Process for forming equal-wall-thickness reducing fuel spray rod through selective laser melting

A technology of laser selective melting and process method, applied in the field of additive manufacturing, can solve the problems of large welding deformation of fuel spray rod, long repair cycle of heat shield, large residual stress of assembly, etc., so as to solve the problem of long repair cycle and improve manufacturing accuracy and compliance, the effect of eliminating welding distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them.

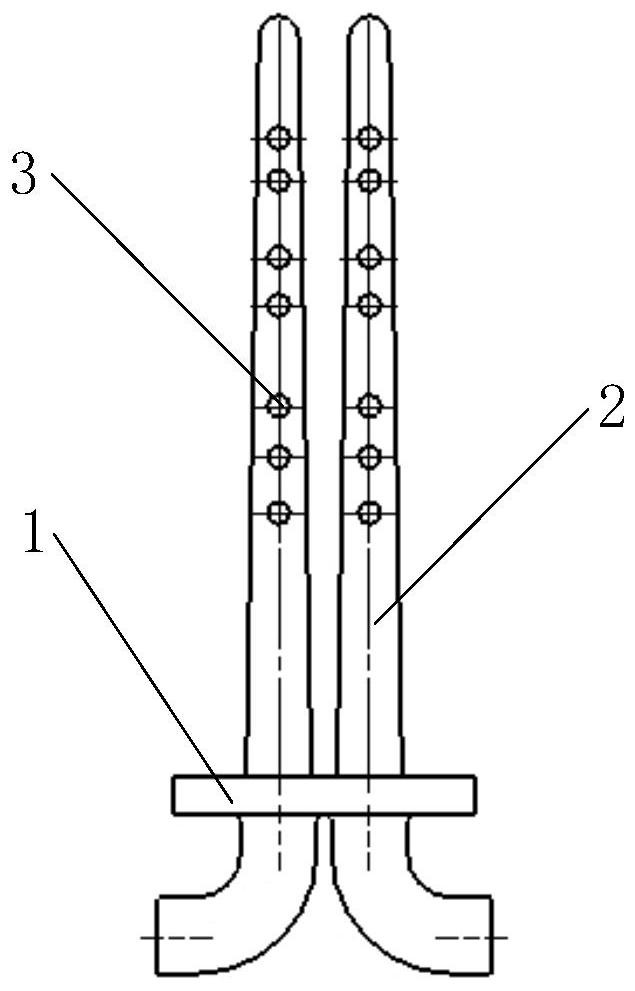

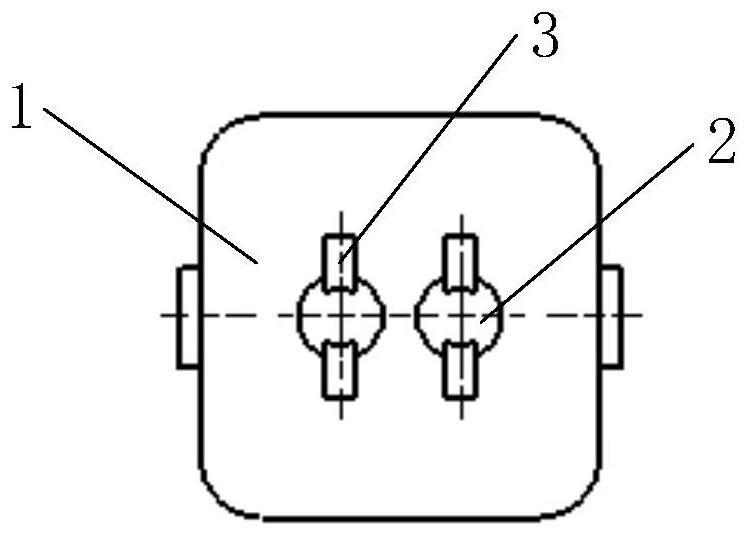

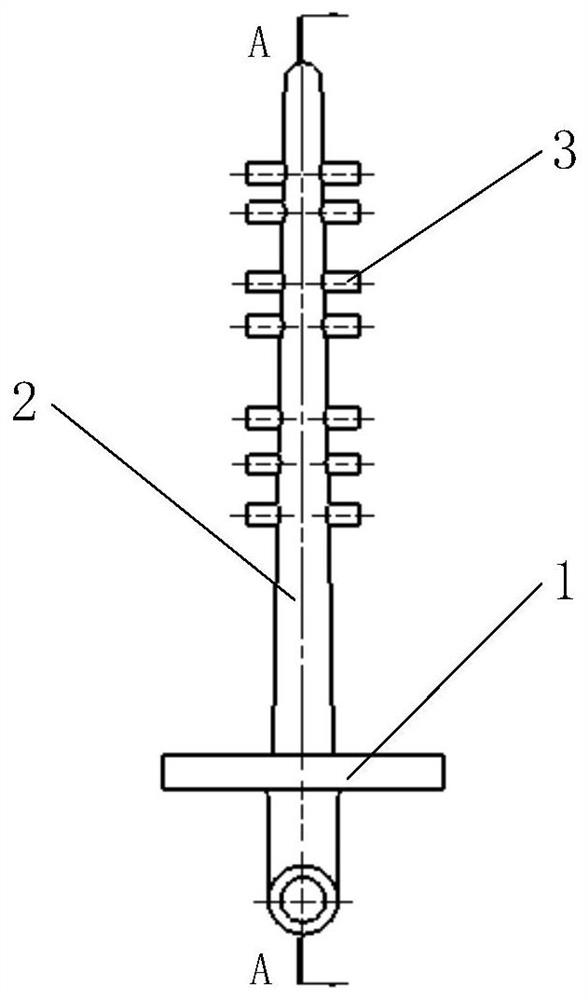

[0048] In order to solve the problems existing in the existing technology, such as Figure 1 to Figure 10 As shown, the present invention provides a process for laser selective melting and forming equal-wall-thickness variable-diameter fuel spray rods. The equal-wall-thickness variable-diameter fuel spray rods include a nozzle seat 1, a spray rod portion 2 and a fuel injection nozzle 3. The process of laser selective melting forming equal-wall-thickness variable-diameter fuel injection rod includes the following steps:

[0049] S1. Establish a three-dimensional model of the fuel spray rod with equal wall thickness and variable diameter, and use UG to es...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com