Steel component concrete encasement construction technique

A technology for outsourcing concrete and construction technology, which is applied to building components, elongated structural components for load-bearing, structural elements, etc., can solve problems such as construction difficulties, small cross-section of outsourced concrete, and guarantees, and saves costs and construction time. , The effect of shortening the construction period and reducing the investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Square steel pipe outsourcing concrete construction process:

[0027] Concrete configuration prescription: per cubic meter of concrete

[0028] Cement (Jilin Jinyuan brand P.O42.5R grade cement) 180kg; water 180kg; accelerator (produced by Huludao Jinxing Admixture Factory) 18.0kg; high-efficiency water reducer (Changchun Dongkan Building Material Factory SKY) 4.5kg; Silica fume (Norway Elkem) 45kg; sand 826kg; stones (Sandaochunhe quarry 5-15mm) 900kg;

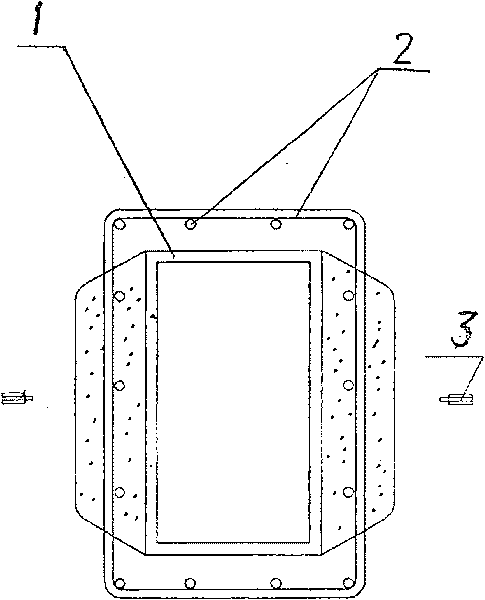

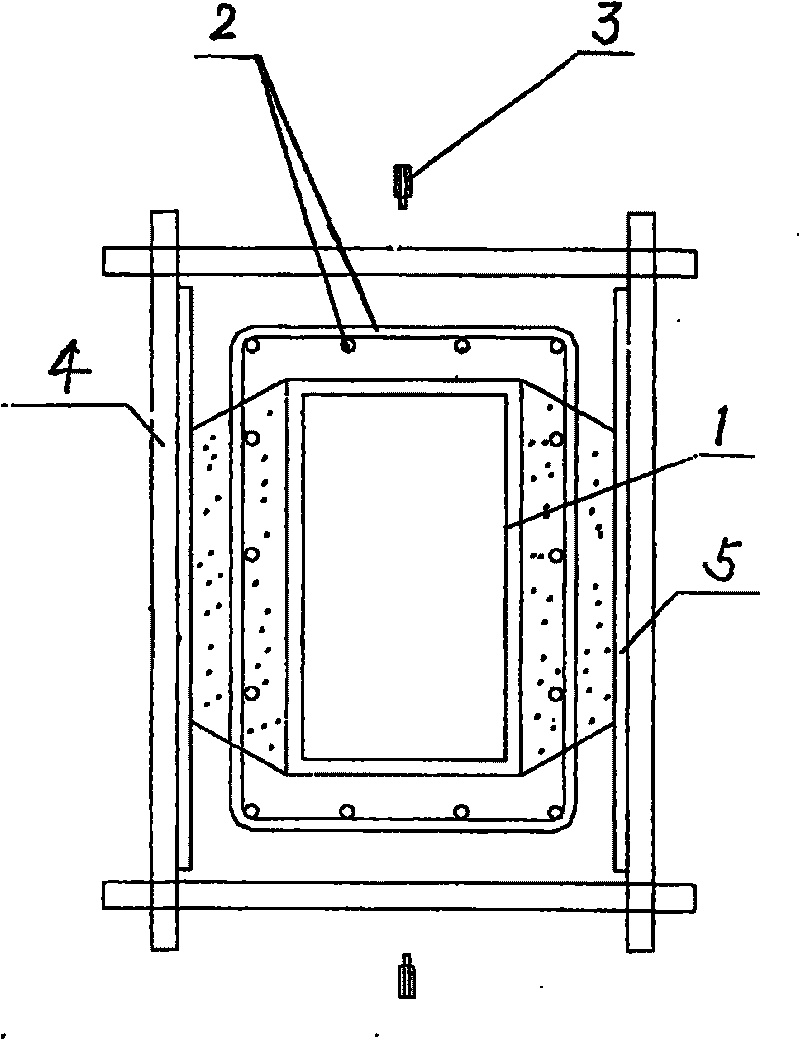

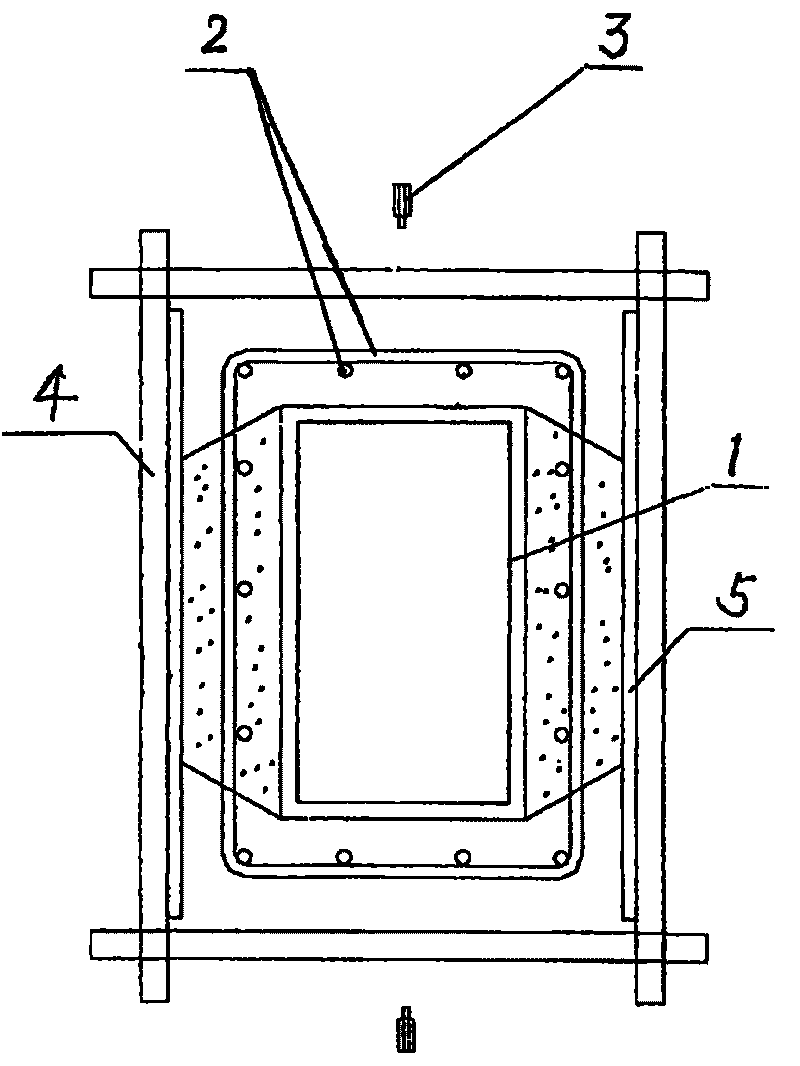

[0029] figure 1 For the top view of two side concrete shot after tying steel bars during construction, figure 1 In the first step, steel bars 2 are arranged outside the rectangular steel pipe 1 with a spacing of 150mm. In the process of spraying concrete on the surface of the steel pipe, in order to ensure the squareness of the shape, this embodiment firstly figure 1 Spray the long side surfaces on both sides, and the nozzle 3 is perpendicular to the sprayed surface. Then if figure 2 The template 5 is supported ...

Embodiment 2

[0031] The construction process of I-beam outsourcing concrete (the specifications and origin of each raw material are the same as in Example 1):

[0032] Concrete configuration prescription: per cubic meter of concrete

[0033] 185kg of cement; 185kg of water; 20.4kg of accelerator; 5.1kg of superplasticizer; 51kg of silica fume; 877kg of sand; 917kg of gravel;

[0034] The first layer of reinforcement is arranged outside the I-beam member. The steel bar spacing is 180mm. Spray concrete on the surface of the I-beam. When spraying on a flat surface to be sprayed, the nozzle is perpendicular to the surface to be sprayed. When spraying the inner corner, the nozzle should be sprayed along the direction of the angle bisector at the angle between the two sprayed surfaces. After the corner has been filled into a curved surface, it will gradually extend to the walls on both sides, and then, Spray at an angle of 90° to the wall. To spray outside corners, aim the nozzle vertically ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com