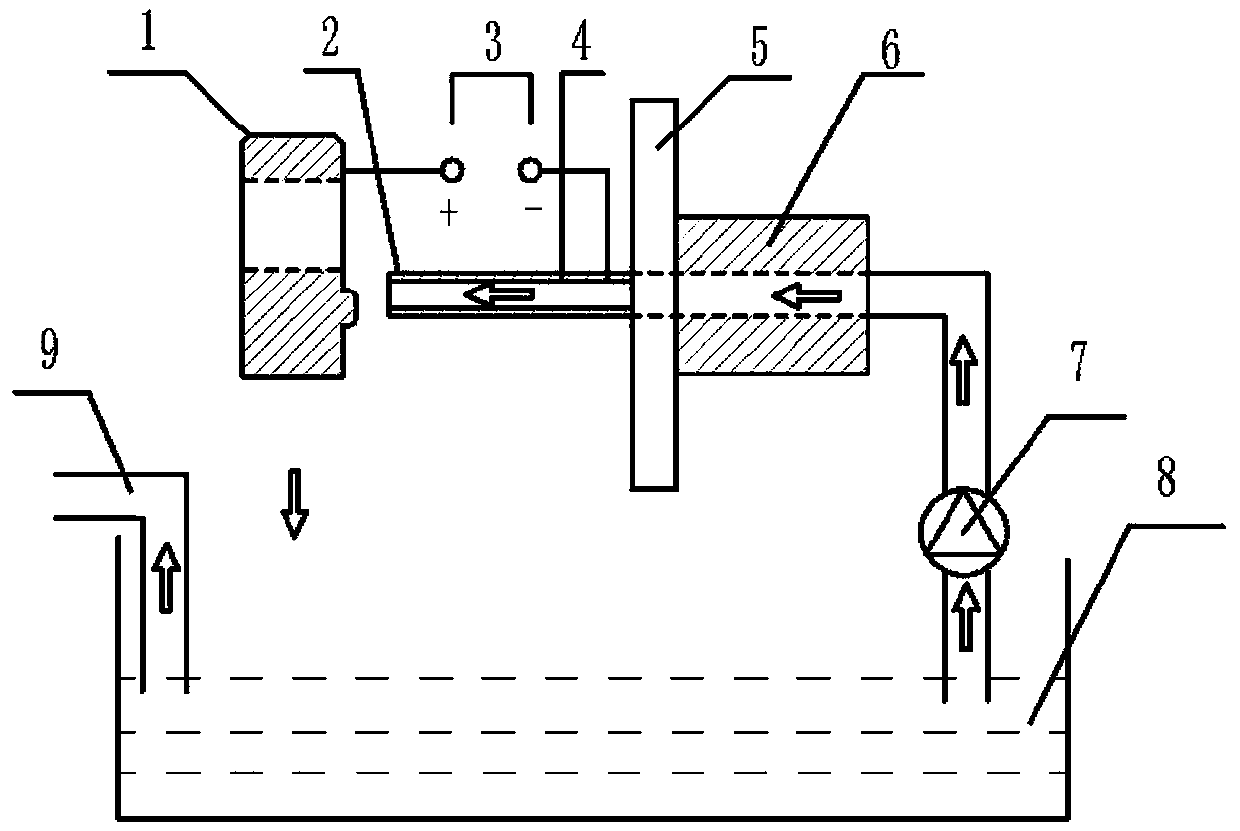

Local micro-arc oxidation device and method for titanium alloy workpieces

A micro-arc oxidation and titanium alloy technology, applied in electrolytic coatings, surface reaction electrolytic coatings, coatings, etc., can solve the problem of large surface area of ship titanium alloy workpieces, unsuitable for overall micro-arc oxidation treatment, and unsuitable for local micro-arc Oxidation and other problems, to achieve the effect of a wide range of process adaptation, convenient removal, and easy on-site construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Use the above-mentioned device to perform partial micro-arc oxidation treatment on a 1 cm × 1 cm area on the TA2 plate. First, use liquid ink to coat and mask the area that does not require micro-arc oxidation. After 6 hours of natural drying at room temperature, the ink coating layer is completely cured. Perform micro-arc oxidation on an unshielded area of 1cm×1cm according to the above-mentioned micro-arc oxidation process, and the stainless steel cathode nozzle is 10mm away from the surface of the workpiece; the solution component Na 3 PO 4 : 10g / L, Na 2 EDTA: 2 g / L; average current density 10A / dm 2 , the termination voltage is 550V, the pulse frequency is 500HZ, the duty cycle is 25%, and the oxidation time is 20min. Rinse the workpiece after oxidation, lift the ink layer by hand, there is no oxide film in the coated area, and an off-white micro-arc oxidation film is formed in the uncoated 1cm×1cm area.

Embodiment 2

[0037] Adjust the distance between the stainless steel cathode tube mouth and the workpiece surface to be 5mm; the solution composition Na 3 PO 4 : 20g / L, Na 2 EDTA: 1g / L; average current density 5A / dm 2 , the termination voltage is 450V, the pulse frequency is 100HZ, the duty cycle is 70%, and the oxidation time is 10min. Others are the same as embodiment 1. Rinse the workpiece after oxidation, lift the ink layer by hand, there is no oxide film in the coated area, and an off-white micro-arc oxidation film is formed in the uncoated 1cm×1cm area.

Embodiment 3

[0039] Adjust the distance between the stainless steel cathode tube mouth and the workpiece surface to be 20mm; the solution composition Na 3 PO 4 : 30g / L, Na 2 EDTA: 3g / L; average current density 2A / dm 2 , the termination voltage is 500V, the pulse frequency is 300HZ, the duty cycle is 50%, and the oxidation time is 15min. Others are the same as embodiment 1. Rinse the workpiece after oxidation, lift the ink layer by hand, there is no oxide film in the coated area, and an off-white micro-arc oxidation film is formed in the uncoated 1cm×1cm area.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com