Aluminum alloy semitrailer longitudinal beam assembly

A longitudinal beam assembly and semi-trailer technology, which is applied to vehicle components, upper structure, lower structure, etc., can solve the problems of insignificant weight reduction effect, poor comprehensive economic benefits, poor corrosion resistance, etc., and achieve improved weight reduction effect , improve the service life, improve the effect of recycling value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

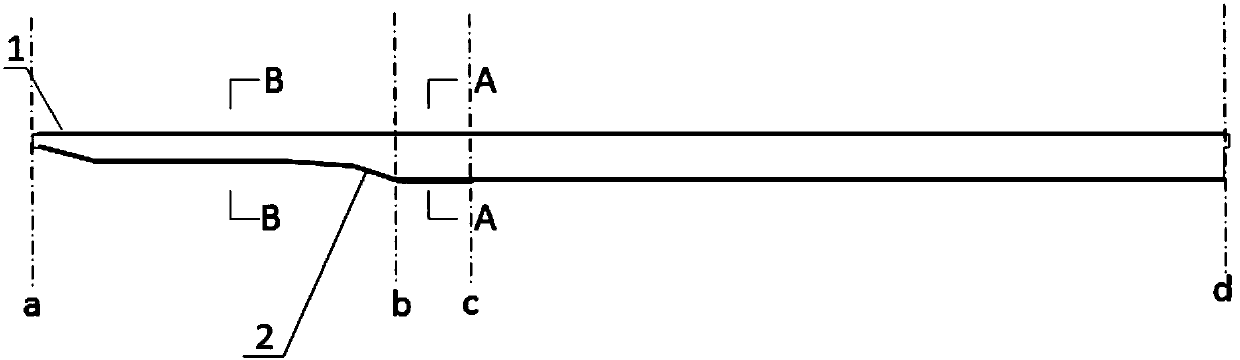

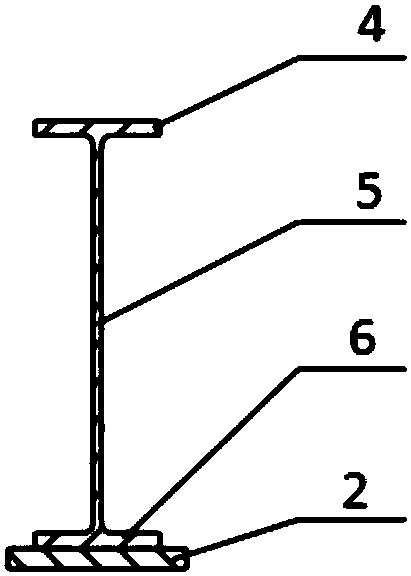

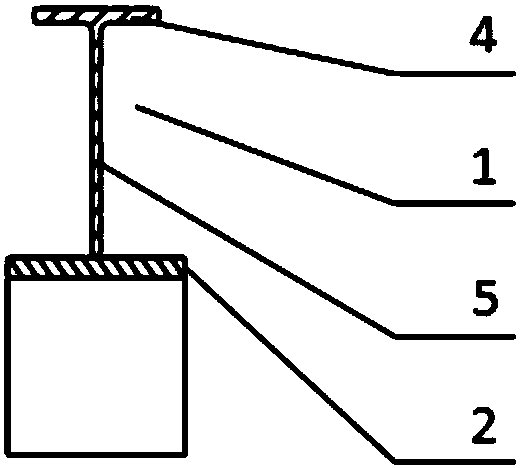

[0029] Such as figure 1 , 2 , 3, 4, and 5 show an aluminum alloy semi-trailer longitudinal beam assembly, which includes a longitudinal beam 1, and the longitudinal beam 1 is made of an aluminum alloy material. Compared with the steel longitudinal beam assembly in the prior art, the longitudinal beam 1 is made of aluminum alloy material, which can improve the weight reduction effect, improve the corrosion resistance, and improve the recovery value and residual value rate while meeting the requirements of the regulations. , economic benefits, and expand application prospects.

Embodiment 2

[0031] On the basis of the aluminum alloy semi-trailer longitudinal beam assembly described in Embodiment 1, the longitudinal beam includes ab section, bc section and cd section, and the ab section, bc section and cd section are integrally formed. Compared with the tailor-welded structure of the longitudinal beam assembly in the prior art, this improvement makes the longitudinal beam 1 have no tailor-welded structure, which can eliminate the stress concentration generated at the welding position, and can eliminate the welding deformation caused by the tailor-welded method of the longitudinal beam 1, effectively Improve the bearing strength, reduce the possibility of longitudinal beam assembly fracture, and improve the service life of the semi-trailer.

Embodiment 3

[0033] On the basis of the aluminum alloy semi-trailer longitudinal beam assembly described in Embodiment 2, the integral molding process of the ab section, bc section and cd section is an aluminum extrusion process. Compared with the tailor welding method of the longitudinal beam assembly in the prior art, the improvement reduces the number of welding parts of the longitudinal beam assembly, reduces the overall error of the longitudinal beam assembly, simplifies the process, and improves the yield.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com