Steel-concrete structure slag stop wall shallow hole loosening blasting demolition method

A steel-concrete structure and loosening blasting technology, which is applied in blasting and other directions, can solve problems such as accidents and secondary economic losses, achieve good reliability, reduce secondary economic investment, and protect personal and property safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with specific examples.

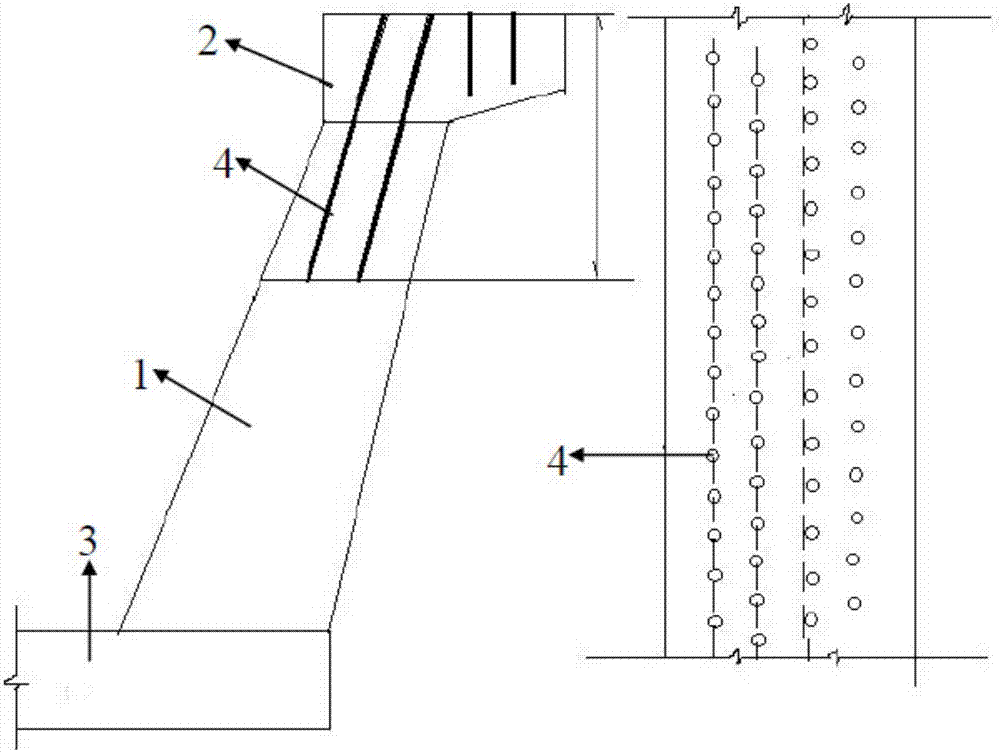

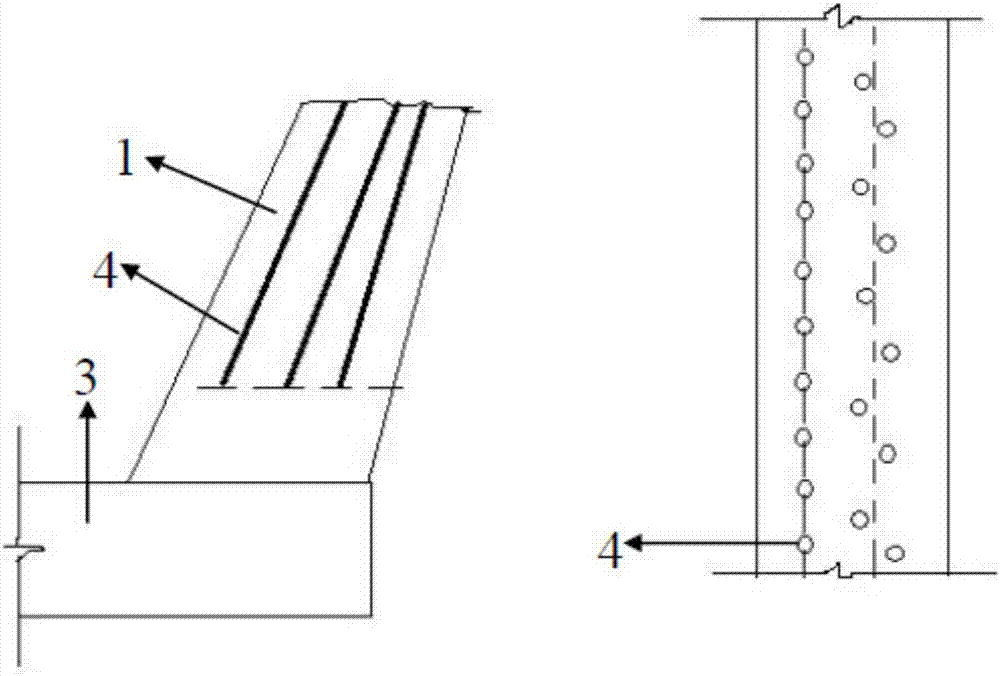

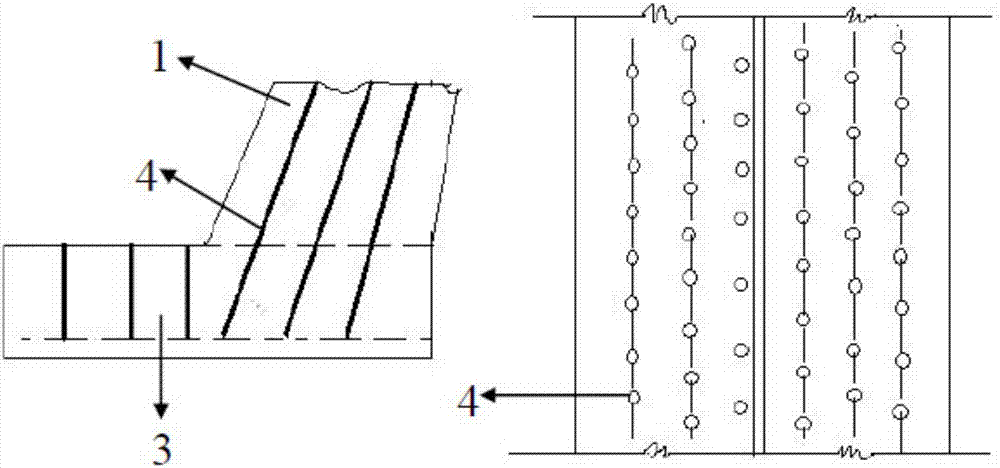

[0038] The blasting demolition project of a steel-concrete structure slag retaining wall is located in the steel yard area. The structural dimensions and specifications of the steel-concrete structure are as follows: the length is about 170m, the cross-section is inclined The inclination angle of the wall is 78.0°; the upper eaves 2 are approximately right-angled trapezoids, the width ratios of the top and bottom are 0.9m and 1.535m, the height of the trapezoid (the width of the eaves 2) is 3.0m, and the demolition volume of the eaves 2 is 669.8m³; the main wall 1 The width of the upper part is 1.572m, the width of the lower part is 2.8m, the vertical height of the main wall 1 is 7.753m, and the demolition volume of the main wall 1 is 2890m³; the width of the bottom plate 3 is 5.3m, the thickness is 1.2m, and the demolition volume is 1081.2 m³. The total demolition volume is 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com