Rapid multifunctional construction equipment for ballast track

A kind of construction equipment and multi-functional technology, applied in the direction of track, track superstructure, road, etc., can solve the problems of unfavorable construction, large structure size, easily damaged rails and sleepers, etc., so as to reduce construction cost, reduce operating personnel and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

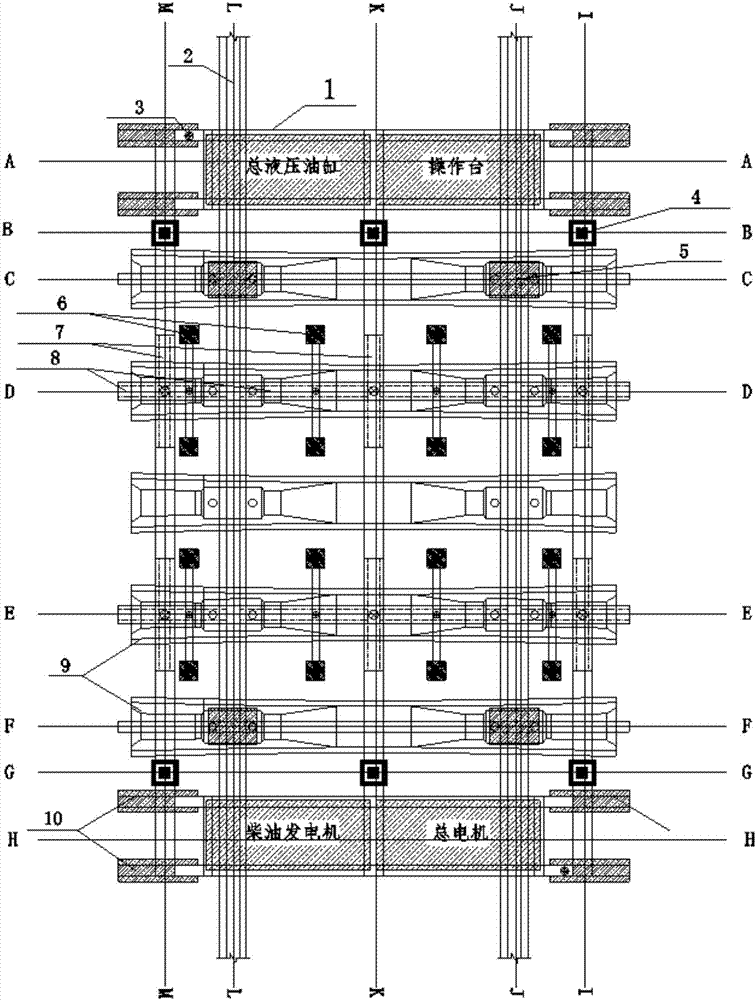

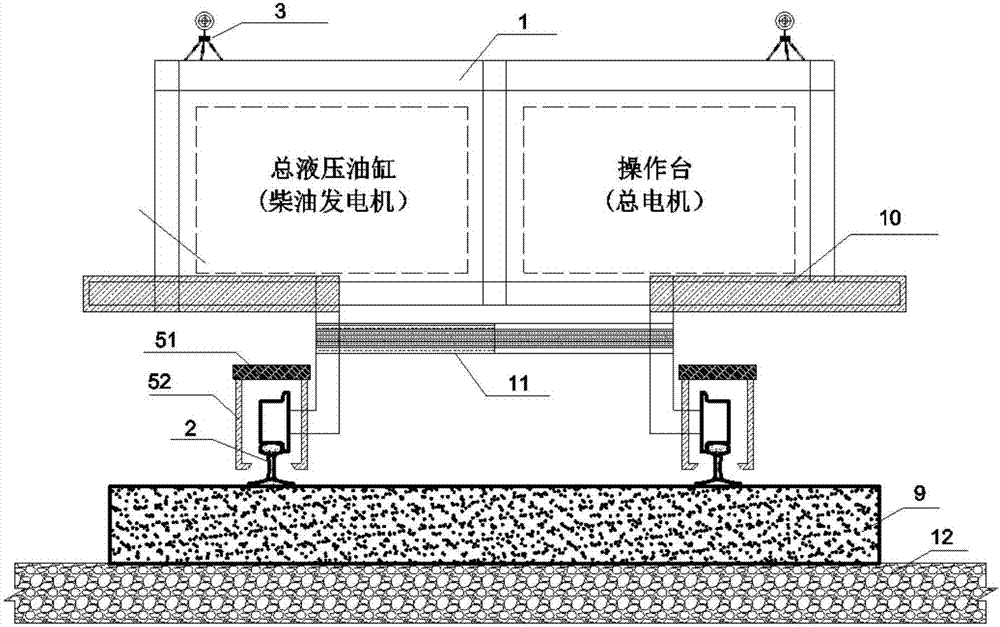

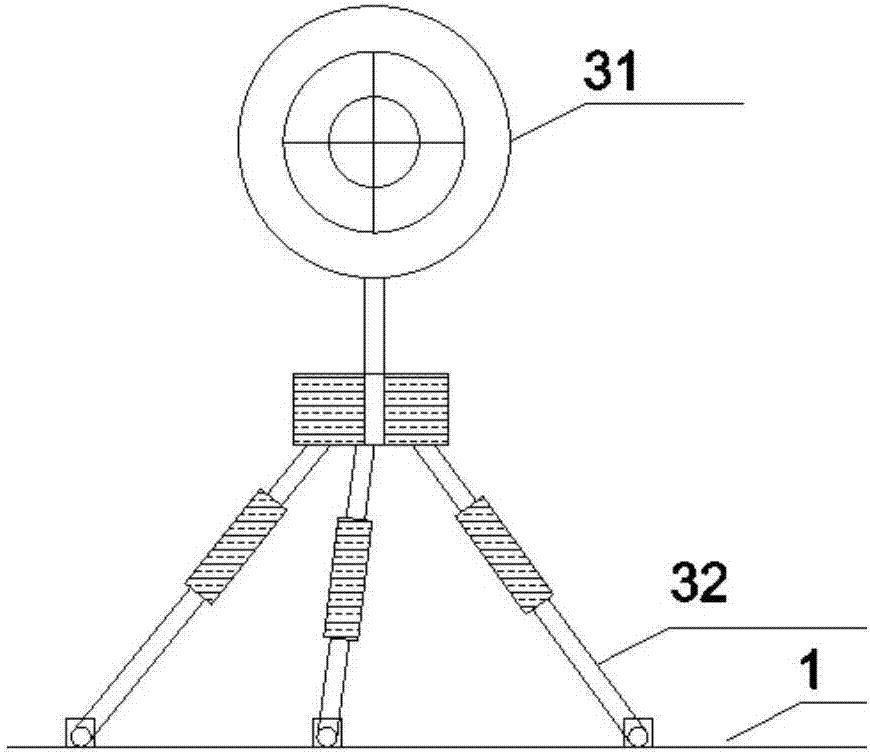

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. Such as figure 1 As shown, a ballast track rapid multifunctional construction equipment includes a horizontally arranged rectangular main frame 1, the front and rear ends of the main frame 1 are respectively provided with supporting frames on both sides of the beam, and the bottom of the supporting frame is provided with 2 for clamping rails. The hydraulic rail clamping device 5; also includes a plurality of sets of lifting combined legs 4 that are arranged on the main frame 1 and are supported on the ballast surface, and the lifting combined legs 4 include movable support rods 42 and movable support rods 42 The outrigger hydraulic cylinder 41; the movable support rod 42 includes a vertical outrigger for lifting the equipment and the rail as a whole to lift up the track, and a diagonal support leg for shifting the equipment and the rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com