Underground pile continuous wall construction method and wall formation device for underground pile continuous wall construction method

A construction method and technology of wall forming equipment, which are applied in sheet pile wall, foundation structure engineering, earth moving machine/shovel excavator, etc. Increase connection solidity, good effect and fast work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

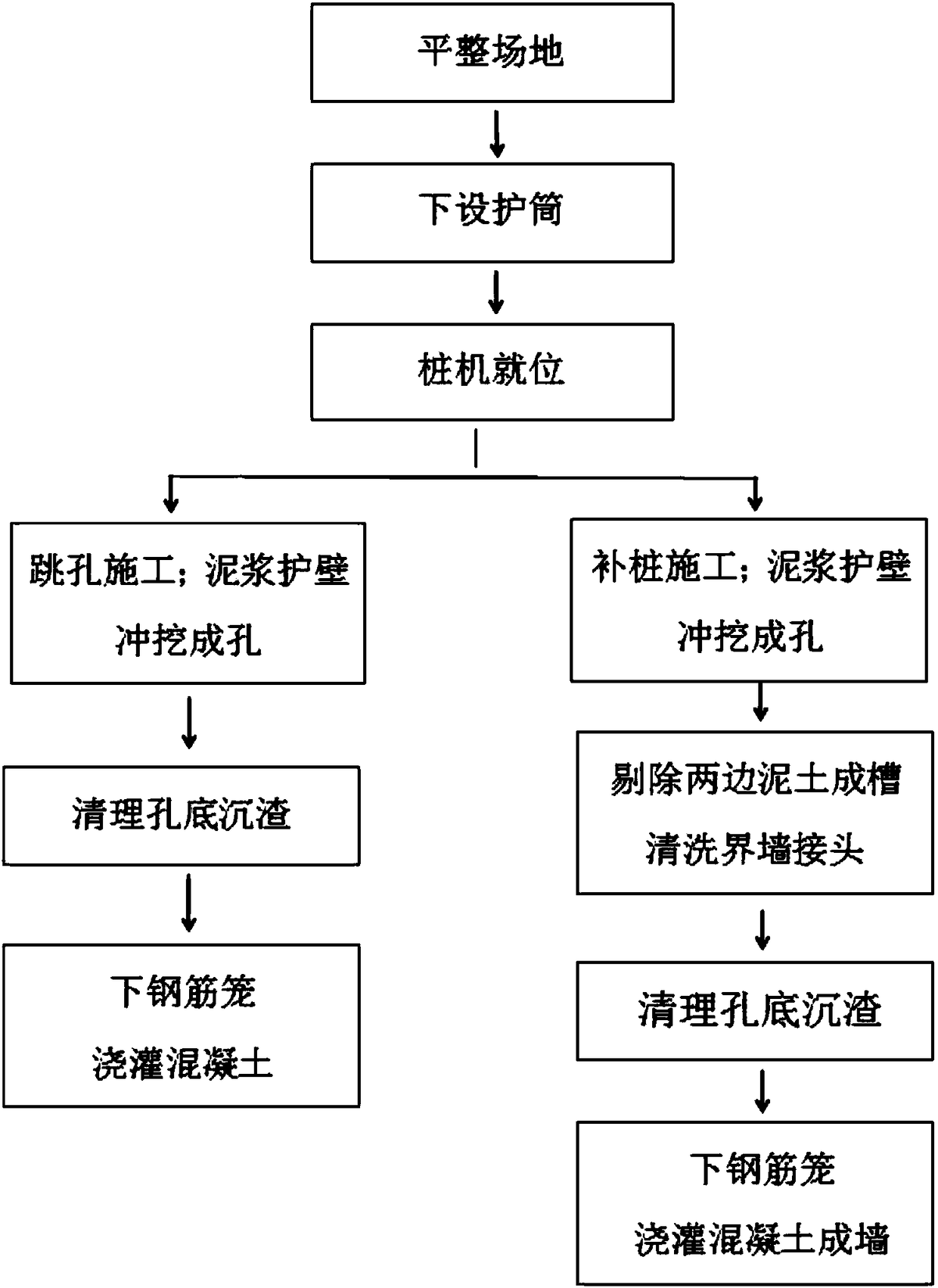

[0066] Through the construction method of underground piles connecting walls, this construction technology is applied to underground piles connecting walls, combined with Figure 2-4 , the steps include the following:

[0067] S1: Leveling the site;

[0068] S2: Underneath the casing;

[0069] S3: the pile driver is in place;

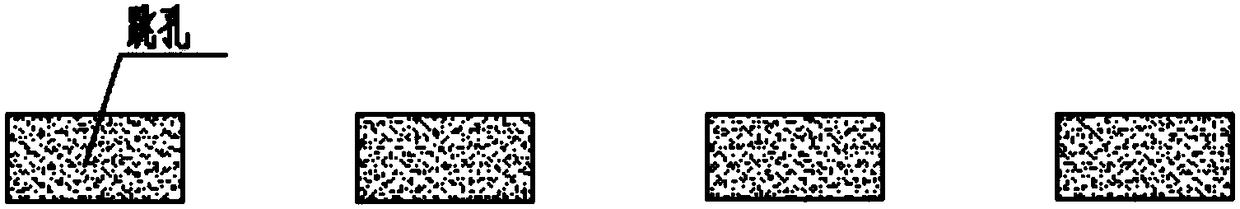

[0070]S4: Start the pile driver to jump the piles in sequence and align them with the pile positions, use the mud retaining head to dig down under the action of the guide rod and the main engine, and use the punching head to grab the soil, debris and stones from the groove and take them out of the ground , carry out step by step according to the above steps, punching and digging the groove to the level of the bottom of the wall, forming a jumping grid unit groove (such as figure 2 shown);

[0071] S5: Clean up the sediment at the bottom of the hole, measure the mud concentration,

[0072] S6: Pour concrete in the lower reinforcement cage to comple...

Embodiment 2

[0078] combined with Figure 5-7 , by the method of the present invention, be used for construction underground pile connecting wall, described steps are as follows:

[0079] S1: Leveling the site;

[0080] S2: Underneath the casing;

[0081] S3: the pile driver is in place;

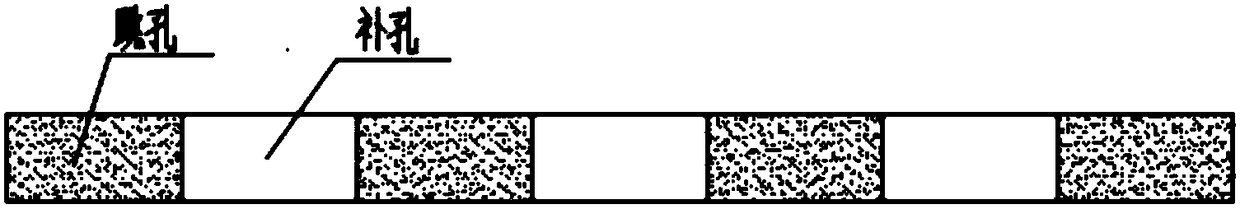

[0082] S4: Arrange jump hole construction according to the pile position, punch and excavate the mud retaining wall to the set depth,

[0083] S5: Clean up the sediment at the bottom of the hole and measure the mud concentration;

[0084] S6: Concrete is poured with reinforcement cages to complete a jump hole unit wall section;

[0085] S7: Pile filling construction, mud retaining wall punching and digging into holes;

[0086] S8: Eliminate the soil on the two boundary walls to form grooves, the high-pressure nozzle moves up and down along the guide rod, and the water slurry punches to clean the joints of the two boundary walls;

[0087] S9: Clean up the sediment at the bottom of the hole and measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com