Red mud iron separation method

A technology for selecting iron and red mud, applied in the field of metallurgy, can solve the problem of high sulfur content in iron concentrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

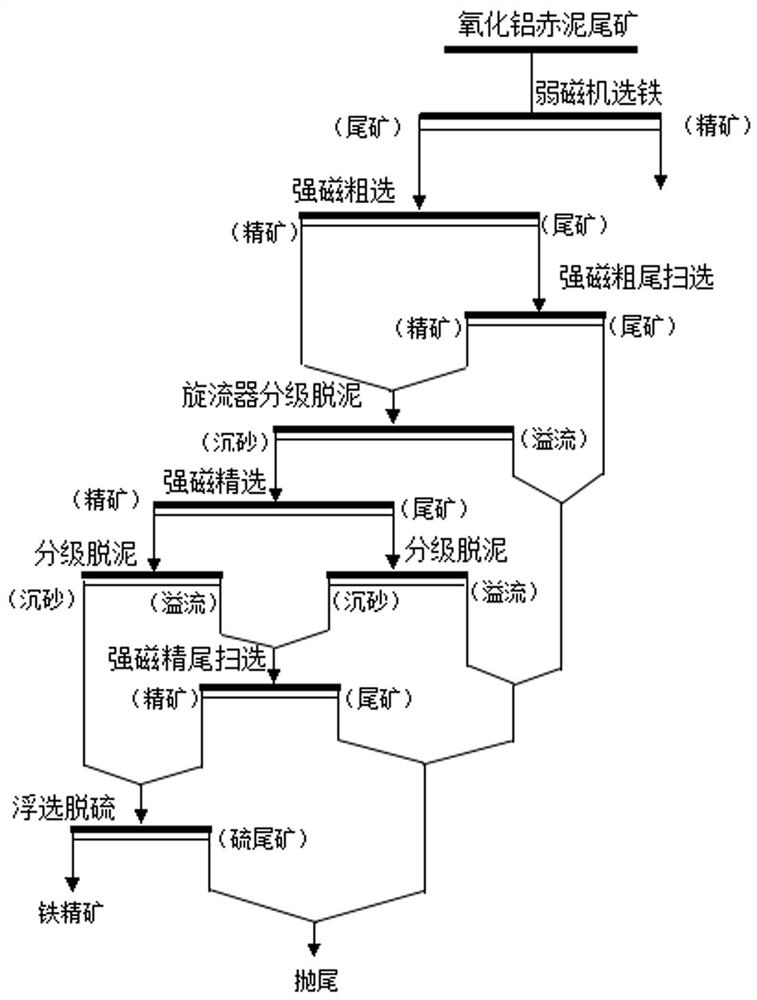

[0025] Example 1: as figure 1 As shown, a red mud iron separation method includes a rough and fine red mud iron separation operation process, and an SLon2000 vertical ring pulse high gradient magnetic separator is added at the rear end of the rough separation tailings for the rough separation tailings sweeping process , the magnetic field strength is at 1.0T, before the rougher concentrate enters the beneficiation section, the rougher concentrate cyclone desliming process is added, and the iron concentrate slurry selected in the beneficiation section is added with a cyclone desliming process, The gangue and mud carried by the high-gradient magnetic separator during the beneficiation process are thrown away; the desliming process of the cyclone is added to the beneficiation tailings.

Embodiment 2

[0026] Example 2: as figure 1 As shown, a red mud iron separation method includes a rough and fine red mud iron separation operation process, and an SLon2000 vertical ring pulse high gradient magnetic separator is added at the rear end of the rough separation tailings for the rough separation tailings sweeping process , the magnetic field strength is at 0.9T, before the roughing concentrate enters the concentrating section, the roughing concentrate cyclone desliming process is added, and the iron concentrate slurry selected in the concentrating section is added with a cyclone desliming process, Throw away the gangue and mud entrained by the high gradient magnetic separator during the beneficiation process; add a cyclone desliming process to the selected tailings; mix the rough tail sweeping concentrate and the roughing concentrate into the roughing concentrate After the ore cyclone is deslimed and concentrated, the bottom flow of the cyclone enters the high gradient magnetic ...

Embodiment 3

[0027] Example 3: as figure 1 As shown, a red mud iron separation method includes a rough and fine red mud iron separation operation process, and an SLon2000 vertical ring pulse high gradient magnetic separator is added at the rear end of the rough separation tailings for the rough separation tailings sweeping process , the magnetic field strength is at 0.8T, before the rougher concentrate enters the beneficiation section, increase the rougher concentrate cyclone desliming process, and increase the cyclone desliming process at the rear end of the iron concentrate slurry selected in the beneficiation section, Throw away the gangue and mud entrained by the high gradient magnetic separator during the beneficiation process; add a cyclone desliming process to the selected tailings; mix the rough tail sweeping concentrate and the roughing concentrate into the roughing concentrate After the ore cyclone is deslimed and concentrated, the bottom flow of the cyclone enters the high grad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com