Method for producing hi-b steel using inherent inhibitor method and slab low temperature heating process

A heating process and casting billet technology, applied in the field of silicon steel production, can solve the problems of complex production process, insufficient inherent inhibitory force, harsh control, etc., and achieve the effect of wide range of process adaptation, reduction of equilibrium precipitation, and expansion of the range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

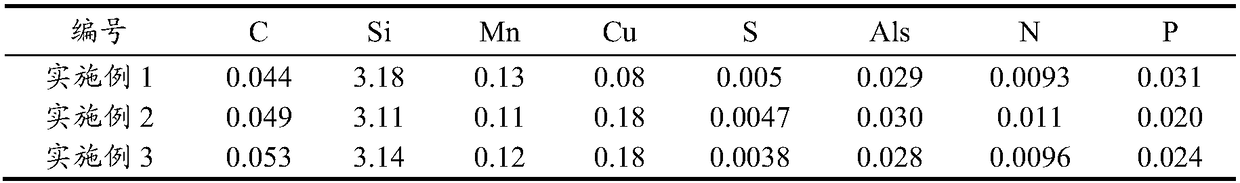

[0074] Example 1 uses the ingredients in Table 1 as raw materials, and adopts a converter for smelting, and the tapping temperature of the converter is 1650°C.

[0075] RH refining adopts alloy fine-tuning twice, the leakage of the vacuum pump system is less than 25Kg, and the vacuum degree is less than or equal to 266Pa. The starting temperature of the RH treatment molten steel is 1635°C, and the treatment end temperature is 1565°C.

[0076]In the continuous casting process, refractory materials are used for the tundish, and carbon-free refractory materials are used for the submerged nozzle of the crystallizer. The long nozzle is protected by argon blowing, and the temperature is measured for 4 to 5 minutes, 20 minutes, and 35 minutes during normal casting. The insertion depth of the thermocouple is 145mm and must be inserted in the middle. The distance between the temperature measuring head and the surrounding wall should be ≥ 250mm. When pouring, the long nozzle must be wo...

Embodiment 2

[0084] The ingredients of Example 2 are as shown in Table 1, and all the other steps are the same as in Example 1.

[0085] Finished product average magnetic induction value B 8 is 1.936T, the average iron loss value P 17 / 50 It is 1.057W / kg.

Embodiment 3

[0087] (1) The composition of Example 3 is shown in Table 1, and the tapping temperature of the converter is 1660°C.

[0088] (2) RH refining adopts two times of alloy fine-tuning, the leakage of the vacuum pump system is less than 25Kg, and the vacuum degree is less than or equal to 266Pa. The starting temperature of RH treatment molten steel is 1640℃, and the treatment end temperature is 1570℃.

[0089] (3) In the continuous casting process, the refractories used for the tundish and the submerged nozzle of the crystallizer are made of carbon-free refractories. The long nozzle is protected by argon blowing, and the temperature is measured for 4 to 5 minutes, 20 minutes, and 35 minutes during normal casting. The insertion depth of the thermocouple is 145mm and must be inserted in the middle. The distance between the temperature measuring head and the surrounding wall should be ≥ 250mm. When pouring, the long nozzle must be worn to protect the casting with argon blowing at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com