Water-resistant dispersible polyurethane rigid foam grouting water-stop reinforcement material and preparation method thereof

A rigid foam, water-resistant dispersion technology, used in shaft equipment, mining equipment, earth-moving drilling, etc., can solve the problems of water source and surrounding ecological environment pollution, threat to long-term stability of the project, difficult to block water inrush or jet flow, etc. It can achieve the effect of adjustable curing time, ensuring grouting operation time, construction safety, and good water resistance and dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

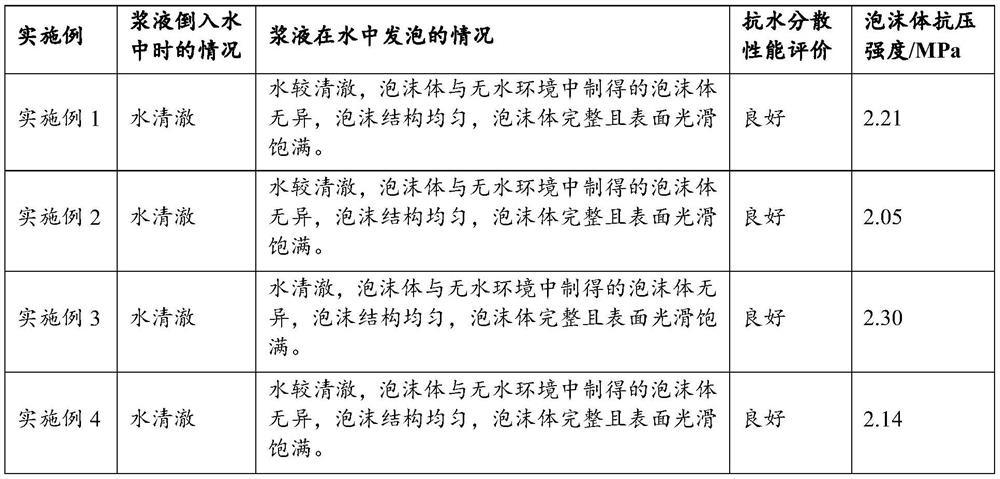

Examples

Embodiment 1

[0041] In this embodiment, the water-resistant dispersion type polyurethane rigid foam grouting water-stop reinforcement material is prepared according to the following method:

[0042] Weigh 7g of propylene carbonate, add 7g of polyvinyl acetate into it and let it stand for 48 hours to obtain a polyvinyl acetate solution. Heat the prepared polyvinyl acetate solution to 60°C and pour it into 230g of preheated Into polymethylene polyphenyl polyisocyanate PM200 at 40°C, and stirred at a speed of 1800r / min for 120s to obtain component A;

[0043] Weigh 46g polyether polyol 4110P, add 9g polyether polyol HKOL-403A, 45g polyester polyol P455N, 20g dioctyl sebacate, 27g dipropylene glycol, 2g foam stabilizer BL-8468, 1.5g Catalyst A33: Stir at a speed of 1200r / min for 60s, then add 10g of fluorodichloroethane to it, and continue stirring at a speed of 1200r / min for 60s to obtain component B;

[0044] Pour the prepared component A into component B, and stir at a speed of 1800r / min f...

Embodiment 2

[0047] In this embodiment, the water-resistant dispersion type polyurethane rigid foam grouting water-stop reinforcement material is prepared according to the following method:

[0048] Weigh 4g of propylene carbonate, add 4g of ethylene carbonate and 8g of polyvinyl acetate, heat to 90°C and stir with a glass rod until translucent homogeneous viscous liquid, pour into 230g while stirring and preheat to 40°C In the polymethylene polyphenyl polyisocyanate PM200, stirred at a speed of 1800r / min for 120s to obtain A component;

[0049] Weigh 80g polyether polyol HK-1302, add 20g polyether polyol 4110G, 25g dioctyl sebacate, 10g glycerol, 2g foam stabilizer BL-8468, 1g catalyst A33; at 1200r / min Stir at a rotating speed of 1200r / min for 60s, then add 10g of fluorodichloroethane to it, and continue to stir at a rotating speed of 1200r / min for 60s to obtain component B;

[0050] Pour the prepared component A into component B, and stir at a speed of 1800r / min for 20s to obtain a wat...

Embodiment 3

[0053] In this embodiment, the water-resistant dispersion type polyurethane rigid foam grouting water-stop reinforcement material is prepared according to the following method:

[0054] Weigh 5g of propylene carbonate, add 7g of polyvinyl acetate into it, heat to 70°C and stir with a glass rod until translucent homogeneous viscous liquid, pour into 220g of polymethylene carbonate preheated to 40°C while stirring In polyphenyl polyisocyanate PM200, stir at a speed of 1800r / min for 120s to obtain component A;

[0055] Weigh 60g polyester polyol P455N, add 40g polyether polyol 4110G, 20g dioctyl terephthalate, 21.5g neopentyl glycol, 2g foam stabilizer BL-8468, 1g catalyst A33; Stir at a speed of 1200r / min for 60s, then add 10g of fluorodichloroethane to it, and continue to stir at a speed of 1200r / min for 60s to obtain component B;

[0056] Pour the prepared component A into component B, and stir at a speed of 1800r / min for 20s to obtain a water-resistant dispersion type polyur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com