Patents

Literature

35results about How to "Wide range of process adaptation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

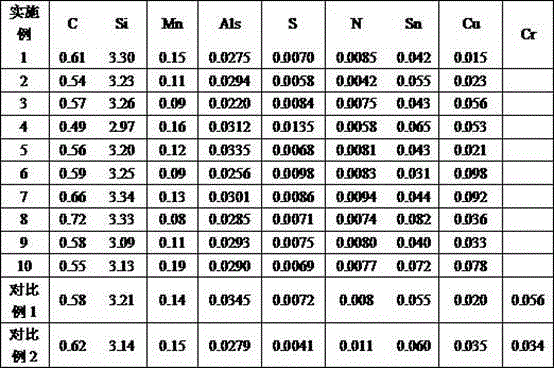

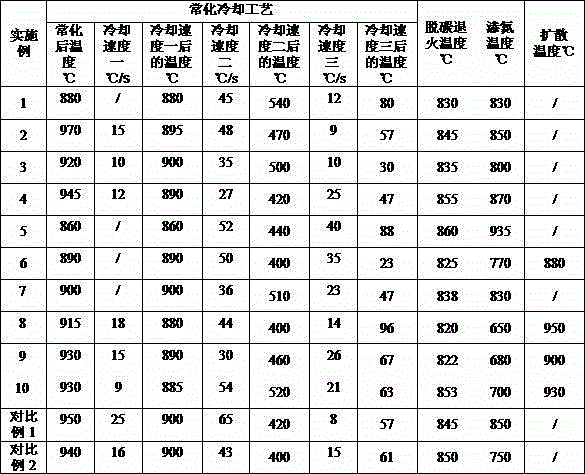

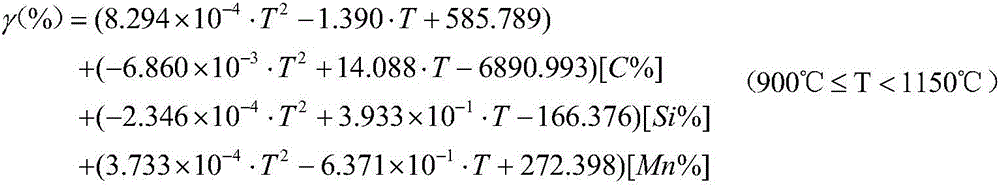

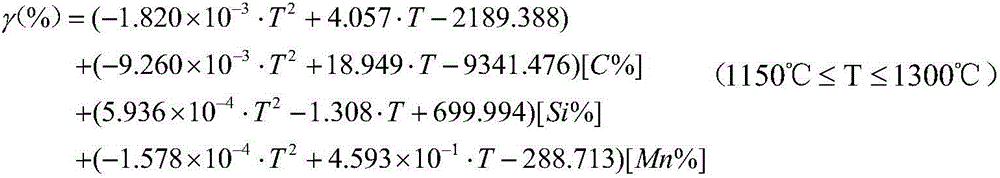

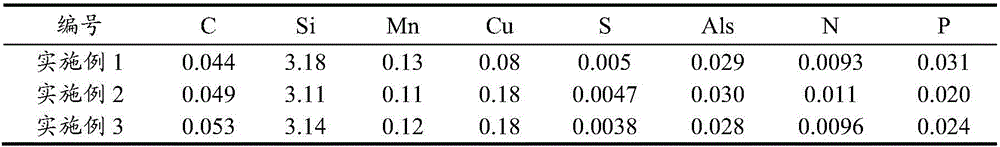

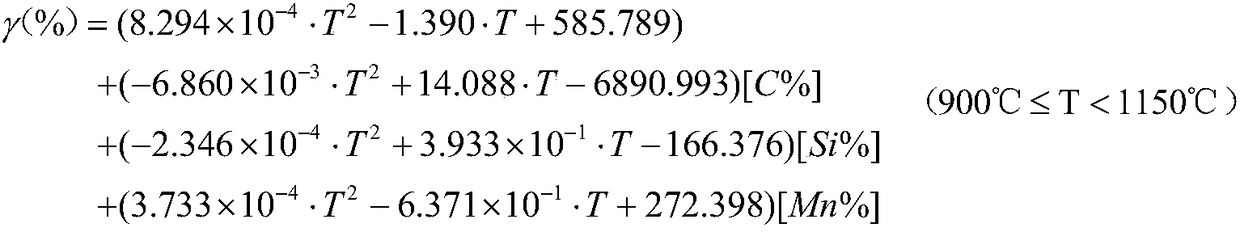

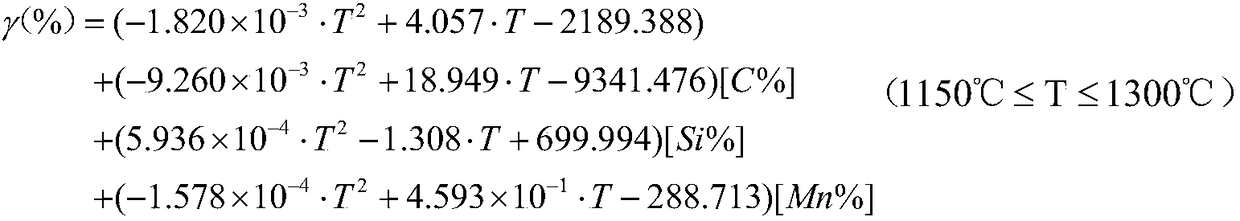

High magnetic induction grain-oriented silicon steel with B800 being more than or equal to 1.94T and production method thereof

The invention discloses high magnetic induction grain-oriented silicon steel with B800 being more than or equal to 1.94T. The silicon steel comprises the following components in percentage by weight: 0.045-0.075 percent of C, 2.95-3.35 percent of Si, 0.05-0.20 percent of Mn, 0.005-0.015 percent of S, 0.004-0.010 percent of N, 0.03-0.10 percent of Sn, 0.01-0.1 percent of Cu and 0.020-0.034 percent of Als. The production method comprises the following steps: smelting, performing continuous casting to form a blank, and heating the cast blank; performing segmented hot rolling; normalizing and cooling in a dry total-nitrogen atmosphere; performing aging and cold rolling by using a one-step cold rolling method; decarburizing and annealing; performing nitriding treatment; performing conventional coating of a release agent; coiling and performing conventional high-temperature annealing, wherein the annealing atmosphere refers to dry or wet nitrogen or hydrogen or conventional nitrogen and hydrogen mixed gas; and performing conventional stretching, flattening, papplying insulating coatings and annealing. The cast blank is heated at a low temperature, the process application range is wide, and the number of effective inhibitors is controlled, so that the B800 is more than or equal to 1.94T, and P1.7 / 50 is less than or equal to 0.88W / kg. The silicon steel is used for preparing common transformers, the materials can be saved, and the overload impact resistance can be improved.

Owner:WUHAN IRON & STEEL (GROUP) CORP

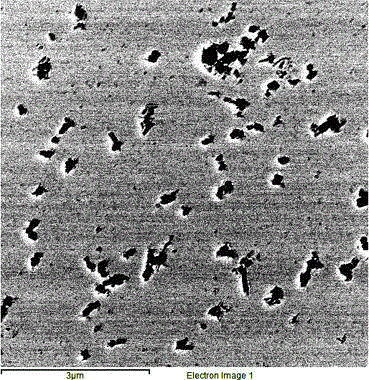

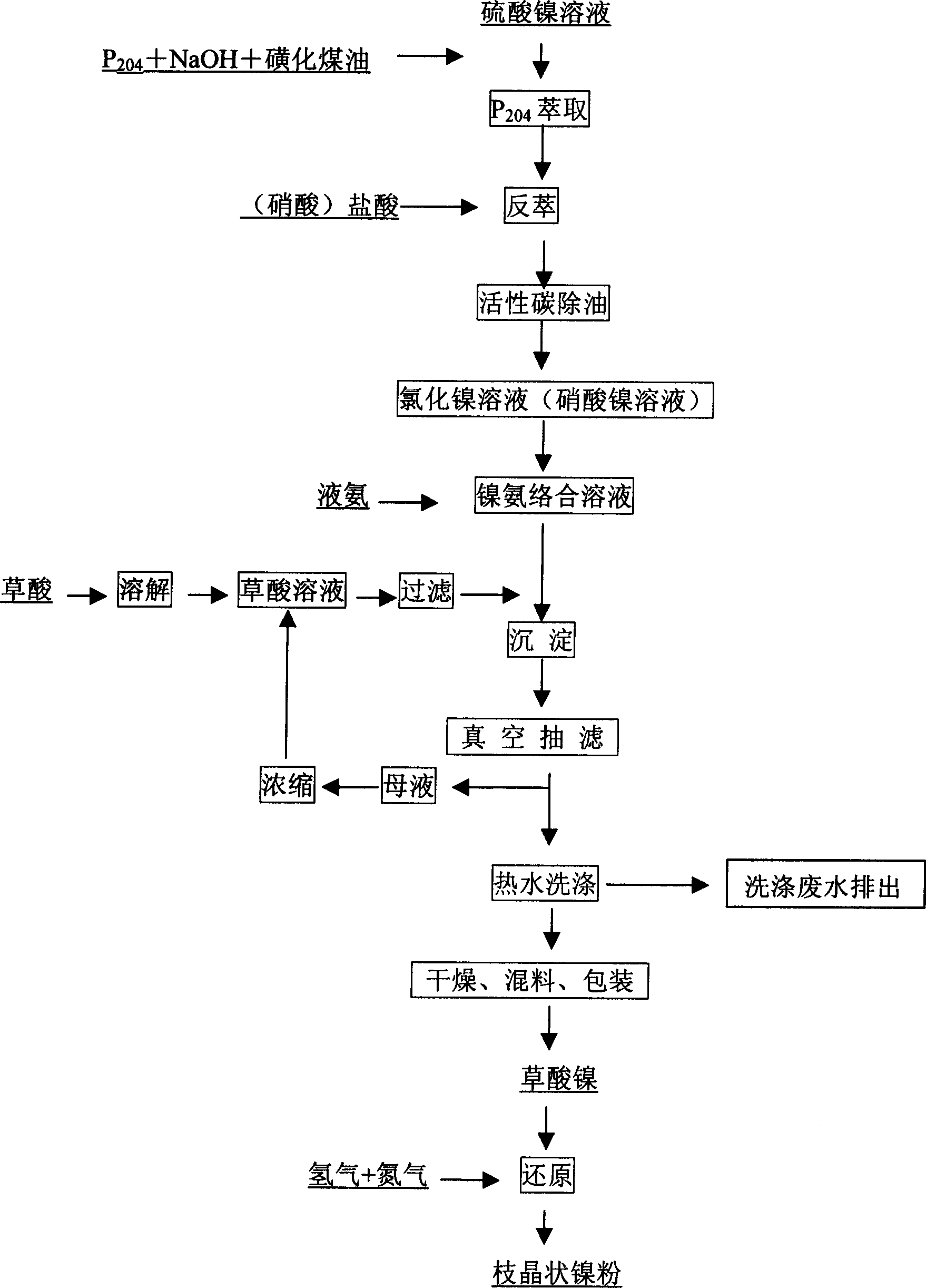

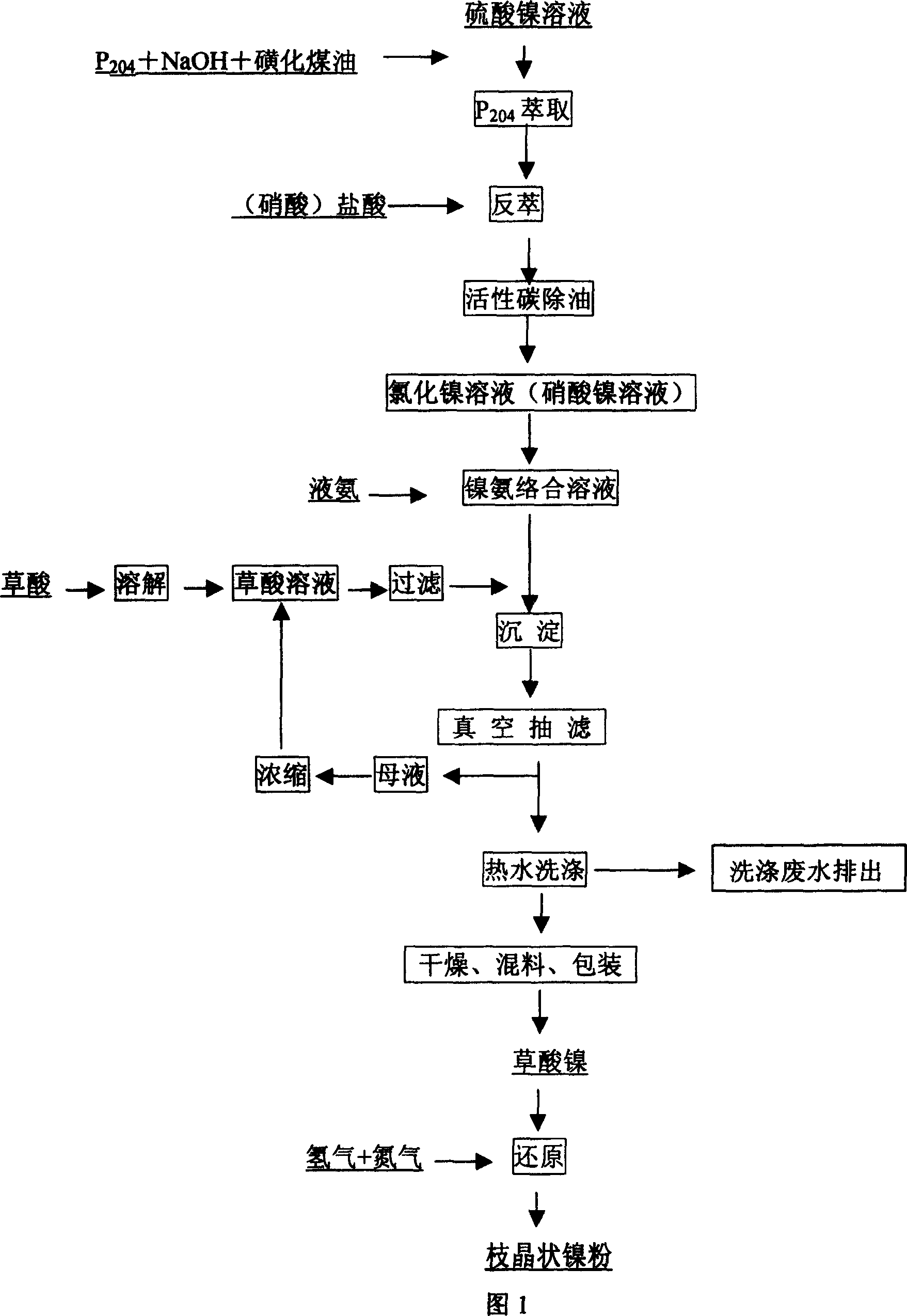

Production method of dentritic morphology nickel powder

A process for preparing the dendritic Ni powder includes such steps as extracting of nickel sulfate solution to become the solution of nickel chloride (or nitrate), preparing nickel-ammonia complex solution, depositing in oxalic acid solution to obtain nickel oxalate, vacuum fitlering, washing, drying, reducing by the mixture of H2 and N2, and pulverizing.

Owner:JINCHUAN GROUP LIMITED

Fast organic waste recycling hot enzyme aerobic treatment technology

ActiveCN103304281AEfficient enzymatic fermentationEfficient and environmentally friendly processFertiliser formsOrganic fertilisersEvery HourDecomposition

The invention discloses a fast organic waste recycling hot enzyme aerobic treatment technology. The fast organic waste recycling hot enzyme aerobic treatment technology comprises the steps of: according to the proportion of (6-8):(2-4), respectively placing organic wastes and crop straw or wood chips into a hot enzyme reactor for stirring for 5-10min, respectively adding 0.05%-0.2% of heat-resistant enzyme and 0.05%-0.3% of thermophilic bacteria according to the weight percentage of the organic wastes and crop straw or wood chips, carrying out primary enzymatic fermentation, thorough decomposition and exhausting through the reactor, controlling the temperature of materials at 70-80 DEG C, controlling the humidity of the materials in the reactor to be 60%-70%, wherein the first-time exhausting amount is 100-500m<3> of per tonnage per hour, the exhausting time is 16-18 hours, and the rotating speed of stirring blade of the reactor is 1-20r / min; 16-18 hours later, finely adjusting the parameters of the hot enzyme reactor automatically, carrying out secondary enzymatic fermentation, thorough decomposition and exhausting, controlling the temperature of the materials to be 80-95 DEG C, the rotating speed of the stirring blade of the reactor to be 1-20r / min for 6-8 hours, wherein the second-time exhausting amount is 150-750m<3> of per tonnage per hour, and the exhausting time lasts for 6-8 hours; and then cooling and sieving, or further pelletizing or embedding to obtain the finished product.

Owner:BIOMAX ECOLOGICAL ENG

Method for recovering rare and precious metal from copper anode slime copper leaching liquid

ActiveCN107746957AStrong process adaptabilityRecycling does not affectProcess efficiency improvementReduction ratePre treatment

The invention relates to a method for recovering rare and precious metal from copper anode slime copper leaching liquid. The method comprises the following steps that 1, rare and precious metal are strengthened and reduced form the copper anode slime copper leaching liquid; and 2, ultrafine particles of rare and precious metal are precipitated, and purification of the copper leaching liquid is synergistically conducted. According to the method for recovering the rare and precious metal from the copper anode slime copper leaching liquid, the copper leaching liquid is pre-treated through the process and can be effectively purified, and the impurity content is reduced, the key point is that the rare and precious metal is efficiently and synergistically recovered, so that the rare and preciousmetal which is dissolved and dispersed in the copper leaching liquid at an ionic state and ultrafine particle state are effectively reduced and enriched, and rare and precious metal concentrate is obtained; and the concentrate is high in valuable element grade and single in element state, and is a source of high quality raw materials for recovering the rare and precious metal, and the method forrecovering the rare and precious metal from the copper anode slime copper leaching liquid has the advantages of high process adaptability, high reduction rate, less impurities and high efficiency.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

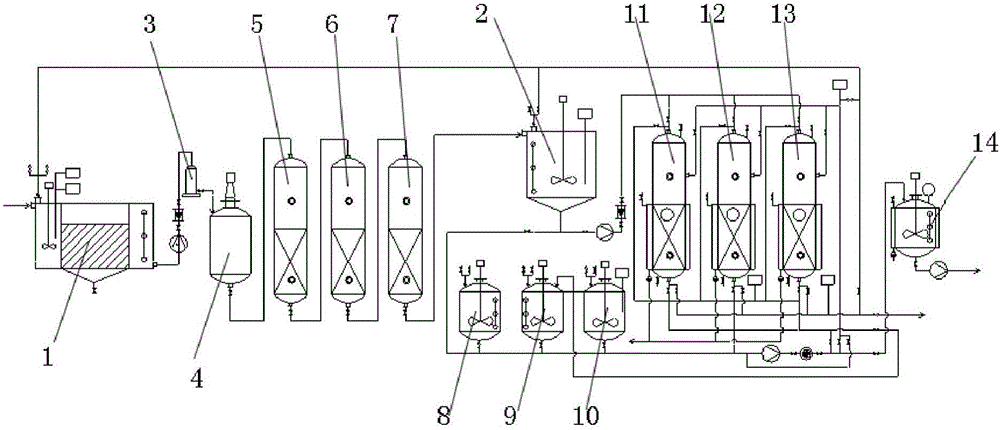

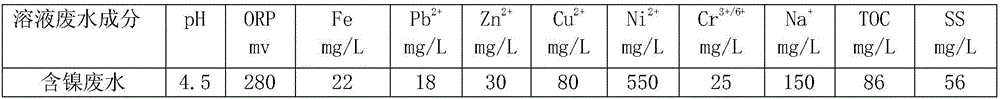

Control technology for extracting and purifying nickel from acid nickel-containing solution

ActiveCN106282560AHigh purityImprove qualityProcess efficiency improvementHigh concentrationNickel salt

The invention relates to a control technology for extracting and purifying nickel from an acid nickel-containing solution. The control technology comprises the technological processes of PH adjustment and oxidation, solid impurity and organic matter removal, foreign ion removal, nickel ion adsorption, cleaning before saturation column regeneration, regeneration and reclaiming agent preparation control, exchange column cleaning, resin conversion, column cleaning after conversion, standby preparation and concentrating. The technical limitations that nickel in an aqueous solution recycled through a traditional ion exchange technology is low in purity, low in concentration and high in acidity are broken through, purifying, extracting and concentrating of the nickel are conducted through combination of a plurality of varieties of ion exchange resin and special processing techniques, a nickel sulfate recovery solution with high purity, high concentration and low acidity is obtained, and the nickel sulfate recovery solution can be directly used for producing high-purity nickel salt, metallic nickel, plated nickel and other nickel products.

Owner:NANJING LINEHOME ENVIRONMENTAL TECH CO LTD

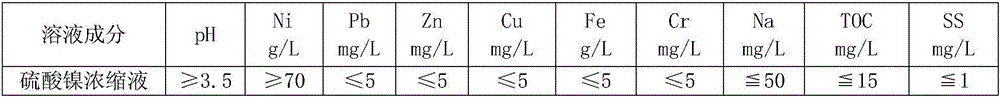

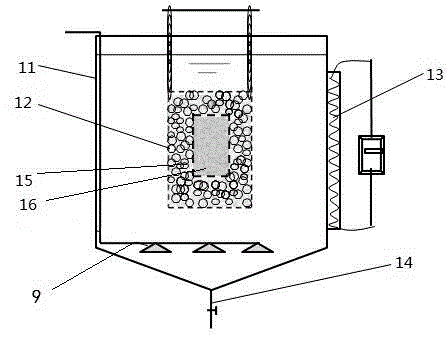

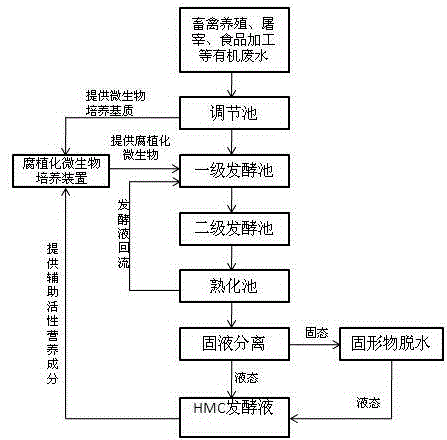

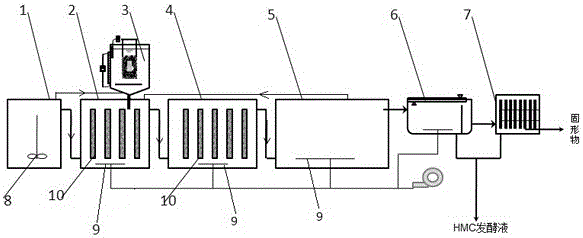

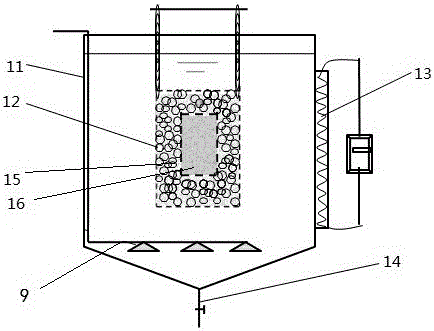

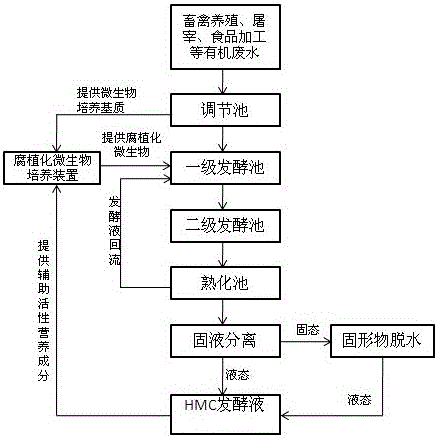

Method and device for achieving organic wastewater liquid composting by virtue of humic microbes

ActiveCN104150992APromote degradationStable in natureClimate change adaptationOrganic fertiliser preparationMicroorganismCulture fluid

The invention belongs to environment microbe techniques and fields of organic waste gases and organic wastewater reclamation, and in particular relates to a method for achieving organic wastewater liquid composting based on a humic microbe culture device. The method comprises the following steps: enriching and culturing humic microbes by using the microbe culture device, supplying a culture liquid which is rich in the humic microbes to a fermentation tank, and constructing a microbial community structure which can prompt smooth progress of organic sewage liquid composting inside the fermentation tank. By adopting the method, a sewage reclamation solving scheme with low cost and high additional values is provided for pollution discharge companies, an ecologic circulation production structure which emphasizes on organic sewage reclamation and application of reclamation products is formed, the pollution control investment is reduced, the environment is improved, and the benefits are improved.

Owner:杭州希水生物科技有限公司

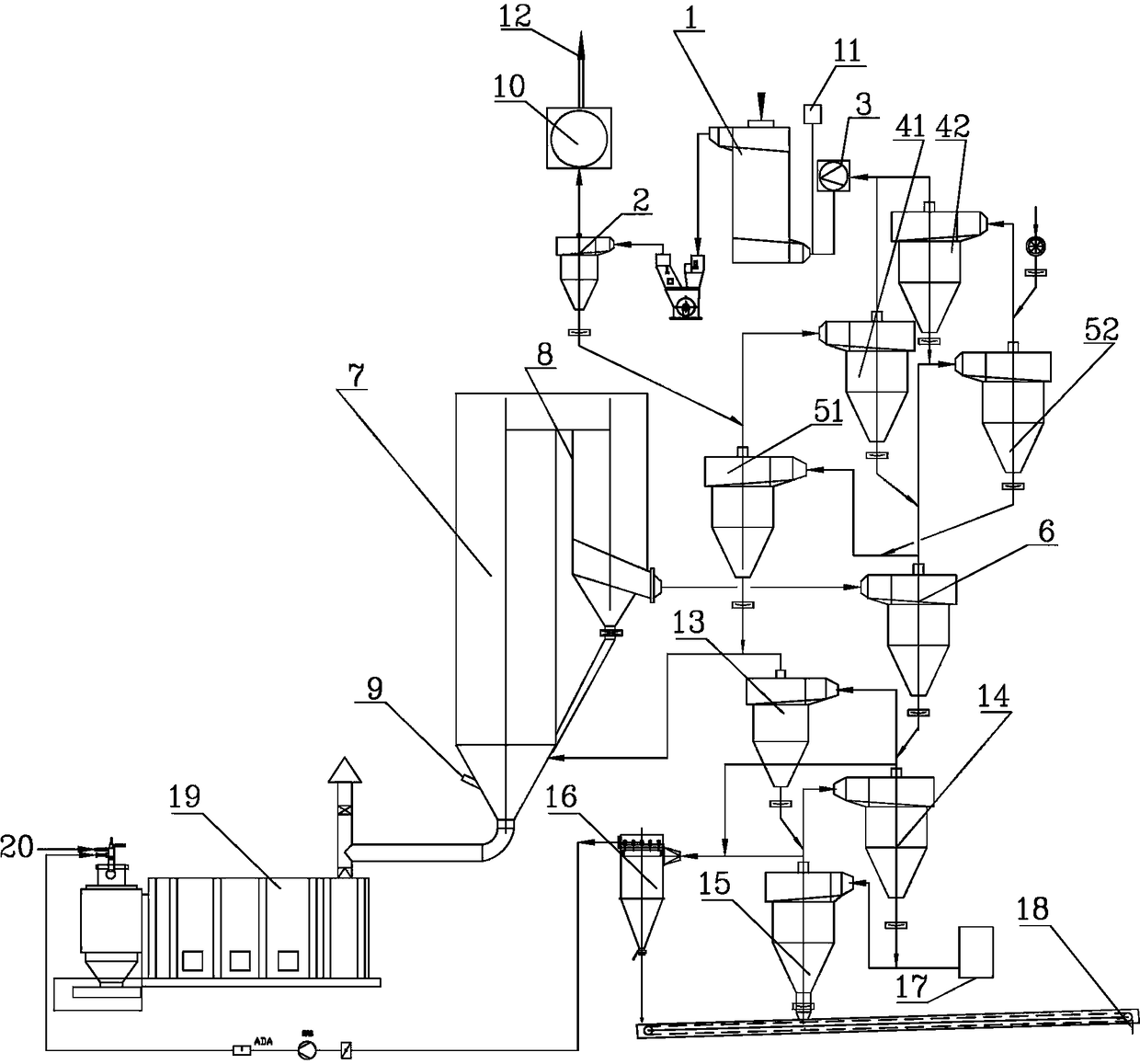

Method for producing Hi-B steel through intrinsic inhibitor method and casting blank low-temperature heating process

The invention belongs to the technical field of silicon steel production, and particularly relates to a method for producing Hi-B steel through an intrinsic inhibitor method and a casting blank low-temperature heating process. The method comprises the steps of converter smelting, RH refining, continuous casting, plate blank heating, hot rolling, normalizing, cold rolling, decarburizing annealing and high-temperature annealing. Casting blanks are subjected to low-temperature heating, and the process is wide in application range, and the inhibiting ability is sufficient; and according to the Hi-B steel obtained through the method, the B<8> value is up to 1.988 T, and P<17 / 50> is as low as 0.836 W / kg.

Owner:ZHONG NAT ENG & RES CENT

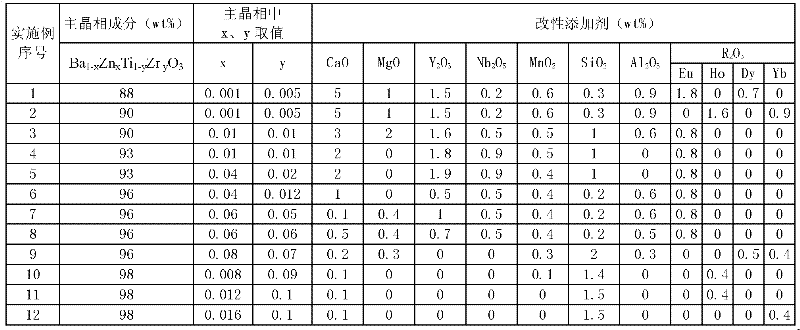

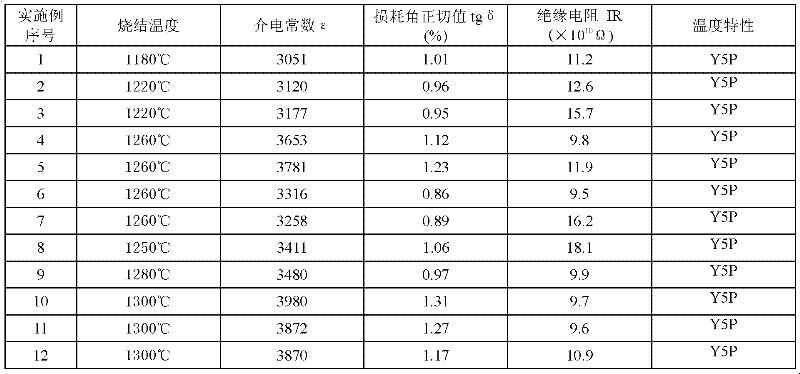

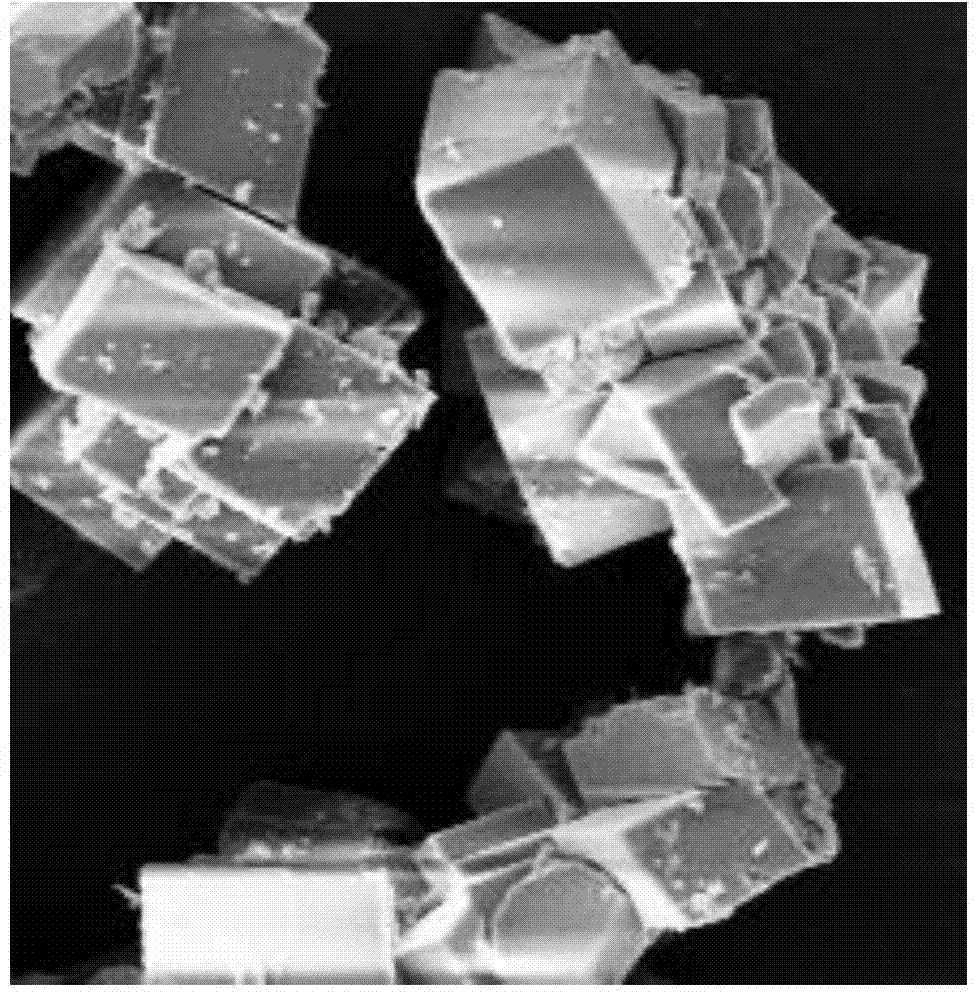

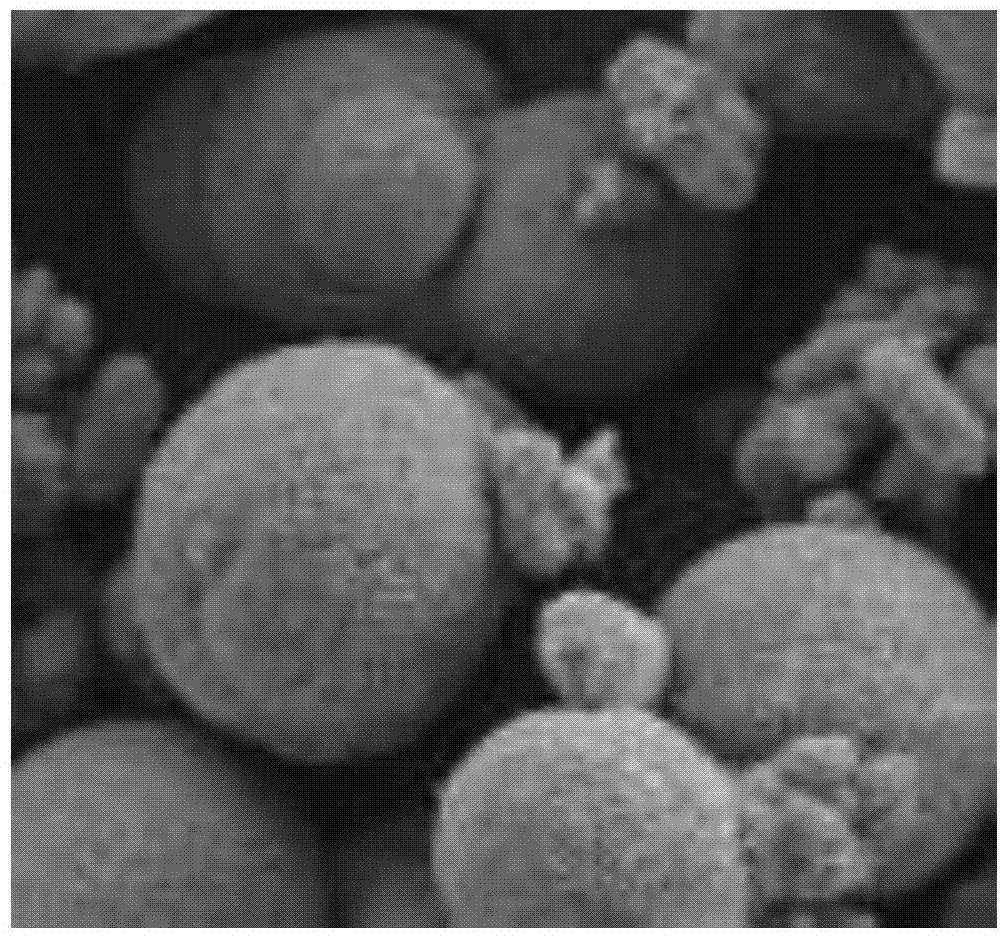

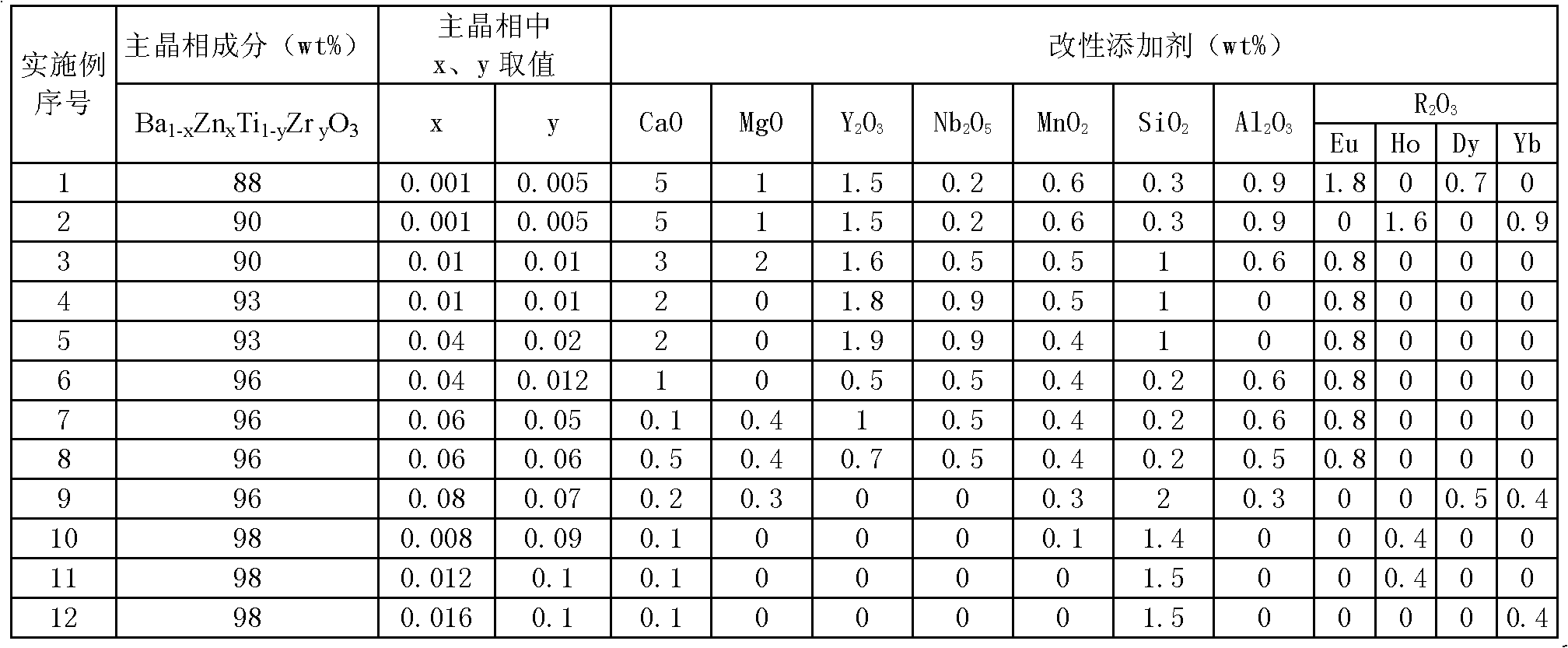

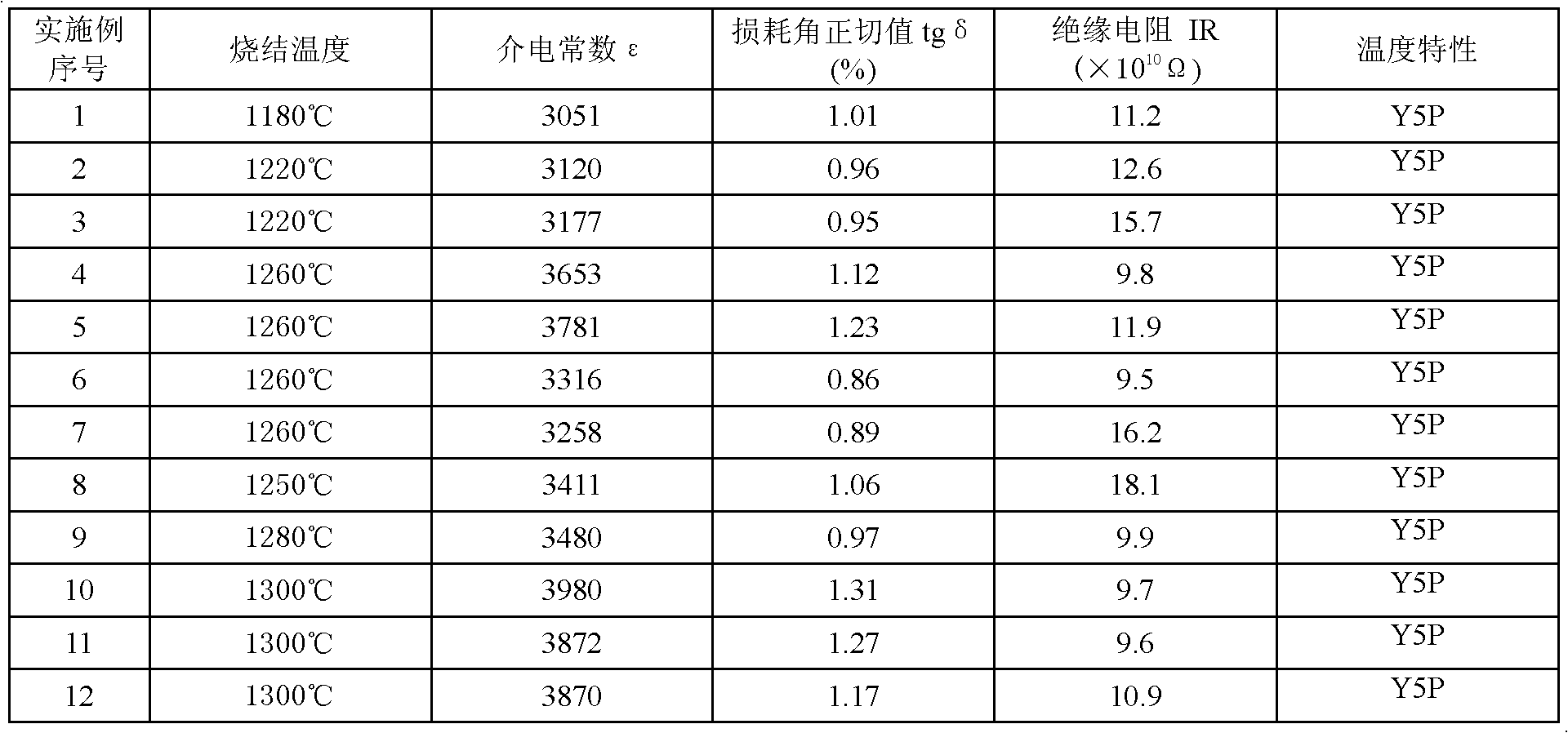

Ceramic dielectric material and manufacture method thereof and ceramic capacitor and manufacture method thereof

ActiveCN102531579AMeet environmental protection requirementsGood dispersionFixed capacitor electrodesFixed capacitor dielectricMetallurgyCeramic capacitor

The invention relates to a ceramic dielectric material and a ceramic capacitor. The ceramic dielectric material and a manufacture method of the ceramic dielectric material adopt Ba1-xZnxTi1-yZryO3 (wherein 0.001<=x<=0.10, 0.005<=y<=0.10) synthesized through a solid phase reaction method as main crystalline phase materials, and main crystalline phase components account for 88-98% of components of dielectric material by weight percentage; and then three or more than three of CaO, MgO, Y2O3, Nb2O5, MnO2, SiO2, Al2O3, R2O3 (R is at least one of Eu, Ho, Dy and Yb) as modifiers are added, and the modifiers account for 2-12% of the components of the dielectric material by weight percentage. According to the components, the ceramic dielectric material with Y5P temperature characteristics and capable of being sintered in a restoring atmosphere can be obtained. Simultaneously, the invention provides the ceramic capacitor manufactured by the ceramic dielectric materials.

Owner:XIAMEN WANMING ELECTRONICS

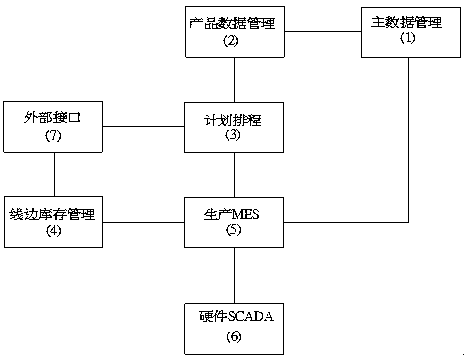

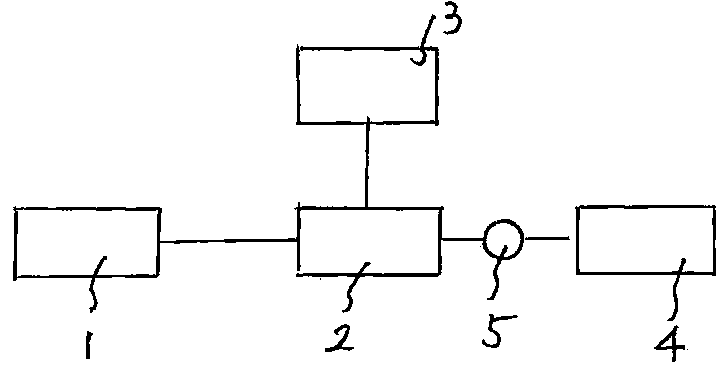

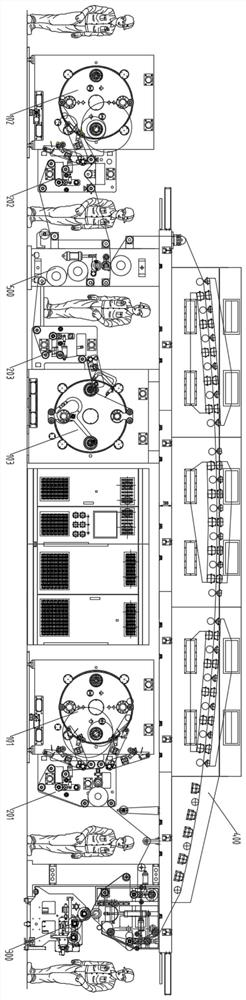

High-efficiency pipe intelligent production line digital management system

PendingCN111459116AFlexible productionWide range of process adaptationTotal factory controlProgramme total factory controlProduct dataMaster data management

The invention discloses a high-efficiency pipe intelligent production line digital management system, and the system comprises: a main data management module which is used for material main data management and production project information management; a product data management module which is used for converting the model file into a production BOM; a plan scheduling module which is used for production scheduling of the pipes under one task package; a line edge inventory management module which is used for managing the line edge inventory of a workshop and managing the furnace batch number ofa pipe; a production MES module which is used for managing the whole production process of the pipe; a hardware SCADA monitoring module which is used for monitoring the equipment state of the production line and sending a production instruction to the automatic production line; and an external interface module which is used for data interaction between the management system and other systems. Thecharacteristics of intelligence, high efficiency and flexibility in production are considered, the process application range is wide, the capacity is expandable, the informatization planning scheme concept and configuration of the intelligent pipe production line are advanced, and the intelligent development direction is met.

Owner:CHINA MERCHANTS HEAVY IND JIANGSU

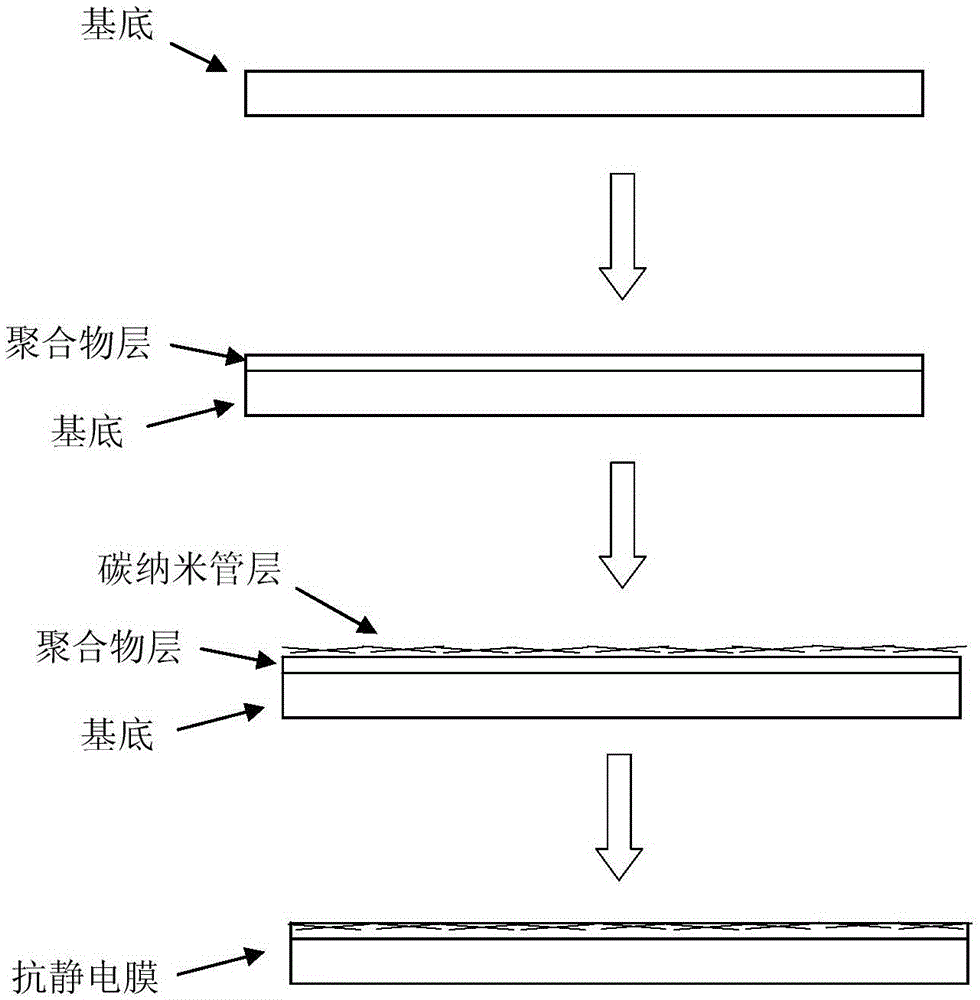

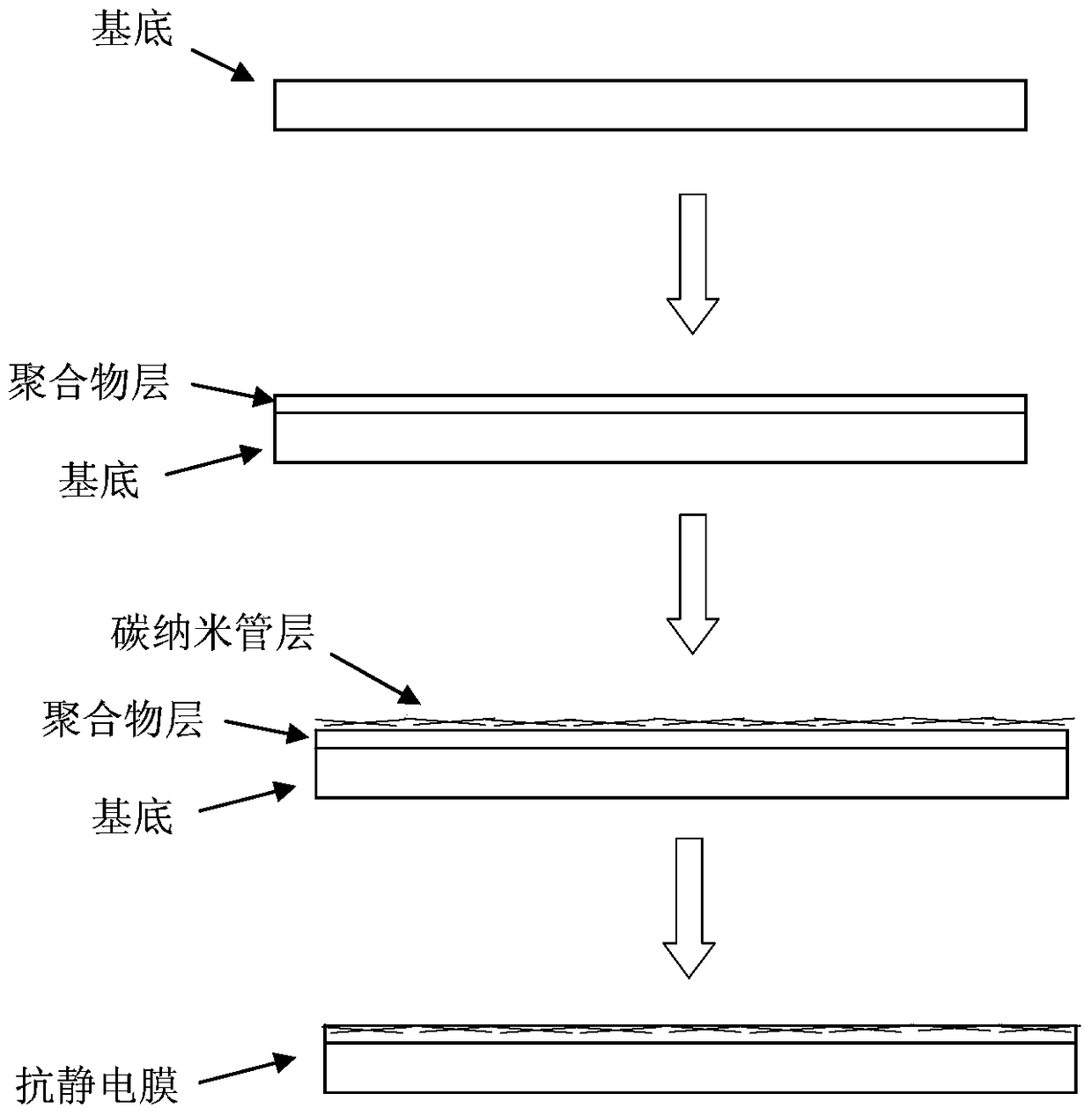

Carbon nano tube antistatic film and preparation method thereof

The invention discloses a carbon nano tube antistatic film and a preparation method thereof. The preparation method comprises the following steps: covering a substrate surface with a polymer layer to form a composite film; arranging uniformly-distributed carbon nano tubes on the surface of the polymer layer of the composite film; heating the polymer layer to at least enable the surface of the polymer layer to be in a viscous flow state, and part of carbon nano tubes on the surface of the polymer layer to be automatically embedded in the polymer layer; cooling the polymer layer, and using a cross-linking agent to at least enable polymers on the surface of the polymer layer to cross-link, thereby obtaining the carbon nano tube antistatic film. The preparation method provided by the invention is simple in process and wide in application range, and facilitates large-scale preparation; the formed antistatic film is excellent in comprehensive performance, for example, the light transmittance and the electrical conductivity of the antistatic film are excellent, and meanwhile, the antistatic film has excellent water resistance, alcohol resistance, wearing resistance and the like.

Owner:SUZHOU NANOPLASTIC NEW MATERIAL CO LTD

Reduction-resistant Y5P ceramic capacitor dielectric porcelain

The invention relates to a reduction-resistant ceramic dielectric material and a preparation method thereof. Ba1-xZnxTi1-yZryO3 (wherein x is more than or equal to 0.001 and less than or equal to 0.10 and y is more than or equal to 0.005 and less than or equal to 0.10) which is synthesized by a solid state reaction is taken as a main crystal phase material which accounts for 88 to 98 mass percent of the dielectric material; and three or more than three of CaO, MgO, Y2O3, Nb2O5, MnO2, SiO2, Al2O3 and R2O3 (R refers to at least one of Eu, Ho, Dy and Yb), which serve as modifiers, are added into the main crystal phase material, wherein the modifiers accounts for 2 to 12 mass percent of the dielectric material. Therefore, the ceramic dielectric material with Y5P temperature characteristic and capable of being sintered in reducing atmosphere is obtained.

Owner:XIAMEN WANMING ELECTRONICS

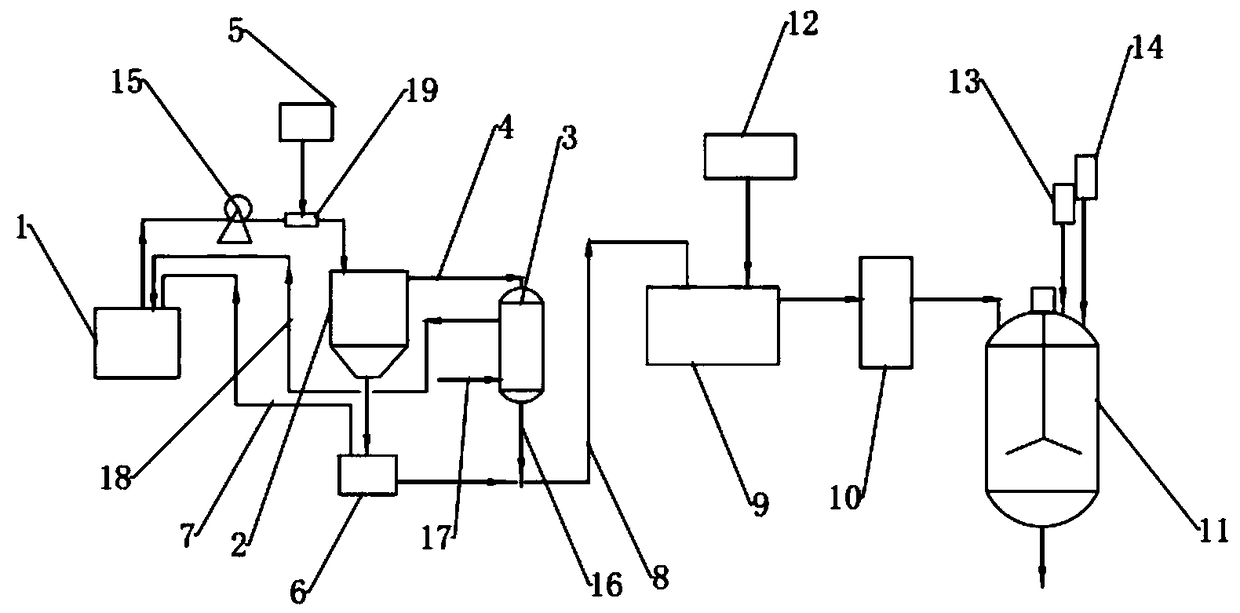

Crystallization method

ActiveCN103977594AOvercome many disadvantages such as deterioration of heat transfer effectReduce shock loadSolution crystallizationPhysical chemistryCirculating pump

The invention discloses a crystallization method. The crystallization method comprises the following steps: feeding one part of mother solution from a centrifugal mother solution collection container to a front section through a mother solution pump, transferring the other part of the mother solution to a low-temperature mother solution preparation tank through the mother solution pump; associating the mother solution in the low-temperature mother solution preparation tank with a low-temperature water preparation unit through a low-temperature mother solution circulating pump, cooling the mother solution through the low-temperature water preparation unit, and maintaining the temperature of the mother solution in the low-temperature mother solution preparation tank in a set range; pumping the low-temperature mother solution from the low-temperature mother solution preparation tank into each mixing and cooling crystallization kettle through the low-temperature mother solution pump, mixing the mother solution with hot materials in the mixing and cooling crystallization kettle, carrying out solid-liquid separation in a centrifugal machine after the temperature and crystallized product in the mixing and cooling crystallization kettle are stabilized, feeding the mother solution into the mother solution collection container for recycling. According to the method, the crystallization efficiency can be effectively improved, and energy conservation and consumption reduction are realized.

Owner:JIANGSU JIUJIUJIU TECH

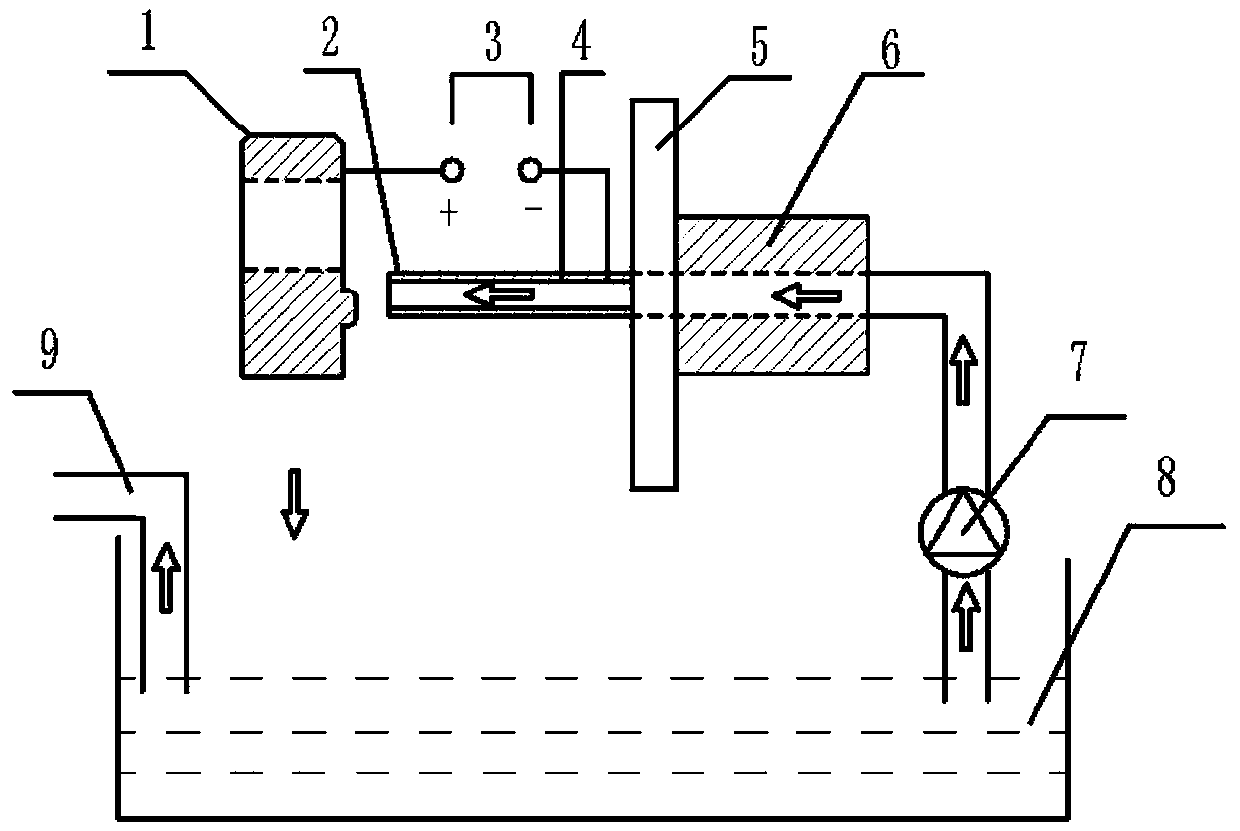

Local micro-arc oxidation device and method for titanium alloy workpieces

InactiveCN110565147AWide range of process adaptationGood masking effectSurface reaction electrolytic coatingPlasma electrolytic oxidationMicro arc oxidation

The invention relates to a local micro-arc oxidation device and method for titanium alloy workpieces, and belongs to the technical field of titanium alloy surface treatment. The device comprises a mobile micro-arc oxidation power supply, to-be-machined workpieces, a stainless steel cathode tube, an oxidation tank, a solution circulation recovery device and a solution cooling system. The device andmethod have the beneficial effect that firstly, a region where micro-arc oxidation is not needed is shielded through the ink during use, then a local micro-arc oxidation process is used for repairingtreatment, the electric fields of the surfaces of the workpieces are restrained through the tubular stainless steel cathode tube to realize local micro-arc oxidation control on the surface of the titanium alloy, solution flows through the surfaces of the to-be-machined workpieces through a tubular stainless steel cathode port, then the solution flows back to the oxidation groove, shapes and oxidation parts of the workpieces are not explicitly required, and the process adaptation range is wide.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Harmless treatment device and process for steel pickling waste liquid

InactiveCN109368857ARealize harmless and clean productionLess investmentTreatment involving filtrationWaste water treatment from metallurgical processLiquid wasteLiquid storage tank

The invention discloses a harmless treatment device and process for steel pickling waste liquid, and belongs to the technical field of waste liquid recovery and treatment. The device comprises a wasteliquid storage tank, a sedimentation tank and a sand filter tank which are sequentially connected by a pipeline, the sedimentation tank is communicated with the sand filter tank through a drainage pipe, and a venturi mixer is disposed between the sedimentation tank and the waste liquid storage tank and communicated with a lye tank through a pipeline. The bottom of the sedimentation tank is connected with a concentration tank which is communicated with the waste liquid storage tank through a wastewater pipeline. The concentration tank is sequentially connected with a pickling waste acid tank,a filtering device and a reaction kettle through a residue discharging pipeline, a scrap iron tank is connected to the top of the pickling waste acid tank, and a stabilizer tank and an oxidizer tank are connected to the top of the reaction kettle. Wastewater and waste acid produced by steel pickling in steel machining enterprises are comprehensively treated and utilized, and no wastewater, waste gas or waste residues are produced, so that the enterprises can truly achieve harmless clean production.

Owner:高密天福家纺有限公司

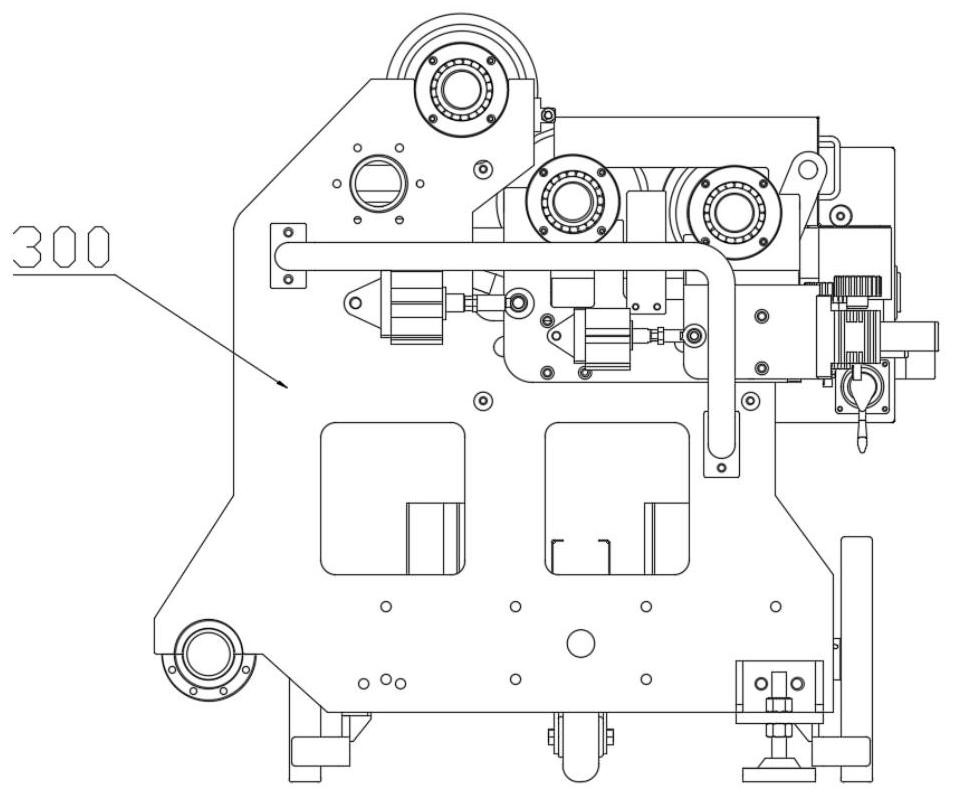

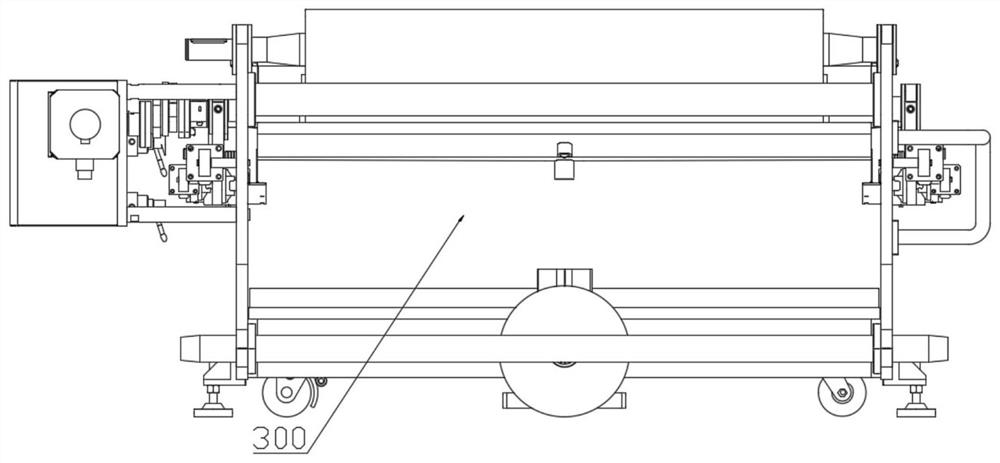

Full-servo control high-speed multifunctional dry-type coating compound machine

PendingCN112959796AHigh speedImprove yieldLamination ancillary operationsLaminationCircular discAdhesive glue

The invention discloses a full-servo control high-speed multifunctional dry type coating compound machine. The compound machine comprises disc gear shaftless charging winding and unwinding equipment for winding a coating base material, a movable semi-flexographic plate coating device for coating glue on the surface of the coating base material, a drying system for drying the base material coated with the glue by the movable semi-flexographic plate coating device, and a composite cooling unit which is used for laminating and bonding the coated base material coated with the glue and dried with other base materials; the disc gear shaftless charging winding and unwinding equipment comprises three groups of high-speed disc gear shaftless charging winding and unwinding devices; a first disc unwinding device works to release a first coating base material wound on the first disc unwinding device, and one side of the released first coating base material is coated with glue through a movable semi-flexographic plate coating device; and after being coated with glue, the base material is fed into the drying system for drying treatment and is simultaneously fed to the composite cooling unit together with a second coating base material wound on the second disc unwinding device, and the two base materials are laminated by the composite cooling unit.

Owner:广东汕樟轻工股份有限公司

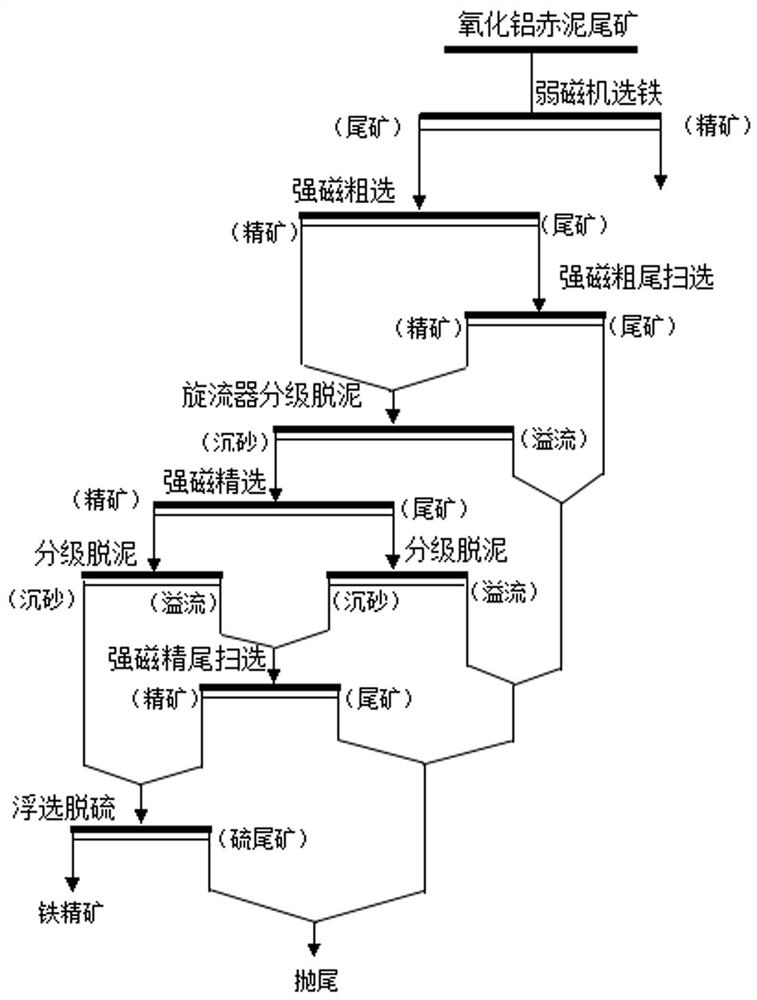

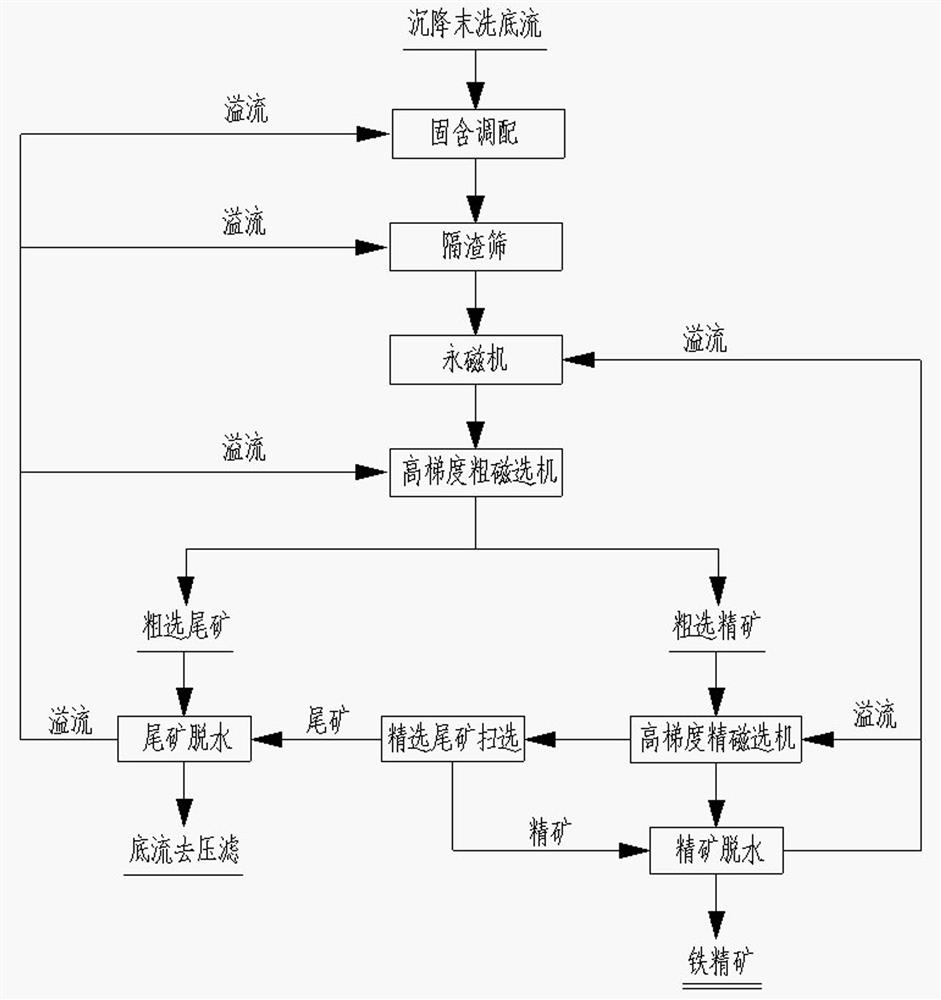

Red mud iron separation method

PendingCN111644261AReduce inputMinus investment fundsMechanical material recoveryWet separationRed mudEngineering

The invention provides a red mud iron separation method and relates to a method for recovering iron from red mud. On the basis of a rough and fine red mud iron separation operation process, a tailingsscavenging process, a rough concentrate cyclone desliming process, a fine concentrate pulp desliming process, a tailings desliming process and a desulfurization process are added. The problem of highsulfur content in iron concentrate is solved, the metal recovery rate is increased, and the concentrate grade is improved.

Owner:云南九州再生资源开发有限公司

Carbon nanotube antistatic film and preparation method thereof

The invention discloses a carbon nano tube antistatic film and a preparation method thereof. The preparation method comprises the following steps: covering a substrate surface with a polymer layer to form a composite film; arranging uniformly-distributed carbon nano tubes on the surface of the polymer layer of the composite film; heating the polymer layer to at least enable the surface of the polymer layer to be in a viscous flow state, and part of carbon nano tubes on the surface of the polymer layer to be automatically embedded in the polymer layer; cooling the polymer layer, and using a cross-linking agent to at least enable polymers on the surface of the polymer layer to cross-link, thereby obtaining the carbon nano tube antistatic film. The preparation method provided by the invention is simple in process and wide in application range, and facilitates large-scale preparation; the formed antistatic film is excellent in comprehensive performance, for example, the light transmittance and the electrical conductivity of the antistatic film are excellent, and meanwhile, the antistatic film has excellent water resistance, alcohol resistance, wearing resistance and the like.

Owner:SUZHOU NANOPLASTIC NEW MATERIAL CO LTD

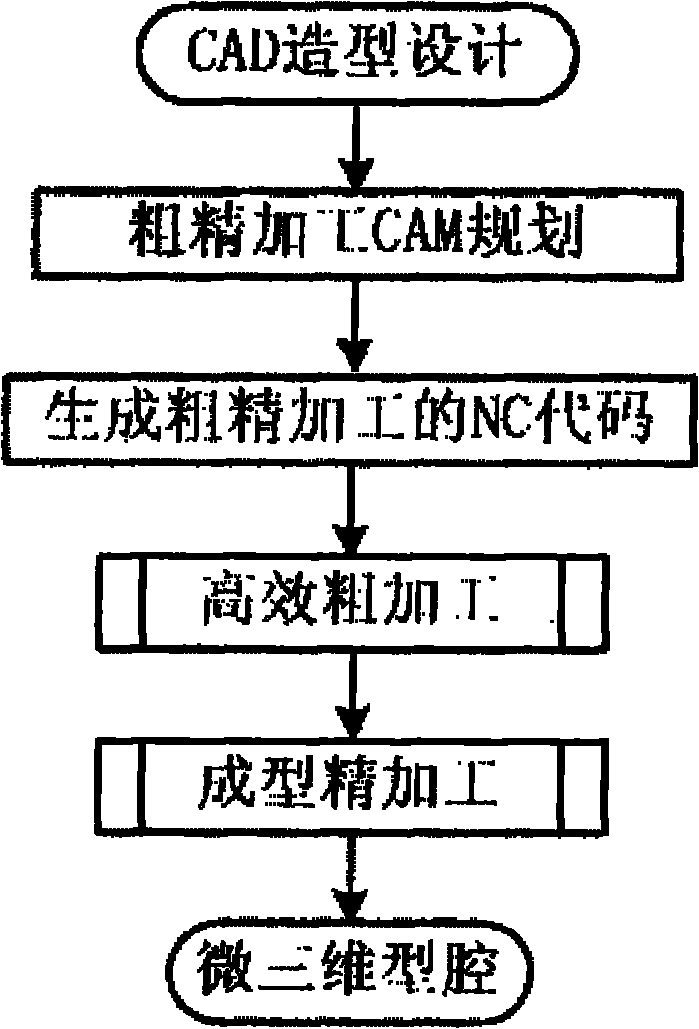

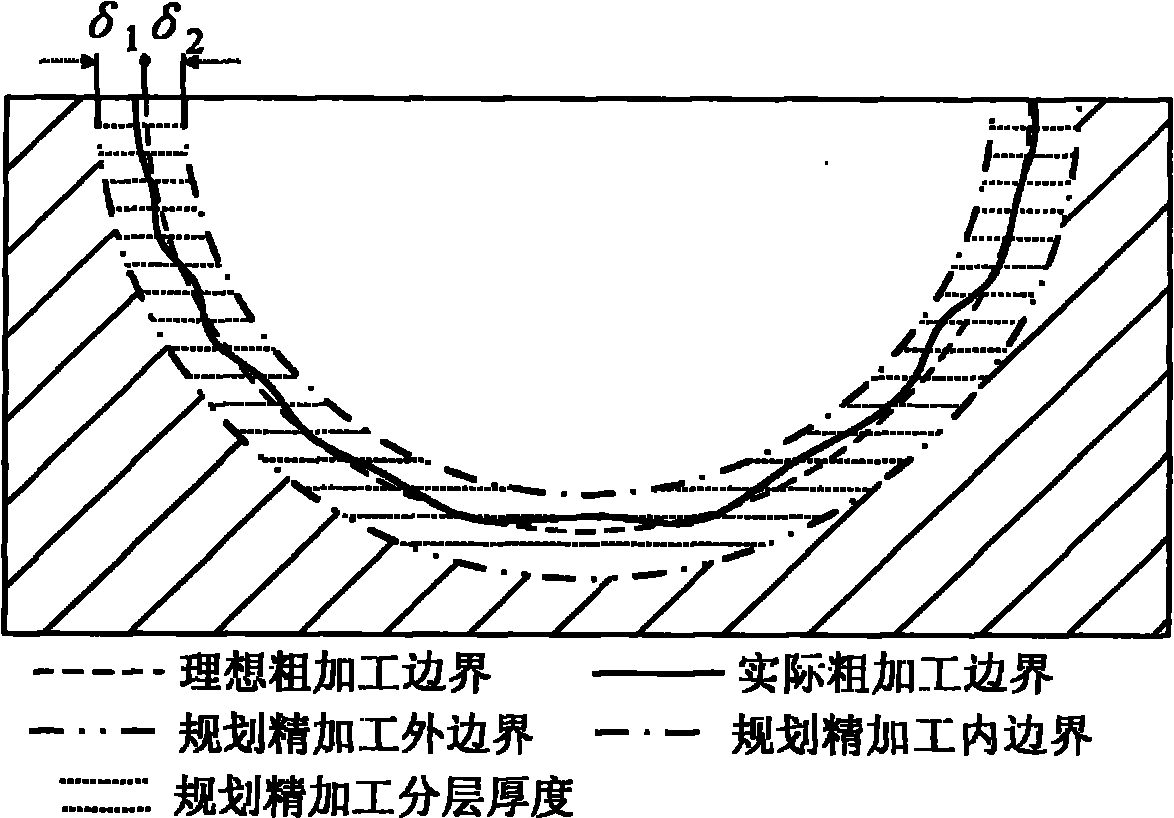

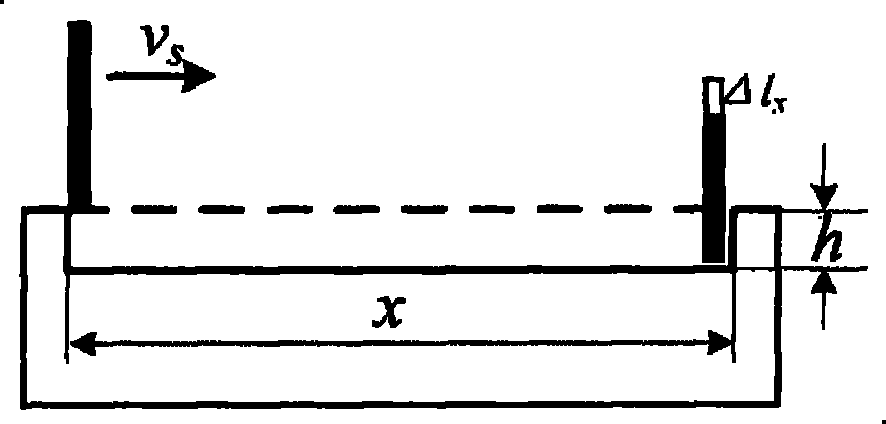

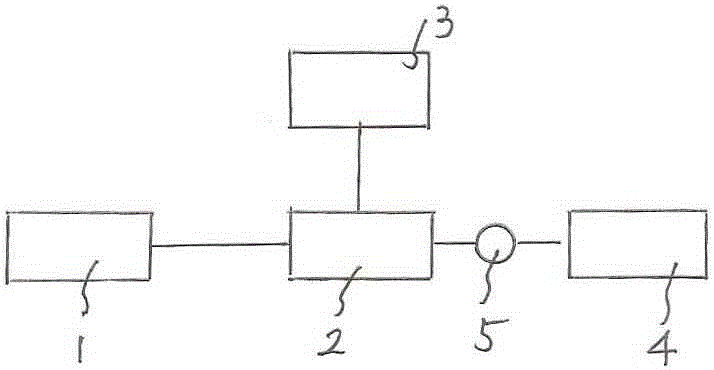

Three-dimensional fine electric spark servo scanning rough and finish machining combined process

A three-dimensional fine electric spark servo scanning rough and finish machining combined process belongs to the technical field of special micro machining. The process which is adaptive to machining of micro three-dimensional cavities with millimeter-sized and utilizes a servo control discharge clearance to realize real-time on-line compensation of axial consumption of an electrode includes removing a large quantity of cavity materials rapidly when in rough machining, applying a maximum method of servo feed depth of an tool electrode of each scanning point to avoid and reduce lack of machining and over-cutting machining and guarantee consistency of processed depths of different layers when in finish machining, further, feeding back processed depth of each layer by combing with tool electrode low-voltage electric contact in a closed loop form, then applying a variable velocity servo scanning method to compensate depth error, and finally completing molding process with high surface precision and high size precision by adopting low discharge energy and thin dividing thickness. The combined process resolves the problem of precision limitation of processed depth of three-dimensional servo scanning, eliminates contradiction between high precision and high efficiency, and can be applied to high-precision and high-efficiency machining of micro three-dimensional cavities made of metal alloy and conductive silica-based materials.

Owner:TSINGHUA UNIV

Process for extracting glyphosate from acid mother liquor

ActiveCN102079757BWide range of process adaptationGroup 5/15 element organic compoundsGlyphosate toxicityChemistry

The invention relates to a process for extracting glyphosate from acid mother liquor and aims to provide a process capable of processing all kinds of acid mother liquor and extracting glyphosate from the acid mother liquor. The process comprises the steps of heating, preparing extractant, extraction and the like, and overcomes the drawback of incapability of performing extraction on acid mother liquid of slightly low quality or acid mother liquor made by different processes in the prior art, can perform extraction on acid mother liquor of any quality and acid mother liquor made by different processes, and can be applied more widely.

Owner:SICHUAN LESHAN FUHUA TONGDA AGRO-CHEM TECH CO LTD

a method of crystallization

ActiveCN103977594BShort timeImprove efficiencySolution crystallizationPhysical chemistryCirculating pump

The invention discloses a crystallization method. The crystallization method comprises the following steps: feeding one part of mother solution from a centrifugal mother solution collection container to a front section through a mother solution pump, transferring the other part of the mother solution to a low-temperature mother solution preparation tank through the mother solution pump; associating the mother solution in the low-temperature mother solution preparation tank with a low-temperature water preparation unit through a low-temperature mother solution circulating pump, cooling the mother solution through the low-temperature water preparation unit, and maintaining the temperature of the mother solution in the low-temperature mother solution preparation tank in a set range; pumping the low-temperature mother solution from the low-temperature mother solution preparation tank into each mixing and cooling crystallization kettle through the low-temperature mother solution pump, mixing the mother solution with hot materials in the mixing and cooling crystallization kettle, carrying out solid-liquid separation in a centrifugal machine after the temperature and crystallized product in the mixing and cooling crystallization kettle are stabilized, feeding the mother solution into the mother solution collection container for recycling. According to the method, the crystallization efficiency can be effectively improved, and energy conservation and consumption reduction are realized.

Owner:JIANGSU JIUJIUJIU TECH

Indirect process of preparing light calcium carbonate based on medium strengthening

InactiveCN103539187BWide variety of sourcesLow costCalcium/strontium/barium carbonatesAtherion elymusCalcite

The invention relates to an indirect process of preparing light calcium carbonate based on medium strengthening. The indirect process comprises the following steps of: adding calcium-rich ion liquor containing inorganic soluble calcium salt into insoluble organic amine as well as a phase regulator, stirring to uniformly mix the liquor until pH of the mixed liquor is kept stable, wherein pH of the mixed liquor is over 9.5; ventilating a CO2 gas or purified industrial smoke gas into the mixed liquor to react with the mixed liquor, controlling a reaction temperature at 5 DEG C-40 DEG C, and stopping the reaction when pH is lowered to 7-8; filtering, drying and grinding the prepared calcium carbonate precipitates to obtain calcium carbonate of different crystalline forms. According to the indirect process disclosed by the invention, the liquor rich in calcium ions and carbon dioxide react under a higher pH environment and an oil-water mixed state which are respectively provided and created by insoluble organic amine and the phase regulator; temperature is controlled, so that preparation of calcite type as well as vaterite type fine light calcium carbonate is realized.

Owner:SHANDONG UNIV

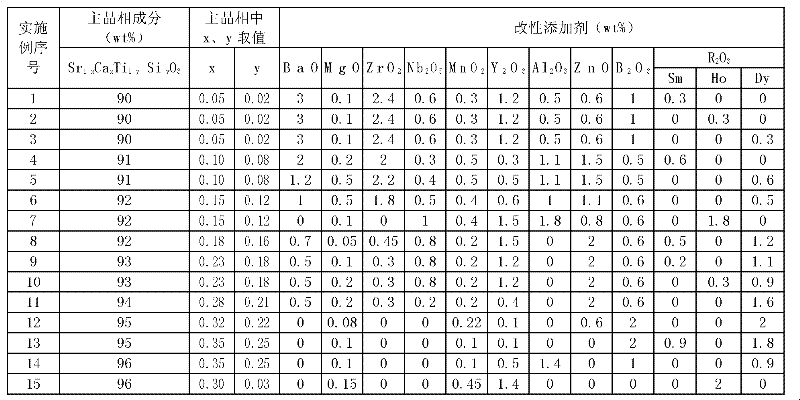

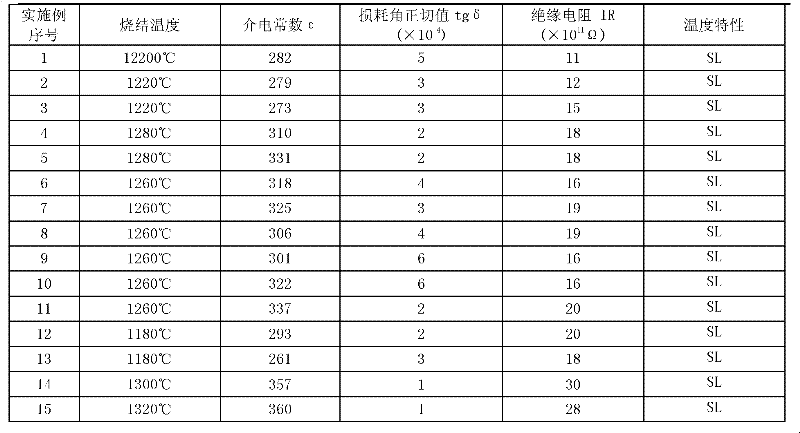

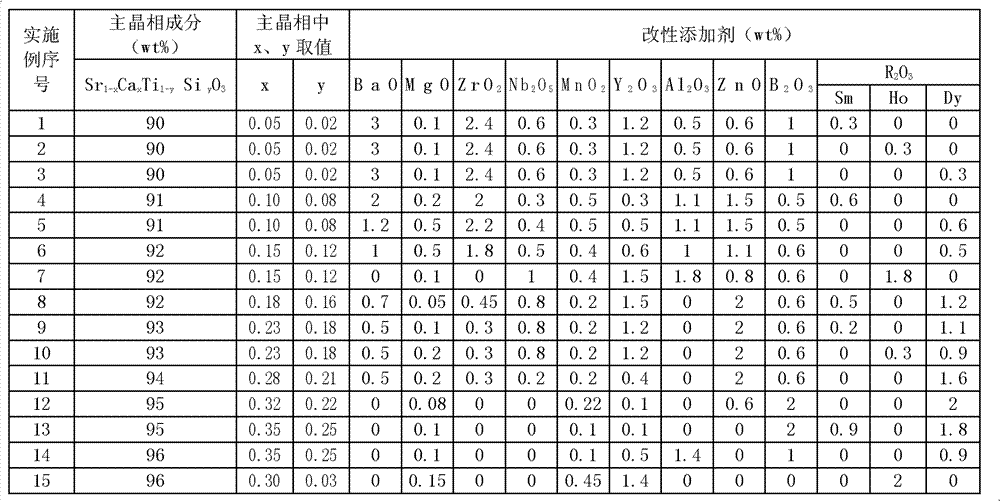

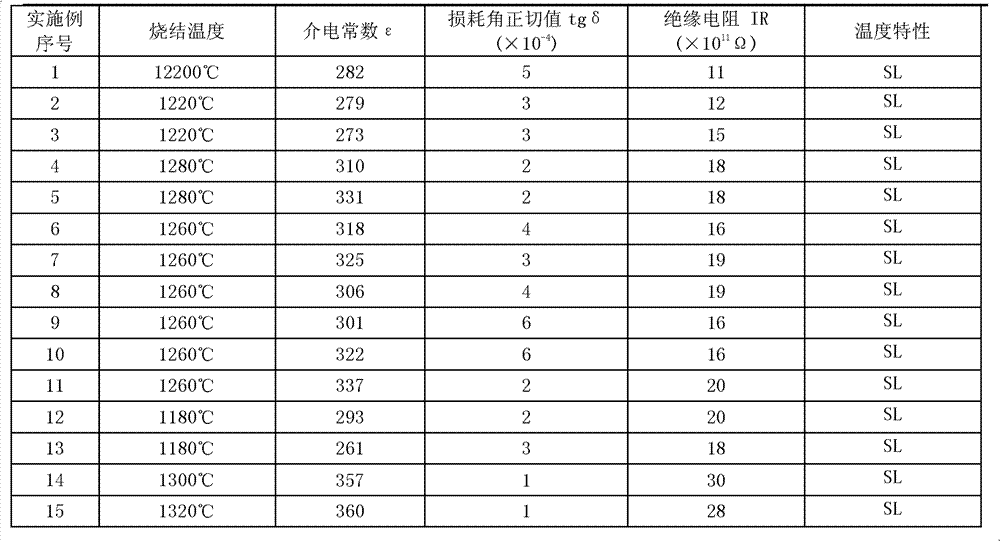

Ceramic dielectric material and manufacture method thereof and ceramic capacitor and manufacture method thereof

ActiveCN102531579BMeet environmental protection requirementsGood dispersionFixed capacitor electrodesFixed capacitor dielectricCeramic capacitorReducing atmosphere

The invention relates to a ceramic dielectric material and a ceramic capacitor. The ceramic dielectric material and a manufacture method of the ceramic dielectric material adopt Sr<1-x>CaxTi<1-y>SiyO3 (wherein 0.05<=x<=0.35, 0.02<=y<=0.25) synthesized through a solid phase reaction method as main crystalline phase materials, and main crystalline phase components account for 90-96% of components of dielectric material by weight percentage; and then four or more than three of BaO, MgO, ZrO2, Nb2O5, MnO2, Y2O3, Al2O3, ZnO, B2O3 and R2O3 (R is at least one of Sm, Ho, Dy) as modifiers are added, and the modifiers account for 10-4% of the components of the dielectric material by weight percentage. According to the components, the ceramic dielectric material with reducibility and without harmful element such as lead and capable of being sintered in a restoring atmosphere can be obtained. Simultaneously, the invention provides the ceramic capacitor manufactured by the ceramic dielectric materials.

Owner:XIAMEN WANMING ELECTRONICS

Production method of dentritic morphology nickel powder

ActiveCN1305617CReduce contentWide variety of sourcesProcess efficiency improvementHydrometallurgyNitrogen gas

A process for preparing the dendritic Ni powder includes such steps as extracting of nickel sulfate solution to become the solution of nickel chloride (or nitrate), preparing nickel-ammonia complex solution, depositing in oxalic acid solution to obtain nickel oxalate, vacuum fitlering, washing, drying, reducing by the mixture of H2 and N2, and pulverizing.

Owner:JINCHUAN GROUP LIMITED

Method and device for realizing liquid composting of organic wastewater by using humifying microorganisms

ActiveCN104150992BPromote degradationStable in natureClimate change adaptationOrganic fertiliser preparationBiotechnologyMicroorganism

The invention belongs to environment microbe techniques and fields of organic waste gases and organic wastewater reclamation, and in particular relates to a method for achieving organic wastewater liquid composting based on a humic microbe culture device. The method comprises the following steps: enriching and culturing humic microbes by using the microbe culture device, supplying a culture liquid which is rich in the humic microbes to a fermentation tank, and constructing a microbial community structure which can prompt smooth progress of organic sewage liquid composting inside the fermentation tank. By adopting the method, a sewage reclamation solving scheme with low cost and high additional values is provided for pollution discharge companies, an ecologic circulation production structure which emphasizes on organic sewage reclamation and application of reclamation products is formed, the pollution control investment is reduced, the environment is improved, and the benefits are improved.

Owner:杭州希水生物科技有限公司

A kind of anti-reduction y5p ceramic capacitor dielectric material

ActiveCN102531592BGood dispersionImprove uniformityFixed capacitor dielectricCeramic capacitorReducing atmosphere

The invention relates to a reduction-resistant ceramic dielectric material and a preparation method thereof. Ba1-xZnxTi1-yZryO3 (wherein x is more than or equal to 0.001 and less than or equal to 0.10 and y is more than or equal to 0.005 and less than or equal to 0.10) which is synthesized by a solid state reaction is taken as a main crystal phase material which accounts for 88 to 98 mass percent of the dielectric material; and three or more than three of CaO, MgO, Y2O3, Nb2O5, MnO2, SiO2, Al2O3 and R2O3 (R refers to at least one of Eu, Ho, Dy and Yb), which serve as modifiers, are added into the main crystal phase material, wherein the modifiers accounts for 2 to 12 mass percent of the dielectric material. Therefore, the ceramic dielectric material with Y5P temperature characteristic and capable of being sintered in reducing atmosphere is obtained.

Owner:XIAMEN WANMING ELECTRONICS

Method for producing hi-b steel using inherent inhibitor method and slab low temperature heating process

The invention belongs to the technical field of silicon steel production, and particularly relates to a method for producing Hi-B steel through an intrinsic inhibitor method and a casting blank low-temperature heating process. The method comprises the steps of converter smelting, RH refining, continuous casting, plate blank heating, hot rolling, normalizing, cold rolling, decarburizing annealing and high-temperature annealing. Casting blanks are subjected to low-temperature heating, and the process is wide in application range, and the inhibiting ability is sufficient; and according to the Hi-B steel obtained through the method, the B<8> value is up to 1.988 T, and P<17 / 50> is as low as 0.836 W / kg.

Owner:ZHONG NAT ENG & RES CENT

Fast organic waste recycling hot enzyme aerobic treatment technology

ActiveCN103304281BEfficient enzymatic fermentationEfficient and environmentally friendly processFertiliser formsOrganic fertilisersDecompositionOxygen

Owner:BIOMAX ECOLOGICAL ENG

A method for recovering active lime from pulping and papermaking white mud

ActiveCN106396432BIncrease productivityIncrease heat transfer areaLime productionThree levelCalcination

Owner:王桂林

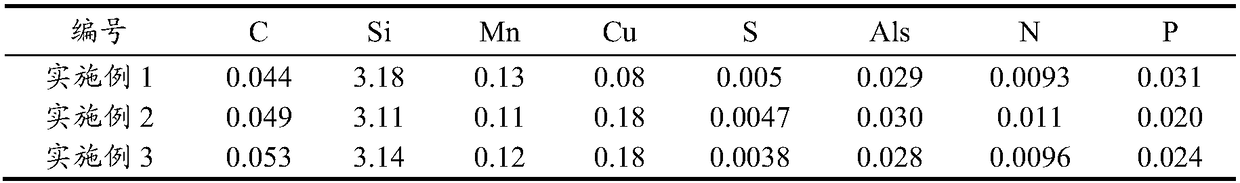

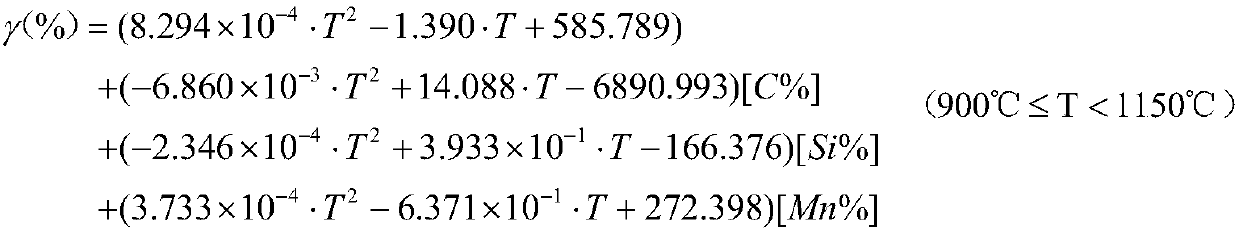

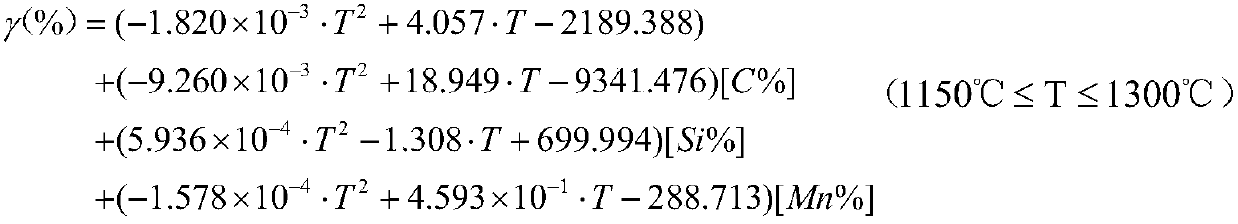

A kind of hi-b steel manufactured by inherent inhibitor method and slab low temperature heating process

ActiveCN106399822BAccelerated precipitationReduce equilibrium precipitationChemical compositionSilicon

The present invention belongs to the technical field of silicon steel production, and in particular relates to a Hi-B steel produced using an intrinsic inhibitor method and a casting blank low-temperature heating process. The liquid Hi-B steel contains the following chemical components in mass percent: 0.04-0.065% of C, 3.1-3.3% of Si, 0.08-0.60% of Mn, 0.01-0.03% of P, less than or equal to 0.01% of S, 0.025-0.055% of Als, 0.007-0.013% of N, and 0.1-1.0% of Cu. The Hi-B is prepared with a sulfide serving as an auxiliary inhibitor and by means of the casting blank low-temperature heating process. According to the present invention, not only is low-temperature heating used for a casting blank, but also the process is wide in application range and sufficient in inhibition capability; and the Hi-B steel obtained according to the present invention has a value of B8 as high as 1.988T, and a value of P17 / 50 as low as 0.836W / kg.

Owner:ZHONG NAT ENG & RES CENT

A method for recovering rare and precious metals from copper anode slime copper separation liquid

ActiveCN107746957BStrong process adaptabilityRecycling does not affectProcess efficiency improvementReduction rateCopper anode

The invention relates to a method for recovering rare and precious metal from copper anode slime copper leaching liquid. The method comprises the following steps that 1, rare and precious metal are strengthened and reduced form the copper anode slime copper leaching liquid; and 2, ultrafine particles of rare and precious metal are precipitated, and purification of the copper leaching liquid is synergistically conducted. According to the method for recovering the rare and precious metal from the copper anode slime copper leaching liquid, the copper leaching liquid is pre-treated through the process and can be effectively purified, and the impurity content is reduced, the key point is that the rare and precious metal is efficiently and synergistically recovered, so that the rare and preciousmetal which is dissolved and dispersed in the copper leaching liquid at an ionic state and ultrafine particle state are effectively reduced and enriched, and rare and precious metal concentrate is obtained; and the concentrate is high in valuable element grade and single in element state, and is a source of high quality raw materials for recovering the rare and precious metal, and the method forrecovering the rare and precious metal from the copper anode slime copper leaching liquid has the advantages of high process adaptability, high reduction rate, less impurities and high efficiency.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com