Expandable polystyrene resin with ultra-large particle size and method for preparing same

A technology of expandable polystyrene and polystyrene, applied in the direction of layered products, etc., can solve the problems of unsatisfactory customers, uneven quality, technical difficulties, etc., and achieve stable and uniform quality, perfect appearance and broad development prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

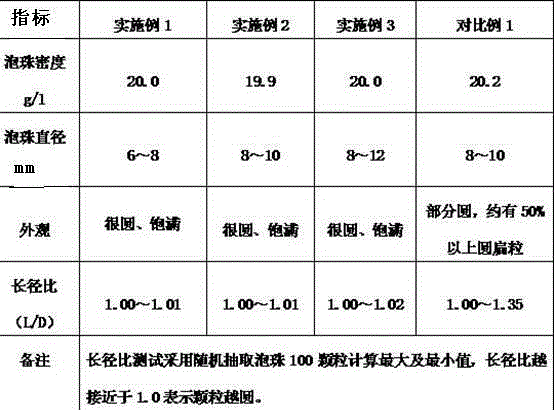

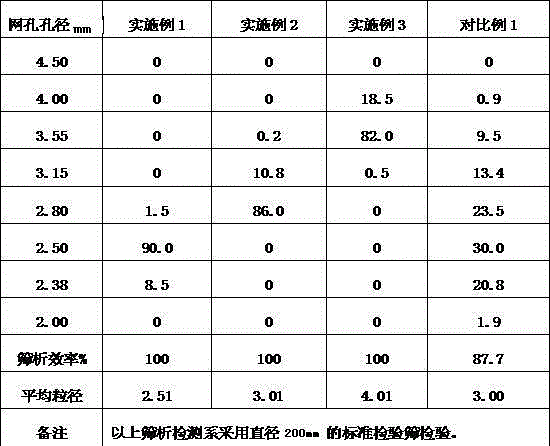

Embodiment 1

[0055] Add 2,500 grams of deionized water and 16 grams of tricalcium phosphate as a dispersant to a 5-liter reactor, start stirring, then raise the temperature to 60°C, add 500 grams of polystyrene seeds with a particle size of 0.3 to 0.5 mm, and then use Slowly add 1,500 grams of styrene monomer, 7 grams of initiator dibenzoyl peroxide, 5 grams of tert-butyl peroxybenzoate, and 2 grams of plasticizer mixed xylene in a dropwise manner. Adding time is controlled within 3 hours. After the styrene monomer is added, continue to heat up to 90°C for low-temperature suspension polymerization. After reacting for 6 hours, add 140 grams of foaming agent and heat up to 125°C for high temperature Polymerization reaction, reaction for 8 hours, the total polymerization reaction time is 14 hours, the pressure is 0.4-0.9MPa, after the reaction is completed, cool the material and transfer it to the middle tank, add hydrochloric acid to adjust the pH value to 4-6, and wash it. Adopt separator d...

Embodiment 2

[0058]Add 2500 grams of deionized water and 18 grams of dispersant tricalcium phosphate into a 5-liter reactor, start stirring, then raise the temperature to 50°C, add 500 grams of polystyrene seeds with a particle size of 0.5-0.8 mm, and then use Slowly add 1,500 grams of styrene monomer, 7 grams of initiator dibenzoyl peroxide, 5 grams of tert-butyl peroxybenzoate, and 1.5 grams of plasticizer mixed xylene, in which the drop of styrene monomer Adding time is controlled within 2.5 hours. After adding styrene monomer, continue to heat up to 90°C for low-temperature suspension polymerization. After reacting for 7 hours, add 150 grams of foaming agent and heat up to 120°C for high temperature Polymerization reaction, reaction for 8 hours, the total polymerization reaction time is 15 hours, the pressure is 0.4~0.9MPa, after the reaction is completed, cool the material and transfer it to the middle tank, add hydrochloric acid to adjust the pH value to 4~6, and wash it. Adopt separ...

Embodiment 3

[0061] Add 2500 grams of deionized water and 18 grams of tricalcium phosphate as a dispersant to a 5-liter reactor, start stirring, then raise the temperature to 50°C, add 500 grams of polystyrene seeds with a particle size of 0.8 to 1.0 mm, and then use Slowly add 1300 grams of styrene monomer, 7 grams of initiator dibenzoyl peroxide, 10 grams of dicumyl peroxide, and 1 gram of mixed xylene as a plasticizer, in which the dropwise addition of styrene monomer The time is controlled within 2 hours. After the styrene monomer is added, continue to heat up to 90°C for low-temperature suspension polymerization. React for 7 hours, then add 150 grams of foaming agent, and heat up to 125°C for high-temperature polymerization Reaction, reaction for 8 hours, the total polymerization reaction time is 15 hours, and the pressure is 0.4-0.9MPa. After the reaction is completed, cool the material and transfer it to the middle tank, add hydrochloric acid to adjust the pH value to 4-6, and wash i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com