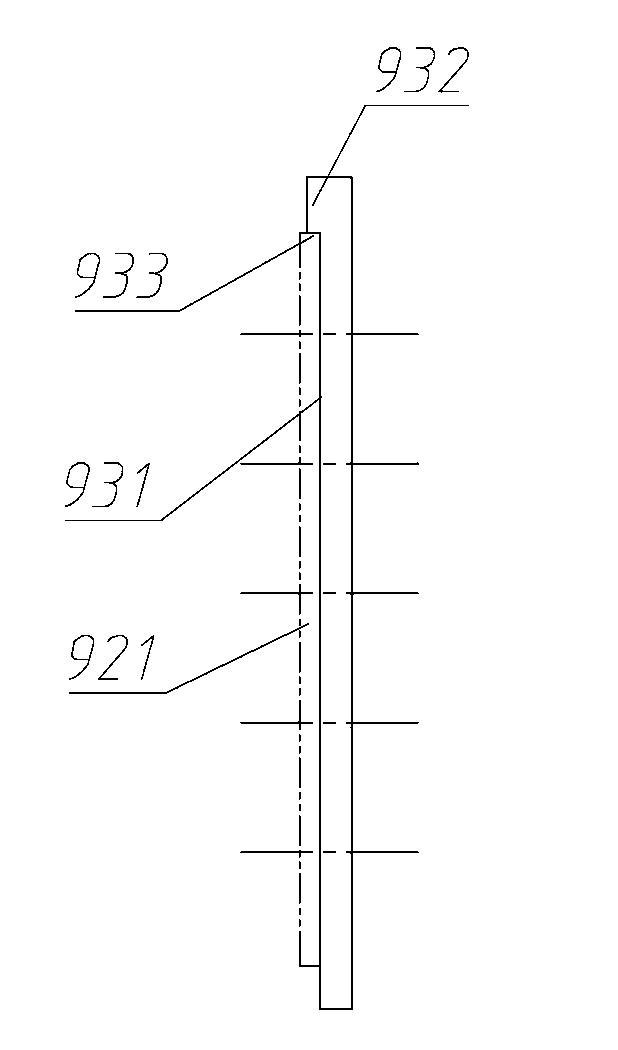

[0037] Each support table 7 includes a bottom support 8, a square box 9 and a fixing device for pressing and fixing the square box 9 to the bottom support 8. The square box 9 is a cuboid-shaped box structure, and the bottom plate of the square box 9 The edges of the two sides extend out of the outer surface of the side plates, the corresponding pressing plate 18 of the fixing device can be laid on the edge, and then the pressing plate 18 is fixed to the bottom support 8 through the corresponding bolts, and the square box 9 can be compressed Fixed on the bottom support 8. The st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com