Low-density grouting material and preparation method thereof

A grouting material and low-density technology, applied in the field of low-density grouting materials and preparation, can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

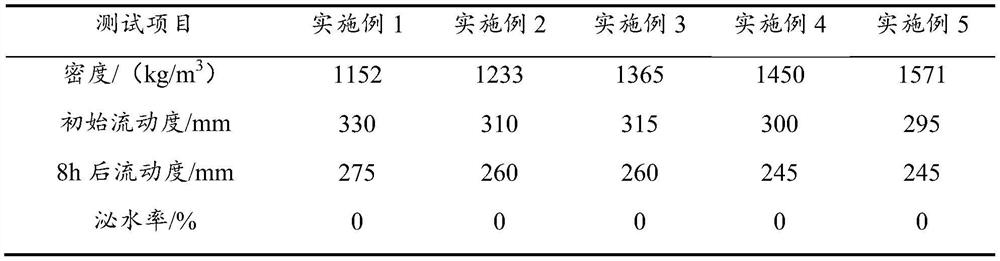

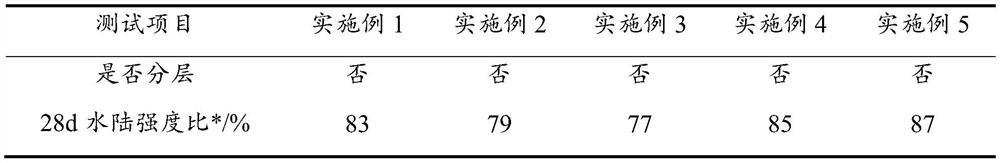

Embodiment 1

[0022] The density of silt on the surface of the seabed in a sea area is about 1200-1400kg / m 3 , in the negative pressure barrel fan foundation grouting filling project, the density of the grouting material must be less than or equal to 1200kg / m 3 .

[0023] It is now formulated that the density is less than or equal to 1200kg / m 3 grouting material:

[0024] Mix 10 parts of P·Ⅱ52.5 cement, 30 parts of silica fume, 24.89 parts of fly ash, 30 parts of polyphenylene particles, 5 parts of cellulose ether, 0.01 part of polycarboxylate superplasticizer and 0.01 part of plastic expansion agent, Form a dry mixture, then add 100 parts of fresh water, and stir evenly, that is, the density is less than or equal to 1200kg / m 3 grouting material.

Embodiment 2

[0026] The density of silt on the surface of the seabed in a sea area is about 1250-1380kg / m 3 , in the negative pressure barrel fan foundation grouting filling project, the density of the grouting material must be less than or equal to 1250kg / m 3 .

[0027] It is now formulated that the density is less than or equal to 1250kg / m 3 grouting material:

[0028] Mix 30 parts of P·O42.5 cement, 10 parts of silica fume, 30 parts of mineral powder, 26.67 parts of expanded perlite, 3 parts of sodium polyacrylate, 0.3 parts of sodium lignosulfonate water reducer and 1 part of plastic expansion agent , to form a dry mixture, then add 80 parts of fresh water, and stir evenly, that is, the density is less than or equal to 1250kg / m 3 grouting material.

Embodiment 3

[0030] The density of silt on the surface of the seabed in a sea area is about 1400-1600kg / m 3 , in the negative pressure barrel fan foundation grouting filling project, the density of the grouting material must be less than or equal to 1400kg / m 3 .

[0031] It is now formulated that the density is less than or equal to 1400kg / m 3 grouting material:

[0032] Mix 13.45 parts of sulphoaluminate cement, 70 parts of silica fume, 15 parts of expanded vermiculite, 1 part of cellulose ether, 0.5 parts of naphthalene-based water reducer and 0.05 parts of plastic expansion agent to form a dry material, and then add 70 parts Fresh water, stir evenly, that is, the density is less than or equal to 1400kg / m 3 grouting material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com