Application process of construction waste roadbed filling aggregate

A technology of construction waste and roadbed, which is applied in construction, on-site paved cohesive pavement, roads, etc., can solve problems such as inapplicability, safety problems, and inability to guarantee project quality, and achieve good economic benefits, convenient construction, and satisfying construction requirements. The effect of quality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

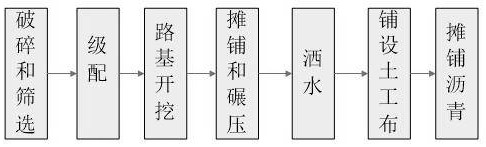

[0041] The present invention provides a technical solution: an application process of construction waste subgrade filling aggregate, comprising the following steps:

[0042] Step 1. Select raw materials

[0043] The particle size of the first grade of construction waste recycled aggregate is 9mm~15mm, the particle size of the second grade of construction waste recycled aggregate is 5mm~9mm; the particle size of the third grade of construction waste recycled aggregate is less than 5mm;

[0044] Step 2, preparing roadbed filling materials

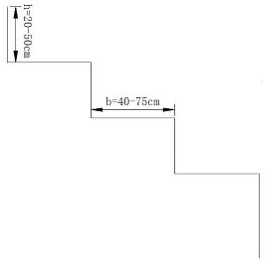

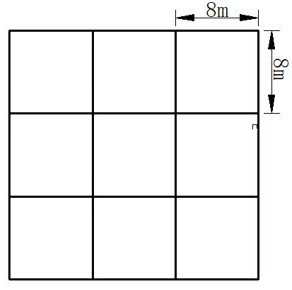

[0045] Select all levels of construction waste recycled aggregate according to the proportion and mix it evenly with other raw materials to obtain the construction waste mixture as the roadbed filling material; first put the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com