Anti-charging anti-demounting valve for liquefied gas steel cylinders

A technology of liquefied gas and anti-dismantlement, applied in the direction of valve details, valve devices, valve operation/release devices, etc., can solve the safety hazards of liquefied gas cylinders, damage to the opening and closing of the valve core of the gas cylinder, and threaten the safety of users' lives and property and other issues to achieve the effect of protecting personal and property safety and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

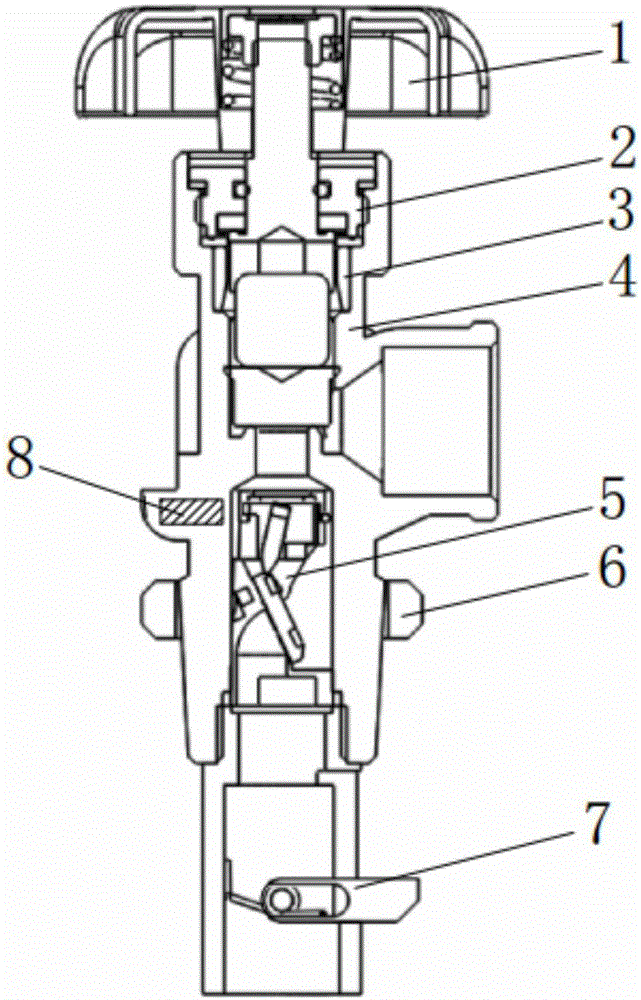

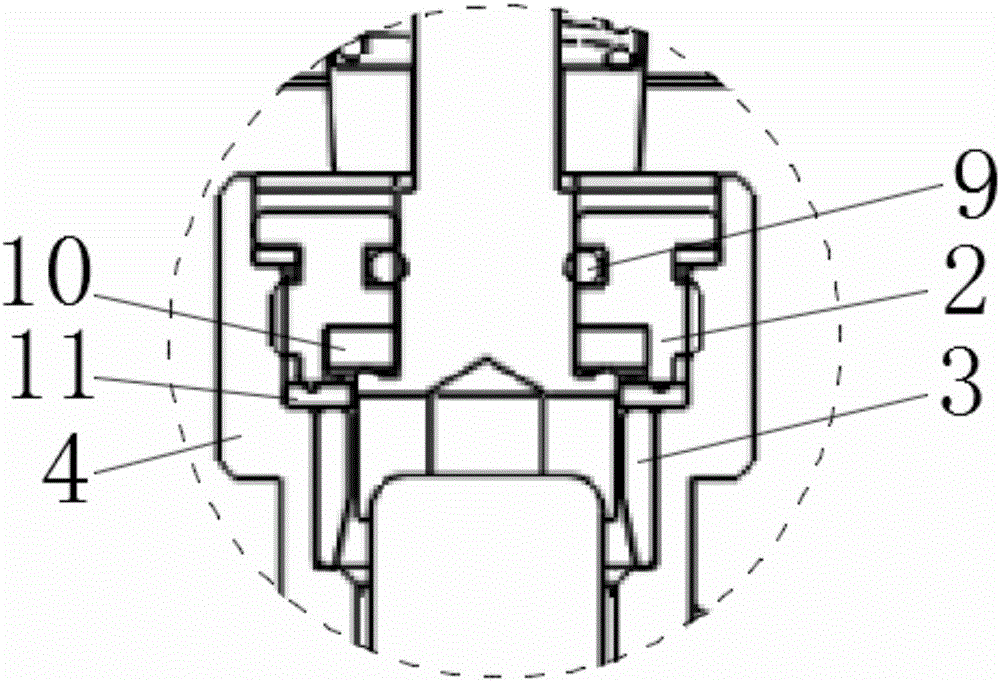

[0066] Embodiment 1: The valve top anti-dismantling device 2.

[0067] Such as Figure 3~10 As shown, the valve top anti-tamper device 2 is integrally formed in a circular shape with a through hole in the middle. An external thread is provided on the outer side wall of the valve top anti-tamper device 2 and is threaded with the valve body 4 through the external thread. The external thread is an interference fit thread. The upper surface edge of the valve top anti-dismantling device 2 is in close contact with the inner wall surface of the valve body 4, and the upper end surface of the valve top anti-dismantling device 2 is provided with two anti-disassembly grooves 21, The two anti-disassembly grooves 21 are symmetrical with the above-mentioned through holes. An interference copper ring 3 is provided under the valve top anti-disassembly device 2, and the outer wall of the interference copper ring 3 is in close contact with the wall surface of the inner cavity of the valve body 4. ...

Embodiment 2

[0071] Example 2: Valve core 5.

[0072] Please refer to the attached Figure 11~17 , The valve core 5 is installed in the cavity of the valve body 4, the upper air inlet end of the valve core 5 communicates with the diversion hole, and the lower air outlet end communicates with the air outlet end of the valve body. The valve core 5 includes a fairing 51 and a valve core The body 52, the sealing plate 53, and the sealing plate card 54;

[0073] The valve core body 52 is cylindrical as a whole, with inclined grooves on its side walls, which separate the upper and lower flow passages of the valve core, and the groove surface of the inclined groove faces the oblique upward direction. An air guiding hole 526 is provided, and a ring of convex ring is arranged on the edge of the air guiding hole 526. The air guiding hole 526 is connected to the dismounting hole 527 at the lower part of the valve core. A disc-shaped boss 525 is also provided on the groove surface of the inclined groove, ...

Embodiment 3

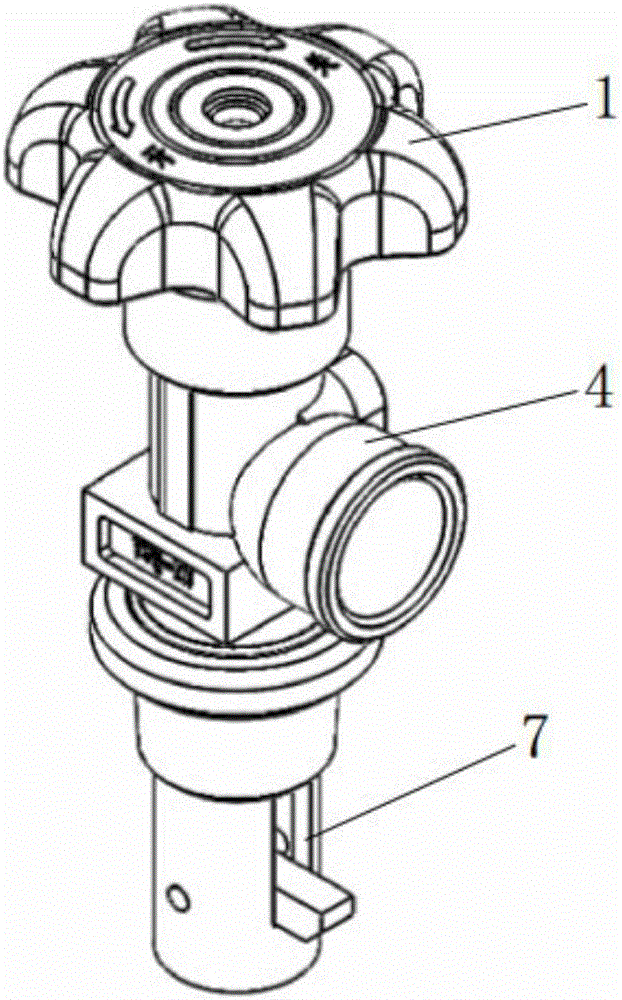

[0084] Embodiment 3: Valve bottom anti-dismantling device 7.

[0085] Please refer to the attached Figure 18~7 1. The valve bottom anti-tamper device 7 is placed under the valve core anti-tamper hole, and the lower part of the valve body 4 is connected to the anti-tamper device. The anti-tamper device includes a filter 71 and an anti-tamper body 76, which is integrally formed, The upper part is a cylinder with a smaller outer diameter, and the lower part is a cylinder with a larger outer diameter. The two cylinders are connected together. A filter 71 is provided at the inlet port of the small cylinder; in the lower area of the large cylinder cavity There are two round holes on the diameter of the cavity wall of the anti-tamper body 76, and a tamper-proof component is arranged between the two round holes. The side wall of the anti-tamper body 76 is vertical and perpendicular to the two round holes. An opening is provided on the linear center plane where it is located, and a ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com