Method for positioning template corner

A positioning method and formwork technology, which is applied in the direction of formwork/formwork/work frame, connection parts of formwork/formwork/work frame, and ship lifting device, which can solve the difficulty in meeting the accuracy requirements for formwork reinforcement and the inability to form tie rods. Reinforcement and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

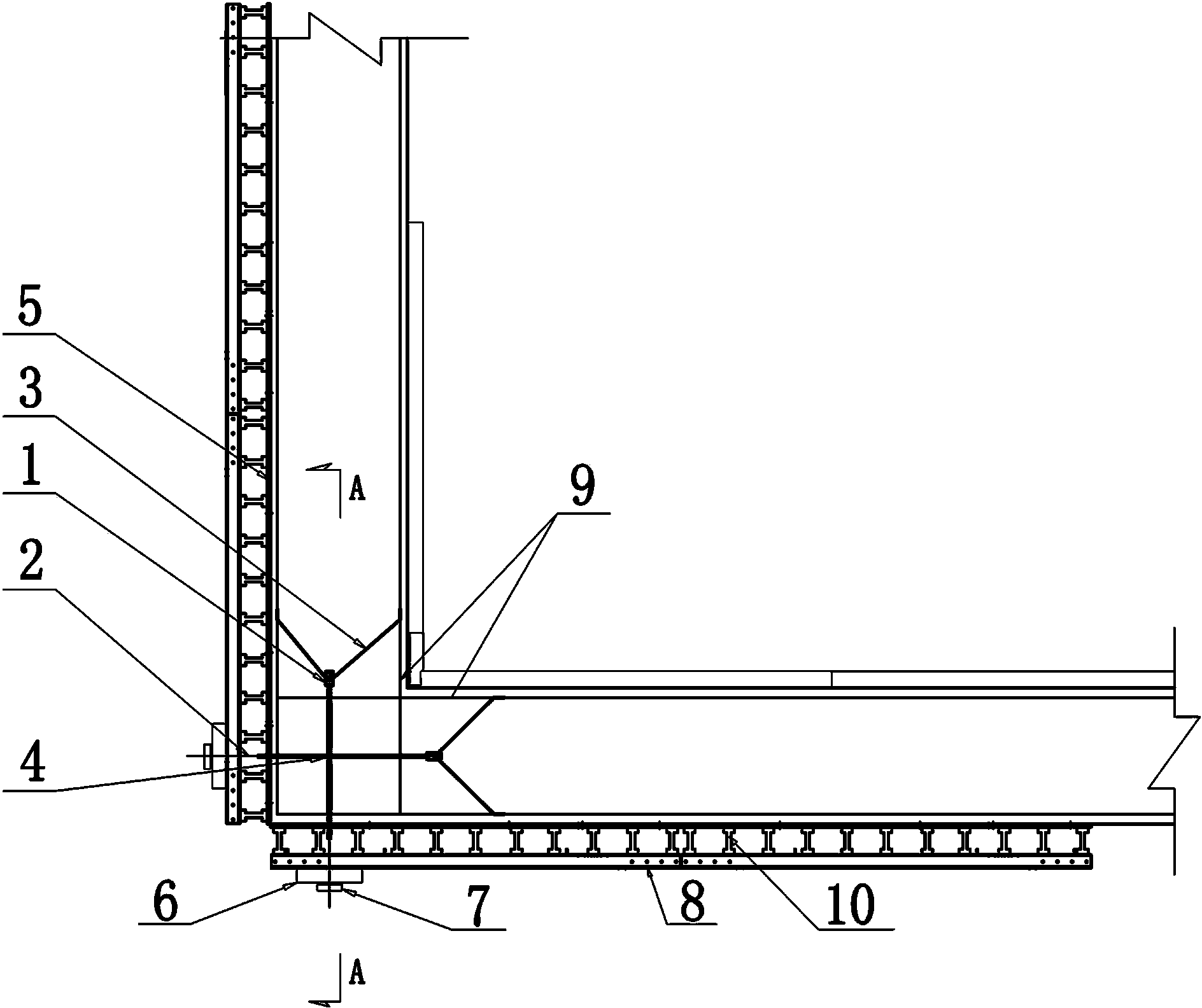

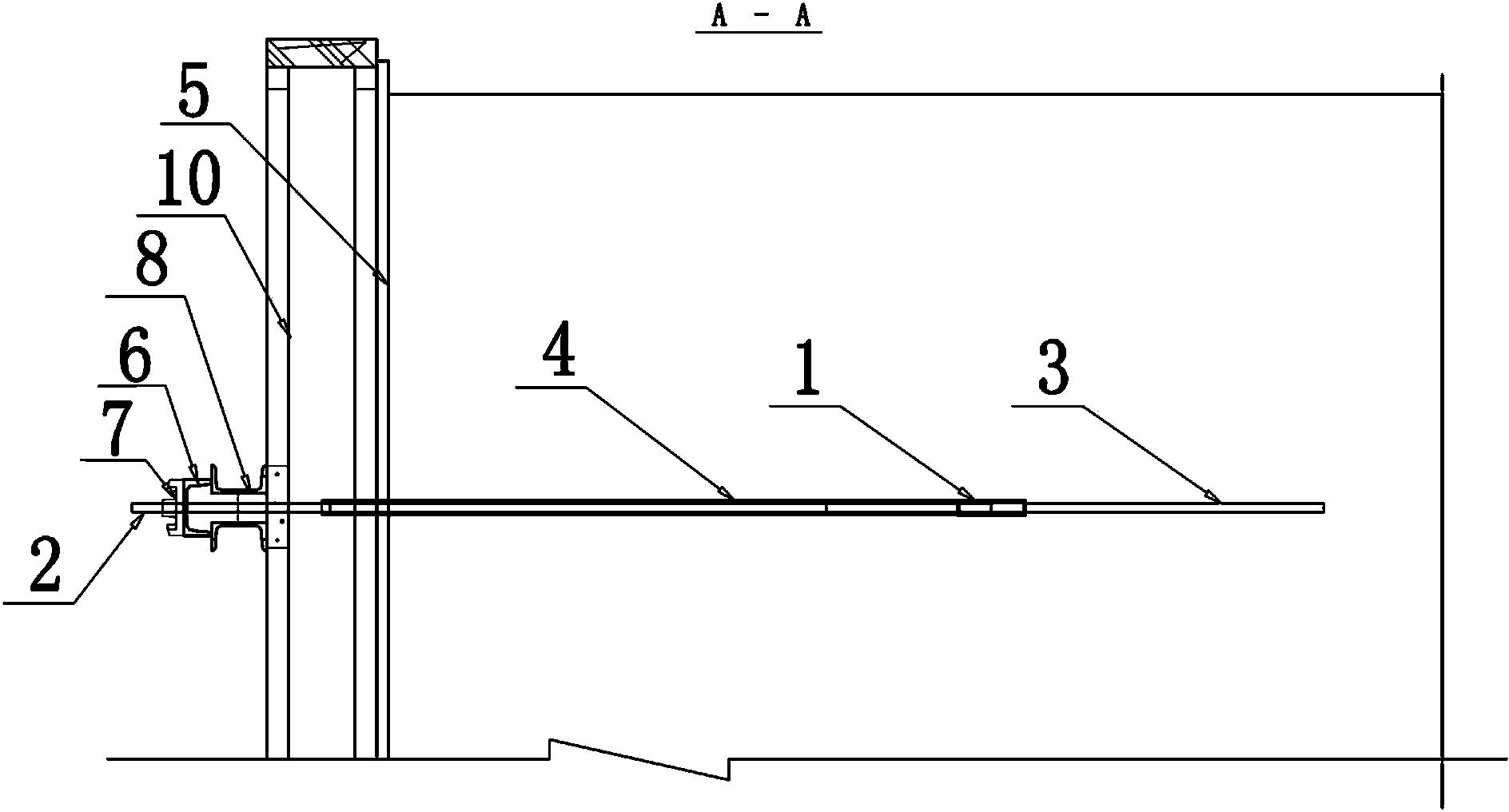

[0020] Such as figure 1 , figure 2 Among them, a formwork corner positioning device, including a formwork 5, the formwork 5 is provided with a longitudinal enclosure 10 and a transverse enclosure 8, a tie screw 2 is installed at the corner of the formwork 5, and one end of the tie screw 2 passes through the liner 6 and the nut 7 are connected with the template 5, and the other end is connected with the weldable sleeve 1; the corner parts mentioned here also include the parts where the braces cannot be pulled against each other in the "T"-shaped parts.

[0021] The weldable sleeve 1 is welded and connected to the steel bar 9 in the warehouse through the brace 3 .

[0022] The weldable sleeve 1 is made of a weldable material with an outer diameter of 24mm and a length of 12-15cm, such as No. 45 steel. The weldable sleeve 1 is internally processed with an internal thread that cooperates with the rod screw 2 .

[0023] The said bracing screw 2 is provided with a casing 4, one e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com