A method for recovering active lime from pulping and papermaking white mud

A technology of activated lime, pulping and papermaking, applied in lime production, etc., can solve the problems of insufficiently decomposed or decomposed lime, slow cooling speed, overburning, etc., and achieve lower calcination temperature, higher production efficiency, and faster heat transfer speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

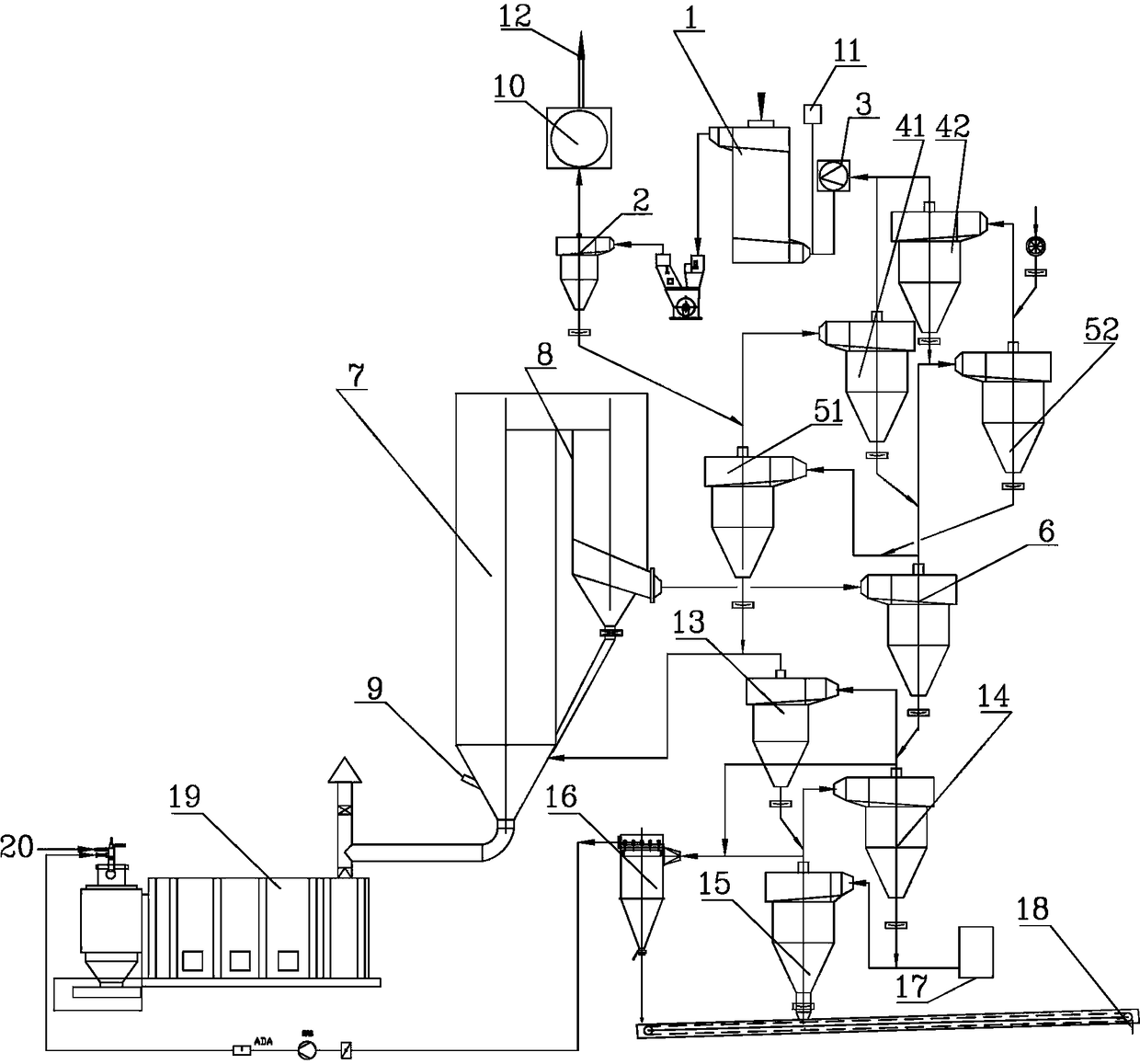

[0031] Depend on figure 1 As can be seen, a kind of pulping and papermaking lime mud reclaims the method for active lime, and it may further comprise the steps:

[0032] (1) Purification treatment: Purify the causticized green liquor to remove (SiO 2 , Fe 2 o 3 Plasma) impurities;

[0033] (2) Dehydration: The causticizing lime mud is forced to dehydrate through a filter to generate water-containing lime mud powder with a water content of ≤ 35% (the water content in this embodiment is 35%);

[0034] (3) Calcination and decomposition: start the high-temperature blower 3 at the outlet of the cyclone of the first-stage preheater 41 and the second-stage preheater 42 as a suspension power source, and use the gas produced by the gas generator or coal powder as fuel, Delivered to the hot blast furnace combustion device 19 through the fuel pipeline, the calcining and decomposing high-temperature hot air environment required by the calcining and decomposing furnace 7 is produced, a...

Embodiment 2

[0049] The water content of the water-containing lime mud powder in step (2) of this embodiment is 20%; the high temperature environment is maintained at 1100° C. in step (3).

[0050] The residual alkali content of the lime mud obtained by the step (1) of the present invention is ≤0.5%, the sulfur content is ≤0.1%, and the excess ash is ≤0.5% (in this embodiment, the residual alkali content is 0.35%, the sulfur content is 0.08%, and the excess ash is 0.3%); The pulverized coal described in step (3) is the sulfur-free coal used, the temperature of the calcination and decomposition high-temperature hot air environment is 850-900°C (900°C in this embodiment), and the high-temperature environment is 900°C-1100°C ( This embodiment is 1100 ℃), the air flow formed by the high temperature blower 3 is 4000-4500m 3 / t white mud powder (4500m in this example 3 / t)

[0051] The section wind speed of the dry separator 2 described in step (4) of the present invention is: 2.0 m / s~3.0m / s (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com