Patents

Literature

95results about How to "No quality problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Auxiliary agent of formulation for dyeing Terylene

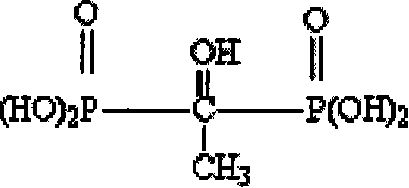

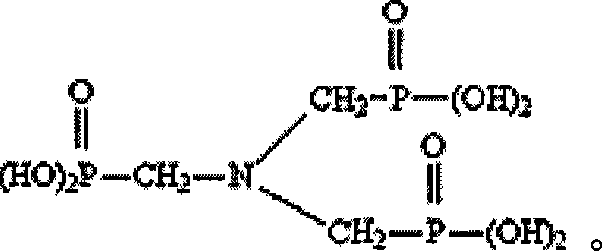

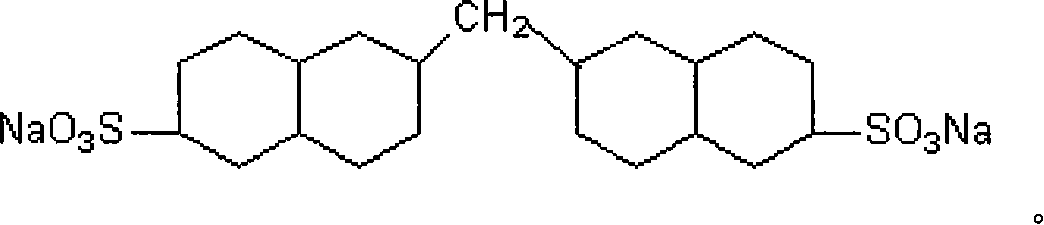

This invention discloses an aid used in terylene dyeing characterizing in including the following components in weight percentage: acid aid 10-20%, organic phosphonic acid 2-5%, organic carboxylic acid 3-7%, naphthalenesulfonate 10-18%, PEG 400 single oleic acid ester 5-8%, non-ion PAA 0-2%, polytrimethylene polyethenoxy aether 0-3% and water.

Owner:夏建明 +1

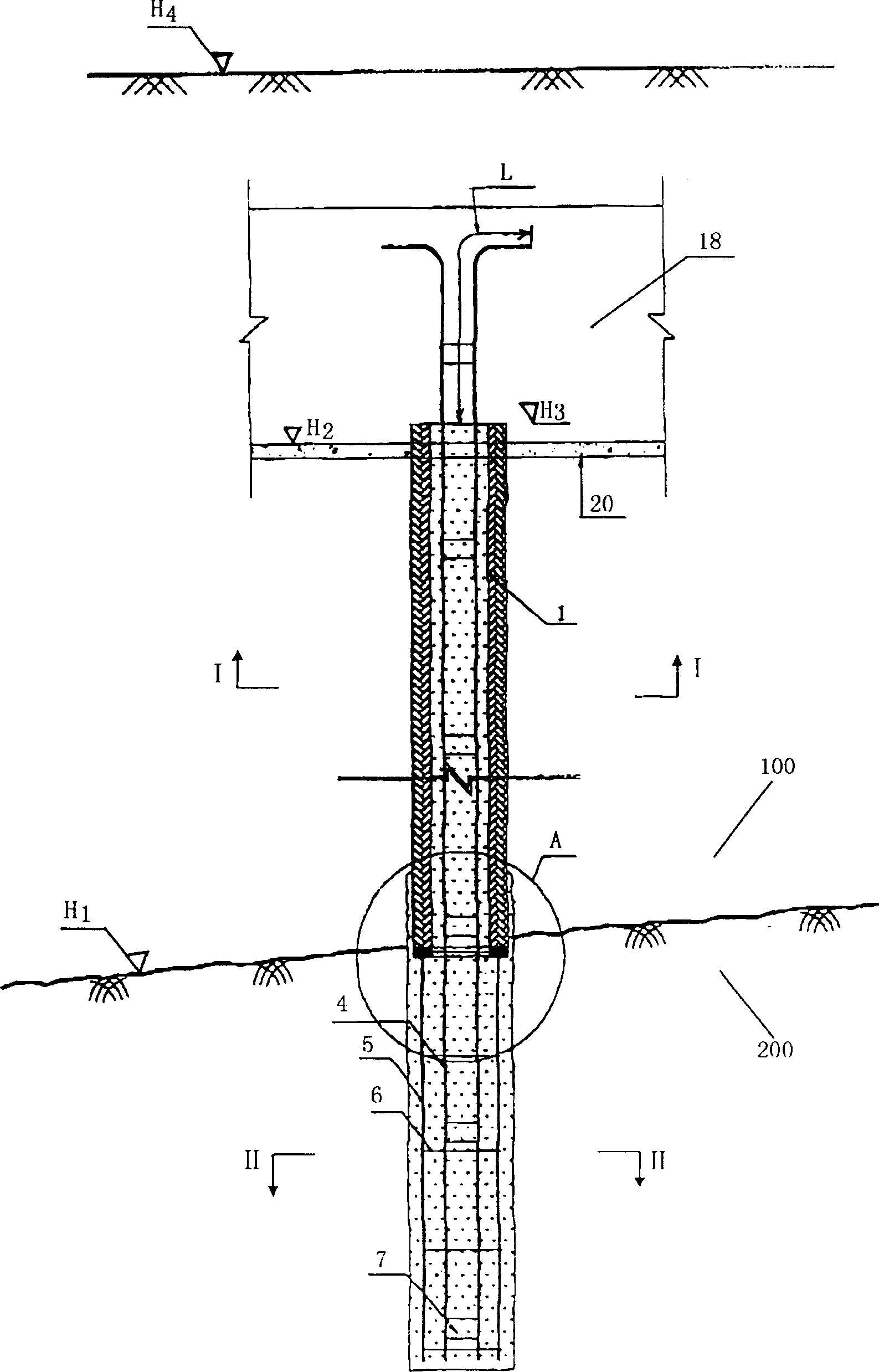

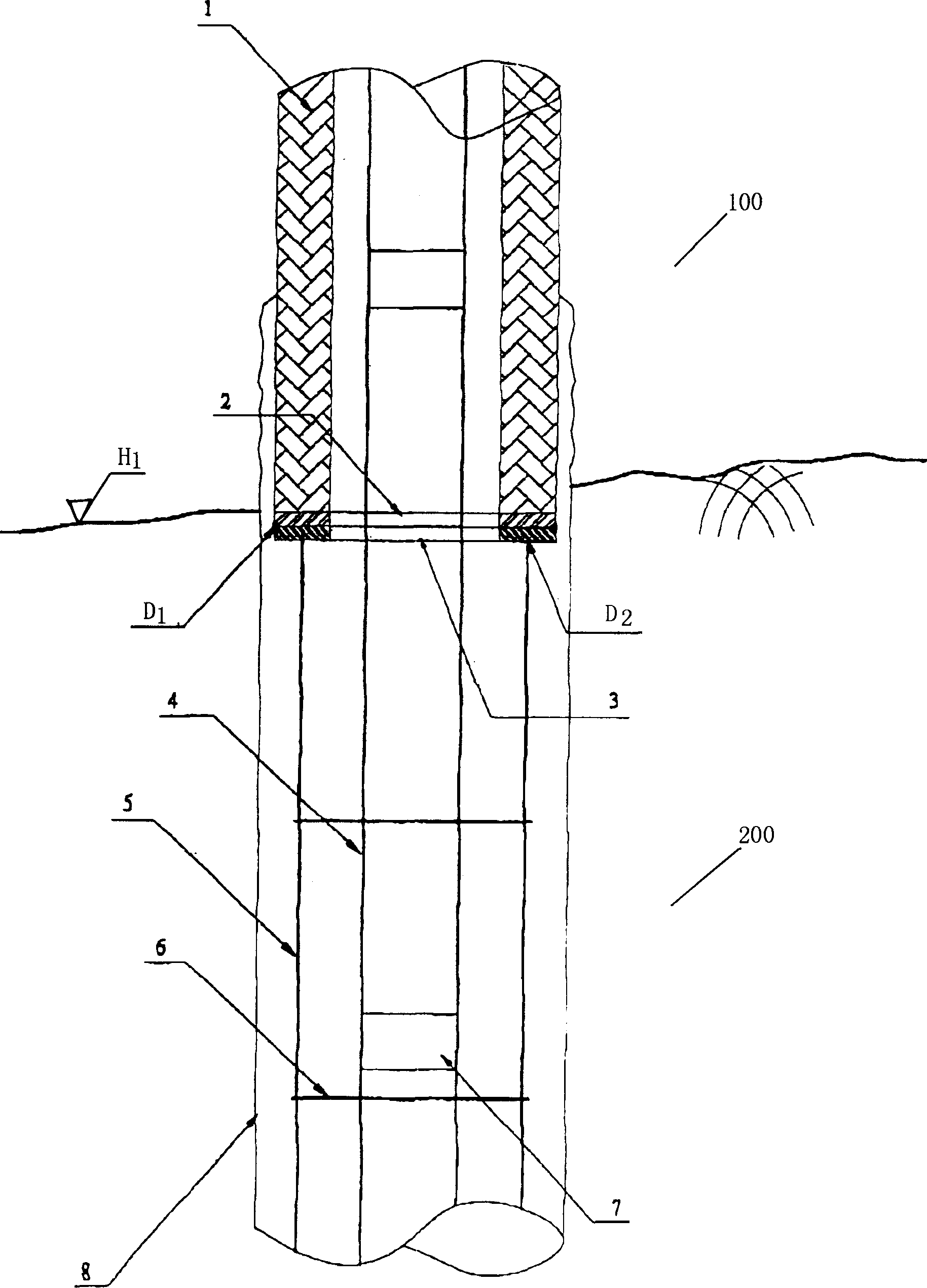

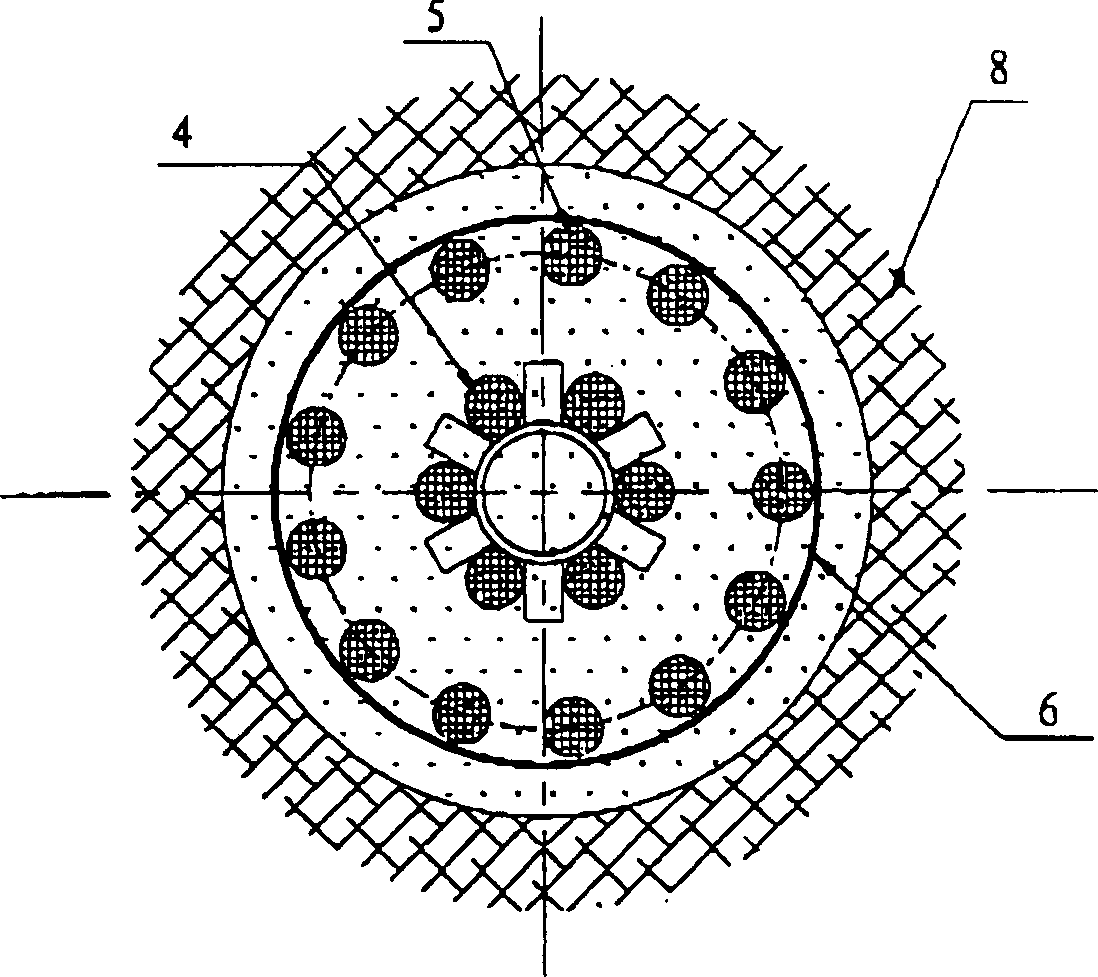

Combined rock-embedding pile and its construction method

A combined pile embedded in rock is constructed through prefabricating reinforced concrete pipe or other pile with reinforcing bars used as the load bearing member in soil layer, embedding the reinforced concrete member or steel member with reinforcing bars in the drilled hole in rock, and grouting in-situ. At least one group of reinforcing bars passes through said member and cast inside it for bearing pressure or pull and improving the integrity of whole pile. Its advantages are high load-bearing power, simple structure and low cost.

Owner:LIJI ENG

Case deep hole processing method and application thereof

InactiveCN110497152AGuaranteed positionPrevent deviationBoring/drilling machinesCyclic processPilot hole

The invention discloses a case deep hole processing method and application thereof in aluminum-magnesium case deep hole processing. The case deep hole processing method comprises the steps of (S1) processing a pilot hole; and (S2) peck drilling and cycling. The peck drilling and cycling step comprises the steps of firstly controlling a long drill bit to enter the pilot hole at low rotary speed; when at a predetermined safety distance away from the working allowance, increasing the rotary speed to the processing rotary speed, then carrying out peck drilling processing, pausing for the predetermined time after drilling for the depth which is 1 to 2 times of the diameter of the drill bit every time in the peck drilling process every time, breaking a produced continuous chip and discharging out of a hole port through the feeding pause of the long drill bit, and retreating the long drill bit to the position at the predetermined drilling depth far away from a drill hole port after peck drilling for the predetermined depth every time so as to remove chips and cool; and repetitively circulating until processing to the target depth. According to the method, in the deep hole peck drilling circulating process, pause and chip breaking is adopted, the position of drill bit retraction is controlled, and the pilot hole is used for guiding and supporting the long drill bit, so that the problems of deflection and unsmoothness in chip removal are effectively avoided, and the processing quality and the stability are ensured.

Owner:CHINA HANGFA SOUTH IND CO LTD

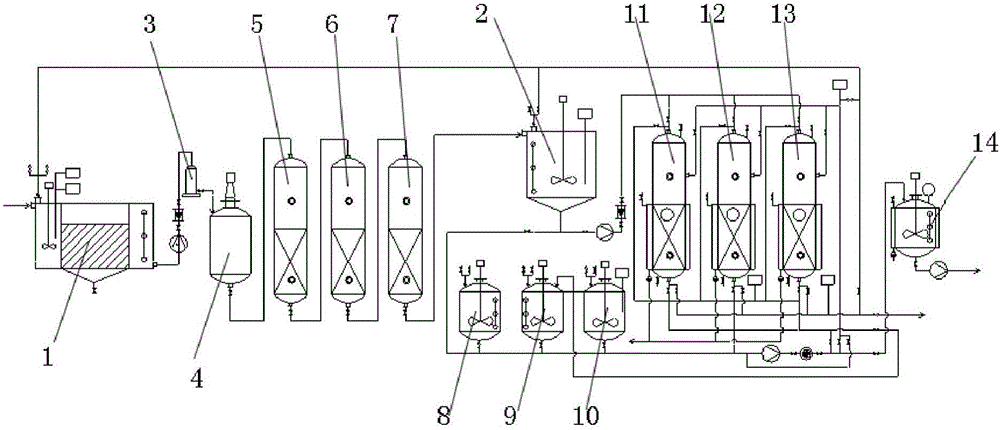

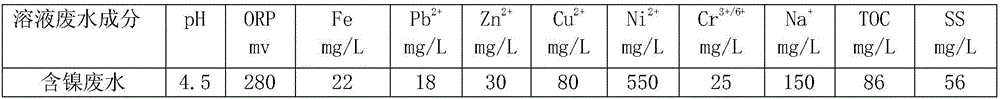

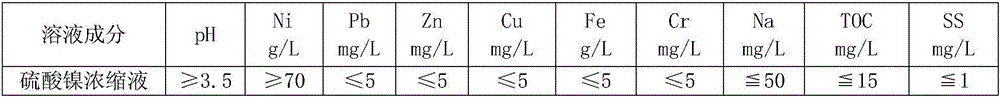

Control technology for extracting and purifying nickel from acid nickel-containing solution

ActiveCN106282560AHigh purityImprove qualityProcess efficiency improvementHigh concentrationNickel salt

The invention relates to a control technology for extracting and purifying nickel from an acid nickel-containing solution. The control technology comprises the technological processes of PH adjustment and oxidation, solid impurity and organic matter removal, foreign ion removal, nickel ion adsorption, cleaning before saturation column regeneration, regeneration and reclaiming agent preparation control, exchange column cleaning, resin conversion, column cleaning after conversion, standby preparation and concentrating. The technical limitations that nickel in an aqueous solution recycled through a traditional ion exchange technology is low in purity, low in concentration and high in acidity are broken through, purifying, extracting and concentrating of the nickel are conducted through combination of a plurality of varieties of ion exchange resin and special processing techniques, a nickel sulfate recovery solution with high purity, high concentration and low acidity is obtained, and the nickel sulfate recovery solution can be directly used for producing high-purity nickel salt, metallic nickel, plated nickel and other nickel products.

Owner:NANJING LINEHOME ENVIRONMENTAL TECH CO LTD

Foamed basalt insulation material and preparation method thereof

InactiveCN107602147AImprove performanceLow thermal conductivityCeramicwareThermal insulationMetallic materials

The invention relates to a foamed basalt insulation material and a preparation method thereof, which belong to the field of the insulation material. The foamed basalt insulation material is prepared by the following main components in parts by weight: 50-90 parts of basalt ore, 0.3-10 parts of a foaming agent, 5-25 parts of a fluxing agent, 3-10 parts of a foam stabilizer, 0.1-0.5 parts of a dispersant, and 0.1-0.7 parts of an auxiliary material, The foamed basalt insulation material is prepared by the steps of crushing, ball milling, spray drying, and foaming. The foamed basalt insulation material is the inorganic non-metallic material having excellent performance, has the advantages of no toxicity and no radiation, low heat conduction coefficient, good thermal insulation performance, andstable chemical property, wherein the pH value is 7-8, the foamed basalt insulation material is neutral or weakly alkaline, and has no corrosion on the metal materials such as carbon steel, stainlesssteel and aluminium; refractiveness is good, the melting point is higher than 1200 DEG C, and a fireproof grade can reach a A-grade standard; and the compressive strength and shearing intensity are high.

Owner:哈尔滨时代创新科技发展有限公司

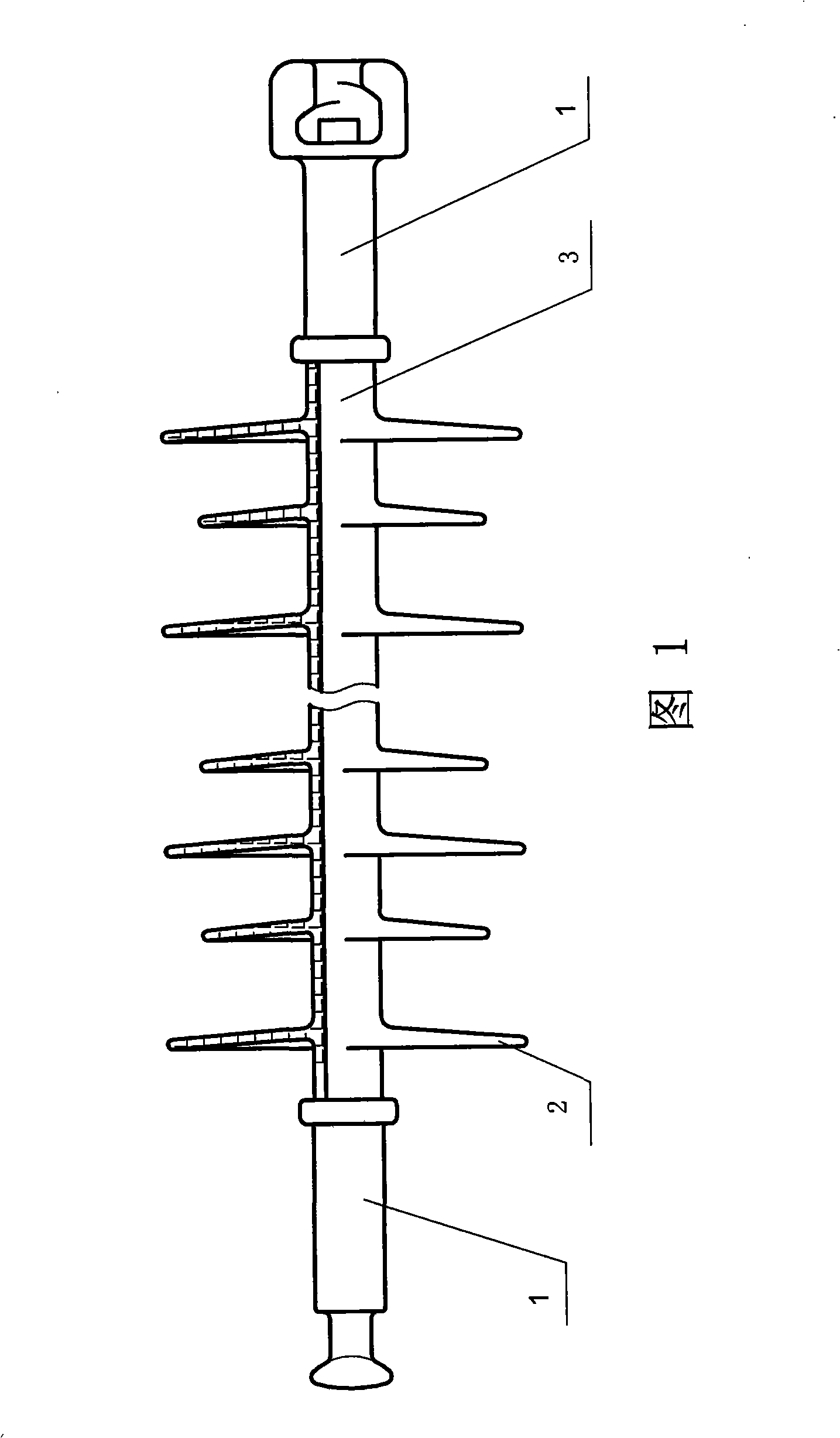

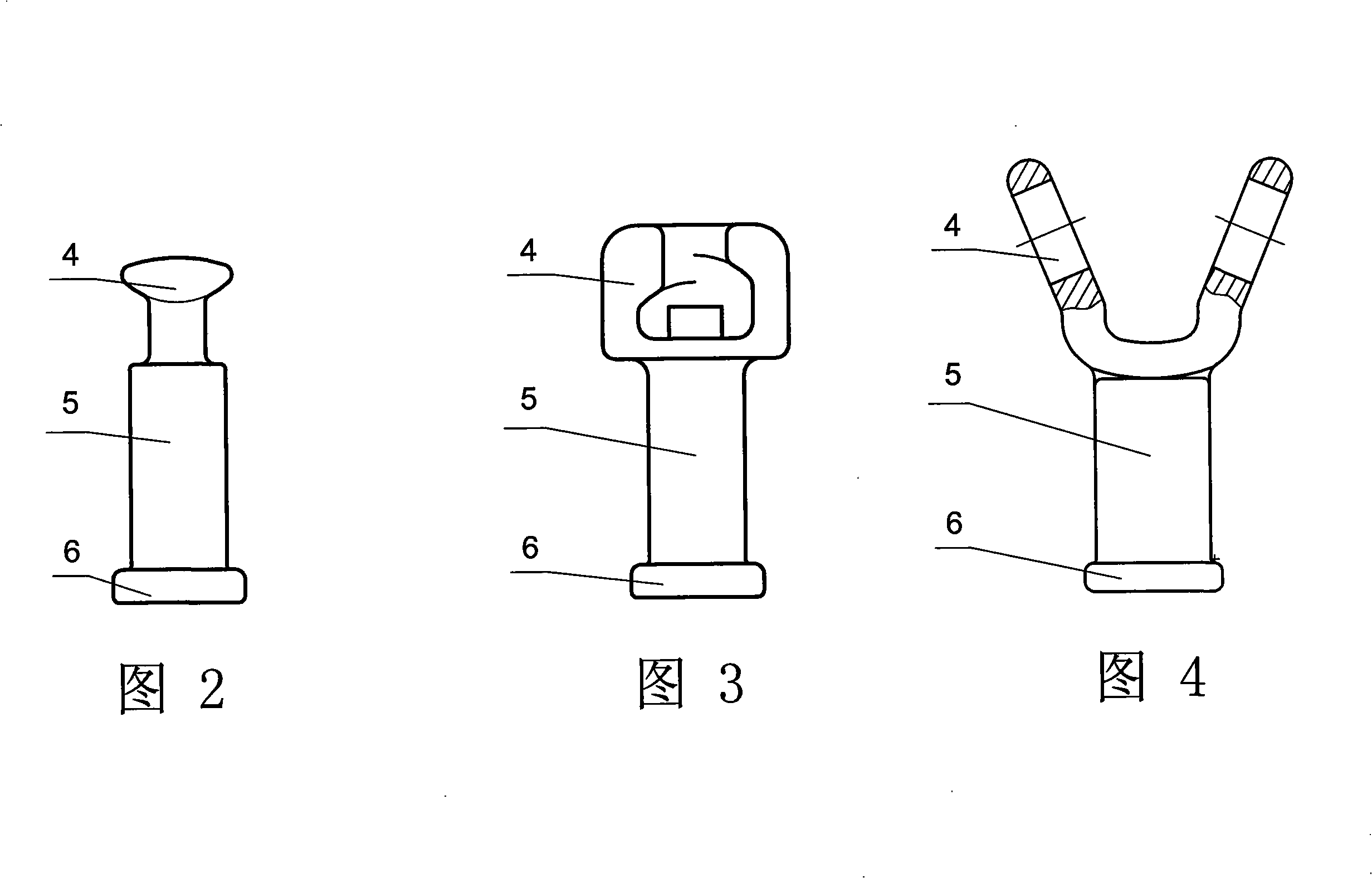

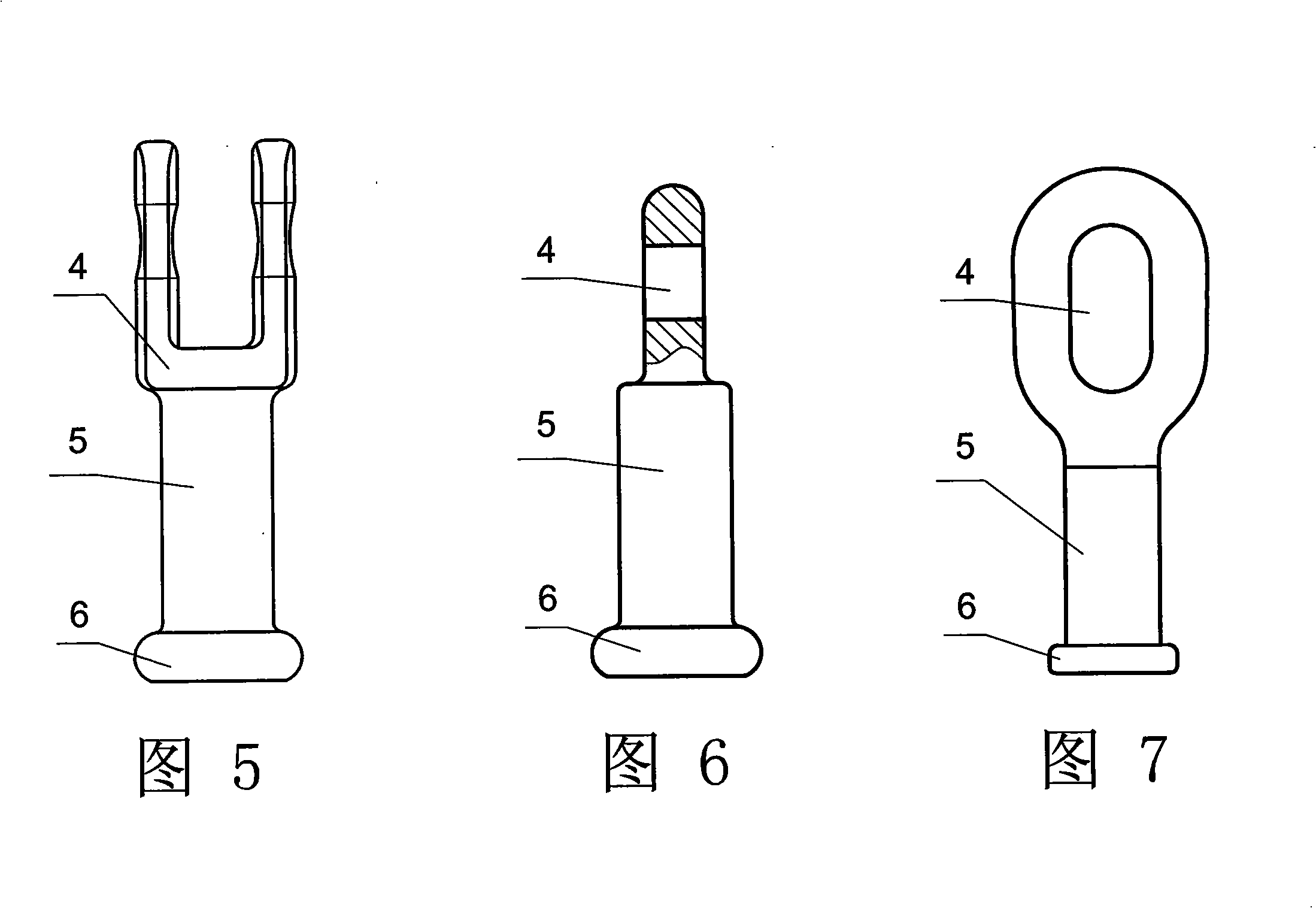

Combined insulator gold tool and method for manufacturing the same

InactiveCN101303925AEasy to industrializeImprove qualitySuspension/strain insulatorsFriction weldingEngineering

The invention discloses a piece of combined insulator hardware and a production method thereof. A standard joint of the combined insulator hardware and a connection bar adopt a split type structure and are fixed together by friction welding. The connection bar and a seal-adhesive seat of the insulator adopt an integrated structure or a split type structure; the connection bar and the seal-adhesive seat are fixed together by friction welding if the connection bar and the seal-adhesive seat adopt a split type structure. The standard joint is a Y-shaped double-ear or a ball head or a ball socket or a U-shaped double-ear or a straight line shaped single ear or a hanging ring-shaped single ear. The production method is that: according to the application characteristics of the specific parts of the hardware, a piece of hardware is divided into two or three parts and respectively produced to satisfy different strength and hardness requirements; then all the parts are fixedly welded together by friction welding technique. By adopting the invention, industrialization of the production of the insulator hardware can be easily realized, product quality and qualified rate in production are enhanced, the working efficiency is improved, the management difficulty in production is reduced and good social and economical benefits can be achieved.

Owner:ZHENGZHOU JINGWEI ELECTRIC POWER TECH

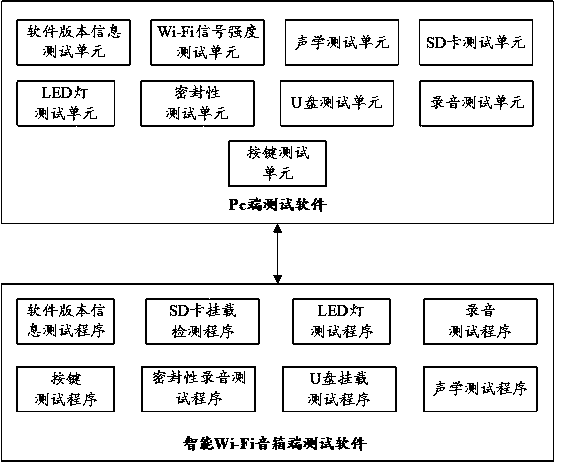

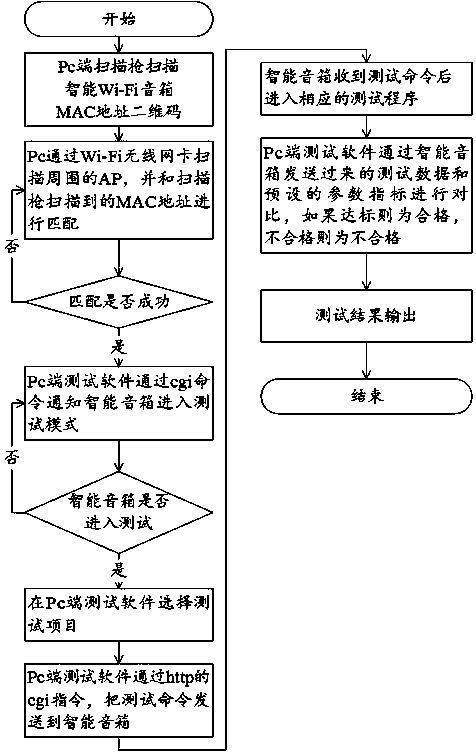

Intelligent Wi-Fi sound box automatic production test system and method

InactiveCN110446150AGuaranteed functionSealing up to standardElectrical apparatusWi-FiProduction line

The invention belongs to the field of acoustic equipment automatic detection equipment and use methods, and particularly relates to an intelligent Wi-Fi sound box automatic production test system andmethod, and the system comprises Pc end test software, sound box end test software and a scanning gun. When the intelligent Wi-Fi sound box is tested, a tester opens Pc end test software, and when theintelligent Wi-Fi sound box is connected to the tested intelligent Wi-Fi sound box, a test item is selected for testing; the test items comprise version information, Wi-Fi signal intensity, acoustics, USB flash disk or SD card mounting, recording, keys, sealing performance and LED lamps. The beneficial effects are that through automatic test programs of the Pc end and the intelligent Wi-Fi soundbox end, the free cutting space of testers is reduced, the requirement for professional knowledge ability of production line testers is reduced, and the production cost is reduced while the productionefficiency is improved for the production line.

Owner:厦门市思芯微科技有限公司

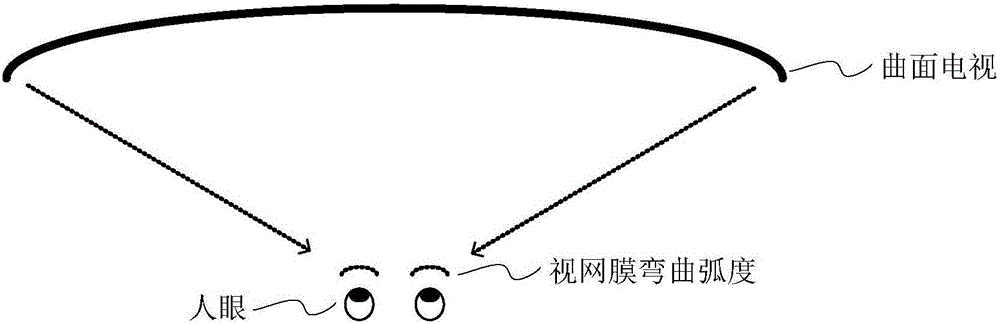

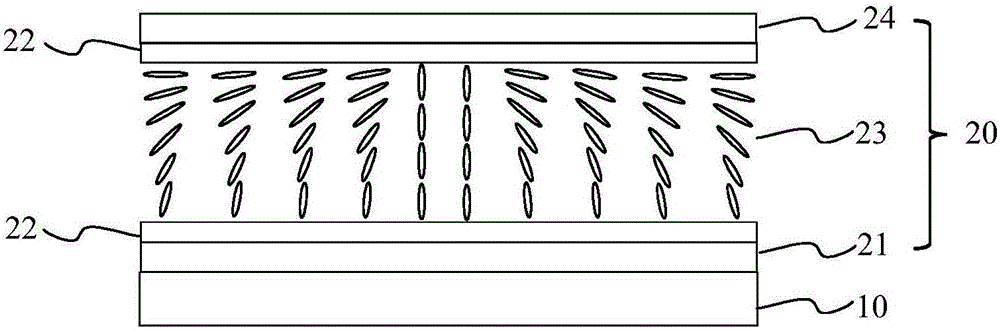

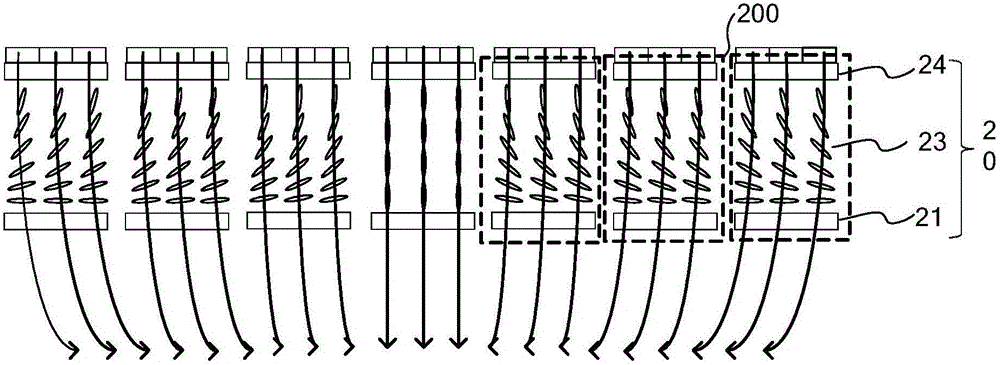

Liquid crystal lens, display device and hook face display method

ActiveCN106094386ASimple structureProduction process compatibleNon-linear opticsPhysical spaceLiquid-crystal display

The invention discloses a liquid crystal lens, a display device and a hook face display method and relates to the display field. Hook face display can be achieved, manufacturing is easy, cost is low, service life is long, and occupied physical space is small. The liquid crystal lens is used for being attached to the outer side of a flat panel display device to realize the hook face display effect and comprises multiple lens units. Each lens unit comprises a liquid crystal layer, an orientation layer, a first electrode and a second electrode, wherein the first electrode and the second electrode are used for driving the liquid crystal layer. The lens units are independently driven so that the refractive indexes of the lens units arranged along an equivalent hook face can become larger gradually from a position corresponding to the optimal observation point to two sides.

Owner:BOE TECH GRP CO LTD +1

Biological essence polypeptide composition as well as preparation method and application of lipidosome nanocrystallization of biological essence polypeptide composition

PendingCN113576939ANo quality problemsGood storage stabilityCosmetic preparationsToilet preparationsFacial skinPolypeptide composition

The invention relates to a biological essence and polypeptide composition as well as technical preparation and application of lipidosome nanocrystallization of the biological essence and polypeptide composition. The composition is prepared from oligopeptide-1, tripeptide-1, hexapeptide-9, palmitoyl pentapeptide-4, palmitoyl tripeptide-5, palmitoyl tetrapeptide-7, algal polysaccharides, a moutan bark extract, a radix scutellariae extract, arbutin, a stephania tetrandra extract, a radix gentianae extract, a citrus extract, a chamomilla recutita flower extract, a polygonum cuspidatum extract, a centella asiatica extract and water. According to the invention, human skin tests show that facial skin problems, such as darkness, stains, wrinkles and the like, can be remarkably improved, and the compound liposome of the plant essence and the polypeptide composition has the effect of remarkably improving the skin problems.

Owner:北京清大赛尔生物科技有限公司

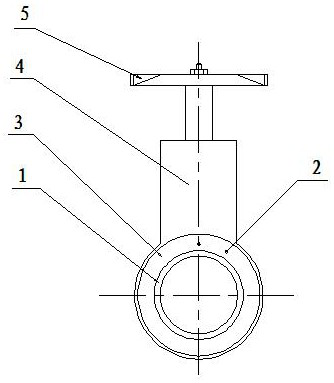

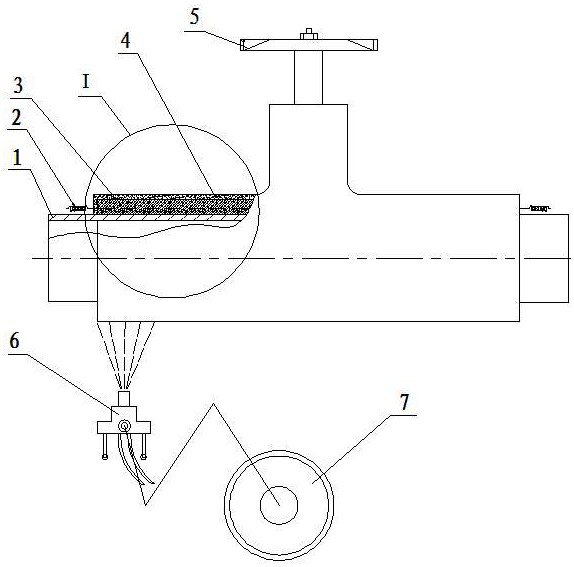

Valve body lost mould and using method thereof

ActiveCN105215287AHigh precisionProlong clotting timeFoundry mouldsFoundry coresAfter treatmentMaterials science

The invention discloses a valve body lost mould and a using method thereof. The valve body lost mould comprises a lost mould, a sprue cup and an ingate, wherein the lost mould comprises a sealing surface and a valve seat; the ingate is divided into a straight pouring gate, a transverse pouring gate, a vertical pouring gate and a flow gate; the flow gate is arranged on a joint of the transverse pouring gate and the vertical pouring gate; the sprue cup is connected with the straight pouring gate; the straight pouring gate is connected with a second transverse pouring gate; a sealing surface is arranged on the upper part of the flow gate; and the valve body is parallel to the transverse pouring gate. The using method of the valve body lost mould comprises eleven operation steps. A method for inversely casting a valve body is adopted, and the sealing surface in the valve body is connected with the ingate, so that pouring liquor coagulation time of a sealing surface part can be delayed, the precision of the sealing surface is improved, the principle that the important surface faces downwards in foundry practice is satisfied, the yield can be increased by 7-10%, and the after-treatment cost can be reduced by 10-30%; and meanwhile, the bottom is free of a quality problem, and materials and labor power can be saved.

Owner:埃维柯精密铸造(安徽)有限公司

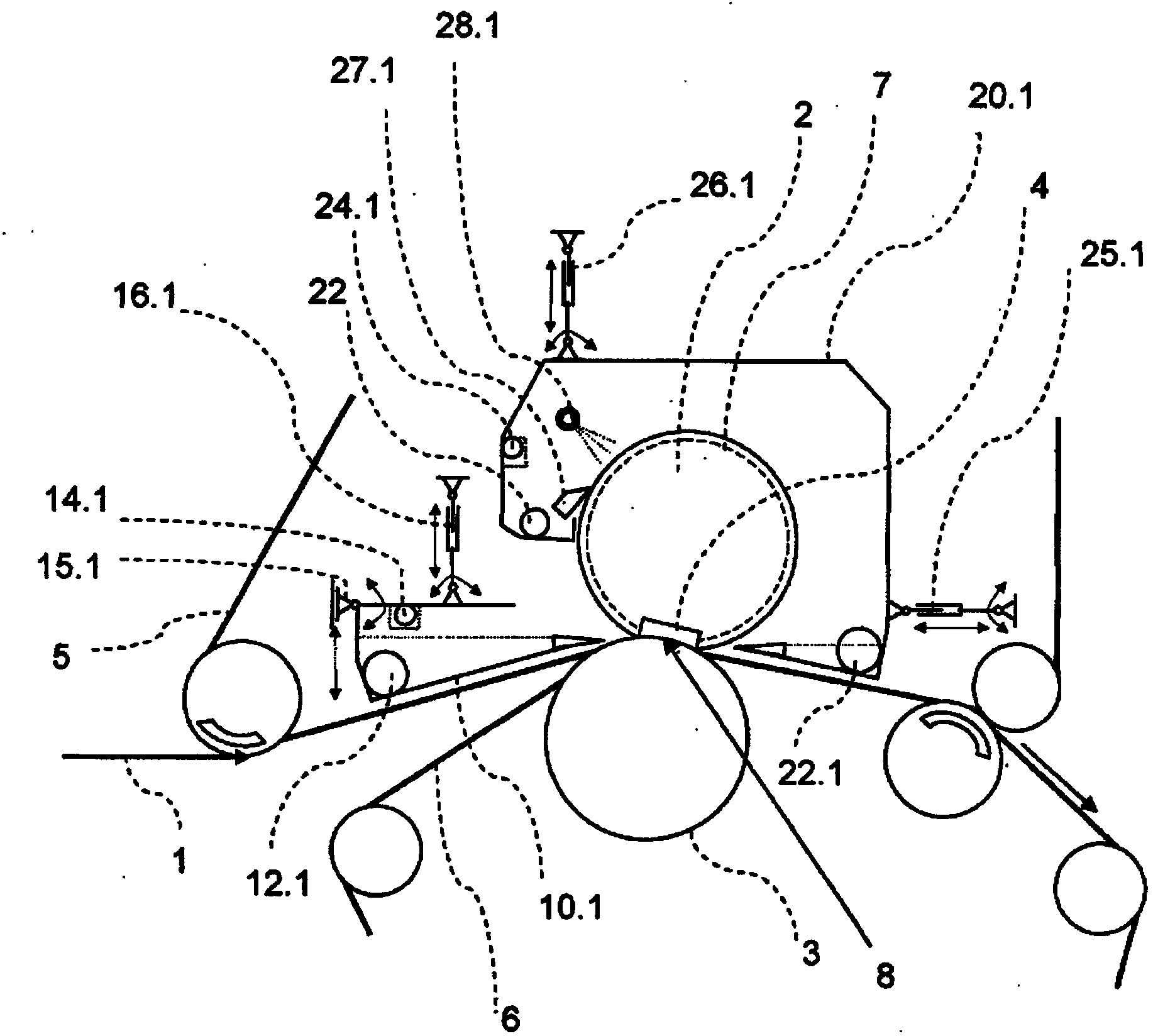

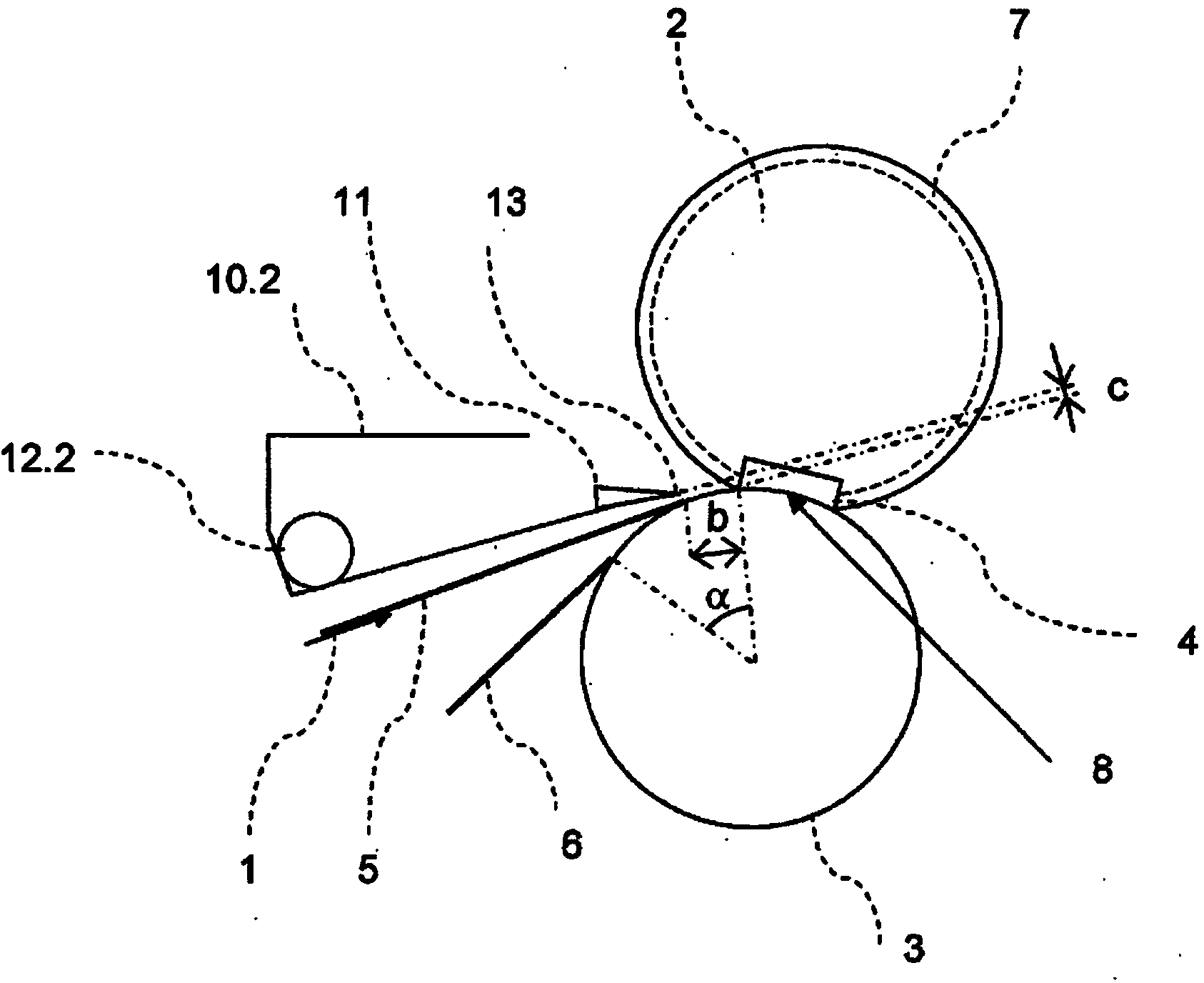

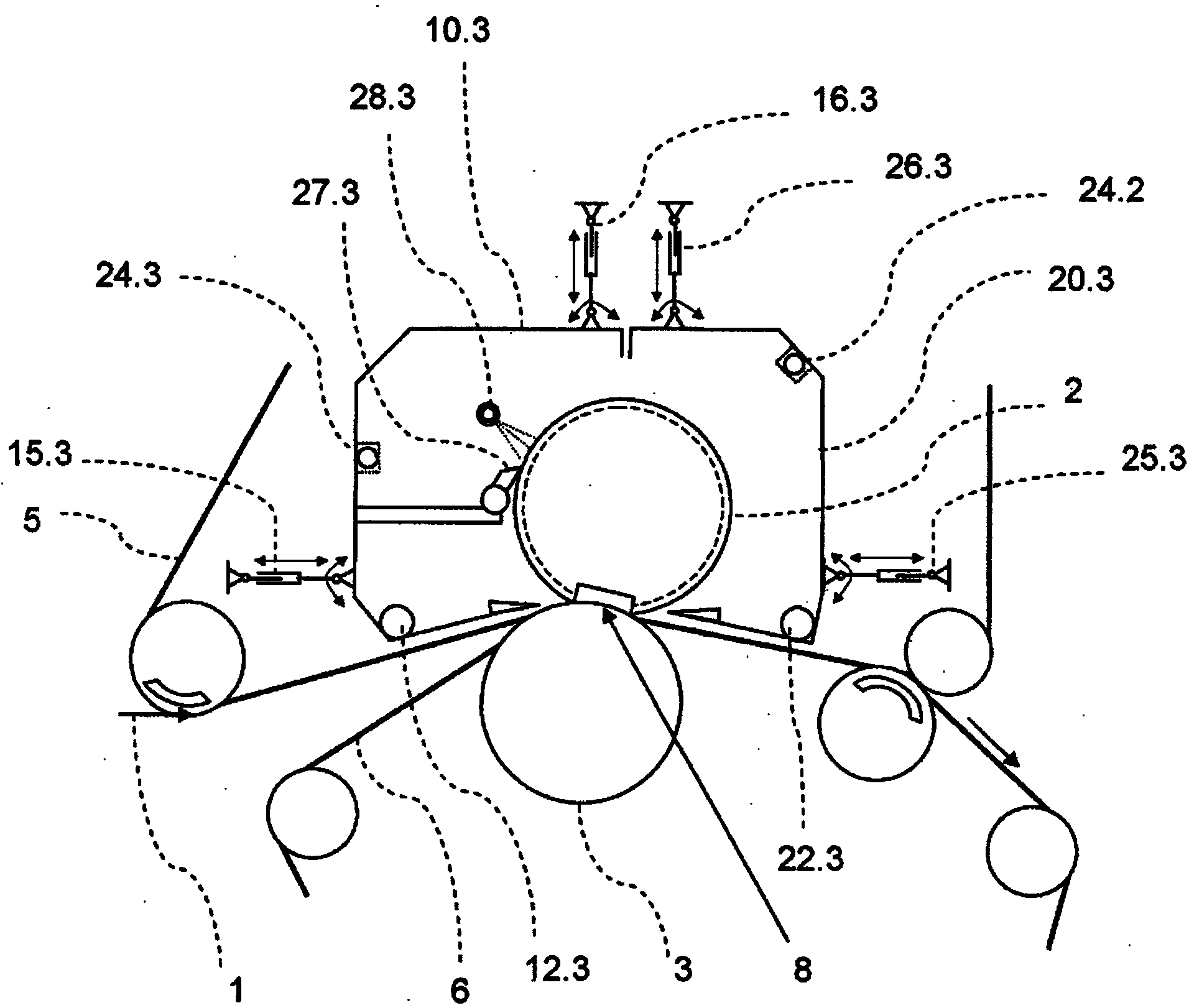

Press section of a machine for producing a fibrous web

The invention relates to a press section for dewatering in a machine for producing a fibrous web (1), in particular a paper, cardboard, or tissue web, comprising a shoe press nip (8) formed by a press roll (2) and a counter roll (3), wherein the press roll (2) has a circumferential flexible cylindrical surface, a supporting stationary yoke, a pressing element (4), and press-on devices, and wherein the press-on devices press the pressing element (4) against the cylindrical surface (7) and thus the cylindrical surface (7) against the counter roll (3), and wherein a collecting tray (20.1, 20.3, 20.4) is provided downstream of the shoe press nip (8) in the running direction of the web; the cylindrical surface (7) is grooved, wherein the length of the grooves in the circumferential direction is greater than the nip length (L), and a collecting tray (10.1, 10.2, 10.3, 10.4) is provided upstream of the shoe press nip (8) on the side of the press roll (2) so that a large amount of water sprays back from the shoe press nip in a direction opposite the running direction of the web and contributes to the improvement of the dewatering performance.

Owner:VOITH PATENT GMBH

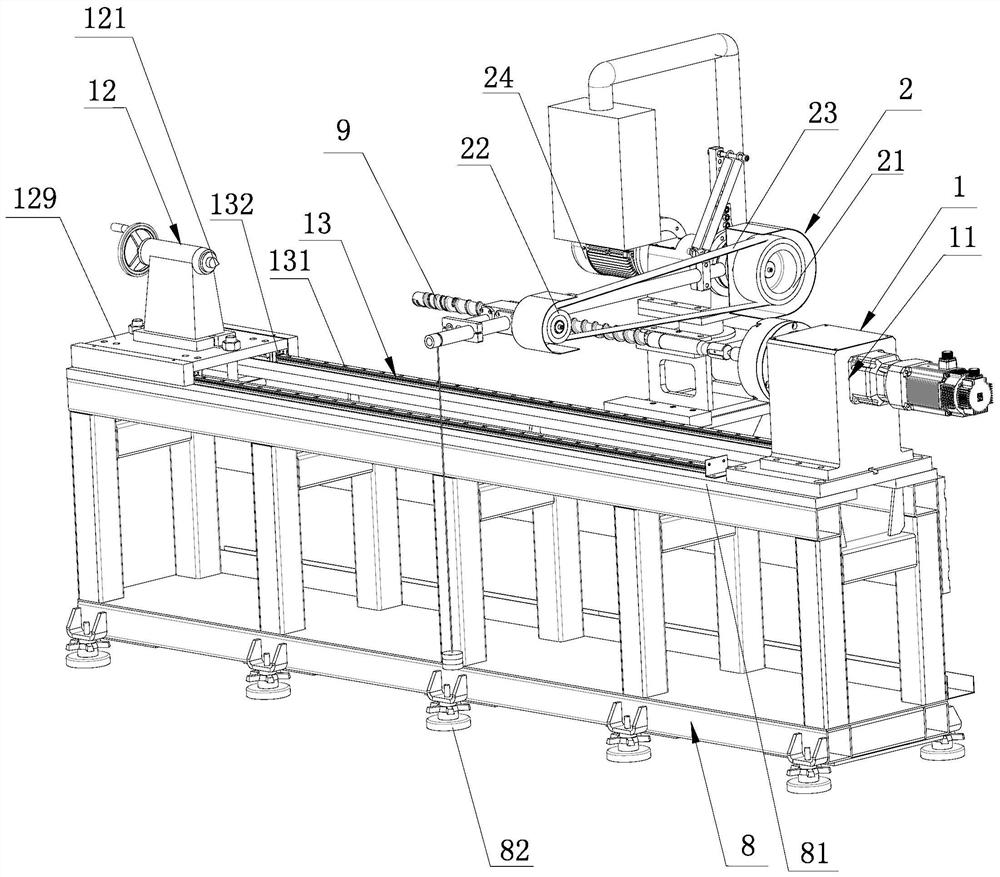

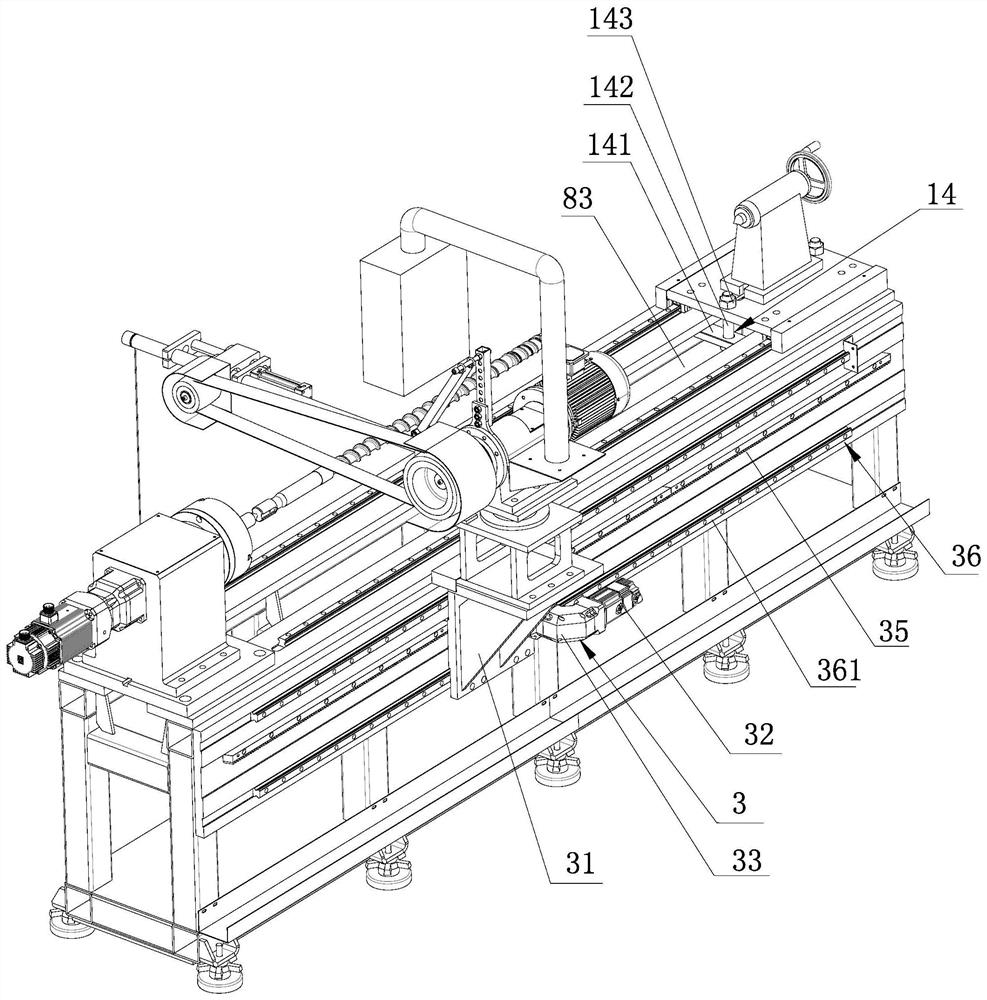

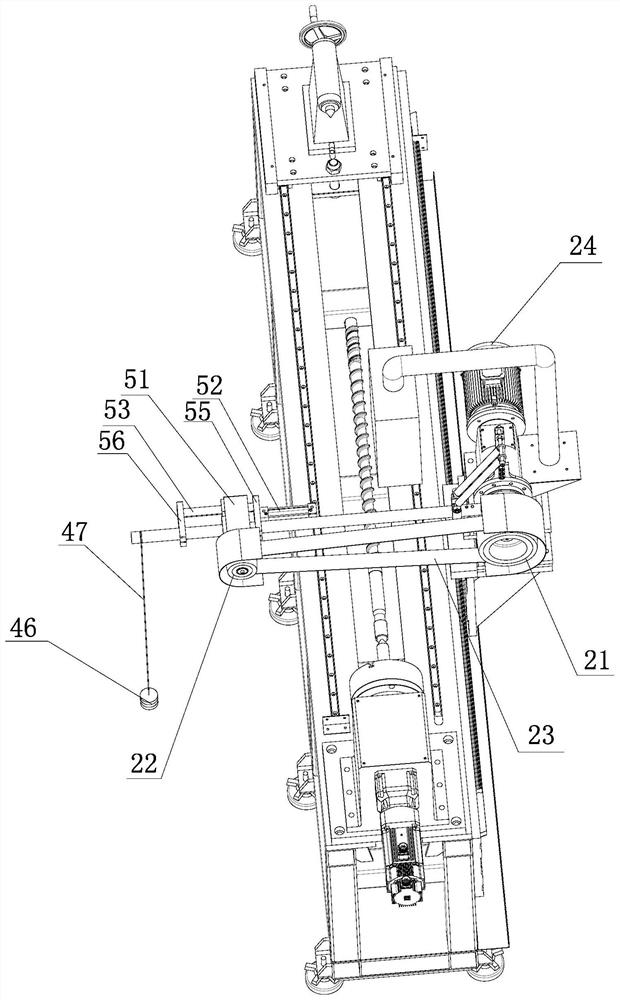

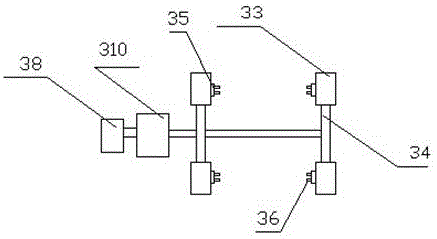

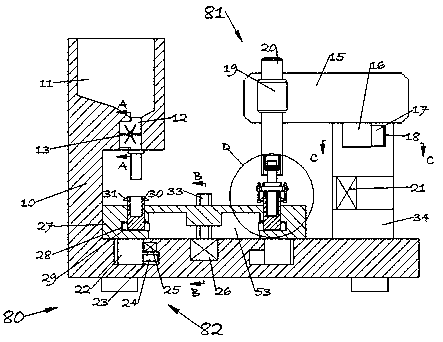

Screw rod polishing and trimming all-in-one machine

ActiveCN113182992AHigh degree of automationControllable polishing qualityGrinding carriagesBelt grinding machinesDrive wheelElectric machinery

The invention discloses a screw rod polishing and trimming all-in-one machine which comprises a main shaft tail base rotating mechanism, a polishing wheel high-speed rotating mechanism, a sanding belt feeding transmission mechanism, a mechanical balance weight pressure control mechanism and a trimming wheel. The main shaft tail base rotating mechanism is used for clamping a screw rod and enabling the screw rod to rotate at a constant speed. The polishing wheel high-speed rotating mechanism is composed of a driving wheel, a driven wheel, a sanding belt tensioned between the driving wheel and the driven wheel, and a high-rotating-speed motor used for driving the driving wheel to drive the sanding belt to rotate at a high speed. The angle of the sanding belt is consistent with that of the lead angle of the screw rod clamped by the main shaft tail base rotating mechanism. The sanding belt feeding transmission mechanism is used for automatically feeding the sanding belt at a constant speed according to the screw pitch of the screw rod clamped by the main shaft tail base rotating mechanism. The mechanical balance weight pressure control mechanism is used for enabling the sanding belt to press down constant down pressure on the bottom diameter and the rear angle of the screw rod clamped by the main shaft tail base rotating mechanism to polish the bottom diameter and the rear angle of the screw rod. The trimming wheel is used for trimming the angle between the front angle and the bottom diameter of the screw rod clamped by the main shaft tail base rotating mechanism into a 90-degree angle. The machine has the advantages of being high in automation degree and stable in polishing and trimming quality.

Owner:HAITIAN PLASTICS MACHINERY GRP

A construction method for rapidly filling a subgrade in road construction

InactiveCN107747259AStable structureNo quality problemsRoadwaysEmbankmentsNatural disasterEngineering

The invention discloses a construction method for quickly filling a subgrade in road construction, which comprises the following steps: lofting, surface cleaning, rolling before filling, layered filling, subgrade forming, and side slope shaping. This method can make the subgrade structure stable through a reasonable and standardized treatment method, and there will be no quality problems in subsequent use, which ensures the service life of the road, enhances the ability to resist natural disasters, and solves the existing problem of simple treatment of the subgrade. , did not adopt a standardized treatment method, resulting in problems with the roadbed after a period of use, resulting in settlement of the road, and even road interruption.

Owner:曾时

Water-resisting material for communication optical cable and preparation method thereof

InactiveCN1434095AThere will be no quality problems of sheddingNo quality problemsOther chemical processesInsulatorsYarnAlcohol

The present invention relates to a communication optical cable water-resisting material for wrapping and filling the communication optical cable and its preparation method. Said communication opticalcable water-resisting material is formed from water-expandable water-resisting coating material, special non-woven fabric and aramid fibre yarn. It is characterized by that said water-expandable water-resisting coating material is composed of (wt%) 22-42% of superstrong water-absorbing agent, 1-30% of adhesive and 42-62% of anhydrous alcohol solution. Said water-expandable water-resisting agent can be roll-coated on the special non-woven fabric or immersion-coated on the aramide fibre yarn. Said invention also provides its preparation method.

Owner:WUHAN 21TH CENTURY CHEM MATERIAL

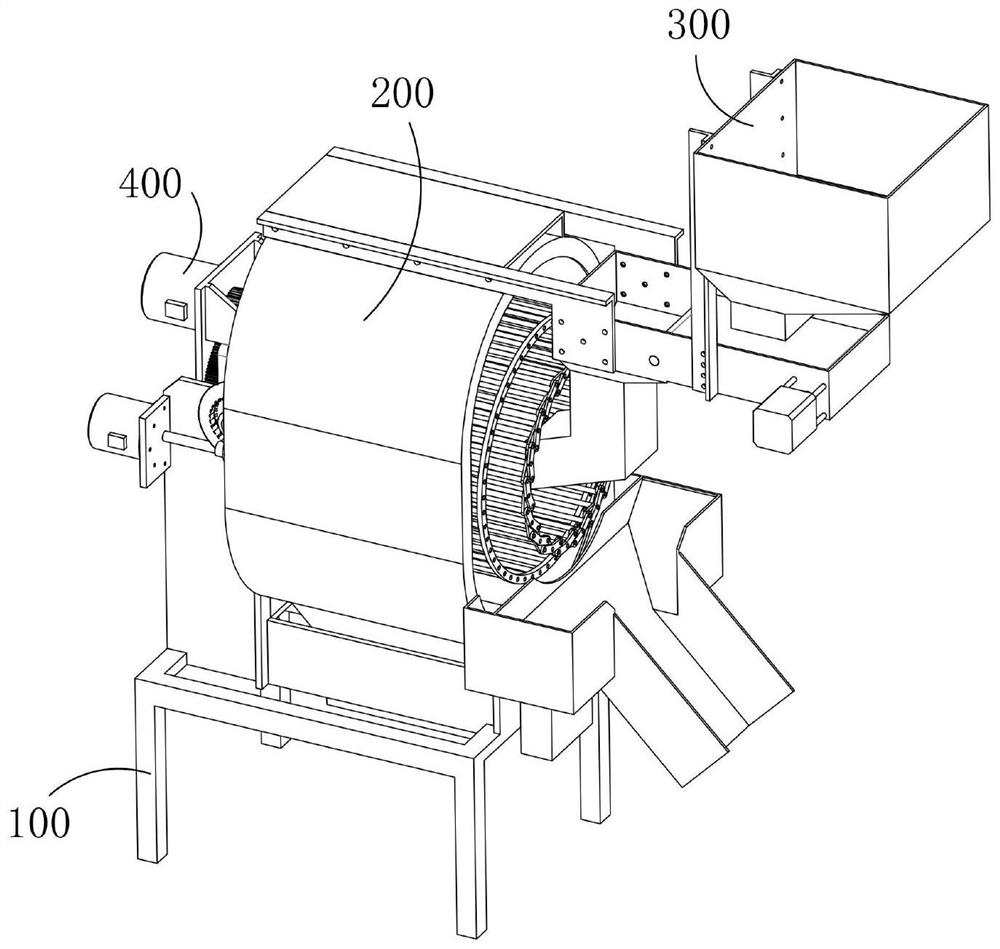

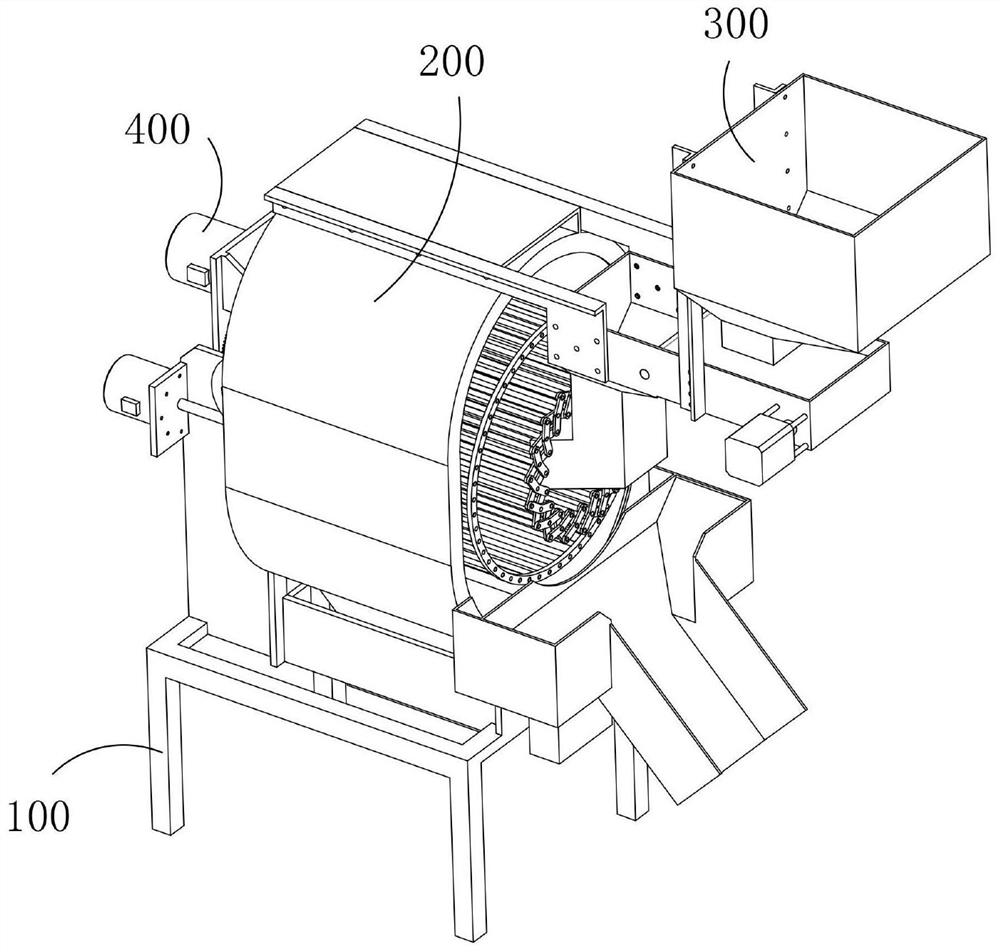

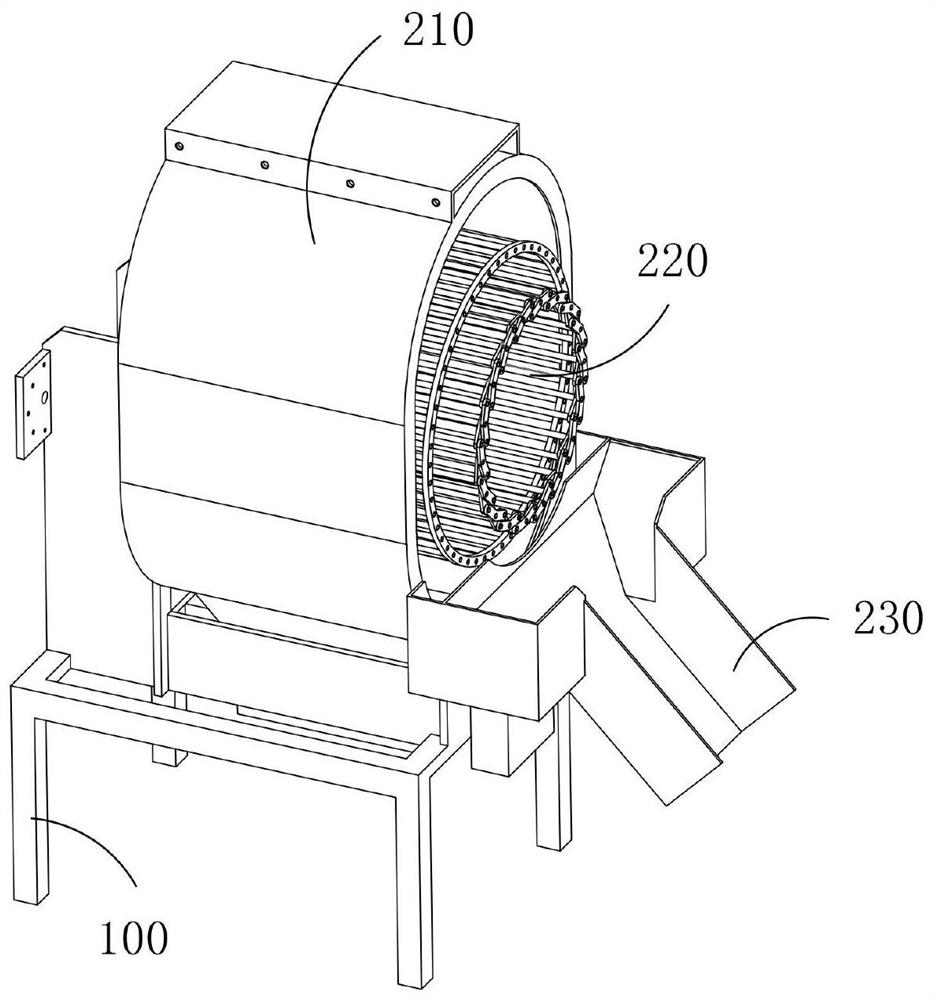

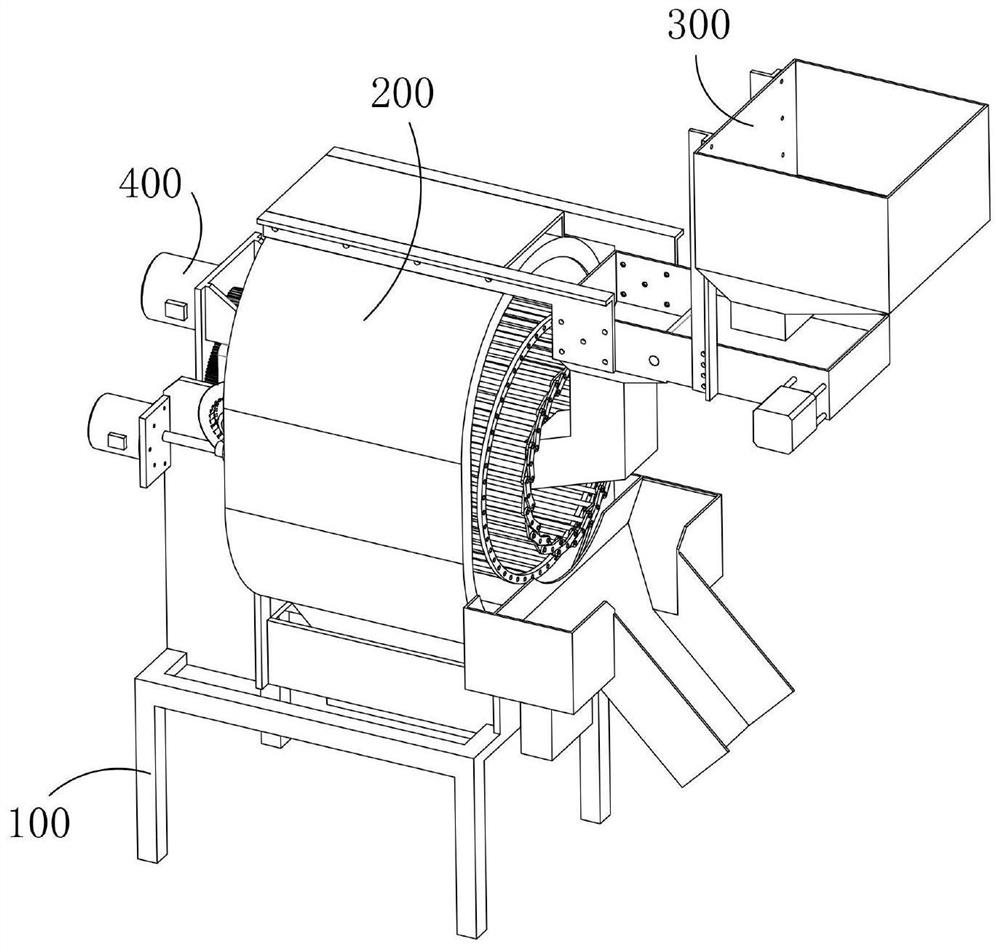

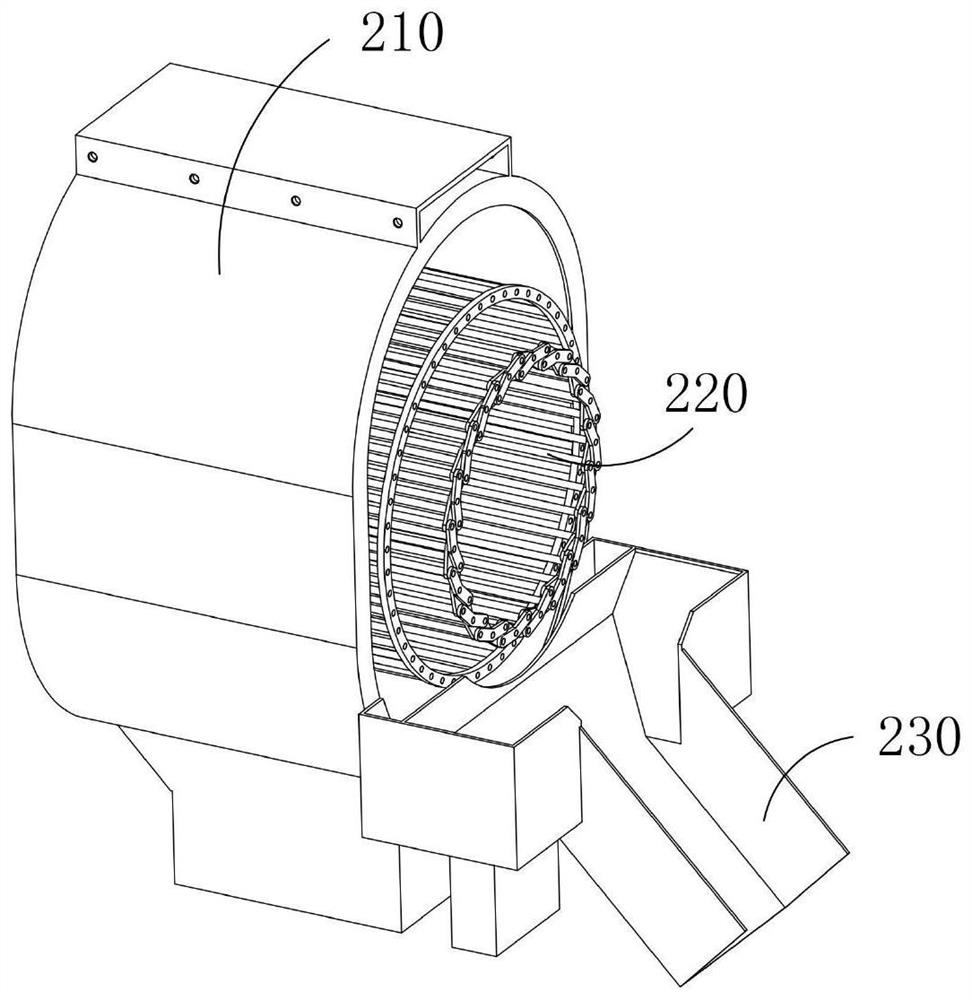

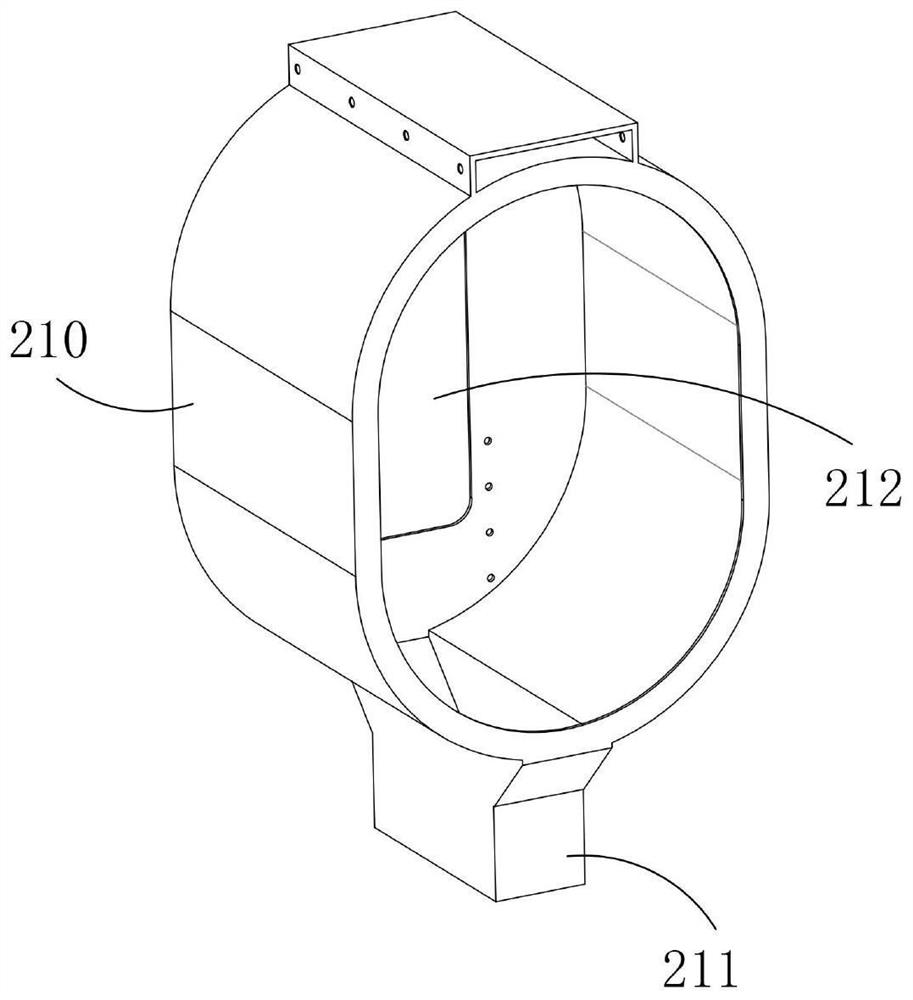

Tea leaf sorting machine capable of improving tea leaf quality

InactiveCN111921832AReduce work intensityImprove classification and screening efficiencySievingScreeningTea leafHorticulture

The invention provides a tea leaf sorting machine capable of improving tea leaf quality. The tea leaf sorting machine comprises a main frame body installed on the ground, the main frame body is provided with a multi-stage sorting device, a guide feeding device and an auxiliary sorting device, and the guide feeding device is used for guiding tea leaves to be sorted to fall into the multi-stage sorting device; the multi-stage sorting device is used for carrying out multi-stage classification screening on the tea leaves according to the sizes of the tea leaves; and the auxiliary sorting device isused for assisting the tea leaf classification screening process and the tea leaf discharging process of the multi-stage sorting device and realizing rapid screening and discharging of the tea leaves. The tea leaf sorting machine is used for screening and classifying the tea leaves to obtain three kinds of tea leaves with different sizes, the whole tea leaf screening process is fully automatic, atea farmer only needs to pour the tea leaves to be screened into the guide feeding device, the working intensity of the tea farmer is greatly reduced, and the tea leaf classifying and screening efficiency is improved; and the tea leaf screening equipment not only can classify the tea leaves, but also can remove impurities from the tea leaves according to different sizes of the tea leaves and impurities.

Owner:安徽硕景机电设计服务有限公司

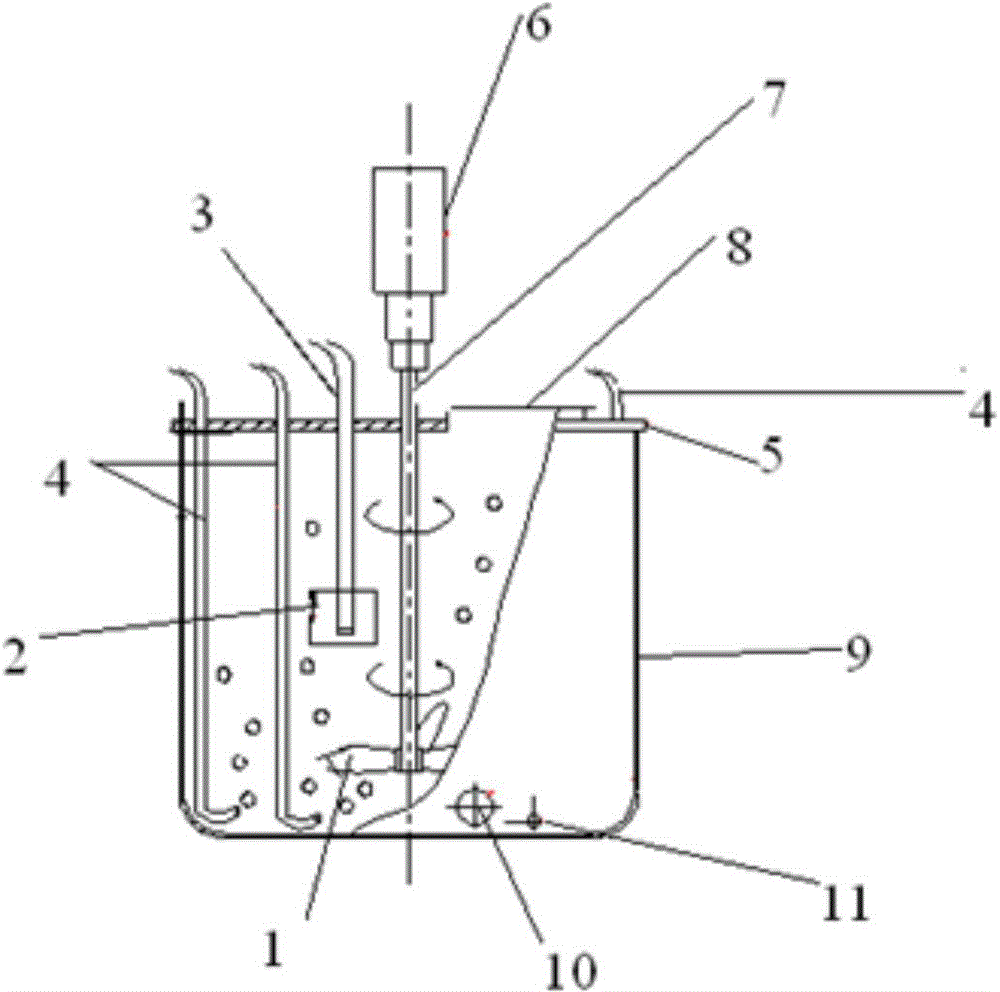

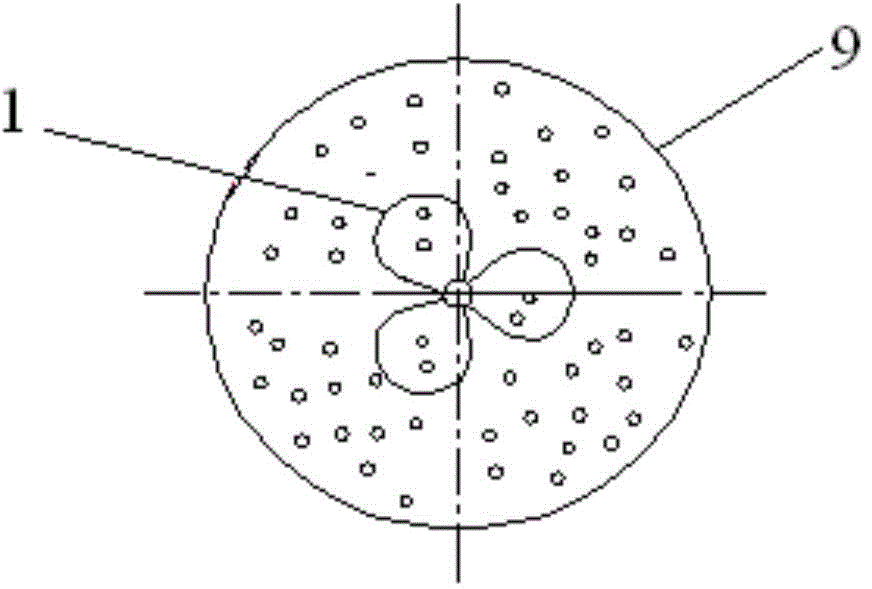

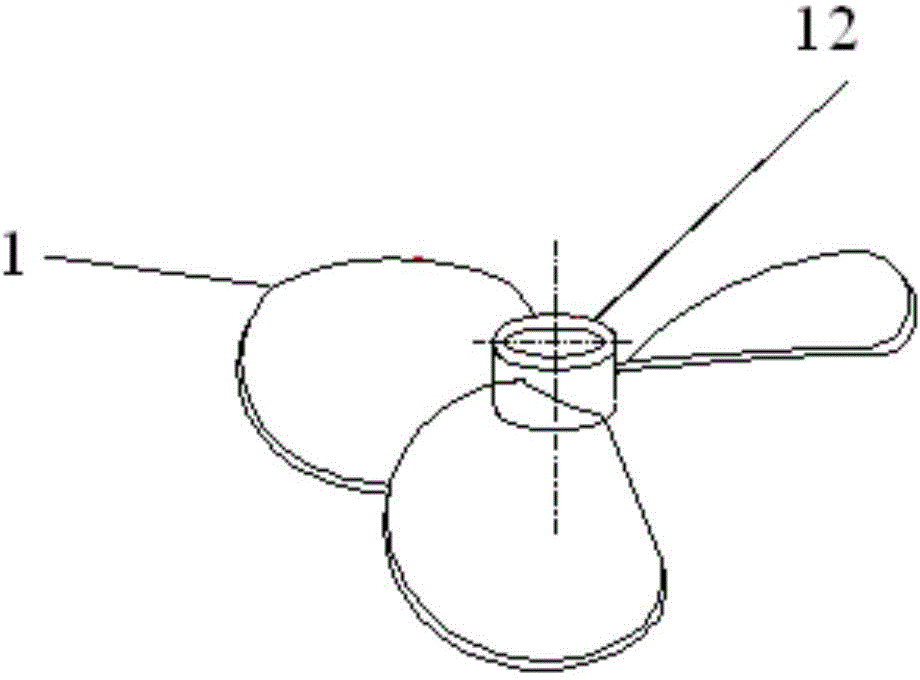

Glue mixing apparatus

ActiveCN105983361AGuaranteed cleanlinessAchieve the purpose of cleaningMixersImpellerPower apparatus

The invention relates to a glue mixing apparatus which includes a glue mixing tank and a uniform power apparatus. The glue mixing tank comprises a tank body (9), and a tank cover (5) which covers an opening of the tank body (9). The uniform power apparatus includes a motor (6), a stirring impeller, and a rotating shaft (7) connecting the motor (6) to the stirring impeller. The apparatus also includes a gas filling device and a backflow device (2). The gas filling device includes a plurality of gas inlet pipes (4) which are directly stretched to the bottom of the tank body (9). The backflow device (2) includes a backflow pipe (3). The stirring impeller is composed of a plurality of elliptic-ladle-shaped blades (1). Compared with the prior art, the apparatus has simple structure, can mix the glue uniformly and is convenient to clean.

Owner:上海东冠纸业有限公司

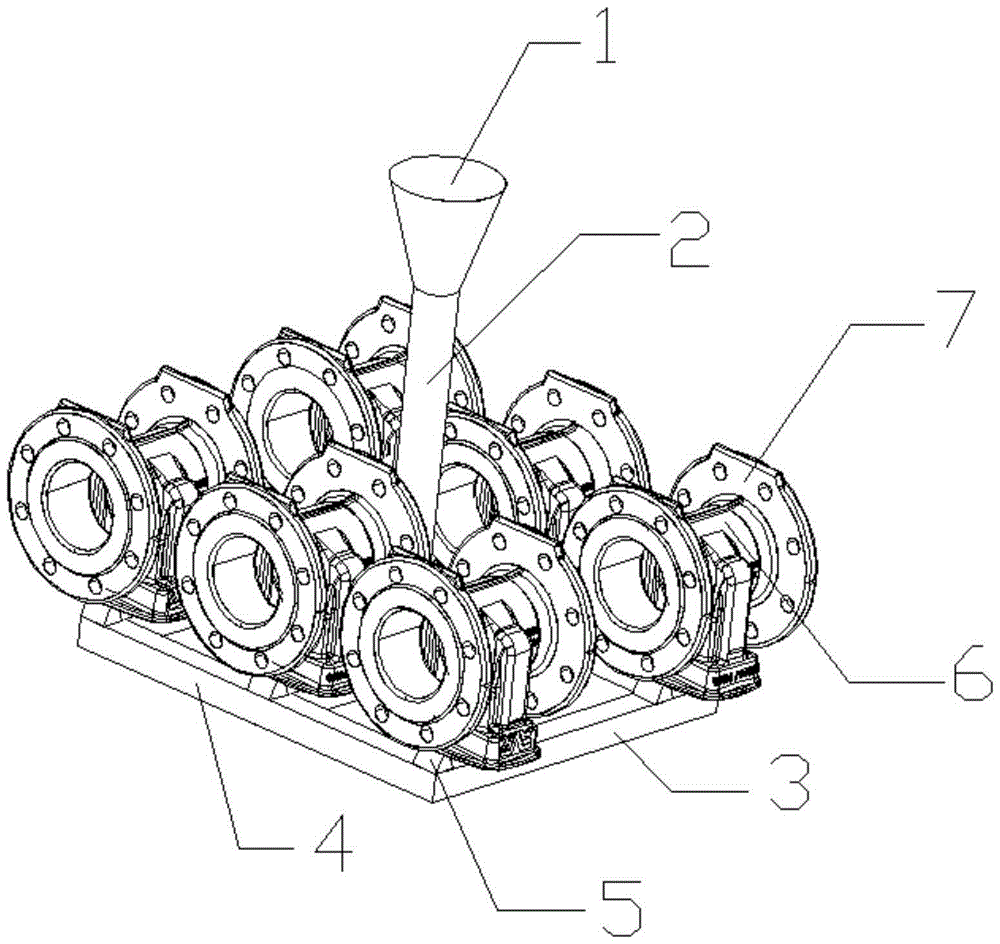

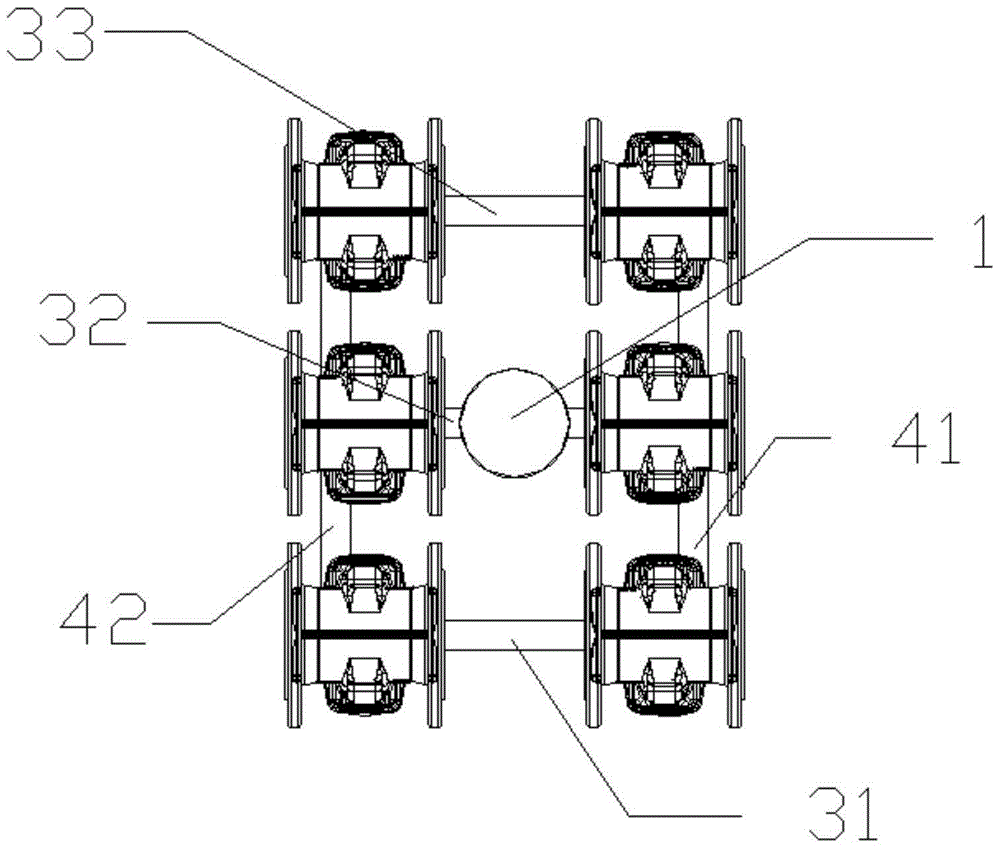

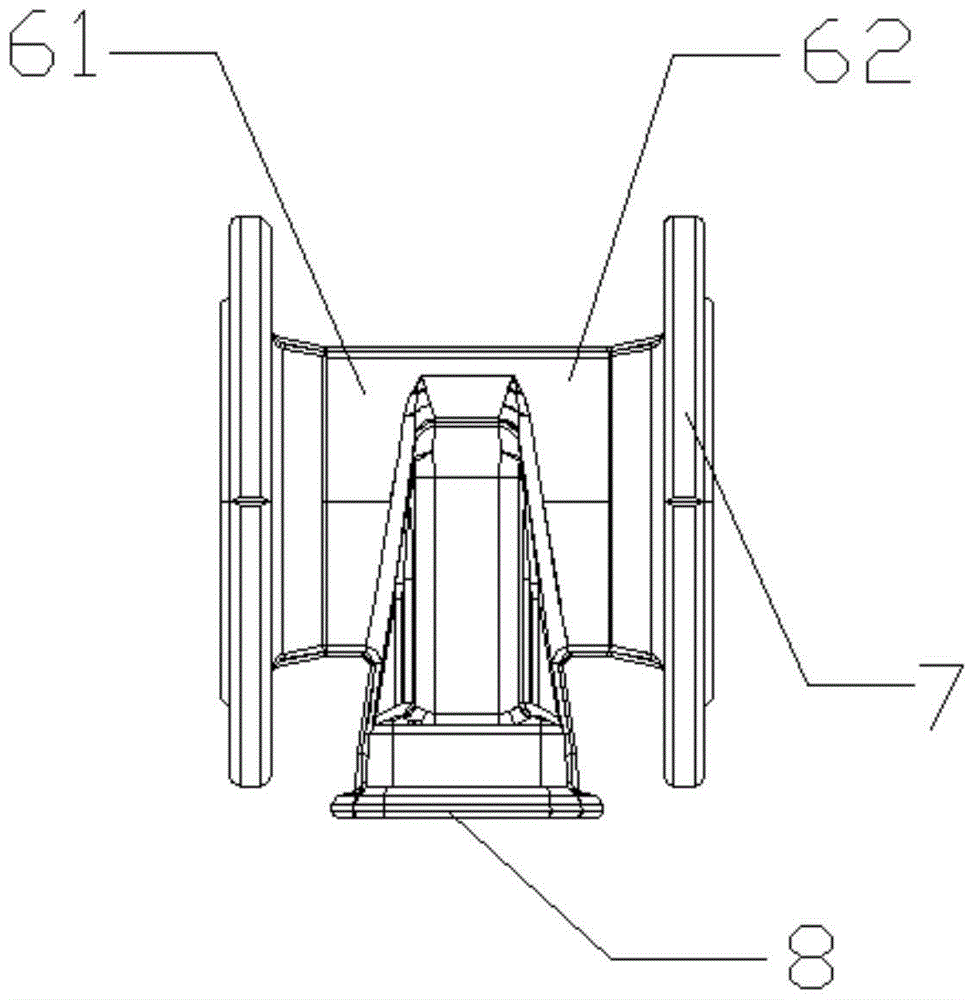

Classifying and screening assembly applied to tea leave production and processing

InactiveCN111921831AReduce work intensityImprove classification and screening efficiencySievingScreeningBiotechnologyTea leaf

The invention provides a classifying and screening assembly applied to tea leave production and processing. The classifying and screening assembly applied to the tea leave production and processing comprises a main frame body (100), a multi-stage sorting mechanism (220) and an auxiliary adjusting mechanism (430), wherein the multi-stage sorting mechanism (220) comprises a first-stage sorting component (2210) and a second-stage sorting component (2220), the first-stage sorting component (2210) is used for receiving to-be-screened and classified tea leaves and primary classification and screening is carried out on the tea leaves, the tea leaves with the size larger than the screening size of the first-stage sorting component (2210) are reserved in the first-stage sorting component (2210), the tea leaves with the size smaller than the screening size of the first-stage sorting component (2210) penetrate through the first-stage sorting component (2210) and fall into the second-stage sortingcomponent (2220), the second-stage sorting component (2220) is used for carrying out secondary sorting and screening on the tea leaves, the tea leaves with the size larger than the screening size ofthe second-stage sorting component (2220) are reserved in the second-stage sorting component (2220), and the tea leaves with the size smaller than the screening size of the second-stage sorting component (2220) penetrate through the second-stage sorting component (2220) and fall downwards to be output.

Owner:安徽硕景机电设计服务有限公司

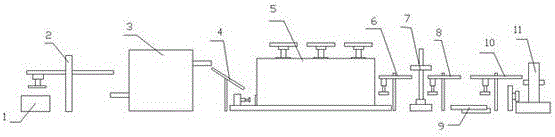

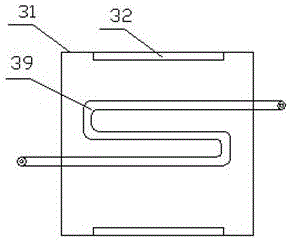

Turbine blade molding line

ActiveCN106334778ARealize continuous moldingPhysical health effectsPower hammersHammer drivesComing outSteam turbine blade

The invention discloses a turbine blade molding line which includes a roughcast warehouse, a conveyer, a heating furnace, a blank forging machine, a blade forming machine, ingot stripper and edge-trimming machine; a conveying swash plate is installed between the said heating furnace and blank forging machine to convey by conveyor; the ingot stripper stripes the mould; blade after the de-molding is transported to edge-trimming machine for end trimming; the said heating furnace includes shell, heater element and sigmoid curve conveying mechanism; and both ends of the sigmoid curve conveying mechanism come out from the shell, and heater element is arranged inside of the shell, and sigmoid curve conveying mechanism is located between heater elements. The invention can realize a continuous molding of turbine blades, which improves molding efficiency, and the blank is heated evenly.

Owner:德阳瑞能电力科技有限公司

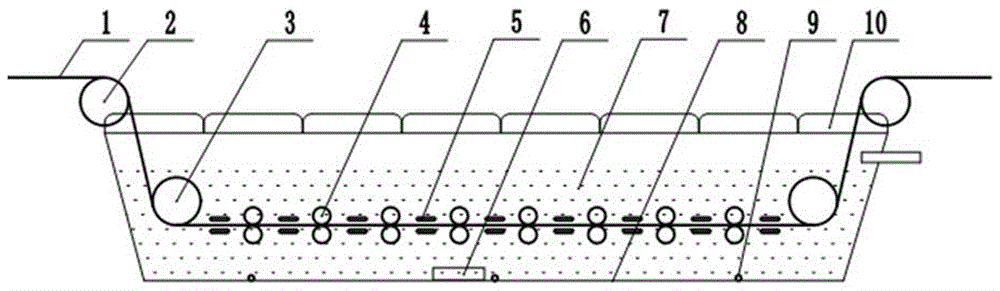

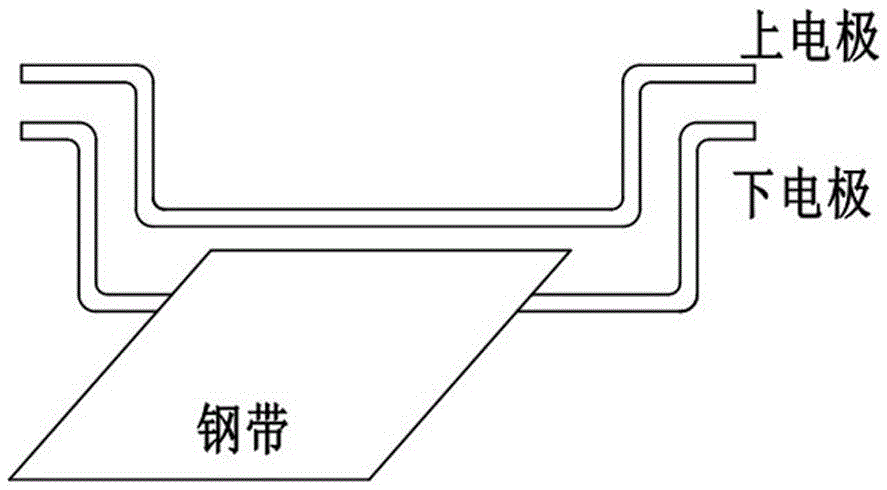

Strip steel electrolysis descaling process and device

InactiveCN106400096AEliminate or reduce pollutionShort electrolysis timeElectrolysis componentsWork treatment devicesElectricityElectrical polarity

The invention provides a strip steel electrolysis descaling process and device and relates to the technical field of steel part surface treatment. The strip steel electrolysis descaling process includes the following electrolysis steps that a neutral electrolyte, namely a Na2SO4 solution, is contained in an electrolytic cell, and the pH of the electrolyte is regulated to be 4-7.0; a plurality of pairs of electrodes are arranged in the electrolytic cell, each pair of electrodes is the same in polarity and arranged up and down, and the pairs of electrodes are divided into positive electrode pairs and negative electrode pairs; and strip steel penetrates through the space between each pair of electrodes, the pair of electrodes at the tail end of the strip discharging end is negative electrodes, and the strip steel is relatively a positive electrode, so that electrolysis descaling is carried out. The electrolysis time is shorter than the acid pickling time, the production is correspondingly increased, corrosion is avoided, environment pollution is eliminated or weakened, using is safe, and the cost is low.

Owner:邢立杰

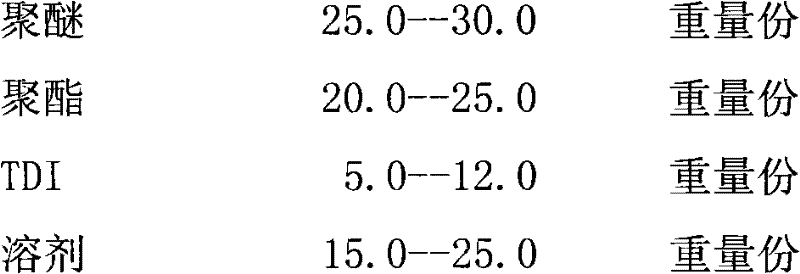

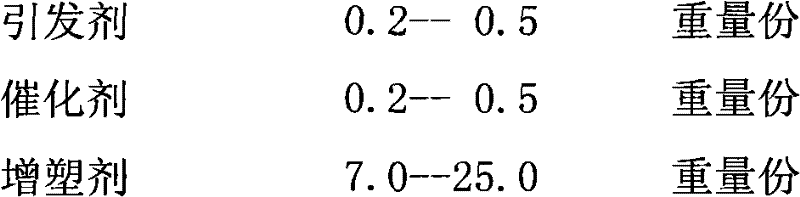

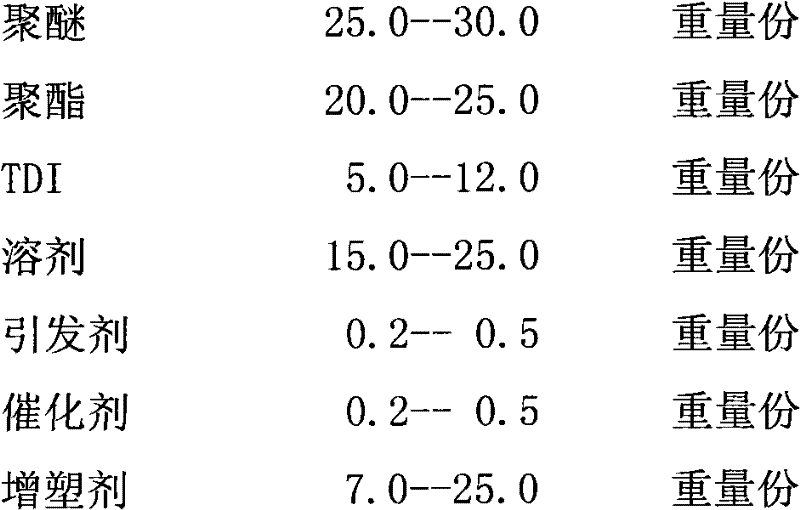

Interlayer bonding agent for spraying spray polyurea waterproof coating and preparation method thereof

InactiveCN102344773AGuarantee the construction qualityNo quality problemsLayered productsPolyureas/polyurethane adhesivesPolyesterEpoxy

The invention provides an interlayer bonding agent for spraying a polyurea waterproof coating. The interlayer bonding agent comprises the following raw materials in parts by weight: 25.0-30.0 parts of polyether, 20.0-25.0 parts of polyester, 5.0-12.0 parts of TDI (Toluene Diisocynate), 7.0-25.0 parts of plasticizer, 15.0-25.0 parts of solvent, 0.2-0.5 part of initiator and 0.2-0.5 part of catalyst. Due to the adoption of the interlayer bonding agent, the defects of inaccurate mixture ratio and non-uniform mixing and stirring during field application as well as containing of harmful solvents such as methylbenzene, dimethylbenzene, trichloroethane and the like in a product existing in the conventional commercially-available bicomponent interlayer bonding agent consisting of epoxy resin and polyurethane are overcome, a single-component high-intensity interlayer bonding agent which is free from toxic solvent is obtained, a complete continuous coating layer can be formed by the waterproof coating in the construction process, and normal performance of mechanical construction is ensured. The interlayer bonding agent is an ideal assorted product for spraying a polyurea waterproof coating.

Owner:BEIJING LIGAO WATERPROOF ENG CO LTD +1

Forming manufacture device of glass water cup

ActiveCN110627347AQuality improvementNo quality problemsWater cleaningWaterborne vesselsEngineeringMaterial transfer

The invention discloses a forming manufacture device of a glass water cup. The forming manufacture device of the glass water cup includes a device box body, wherein a feeding hopper with an upward opening is arranged on a boss of the device box body, the feeding hopper is used for receiving and transferring liquid glass, and a rotary platform is rotatably installed on the top surface of the devicebox body; the liquid glass is put in the feeding hopper, a first motor is started, and a partition is driven by the first motor to rotate for 60 degrees each time, so that intermittent material transfer of the liquid glass on the feeding hopper is achieved; then stamping forming is performed so that the formed glass cup can have good quality, a stamping head for stamping is always clamped on a receiving mold when forming of the glass cup is performed so that no quality problems of the glass cup can be generated during forming, and remaining materials on the mouth of the finally-formed glass cup can be cut off automatically when the glass cup is released out of the mold.

Owner:江西艾客日用品有限公司

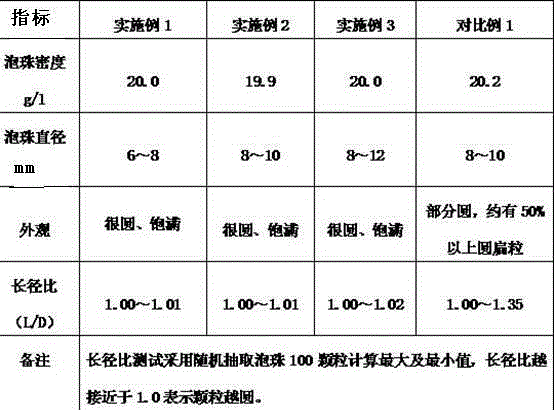

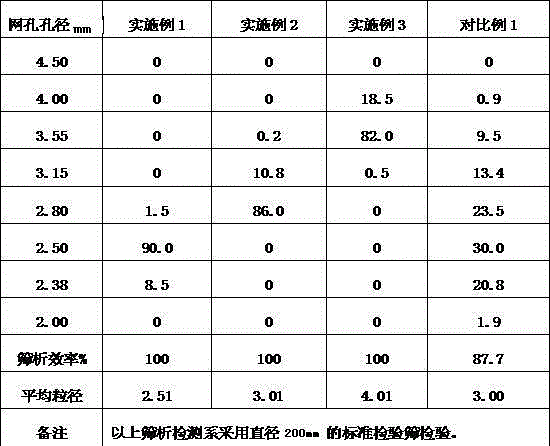

Expandable polystyrene resin with ultra-large particle size and method for preparing same

The invention belongs to the technical field of synthesis of polymer materials and particularly relates to an expandable polystyrene resin with an ultra-large particle size and a method for preparing the expandable polystyrene resin. The foaming-agent free polystyrene particles with the size of 0.2-1.0mm are used as the polystyrene seeds, and the seed polymerization method is adopted to prepare the expandable polystyrene resin with an ultra-large particle size. The product has the advantages of uniform particles, satisfactory appearance and stable and uniform quality and can meet the demand of customers in different fields, thereby having a wide market prospect and creating huge economic benefits for the enterprises.

Owner:东莞新长桥塑料有限公司

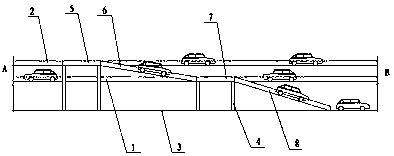

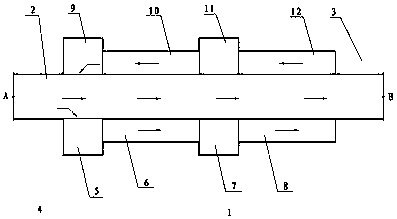

Double-layer high-speed overhead flyover for cars

A double-layer high-speed overhead flyover for cars is suitable for main roads or secondary main roads. The overhead flyover, corresponding to two directions A and B, is composed of a first bridge floor, a second bridge floor, four ramps, four platforms, and pillars. The overhead flyover is specially-designed for cars and is characterized by miniaturization and low weight, is less in occupied materials and is light in weight and low in cost. The overhead flyover can be manufactured and assembled from steel structures through industrial production in factories, so that a new manufacturing industry entity can be formed. The high-speed overhead flyover achieves single-layer and one-way traffic of cars; according to invention, a high-speed crossroad overhead flyover is linked to a crossroad while a high-speed T-junction overhead flyover is linked to a T-junction. The overhead flyover can create a traffic network without traffic lights for whole city, which would be a wonder of city traffic.

Owner:罗克贤

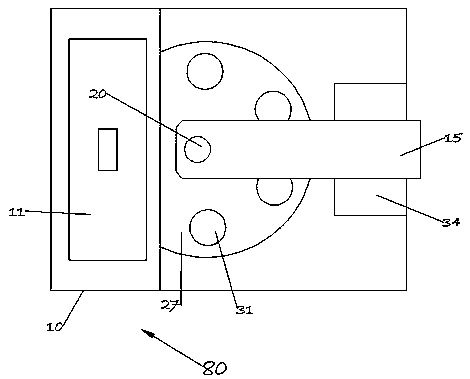

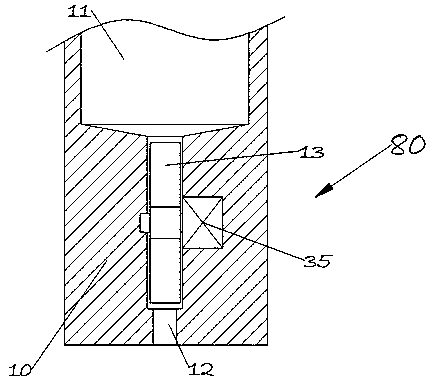

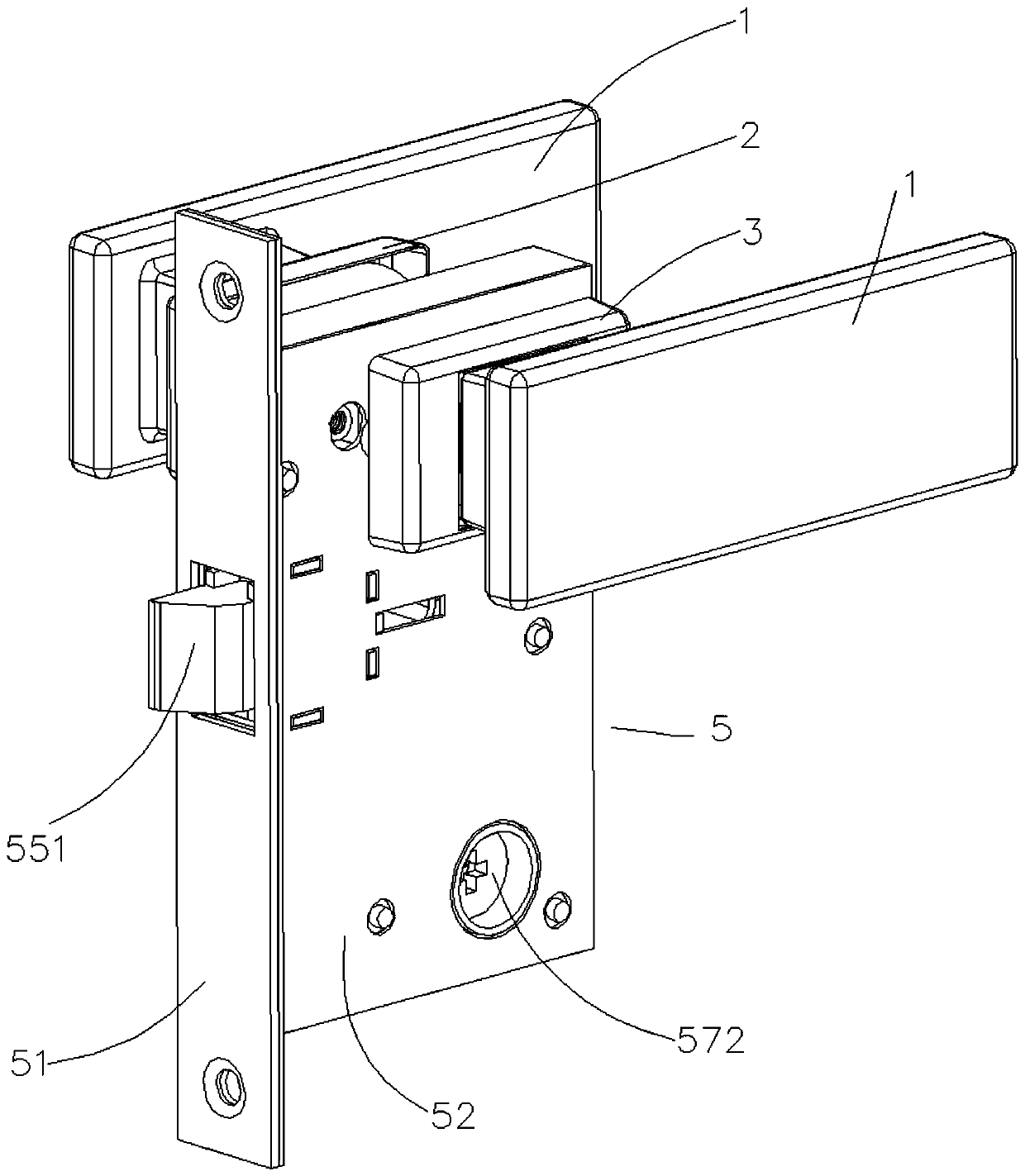

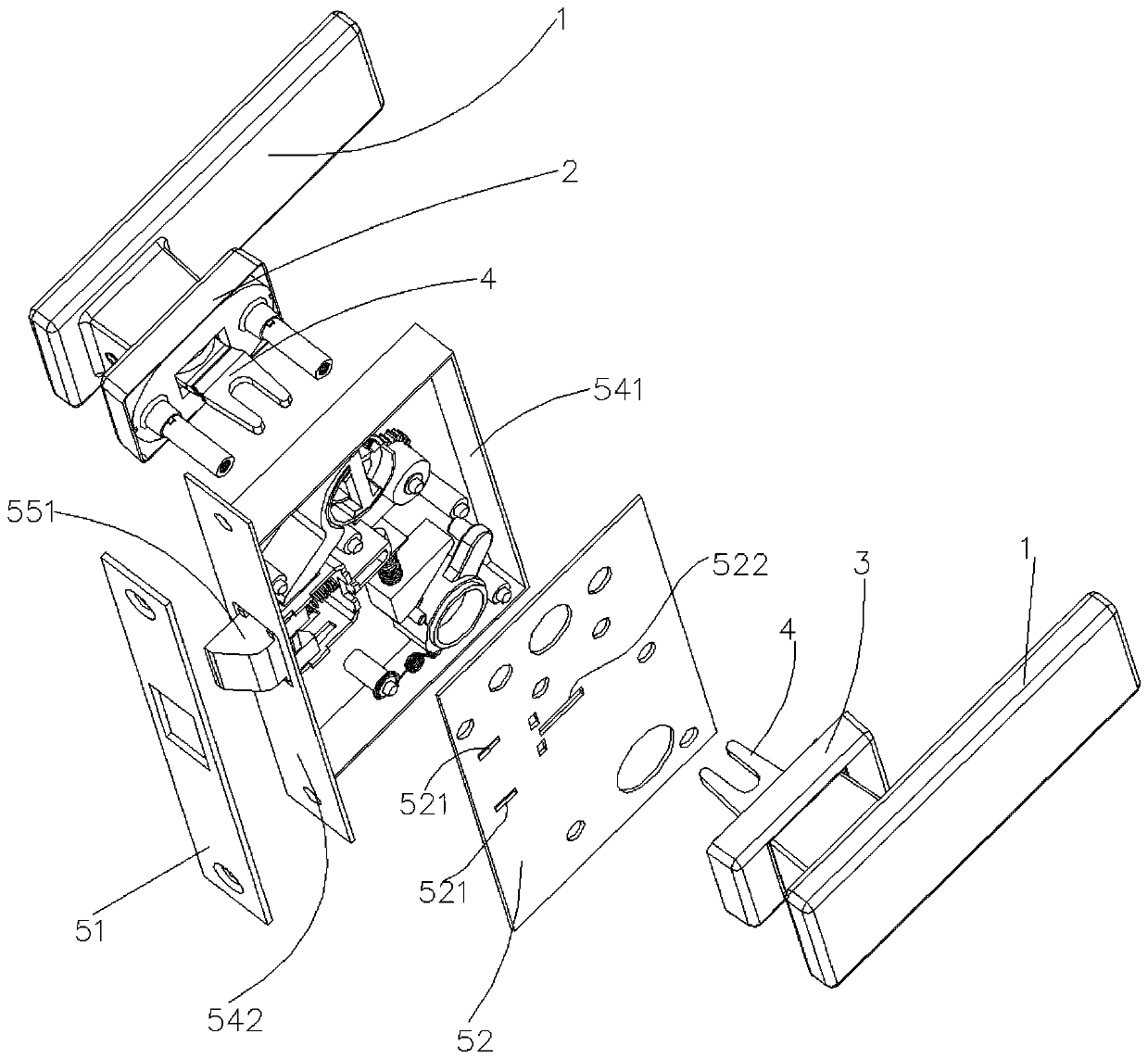

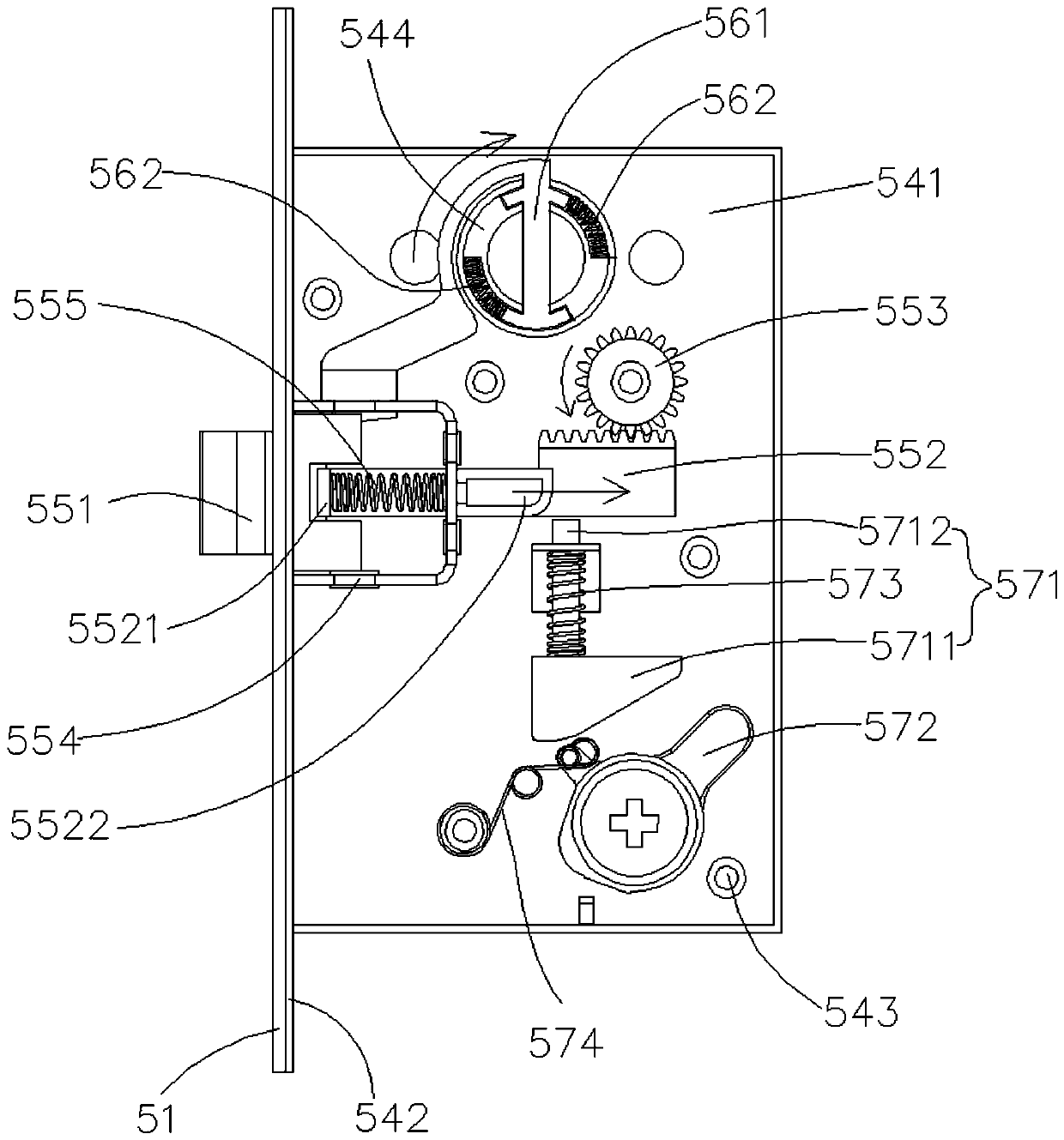

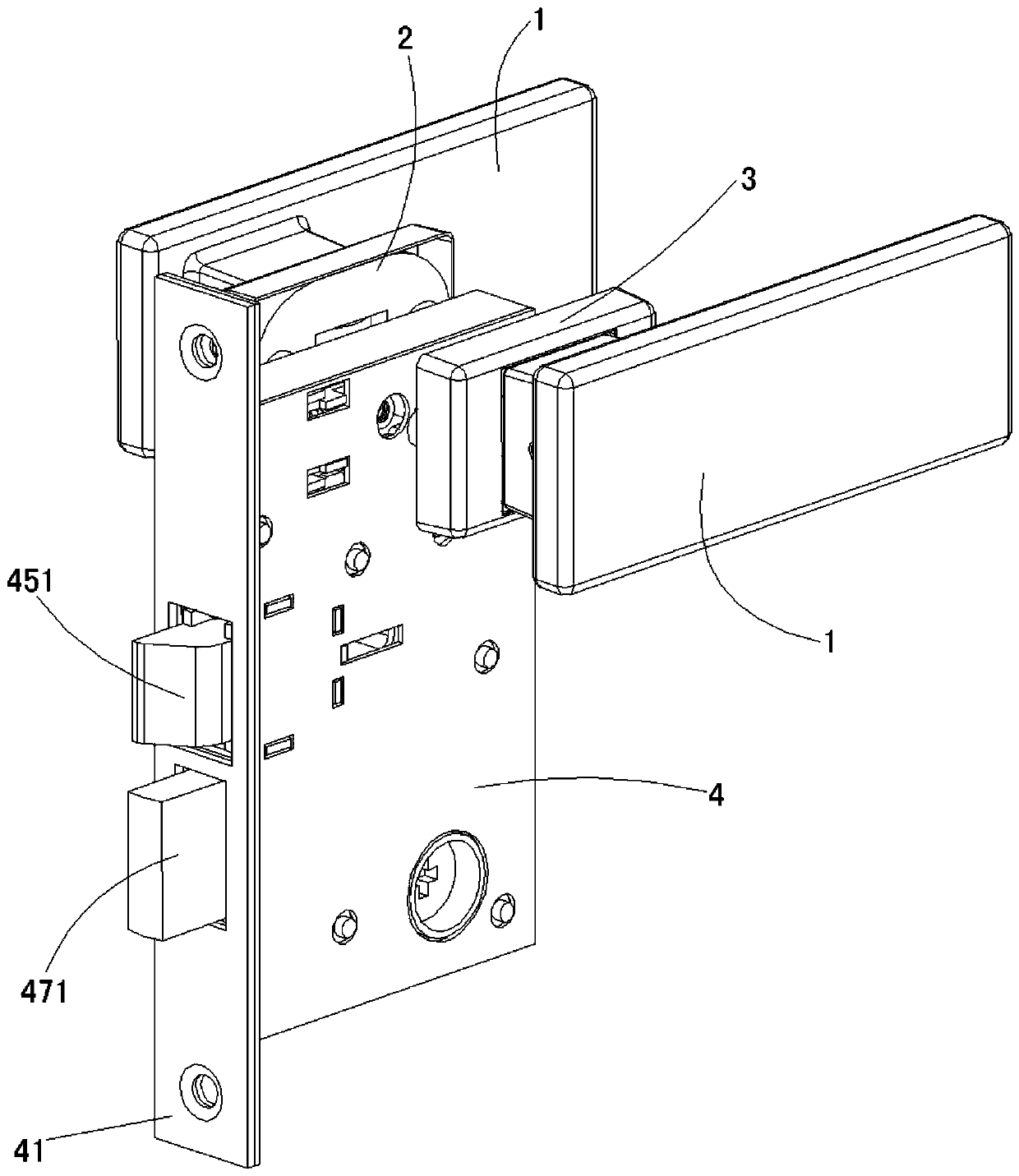

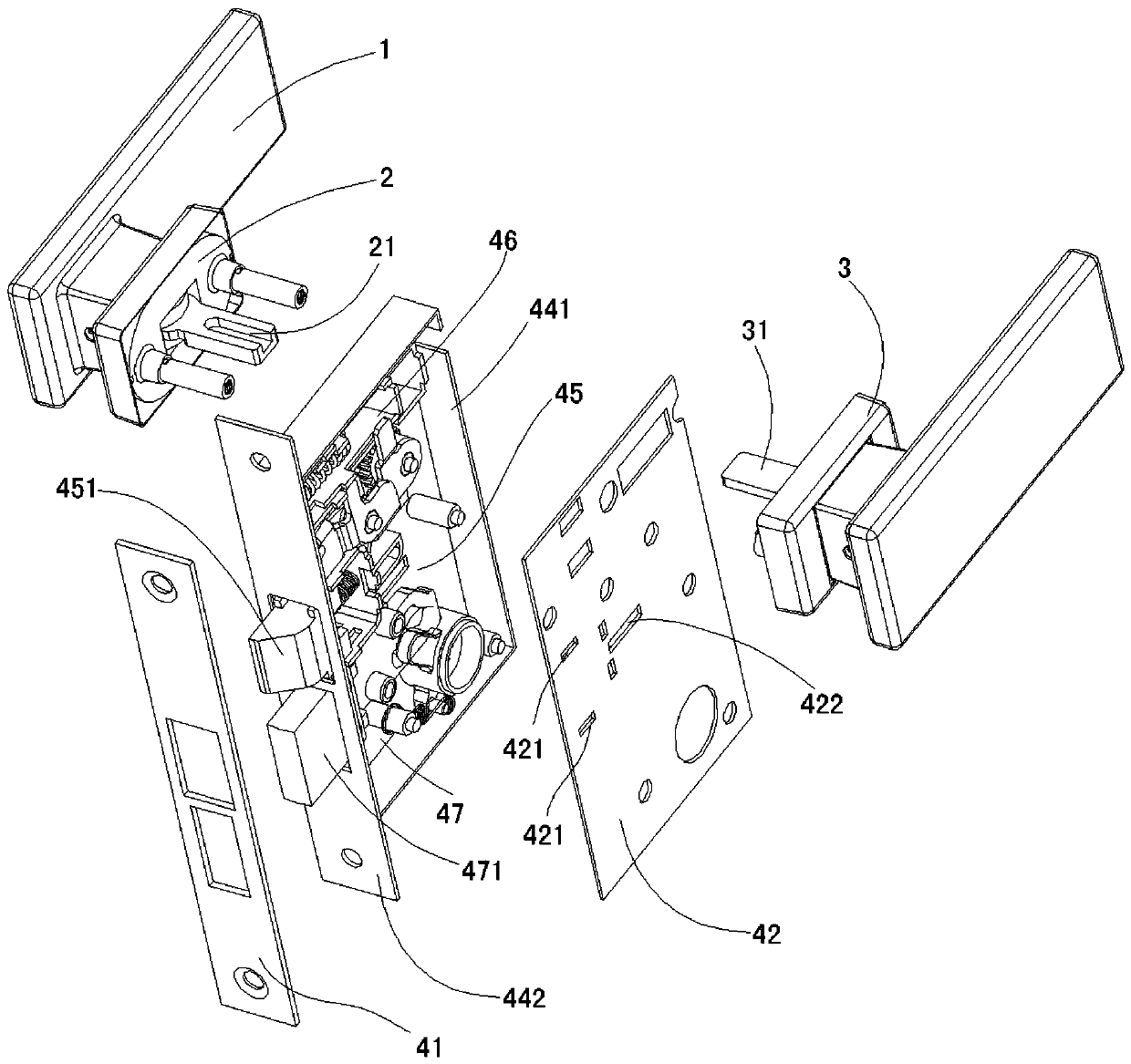

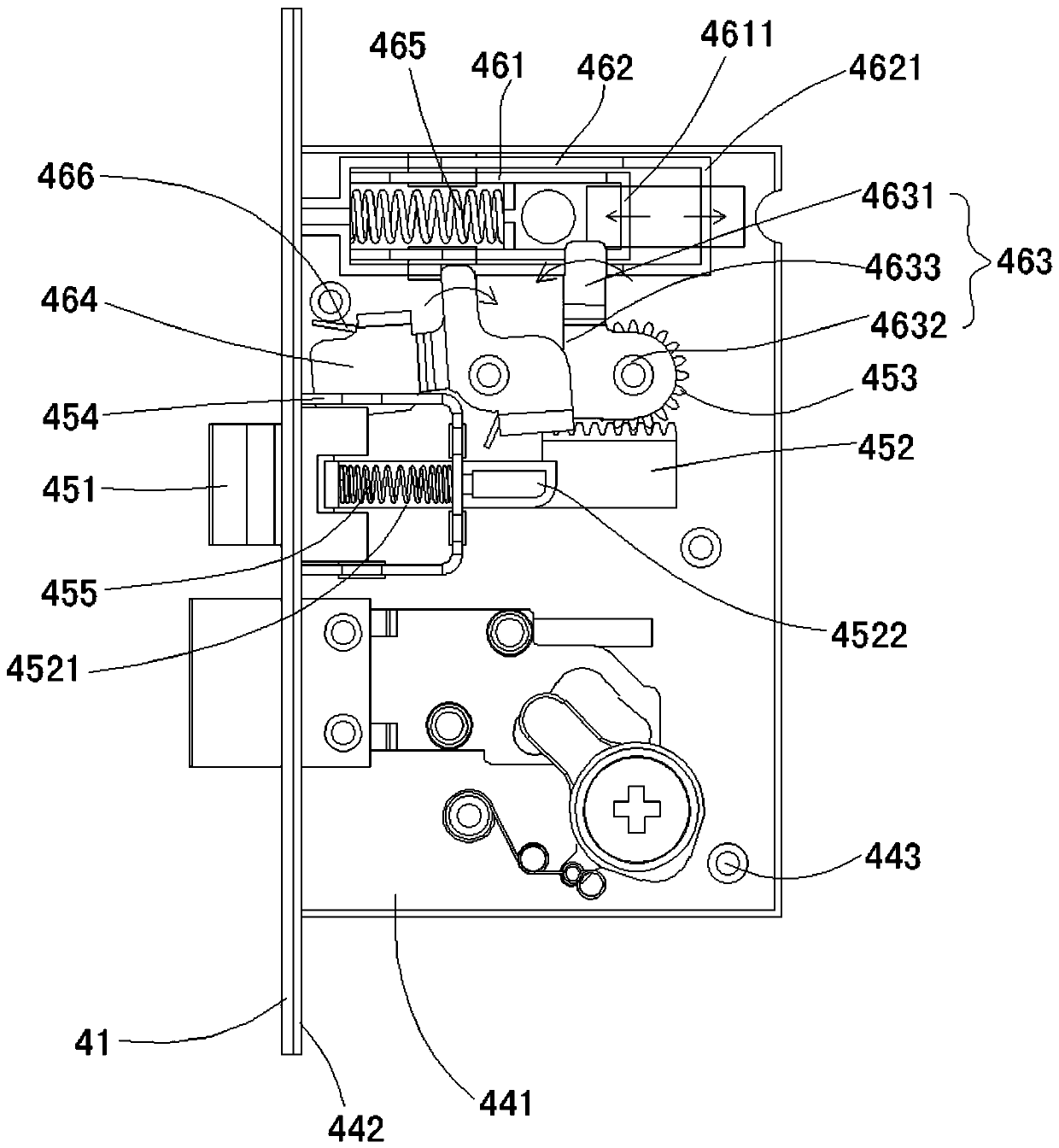

Push-pull door lock

PendingCN109667474AAchieve lockingPrevent backing downKeyhole guardsHandle fastenersPush pullEngineering

The invention relates to the field of door locks and provides a push-pull door lock. The push-pull door lock comprises handles, a front seat, a rear seat and a lock body. The front seat and the rear seat each comprise a double-fork driving lever. The lock body comprises a lock body outer liner plate, a box cover, a box bottom assembly, a tapered tongue assembly, a push-pull assembly and a lockingassembly. The tapered tongue assembly comprises a tapered tongue, a sliding rack, a small gear, a tapered tongue reset spring and a fixed base. The push-pull assembly comprises a rotary block and a rotary block reset spring. The box bottom assembly comprises a lock body inner liner plate, columnar nails, a rotary block carrying seat and a box bottom. The locking assembly comprises a sliding lock bar, a reset spring and a shifting block. According to the push-pull door lock, the tapered tongue assembly adopts a rack and gear engagement transmission manner, can achieve the excellent mute effectand is stable in transmission. The push-pull door lock is quite convenient and fast in the push-pull door opening process, suitable for various occasions and also suitable for various types of peopleand quite high in safety performance, is free of quality problem for long-term use and has the advantage of being stable in performance.

Owner:GUANGDONG MINGMEN LOCKS IND

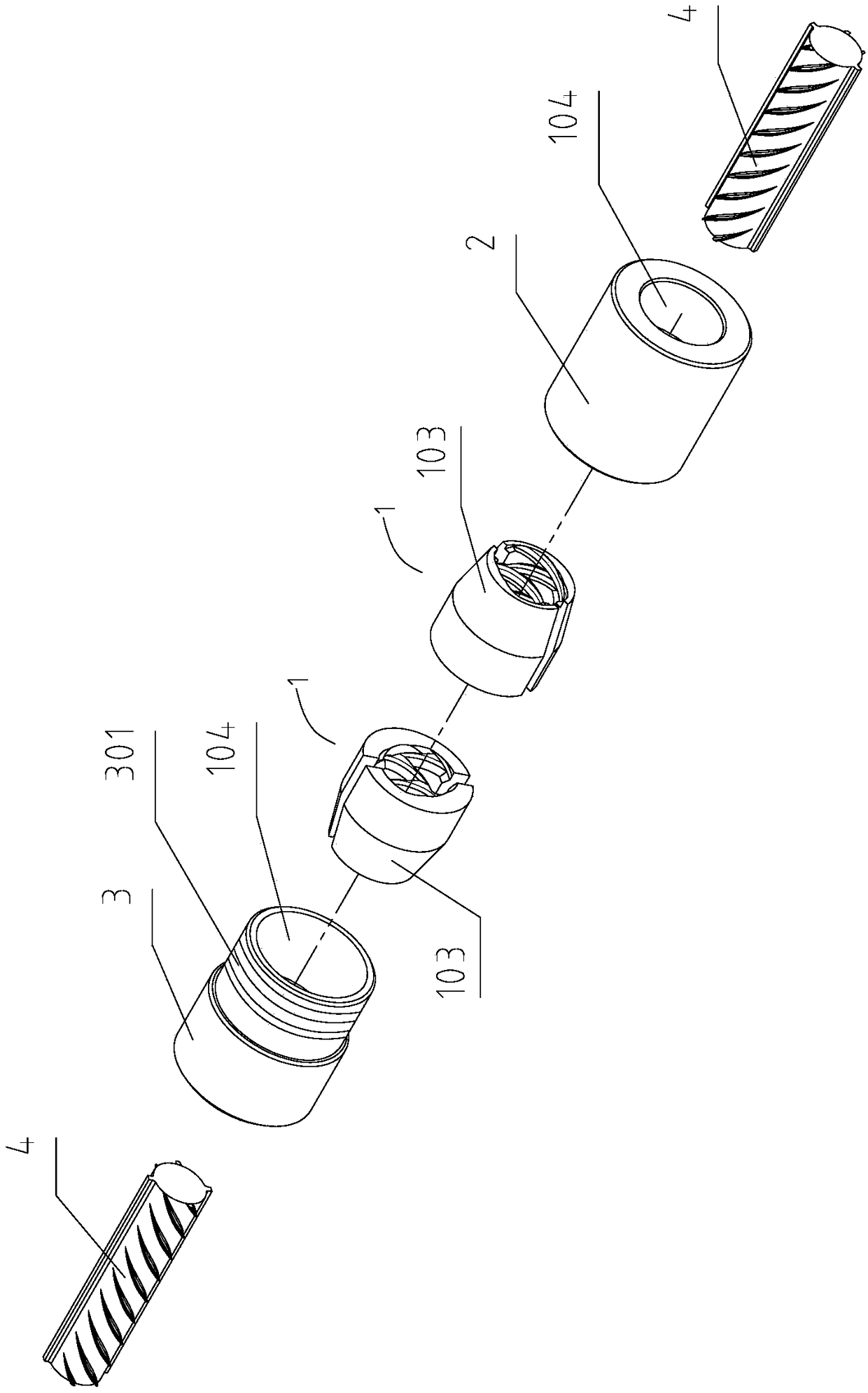

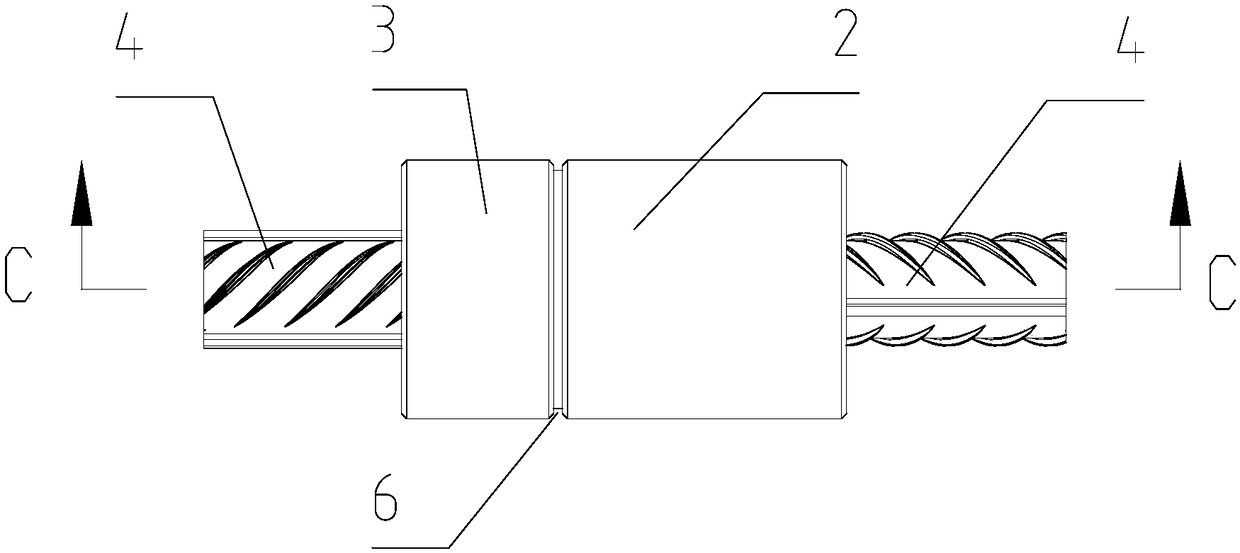

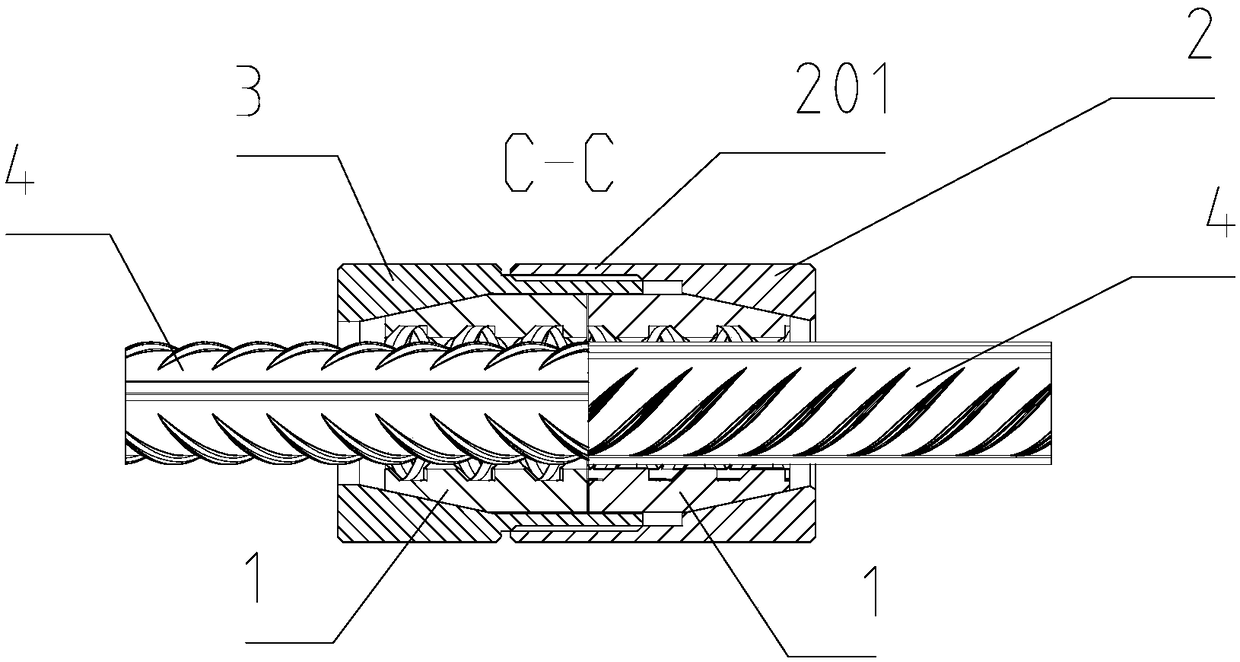

Steel bar mechanical connecting piece and steel bar mechanical connecting method

InactiveCN108756075AFacilitate axial clamping forceNo quality problemsBuilding reinforcementsArchitectural engineeringSteel bar

The invention relates to a steel bar mechanical connecting piece and a steel bar mechanical connecting method. According to the steel bar mechanical connecting piece and the steel bar mechanical connecting method, the technical problems that existing steel bar connecting is unreliable in quality and cumbersome in operation are solved. The steel bar mechanical connecting piece is provided with twoembracing clamping hoops which are located on the left side and the right side correspondingly, embracing inner cavities are formed in the embracing clamping hoops, and steel bars can be embraced in the embracing inner cavities through the embracing clamping hoops; and locking outer conical surfaces are arranged at the tails of the embracing clamping hoops, anti-sliding buckling devices are arranged on the inner surfaces of the embracing inner cavities, anti-sliding buckling clamping grooves serve as the anti-sliding buckling devices, and the direction of the anti-sliding buckling clamping grooves is consistent with the direction of protruding patterns on the outer surfaces of the steel bars. The steel bar mechanical connecting piece can be widely used for mechanical connection of the building steel bars.

Owner:于洋

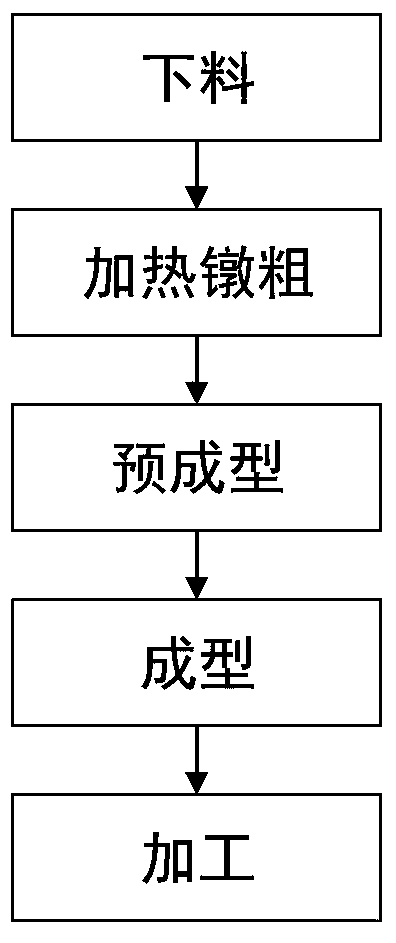

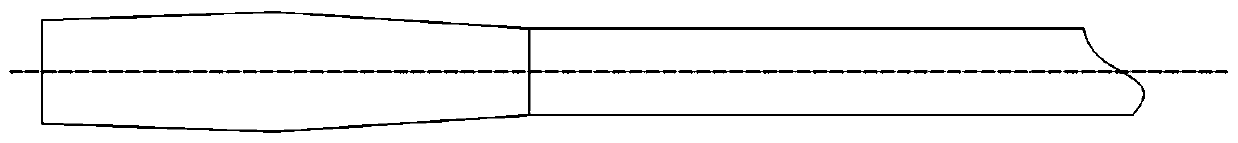

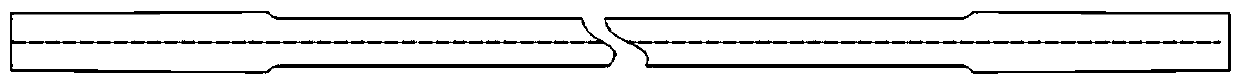

Hot heading molding process for large-size torsion bar of bullet train

InactiveCN108015207AEffective moldingAvoid bendingForging/hammering/pressing machinesDiameter ratioEngineering

The invention discloses a hot heading molding process for a large-size torsion bar of a bullet train. The hot heading molding process comprises the following steps of 1, blanking, wherein a round barmaterial is selected, a part, needing to be machined, of a head of a round bar is divided into a first part and a second part which are the same in length, and the height-diameter ratio of the first part to the second part is less than or equal to four; 2, heating and upsetting, wherein the first part is heated, pressing and positioning are conducted on a middle bar portion through a horizontal forging machine and a vertically-pressing mold, and a movable mold for the head is closed for local molding; 3, premolding, wherein the second part is heated, pressing and positioning are conducted on the middle bar portion through the horizontal forging machine and the vertically-pressing mold, and the movable mold for the head is closed for molding; 4, molding, wherein the step 2 and the step 3 are repeated till heading of the two ends is completed; and 5, machining, wherein finish machining is conducted on a forged piece according to requirements. According to the hot heading molding process,the local heating and molding mode is adopted; when the height-diameter ratio is eight, heading can be conducted on the ends; heading is conducted on a blank through the movable mold and the vertically-pressing mold; and under the condition that the height-diameter ratio achieved in the one-time upsetting process is four, bending and folding caused in the heading process are prevented.

Owner:ZHUZHOU TIANLI FORGING IND

Push-pull type door lock structure

The invention relates to the field of door locks, and provides a push-pull type door lock structure. The push-pull type door lock structure comprises a lever handle, a front base, a rear base and a lock body. The lock body comprises a lock body outer liner plate, a box cover, a box bottom assembly, a spring bolt assembly, an inclined tongue assembly, a push-pull assembly and a locking assembly. The inclined tongue assembly comprises an inclined tongue, a sliding rack, a small gear, a fixing base and an inclined tongue reset spring. The push-pull assembly comprises a pushing sliding sleeve, a pulling sliding sleeve, a pushing stirring block, a pulling stirring block, a sliding sleeve reset spring and a push block reset spring. The locking assembly can lock a spring bolt. The rack and gear meshing transmission manner is adopted in the inclined tongue assembly so that the extremely good silencing effect can be achieved, and transmission is stable. According to the push-pull type door lockstructure, the pushing-pulling door opening process is extremely convenient and fast, the push-pull type door lock structure is suitable for various occasions and also suitable for multiple crowds, safety is extremely high, the quality problem does not occur even when usage is conducted for a long time, and the advantage of stable performance is achieved.

Owner:GUANGDONG MINGMEN LOCKS IND

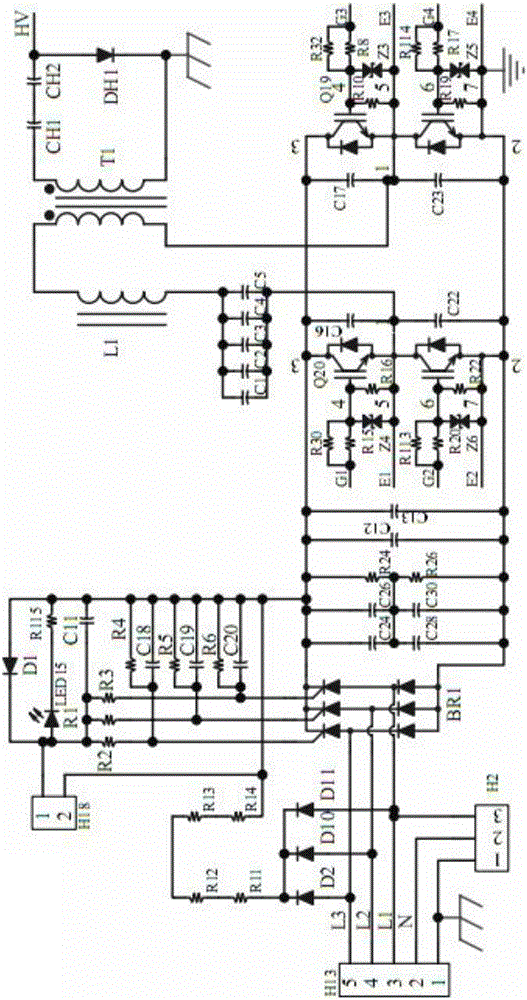

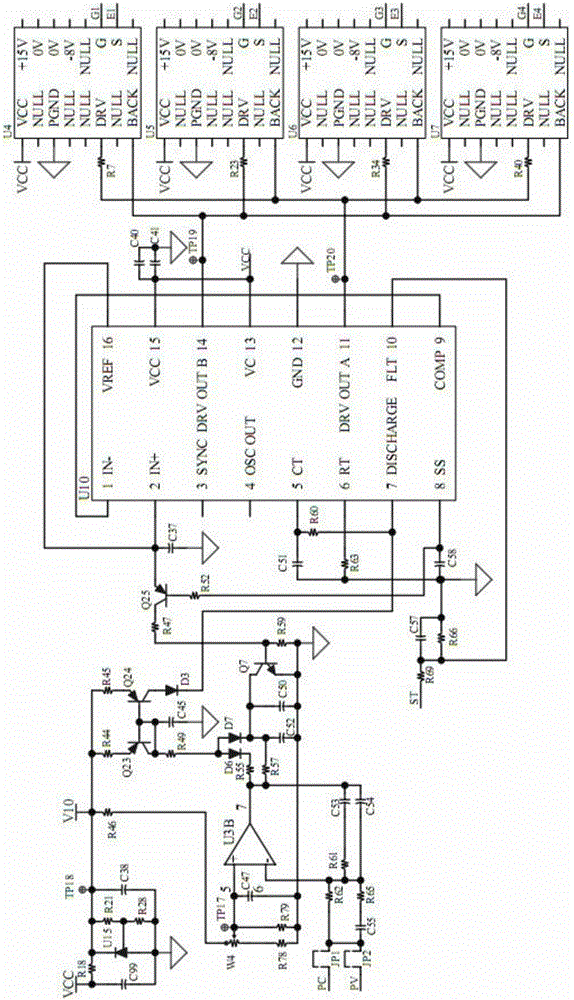

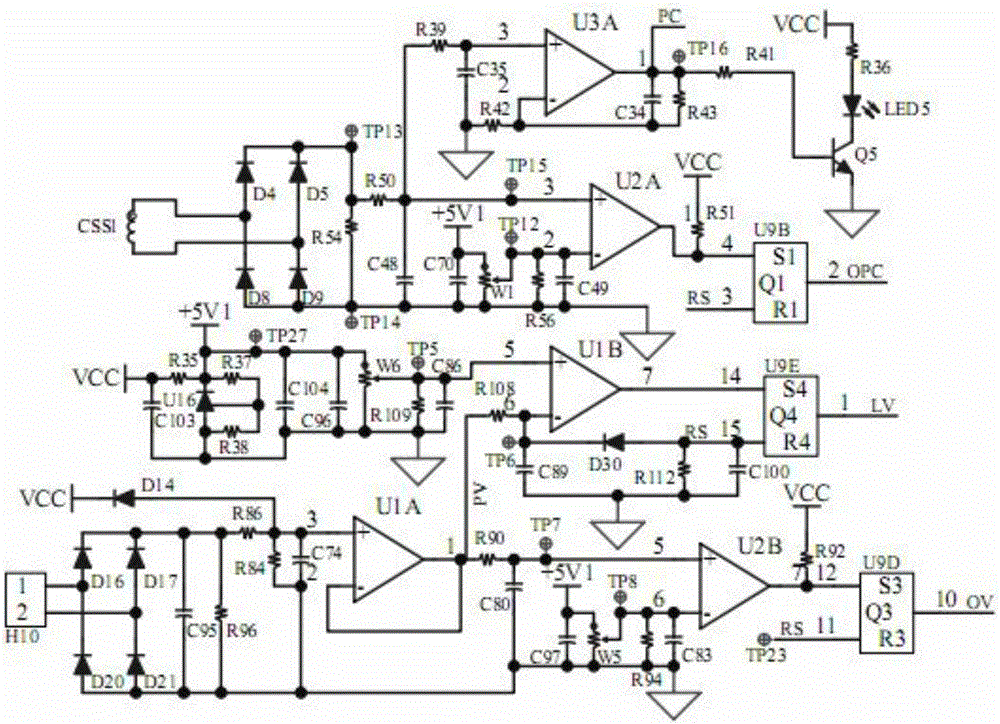

High-voltage plasma power supply

ActiveCN105720953AChange working frequencySolve the closed loop controlEfficient power electronics conversionPulse generation by energy-accumulating elementFull bridgeFrequency conversion

The invention relates to a high-voltage plasma power supply comprising a three-phase half-control rectification circuit, a time-delay starting circuit, a filtering energy storage circuit, a full-bridge circuit, an LC series resonance circuit, a low-voltage rectification circuit, a power regulation circuit, a feedback control circuit, a frequency conversion circuit, an IGBT full-bridge driving circuit, and an alarm circuit, the three-phase half-control rectification circuit is connected with a high-voltage transformer via the full-bridge circuit and the LC series resonance circuit, the power regulation circuit and the feedback control circuit are connected with the feedback control circuit, and the feedback control circuit is connected with the full-bridge driving circuit via the frequency conversion circuit.

Owner:南京威登等离子科技设备有限公司

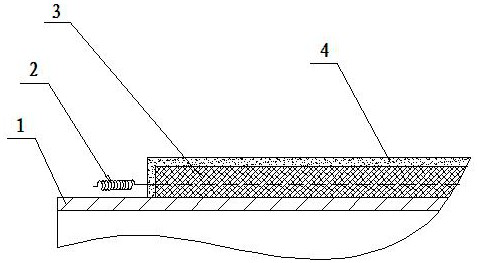

Polyurethane spraying outer protection pipe spraying integrally-formed prefabricated heat preservation valve and spraying method

PendingCN112161101AAvoid economic lossSolve common technical problemsThermal insulationPipe protection by thermal insulationPolymer scienceHeat conservation

The invention discloses a polyurethane spraying outer protection pipe spraying integrally-formed prefabricated heat preservation valve and a spraying method. By adopting a traditional prefabricated directly-buried heat preservation process, a heat supply pipe network and a pipeline valve have the disadvantages of uneven heat preservation forming, halfway splicing and welding of an outer protectionpipe, great heat loss for integral heat preservation and short service life of a heat preservation valve. The heat preservation valve comprises a prefabricated directly-buried heat preservation valvewhich comprises a working pipe, wherein polyurethane protection layers (3) are sprayed to the outer layers of a horizontal pipe and a vertical pipe of the working pie separately through a polyurethane mixing spray head (6), valve welding ports (1) without the polyurethane protection layer are left at two ends of the horizontal pipe, high polymer liquid protection layers (4) are sprayed to the outer surfaces of the polyurethane protection layers by a high pressure spray gun, a group of alarm lines (2) is mounted in each polyurethane protection layer, and the high polymer liquid protection layers are made of high polymer liquid elastic materials with densities being 1.2 q / cm<3> and the coatings are 1-20 mm thick. The invention relates to the polyurethane spraying outer protection pipe spraying integrally-formed prefabricated heat preservation valve.

Owner:融克(北京)资本投资管理有限公司

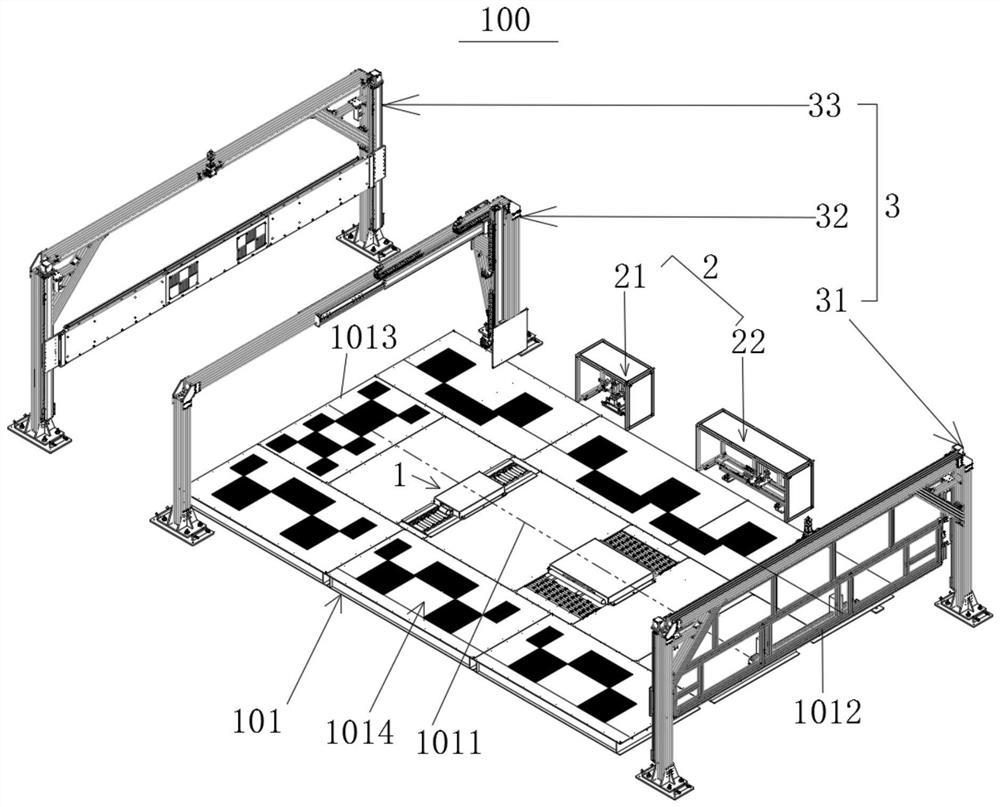

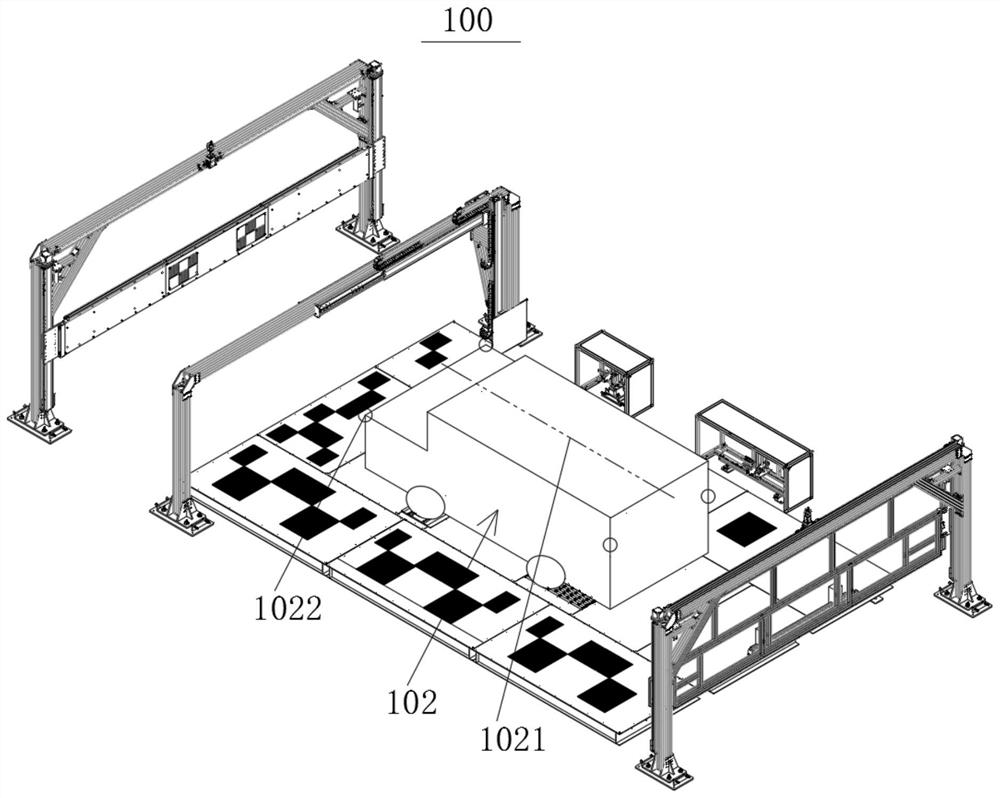

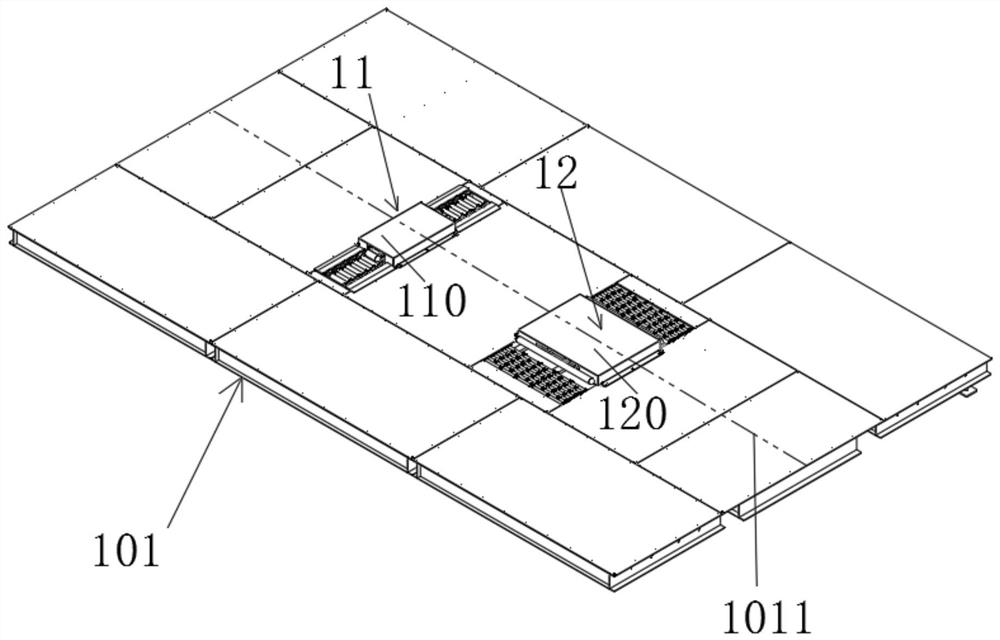

Vehicle delivery detection system

InactiveCN112414311ANo quality problemsWave based measurement systemsUsing optical meansPortal frameReliability engineering

The invention relates to a vehicle delivery detection system which comprises a bearing platform, a centering device, a wheel eyebrow detection device and a portal frame calibration device. The bearingplatform is used for bearing vehicle. The centering device is assembled on the bearing platform and used for centering and positioning the vehicle. The wheel eyebrow detection device is arranged adjacent to the bearing platform and used for detecting the wheel eyebrow height of the vehicle. The portal frame calibration device is arranged adjacent to the bearing platform and used for allowing a vehicle to pass through and calibrating the parameters of the vehicle. The vehicle is centered and positioned through the centering device, and it can be ensured that measurement errors caused by parking deviation of the position of the vehicle in the detection process can be avoided. The wheel eyebrow height of the vehicle is detected through the wheel eyebrow detection device, and then the heightof the vehicle body can be calculated. The parameters of the vehicle are calibrated through the portal frame calibration device, various instruments of the vehicle can be detected, and therefore it can be guaranteed that no quality problem occurs after the vehicle flows into the market.

Owner:浙江友顺机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com