Control technology for extracting and purifying nickel from acid nickel-containing solution

A nickel solution and acid technology, which is applied in the field of extraction and purification control technology of nickel in an acid nickel-containing solution, can solve the problems of low concentration and purity, unfavorable high-quality nickel products and environmental protection, and low metal concentration in the recovered liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

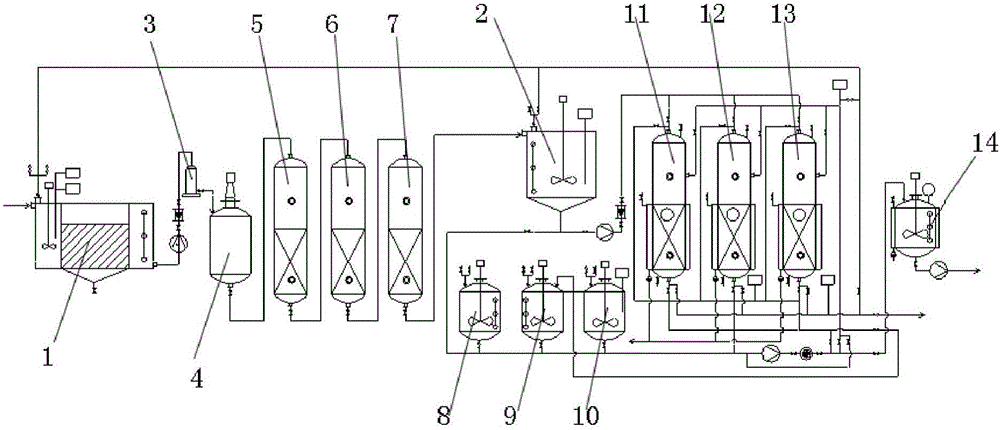

[0043] The extraction and purification control process of nickel in a kind of acidic nickel-containing solution provided by the present embodiment, such as figure 1 Shown, by the first adjustment tank 1, the second adjustment tank 2, bag filter 3, fiber ball filter 4, activated carbon column 5, anion adsorption resin exchange column 6, selective adsorption resin exchange column 7, transformation agent In the device composed of tank 8, regenerant tank 9, column washing tank 10 and exchange column group, the water outlet of the first regulating tank passes through bag filter 3, fiber ball filter 4, activated carbon column 5, anion adsorption resin exchange Column 6 and selective adsorption resin exchange column 7 are connected to the water inlet of the second regulating tank 2, and the water outlet of the second regulating tank 2 is connected to the water inlet of the exchange column group through the water inlet pump, and the exchange column group includes the first exchange col...

Embodiment 2

[0088] The total output of the acidic nickel-containing nickel waste liquid provided in this example is 30 cubic meters per day.

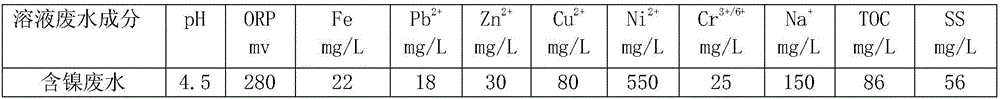

[0089] The composition of wastewater is shown in Table 1

[0090] Table 1

[0091]

[0092] Note 1: The running time is calculated as 20 hours / day

[0093] Note 2: The data in Table 1 are average values.

[0094] Wastewater Treatment Requirements:

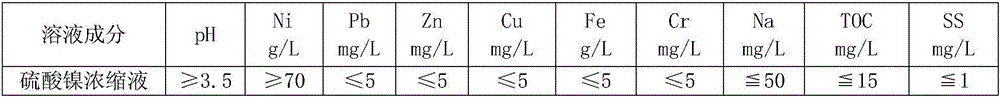

[0095] 1. The recovered nickel in the wastewater is nickel sulfate concentrate, and the quality meets the requirements in Table 2:

[0096] Table 2

[0097]

[0098] 2. Nickel ion content in wastewater discharged after nickel recovery: Ni≦0.5mg / L

[0099] The specific processing steps are as follows

[0100] (1) Wastewater pH adjustment and oxidation treatment:

[0101] The flow rate of nickel-containing waste liquid is adjusted to 1.5m 3 After / h, enter the first adjustment tank 1, the first adjustment tank 1 is composed of a reaction section, a settling section and a water storage section,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com